Professional Documents

Culture Documents

Semi Integral 20

Uploaded by

Edward van MartinoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Semi Integral 20

Uploaded by

Edward van MartinoCopyright:

Available Formats

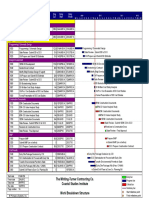

VOL.

V - PART 2

DATE: 11May2007

SHEET 1 of 20

INTEGRAL / JOINTLESS BRIDGES

SEMI-INTEGRAL ABUTMENTS

GENERAL INFORMATION

FILE NO. 20.03-1

GENERAL INFORMATION:

This section of the chapter establishes the practices and requirements necessary for the design

and detailing of semi-integral abutments. For general requirements and guidelines on the use of

semi-integral abutments, see File Nos. 20.01-1 thru -5.

Sample design calculations are provided to assist the designer and are intended to correspond to

the sample details shown in File Nos. 20.03-2 thru -10. Note that calculations are provided for

the backwall and associated structural components only.

Plan and elevation views and sections of the semi-integral abutment are provided in this chapter

for information on the shape of the backwall in relation to the semi-integral backwall and to

illustrate some additional details required on the abutment sheets. Back of stem is the

reference line on the semi-integral abutment and substructure layout sheets. End of slab is the

reference line on remaining sheets.

Additional sample details are provided to assist the designer in the detailing of semi-integral

abutments. These details are provided to show differences in details between steel/concrete

stringers, bridges with/without skew and semi-integral abutment layout.

Preferred practice on semi-integral abutment layout falls in the following order:

1. Wingwalls oriented transversely to traffic, elephant ears, with the terminal wall on the

superstructure. See File Nos. 20.03-11 thru -14.

2. Wingwalls oriented parallel to traffic, u-back wings, with the terminal wall on the

superstructure. Offset the inside face of wall 3 feet from the face of rail/parapet to allow for

dynamic deflection of the attached guardrail. See File Nos. 20.03-15 thru -18.

It is generally desirable to eliminate potential conflicts between superstructure and substructure

components. As such, the second layout preference should only be used where right-of-way

(R/W), maintenance of traffic (MOT) or design restrictions make the preferred layout not feasible.

For design/detailing check list for semi-integral abutments, see File Nos. 20.03-19 and -20.

VOL. V - PART 2

DESIGN OF SEMI-INTEGRAL BRIDGE

Given and Assumptions:

The calculations provided below do not fully correspond to the details shown in File Nos. 20.03-11

thru -14 but are similar.

= 145 pcf Unit weight of soil (select backfill material) (See Manual of

S&B Division Vol. V - Part 2, file no. 17.102-2)

K

p

= 4 Assumes the use of EPS material behind backwall

W = 43.33 Total bridge width

Bridge

L = 250.0 ft Bridge length

Bridge

L

Thermal

= 125.0 ft Length of thermal expansion

H = 6.33 ft Backwall height

Backwall

T = 1.58 ft Backwall thickness

Backwall

S = 9.33 ft Beam spacing

Beam

Overhang = 3.0 ft Slab (and integral backwall) overhang

Cover = 3.5 in Cover over reinforcing steel in backwall

f

c

= 4,000 psi Compressive strength of backwall concrete

f = 3,000 psi Compressive strength of wing concrete

cWall

f

y

= 60,000 psi Yield strength of reinforcing steel

= 30 deg Bridge skew angle

-6

= 6.5 x 10 per deg F Coefficient of thermal expansion

D

AS

= 1.5 ft Depth of approach slab at backwall

H = 3.0 in Height of bearing

Bearing

T = 1 in Thickness of bottom flange

bottomflange

T = 15.0 in Wing thickness

wing

'

c

1.5

s

b

f w

E

n

33

=

= 8 Modular ratio of concrete to steel for backwall

'

