Professional Documents

Culture Documents

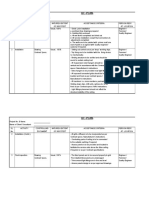

M & E QC Plan - 0064a REV. 0

Uploaded by

Anonymous 3eHGEDbxOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M & E QC Plan - 0064a REV. 0

Uploaded by

Anonymous 3eHGEDbxCopyright:

Available Formats

XYZ

Page 1 of 4

QC~PLAN.

Project No. & Name: Name of Client/ Consultant: SL. No. INITIAL STAGE 1 Check and ensure the survey for routing. ACTIVITY CONTROLLING DOCUMENT Contractual requirement NATURE & EXTENT OF INSP./ TEST ACCEPTANCE CRITERIA - Record of the invert levels of starting, ending points and existing sewer main. - The manhole locations and levels to be indicated. - Clearance from obstructions if any, in the route. - Detailed line map prepared showing invert levels, gradient, curve, slope, depth of trenches etc. - Approved by client. Unless otherwise specified in the Cont. For Gravity Drainage Use UPVC pipes to BS4660 with rubber ring push fit joints or solvent weld system. Min.of pipe size:160mm.dia between manholes & 110 mm. dia connections to manholes. For Pumping Main Use UPVC to BS 3505 class-E. - approved by client. - samples kept at work site after approval. - No damage during transporting and handling. - Stored out of direct sunlight. - Segregated and stored item-wise.

Plumbing Installation (a) Sewer Line Including Hook-up

Doc. No. M & E QC~Plan- 064a/ REV.0 PERSON RESP. AT LOCATION Engineer/ Foremen/ Quality Engineer Inspection report M & E QC~Form064a- 01/ REV. 0 RECORD

2 Obtain the approval on detailed working drawing. 3 Check the selection of materials.

Contract requirement

Engineer/ Foremen/ Quality Engineer Engineer/ Foremen/ Quality Engineer

--

ES-CS-17-13 Sec. 6.2.2 BS 4660

Inspection report M & E QC~Form064a- 01/ REV. 0

4 Check the selection of materials.

ES-CS-17-13 Sec. 3.13 Manufacturers instructions.

Store Keeper --

225439150.xls.ms_office

Date: January 26, 2001

XYZ

Page 2 of 4

QC~PLAN.

Project No. & Name: Name of Client/ Consultant: SL. No. DURING OPERATION 5 Check the route line marking. ACTIVITY CONTROLLING DOCUMENT Constructional drawing. ES-CS-17-13 Sec. 3.11 NATURE & EXTENT OF INSP./ TEST ACCEPTANCE CRITERIA - Set up Min. 3 sight rails always in position at one time. - All manhole locations and branch connection lines properly marked on the ground. - Max. distance between manholes 35 m. Trench width unless specified For 100 mm. dia pipe work - 0.5 m. to a depth of 1.5 m. - 1.0 m. at depths over 1.5 m. For 160 mm. Dia pipe work - 0.55 m. to a depth of 1.5 m. - 1.0 m. at depths over 1.5 m. - Min. cover for pipework 300 mm. - Disposal of earth material on the nearby trench surface and stockpiled for reuse in a safe manner. - Protect from side sliding by using proper sheeting / shoring. - Min. 100 mm. depth pipe cover of hand tamped of pea gravel fill and no sharps. - gravel size passing through 25 mm. sieve but retained on a 5 mm. sieve.

Plumbing Installation (a) Sewer Line Including Hook-up

Doc. No. M & E QC~Plan- 064a/ REV.0 PERSON RESP. AT LOCATION Engineer/ Foremen/ Quality Engineer RECORD Inspection report M & E QC~Form064a- 01/ REV. 0

6 Check the trench excavation.

ES-CS-17-13 Sec. 3, 6.2.3

Engineer/ Foremen/ Quality Engineer

Inspection report M & E QC~Form064a- 01/ REV. 0

7 Check the pre-bedding.

ES-CS-17-13 Sec.3.9, 6.2.3

Engineer/ Foremen/ Quality Engineer

--

225439150.xls.ms_office

Date: January 26, 2001

XYZ

Page 3 of 4

QC~PLAN.

Project No. & Name: Name of Client/ Consultant: SL. ACTIVITY CONTROLLING DOCUMENT Visual Constructional drawing. ES-CS-17-13 Sec.6.2.7, 6.2.8, 6.2.4 & 6.2.5 ES-CS-17-13 Sec.6.2.5 Visual NATURE & EXTENT OF INSP./ TEST ACCEPTANCE CRITERIA - straightness - free from obstructions - adequate pipe support without sunk. - proper sleeve and packing while crossing strctural penetration below ground level. - To maintain invert level of connections to main channel. On Pipeline - 1200 mm. cover. - If cover less than 1200 mm., provide 100 mm. thick concrete raft above 200 mm. of pipe before backfill. - as per approved drawing. - drains joining external to manholes by 135 branches and bends only. - 20 N/mm concrete used in cradles and arches to drains. - not less than 25 N/mm for manhole roof and base slab (or) client's instructions. Internal test pressure At higher end of line Not less than 1.2 m. head of water above the invert of the pipe. At lower end of line Not more than 2.4 m. head of water above the invert of the pipe.

Plumbing Installation (a) Sewer Line Including Hook-up

Doc. No. M & E QC~Plan- 064a/ REV.0 PERSON RESP. AT LOCATION Engineer/ Foremen/ Quality Engineer RECORD Inspection report M & E QC~Form064a- 01/ REV. 0

No. 8 Check the line laying

9 Check the road crossing area.

Engineer/ Foremen/ Quality Engineer

--

10 Check the manhole construction and connections.

ES-CS-17-13 Sec. 6.2.8 & 6.2.4

Engineer/ Foremen/ Quality Engineer

Inspection report M & E QC~Form064a- 01/ REV. 0

11 Check the testing of pipe work

ES-CS-17-13 Sec.6.2.11

Engineer/ Foremen/ Quality Engineer

--

225439150.xls.ms_office

Date: January 26, 2001

XYZ

Page 4 of 4

QC~PLAN.

Project No. & Name: Name of Client/ Consultant: SL. ACTIVITY CONTROLLING DOCUMENT NATURE & EXTENT OF INSP./ TEST ACCEPTANCE CRITERIA Quantity of Water (Minimum) - 3.3 lit/100 m. of 110 mm. pipe - 4.8 lit/100 m. of 160 mm. pipe. - Fill water in line and leave for 2 hours settlement and topping up. - To maintain the test head for 30 minutes and record. - No leakage and ground water infiltration. - Min. of 300 mm. cover hand tamped pea gravel to be laid.

Plumbing Installation (a) Sewer Line Including Hook-up

Doc. No. M & E QC~Plan- 064a/ REV.0 PERSON RESP. AT LOCATION Inspection report M & E QC~Form064a- 01/ REV. 0 RECORD

No. 11 Check the testing of pipe work (contd.)

12 Check the post bedding.

Constructional drawing. Visual Visual

Engineer/ Foremen/ Quality Engineer Engineer/ Foremen/ Quality Engineer Engineer/ Foremen/ Quality Engineer Engineer/ Foremen/ Quality Engineer

--

ON COMPLETION 13 Check the backfill and reinstatement.

14 Check the final connection toES-CS-17-13 existing sewer. Sec. 6.2.9 15 Check the handover of line Visual before commissioning.

16 Check the plan completion. Contract requirement Visual Work Location: Remarks: Quality Engineer: Date:

- refilled and lightly compacted in the trenches. - 300 mm. layer by layer backfilled. - Prior Company written approval. - invert level and gradient maintained to ensure the flow in order. - trenches backfilled. - connections properly done including branches. - all lines tested. - placement of manhole covers. Ensure the activities in accordance with contract requirement.