cWall

1.5

s

w

f w

E

n

33

=

=9 Modular ratio of concrete to steel for wing

DATE: 11May2007

SHEET 2 of 20

INTEGRAL / JOINTLESS BRIDGES

SEMI-INTEGRAL ABUTMENTS

SAMPLE DESIGN CALCULATIONS

FILE NO. 20.03-2

VOL. V - PART 2

DATE: 11May2007

SHEET 3 of 20

INTEGRAL / JOINTLESS BRIDGES

SEMI-INTEGRAL ABUTMENTS

SAMPLE DESIGN CALCULATIONS

FILE NO. 20.03-3

VOL. V - PART 2

Design of Backwall:

Determine backwall moments and shears

2

Backwall p

(H K

2

1

w ) =

Earth pressure resultant per foot

2

ft 33 lbs)(4)(6. k/1000 1 x pcf 145

2

1

w ) ( =

= 11.6 klf

cos

S

L

Beam

=

Beam/girder spacing along skew

ft 10.77

30 cos

ft 9.33

L = =

o

For simplicity, use the following equations to determine moments, shear, and reaction.

2

pos

0.08wl M =

2

= 0.08(11.6 klf)(10.77 ft) = 107.6 ft-kip Maximum positive moment

2 2

neg

0.10wl M = = 0.10(11.6 klf)(10.77 ft) = 134.6 ft-kip Maximum negative moment

= 0.6(11.6 klf)(10.77 ft) = 75.0 k Maximum shear 0.6wl V

max

=

= 1.1(11.6 klf)(10.77 ft) = 137.4 k Maximum reaction at girder 1.1wl R

max

=

Check to make sure overhang does not govern.

=

=

2

OH

cos

Overhang

0.5w M

2

30 cos

ft 3.0

klf) 0.5(11.6

o

DATE: 11May2007

SHEET 4 of 20

INTEGRAL / JOINTLESS BRIDGES

SEMI-INTEGRAL ABUTMENTS

SAMPLE DESIGN CALCULATIONS

FILE NO. 20.03-4

M

OH

= 69.6 ft-kip < M Interior support governs

neg

=

=

cos

Overhang

w V

OH

o

30 cos

ft 3.0

klf) (11.6

= 40.2 k < V Interior support governs

max

VOL. V - PART 2

Design Integral Backwall:

Group IV load combination controls. Group IV allowable overstress is 125%.

**For this example, Group IV loading controls the design. It shall be the responsibility of the

designer to verify which load case controls, and design accordingly.

f

DATE: 11May2007

SHEET 5 of 20

INTEGRAL / JOINTLESS BRIDGES

SEMI-INTEGRAL ABUTMENTS

SAMPLE DESIGN CALCULATIONS

FILE NO. 20.03-5

s

= 125%(0.4F

y

) f

s

= 30,000 psi Allowable stress of steel

f

c

= 125%(0.4f

c

) f

c

= 2,000 psi Allowable of stress of concrete

) f 125%(0.95 v

'

c e c.allowabl

=

v = 75 psi

c.allowable

Allowable shear stress in

concrete

Flexure design using negative moment:

n = 8 Modular ratio of backwall concrete to

steel

h = 19.0 in Height of section resisting flexure h = T

Backwall

D = 76.0 in 18.0 in = 58.0 in Width of section resisting flexure b = H

Backwall AS

d

1

= h Cover = 19.0 in 3.5 in = 15.5 in Depth to first mat of reinforcing steel

d

2

= h 10.0 in = 19.0 in 10 in = 9.0 in Depth to second mat of reinforcing steel

d = 3.5 in Depth to compression steel

Try #6 bars at ~9 spacing. For this backwall height, there are 7 bars in each tension layer.