-Inspection report M & E QC~Form064a- 01/ REV. 0 --

Engineer/ Foremen/ Quality Engineer Engineer / Foremen: Date:

--

225439150.xls.ms_office

Date: January 26, 2001

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Windows Intrusion Detection ChecklistDocument10 pagesWindows Intrusion Detection ChecklistJosé Tomás García CáceresNo ratings yet

- Sample Interview Questions For Planning EngineersDocument16 pagesSample Interview Questions For Planning EngineersPooja PawarNo ratings yet

- SXV RXV ChassisDocument239 pagesSXV RXV Chassischili_s16No ratings yet

- NQA ISO 45001 Implementation GuideDocument36 pagesNQA ISO 45001 Implementation GuideAnonymous 3eHGEDbx100% (11)

- Corporate Restructuring Short NotesDocument31 pagesCorporate Restructuring Short NotesSatwik Jain57% (7)

- Book Speos 2023 R2 Users GuideDocument843 pagesBook Speos 2023 R2 Users GuideCarlos RodriguesNo ratings yet

- M & e MST - 038 Rev. 0Document3 pagesM & e MST - 038 Rev. 0Anonymous 3eHGEDbxNo ratings yet

- 16 Personalities ResultsDocument9 pages16 Personalities Resultsapi-605848036No ratings yet

- VerificationManual en PDFDocument621 pagesVerificationManual en PDFurdanetanpNo ratings yet

- Ransomware: Prevention and Response ChecklistDocument5 pagesRansomware: Prevention and Response Checklistcapodelcapo100% (1)

- Elec Wiring Regs 2007 Rev 01Document240 pagesElec Wiring Regs 2007 Rev 01Anonymous 3eHGEDbxNo ratings yet

- National Gypsum Steel StudPartitionsDocument9 pagesNational Gypsum Steel StudPartitionsAnonymous 3eHGEDbxNo ratings yet

- Historical Record Dimensions and PropertiesDocument145 pagesHistorical Record Dimensions and PropertiesAnonymous 3eHGEDbxNo ratings yet

- Steel Window Service: Scale Drawn CheckedDocument1 pageSteel Window Service: Scale Drawn CheckedAnonymous 3eHGEDbxNo ratings yet

- MOUNT - Fixing PlatesDocument8 pagesMOUNT - Fixing PlatesAnonymous 3eHGEDbxNo ratings yet

- Acoustic Brochure PDFDocument6 pagesAcoustic Brochure PDFAnonymous 3eHGEDbxNo ratings yet

- Pub 100427Document5 pagesPub 100427Engr Nabeel AhmadNo ratings yet

- Purpose: Method Statement M & E No.: M & E Mst-004/ Rev 0 Page 1 of 4 Title: LV Switchgear Installation and TestingDocument4 pagesPurpose: Method Statement M & E No.: M & E Mst-004/ Rev 0 Page 1 of 4 Title: LV Switchgear Installation and TestingAnonymous 3eHGEDbxNo ratings yet

- M & e MST - 036 Rev. 0Document3 pagesM & e MST - 036 Rev. 0Anonymous 3eHGEDbxNo ratings yet

- Xyz Company: PurposeDocument3 pagesXyz Company: PurposeAnonymous 3eHGEDbxNo ratings yet

- 019-Carpentary, Joinery & General FixingDocument2 pages019-Carpentary, Joinery & General FixingAnonymous 3eHGEDbxNo ratings yet

- 021-Suspended CeilingDocument4 pages021-Suspended CeilingAnonymous 3eHGEDbxNo ratings yet

- Xyz Company: PurposeDocument3 pagesXyz Company: PurposeAnonymous 3eHGEDbxNo ratings yet

- Xyz Company: PurposeDocument5 pagesXyz Company: PurposeAnonymous 3eHGEDbxNo ratings yet

- 051 GlazingDocument2 pages051 GlazingAnonymous 3eHGEDbxNo ratings yet

- 018 Insitu FlooringDocument4 pages018 Insitu FlooringAnonymous 3eHGEDbxNo ratings yet