2

A

s1

= 3.08 in A

2

s2

= 3.08 in

+

+

=

s2 s1

2 s2 1 s1

A A

d A d A

d Depth to centroid of tension steel

2

2 2

2 2

in 12.25

in 3.08 in 3.08

in) (9.0 in 3.08 in) (15.5 in 3.08

d =

+

+

=

2

= 3.08 in 7 bars in compression layer A

sc

Performing section analysis (including the compression steel)

Y = 3.75 in Distance from compression face to neutral axis

NA

F

s1

= 29,800 psi < f

s.allowable

= 30,000 psi OK In first layer of tension steel

F

c

= 1,200 psi < f

c.allowable

= 2,000 psi OK

VOL. V - PART 2

Shear Design:

V = V

max

= 75.0 k

( )

psi 106

in) in(12.25 58.0

k) lbs/1 k(1000 75.0

bd

V

v

max

= = =

Actual shear stress in concrete

, Shear reinforcement required v = 75 psi v > v

c.allowable c.allowable

DATE: 11May2007

SHEET 6 of 20

INTEGRAL / JOINTLESS BRIDGES

SEMI-INTEGRAL ABUTMENTS

SAMPLE DESIGN CALCULATIONS

FILE NO. 20.03-6

Use #4 stirrups, with 2 legs in the shear plane, A

v

= 0.4 in

2

.

Equation (8-7) from AASHTO Sec. 8.15.5.3

( )

( )

in 6.7

in psi)58.0 75 psi (106

psi) (30,000 in 0.4

b v v

f A

s

2

e c.allowabl

e s.allowabl v

=

=

Stirrup spacing

Check AASHTO Sec. 8.19.1.2 to see if spacing above is OK.

( )

y

v.min

f

50bs

A =

Rearranging the above equation, with A

v

= 0.4 in

2

:

( )

in 8.3

in) 50(58.0

psi) (60,000 in 0.4

50b

f A

s

2

y v.min

= = =

s = 6.7 in controls

Shear Stud Design at Girder Ends:

Z

r

= 8.12 k

For

7

/

8

AASHTO Sec. 10.38.5.1.1

Z

r

= 125%(8.12 k) Horizontal shear capacity per

stud, with 25% overstress

Z

r

= 10.15 k

13.5

k 10.15

k 137.4

Z

R

n

r

max

studs

= = =

7

/ Therefore, use 7,

8

studs on each side of beam web, for a total of 14 studs.

VOL. V - PART 2

Determine reaction at acute corner and wing buttress:

See lateral force derivation in files nos. 20.07-4 thru -6.

( ) ( )

k 263.8

30 tan

ft 250

ft 43.33

1

30 ft)tan klf(43.33 [11.6

tan

L

W

1

tan W w

R

Bridge

Bridge

Bridge

p

=

+

=

+

=

o

o

]

Determine size of rub plates:

DATE: 11May2007

SHEET 7 of 20

INTEGRAL / JOINTLESS BRIDGES

SEMI-INTEGRAL ABUTMENTS

SAMPLE DESIGN CALCULATIONS

FILE NO. 20.03-7

t

= 120 deg.

= 125.0 ft L

Thermal

t Thermal rub

L

3

2

L

=

in 0.78 F) F)(120 deg. per 10 ft)](6.5 in/1 ft(12 [125

3

2

L

6

rub

=

=

o

Estimated maximum movement in one direction

at abutment. Assume that the temperature

increase will only be two-thirds of the total range.

h

rp

= H - 3 in - 2 in - H T

Backwall Bearing bottomflange

Height of rub plates

(See note 4 on File No. 20.03-19)

= 6.33 ft(12 in/1 ft) 3 in 2 in 3 in 1 in = 67 in h

rp

F

g

= 2,000 psi Maximum galling stress for ASTM A276 Type

316 steel, of which the rub plates are

constructed.

= 0.55 F = 1,100 psi Allowable galling stress f

g g

( )

g rp

p

min

f h

R

w = Minimum rub plate width

in 3.58

psi) in(1,100 67

k) lbs/1 k(1000 263.8

w

min

= =

VOL. V - PART 2

Ensure the minimum rub plate width is maintained during extremes of the temperature cycle.

w = w

DATE: 11May2007

SHEET 8 of 20

INTEGRAL / JOINTLESS BRIDGES

SEMI-INTEGRAL ABUTMENTS

SAMPLE DESIGN CALCULATIONS

FILE NO. 20.03-8

min

+ L = 3.58 in + 0.78 in = 4.36 in

rub

Use 5 in x 64 in x 0.5 in rub plate

Design wing haunch to resist load transferred through the rub plates:

Slope = 1.5 Rate of slop of wing per ft

Assume that the resultant is uniformly

distributed along the rub plate

klf 41.7

ft 6.33

k 263.8

H

R

w

Backwall

p

w

= = =

( )

2

H w

M

2

Backwall w

s

=

Moment about seat level

kip ft 835.4

2

ft) klf(6.33 41.7

M

2

s

= =

VOL. V - PART 2

= 263.8 k Shear force V = R

p

= 2.0 ft + H (Slope) Length of shear plane that is resisting R L

wing Backwall p

= 2.0 ft + 6.33 ft(1.5) = 11.5 ft L

wing

C = 4.5 in Centroid of tension steel

cg

= L C Distance from compression face to cg of d

wing wing cg

tension steel

= 11.5 ft (4.5 in(1 ft/12 in) = 11.1 ft d

wing

) f 125%(0.95 v

'

cwall wing allowable c

=

= 65 psi Allowable shear stress for Group IV v

c allowable wing

= 15.0 in T

wing

psi 132

ft)] in/1 ft(12 in[11.1 15.0

k) lbs/1 k(1000 263.8

d T

V

v

wing wing

= = =

Actual shear stress

DATE: 11May2007

SHEET 9 of 20

INTEGRAL / JOINTLESS BRIDGES

SEMI-INTEGRAL ABUTMENTS

SAMPLE DESIGN CALCULATIONS

FILE NO. 20.03-9

v > v

c allowable

, Shear reinforcement required

2

Use #4 stirrups, with 2 legs in the shear plane, A

v

= 0.4 in .

Equation (8-7) from AASHTO Sec. 8.15.5.3

( )

wing wing allowable c

allowable s v

T v v

f A

s

= Stirrup spacing

( )

in 11.9

in) (15.0 psi 65 - psi 132

psi) (30,000 in 0.4

s

2

= =

Check AASHTO Sec. 8.19.1.2 to see if spacing above is OK.

( )

y

v.min

f

50bs

A =

Rearranging the above equation, with A

v

= 0.4 in

2

:

in 32

in) 50(15.0

psi) (60,000 in 0.4

50T

f A

s

2

wing

y v.min

= = =

s = 11.9 in controls

VOL. V - PART 2

DATE: 11May2007

SHEET 10 of 20

INTEGRAL / JOINTLESS BRIDGES

SEMI-INTEGRAL ABUTMENTS

SAMPLE DESIGN CALCULATIONS

FILE NO. 20.03-10

Design Wing Reinforcement to resist moment due to R

p

:

Try two rows of #5 bars, with 5 bars per row

d

1

= L

wing

Cover Depth to first mat of reinforcing steel

d

1

= 11.5 ft(12 in/1 ft) 3.5 in = 134.5 in

d

2

= d

1

3 in = 134.5 in 3 in = 131.5 in Depth to second mat of reinforcing steel

A

s1

= 1.53 in

2

A

s2

= 1.53 in

2

Performing section analysis (including the compression steel)

f

s1

= 25,940 psi < f

s allowable

= 30,000 psi OK in first layer of tension steel

f

c

= 350 psi < f

c allowable

= 2,000 psi OK

Thickness of the EPS layer:

Thickness of EPS layer as per File No. 20.06-6:

t = 120F

L

= (L

thermal

t) Total range of movement at abutment

due to temperature

L

= 125.0 ft(12in/1ft)(6.5x10

-6

per deg. F

)120F = 1.17 in

EPS

t

= 10(0.01H

Backwall

+ 0.67

L

)

EPS

t

= 10[(0.01)(76.0 in)+ (0.67)(1.17 in)] = 15.4 in

Therefore, use EPS

t

= 16 in.