- M & E QC Plan - 0063b REV. 0Document4 pagesM & E QC Plan - 0063b REV. 0Anonymous 3eHGEDbxNo ratings yet

- 015-Roofing, Insulation &water ProofingDocument4 pages015-Roofing, Insulation &water ProofingAnonymous 3eHGEDbxNo ratings yet

- Medabots-Rokusho Version (European) - Medal Codes (Part 1) (GBA Cheats) - CodeTwink ForumsDocument5 pagesMedabots-Rokusho Version (European) - Medal Codes (Part 1) (GBA Cheats) - CodeTwink Forumsdegraded 4resterNo ratings yet

- A Process Reference Model For Claims Management in Construction Supply Chains The Contractors PerspectiveDocument20 pagesA Process Reference Model For Claims Management in Construction Supply Chains The Contractors Perspectivejadal khanNo ratings yet

- Assessment 4 PDFDocument10 pagesAssessment 4 PDFAboud Hawrechz MacalilayNo ratings yet

- Assignment-For-Final of-Supply-Chain - Management of Courses PSC 545 & 565 PDFDocument18 pagesAssignment-For-Final of-Supply-Chain - Management of Courses PSC 545 & 565 PDFRAKIB HOWLADERNo ratings yet

- Bustax Midtem Quiz 1 Answer Key Problem SolvingDocument2 pagesBustax Midtem Quiz 1 Answer Key Problem Solvingralph anthony macahiligNo ratings yet

- Plant Report Template Class 81Document2 pagesPlant Report Template Class 81Kamran KhanNo ratings yet

- DN12278 - 5008 - Indicative Cable Way Route - Rev BDocument9 pagesDN12278 - 5008 - Indicative Cable Way Route - Rev BArtjoms LusenkoNo ratings yet

- Advanced Physiotherapeutic SyllabusDocument1 pageAdvanced Physiotherapeutic SyllabusAnup SharmaNo ratings yet

- Beer Pilkhani DistilleryDocument44 pagesBeer Pilkhani DistillerySunil Vicky VohraNo ratings yet

- VLSI Implementation of Floating Point AdderDocument46 pagesVLSI Implementation of Floating Point AdderParamesh Waran100% (1)

- USDA List of Active Licensees and RegistrantsDocument972 pagesUSDA List of Active Licensees and Registrantswamu885No ratings yet

- Cheerios Media KitDocument9 pagesCheerios Media Kitapi-300473748No ratings yet

- MN Rules Chapter 5208 DLIDocument24 pagesMN Rules Chapter 5208 DLIMichael DoyleNo ratings yet

- AMO Exercise 1Document2 pagesAMO Exercise 1Jonell Chan Xin RuNo ratings yet

- 02 Chapter 2 - Corporate Governance MechanismDocument19 pages02 Chapter 2 - Corporate Governance MechanismHanis ZahiraNo ratings yet

- PronounsDocument6 pagesPronounsHải Dương LêNo ratings yet

- Datos Adjuntos Sin Título 00013Document3 pagesDatos Adjuntos Sin Título 00013coyana9652No ratings yet

- Uts Cmo Module 5Document31 pagesUts Cmo Module 5Ceelinah EsparazNo ratings yet

- Abbas Ali Mandviwala 200640147: Ba1530: Information Systems and Organization StudiesDocument11 pagesAbbas Ali Mandviwala 200640147: Ba1530: Information Systems and Organization Studiesshayan sohailNo ratings yet

- Trading Journal TDA Branded.v3.5 - W - Total - Transaction - Cost - BlankDocument49 pagesTrading Journal TDA Branded.v3.5 - W - Total - Transaction - Cost - BlankChristyann LojaNo ratings yet

- Paper II - Guidelines On The Use of DuctlessDocument51 pagesPaper II - Guidelines On The Use of DuctlessMohd Khairul Md DinNo ratings yet

- Level Swiches Data SheetDocument4 pagesLevel Swiches Data SheetROGELIO QUIJANONo ratings yet