NOTE: DESIGN FOR PRESTRESSED CONCRETE BEAMS IS SIMILAR.

VOL. V - PART 2

CHECK LIST FOR SEMI-INTEGRAL ABUTMENTS

1 Wing haunch at acute corner shall be designed to resist the moment and shear induced by

the force resulting from the passive earth pressure and the skew. Rub plates and the

additional backwall thickness are only required at the acute corners of skewed bridges. Rub

plates to be centered vertically and horizontally over contact area.

DATE: 11May2007

SHEET 19 of 20

INTEGRAL / JOINTLESS BRIDGES

SEMI-INTEGRAL ABUTMENTS

CHECK LIST

FILE NO. 20.03-19

2 Minimum thickness of the preformed joint filler between the backwall and the wing at the

obtuse corner shall be 1. This may be increased due to thermal expansion in the transverse

direction.

3 Extend wing 6 above finished grade. Not required for bridges without skew or where

terminal wall is on the substructure.

4 Top of rub plate to begin 3 below top of deck. Bottom of rub plate to maintain 2 clear from

top of bottom flange for steel superstructures; 3 clear from bottom of beam for concrete.

Preformed joint filler to extend as shown.

5 Provide distance from back of stem to break in seat to allow for contraction and creep with 1

clear.

6 Delete this note if railings are used or slip forming of parapets is not allowed.

7 Bridge plans shall be arranged such that backwall details follow the Deck Plan. For general

sheet order, see File No. 01.02-4.

8 Show plan and elevation view of integral backwall at a preferred scale of

3

/

8

=1-0. The

elevation view should be projected down from the plan view. When bridge is not on skew

and where sufficient room is not available in elevation view, plan view is not required.

9 Label the location centerline/baseline as shown on the title sheet.

10 End of slab shall be used as the reference line for layout of integral backwalls.

11 Label skew angle (if applicable).

12 The minimum width of integral backwall shall be 1-7 for steel stringers and 1-10 for

concrete stringers. Clipping flanges is preferable to increases in thickness where required

due to skew.

13 All ST series and SV series bars shall be aligned parallel to the beam/girder centerline. The

maximum spacing shall be 12. ST0602 bars between the backwall and the approach slab

(where applicable) are not required outside of the exterior beam/girder.

14 Thickness of backwall shall be increased by 10 at the acute corner of skewed bridges

outside of the exterior stringers. The increase in thickness shall end at the top surface of the

bottom flange for steel stringers or 1 above the bottom of beam for concrete stringers.

15 ST0501, ST0602, SV0402 and SV0504 shall be galvanized. All other backwall reinforcing

steel shall be epoxy-coated.

16 Distance between face of integral backwall and back of stem shall be a minimum of 4.

VOL. V - PART 2

CHECK LIST FOR SEMI-INTEGRAL ABUTMENTS (Continued)

17 The approach slab seat (7) shall be provided on all integral backwalls regardless of whether

the bridge will have an approach slab.

DATE: 11May2007

SHEET 20 of 20

INTEGRAL / JOINTLESS BRIDGES

SEMI-INTEGRAL ABUTMENTS

CHECK LIST

FILE NO. 20.03-20

18 In case of single span semi-integral bridge, use the temporary blocking note shown.

Otherwise, delete it.

19 Show sections taken through the integral backwall at a preferred scale of

3

/

4

= 1-0.

Coordinate the sections to provide the necessary details with repetition only where required.

20 Location and details of holes in the web and the studs should be included with the

beam/girder details.

21 For additional details concerning the use of EPS material and calculations for the required

thickness, see File No. 20.06-6.

22 To ensure adequate cover on ST0602 bar, the designer must modify the approach slab

standard.

23 Maximum spacing is 12.

24 Note not needed for PCBT-53 and larger.

25 The minimum embedment into the backwall is 6 for steel stringers and 9 for concrete

stringers.

26 When approach slab is used with concrete superstructure, hook ST0602 bar and embed as

shown.

27 For instructions on completing the title block, see File No. 03.03.

28 For instructions on completing the project block, see File No. 03.02.

29 For instructions on developing the CADD sheet number, see File Nos. 01.01-7 and 01.14-4.

You might also like

- T Girder Bridge Deck Diaphragm-20 MDocument14 pagesT Girder Bridge Deck Diaphragm-20 MAmitabha DebNo ratings yet

- Design of Bridges Question Bank for III SemesterDocument14 pagesDesign of Bridges Question Bank for III SemesterNarayanan MoorthyNo ratings yet

- Pier Column Design PDFDocument6 pagesPier Column Design PDFJaycee Bareng PagadorNo ratings yet

- Skew Bridges Calculation MethodsDocument9 pagesSkew Bridges Calculation MethodsIsidro P. BuquironNo ratings yet

- Analysis of Deck Slab and Tee Beam of A BridgeDocument59 pagesAnalysis of Deck Slab and Tee Beam of A Bridgenidhisasidharan100% (2)

- Integral Bridges: What Is An Integral Bridge?Document20 pagesIntegral Bridges: What Is An Integral Bridge?Akhilesh Goje100% (1)

- Detail Design of Bridge Abutment 1Document4 pagesDetail Design of Bridge Abutment 1mohammad azimNo ratings yet

- CORUS Composite Steel Highway BridgesDocument28 pagesCORUS Composite Steel Highway BridgesAbdulkhaliq AbdulyimahNo ratings yet

- Transforming Railways Seismic CodeDocument39 pagesTransforming Railways Seismic CodevigneshrajamanickamNo ratings yet

- Design of end diaphragm reinforcementDocument2 pagesDesign of end diaphragm reinforcementAlok vermaNo ratings yet

- RATING RC SLAB BRIDGESDocument14 pagesRATING RC SLAB BRIDGESAndy Acoustic100% (1)

- Balanced Cantilever StabilityDocument12 pagesBalanced Cantilever StabilityTeo Peng KeatNo ratings yet

- Bridge Foundation Design FactorsDocument23 pagesBridge Foundation Design FactorsNisarga KeshavmurthyNo ratings yet

- Super T StandardsDocument16 pagesSuper T Standardschithirai10No ratings yet

- Design Balanced Cantilever BridgesDocument26 pagesDesign Balanced Cantilever BridgesShijo AntonyNo ratings yet

- 5377 68 23Document8 pages5377 68 23JamesNo ratings yet

- Portal BridgeDocument123 pagesPortal Bridgenandu523No ratings yet

- Span 20 MDocument111 pagesSpan 20 MajayNo ratings yet

- Steel Connections-Lacing-Bridge BearingDocument11 pagesSteel Connections-Lacing-Bridge BearingRaheelAfzaalNo ratings yet

- Bridge TrussDocument15 pagesBridge TrussArjunRK100% (1)

- P8 Alok BhowmickDocument15 pagesP8 Alok BhowmickSony JsdNo ratings yet

- End Block Design AidDocument6 pagesEnd Block Design AidAhsan KhanNo ratings yet

- Composite Beam DesignDocument33 pagesComposite Beam DesignihpeterNo ratings yet

- 08 Integral and Semi Integral AbutmentsDocument49 pages08 Integral and Semi Integral AbutmentsBPRSchaefer100% (3)

- Bridge Deck With Link-SlabDocument31 pagesBridge Deck With Link-Slabquithanqui100% (1)

- Alternative Forms of Two Lane T-Beam Bridge Superstructure - Study by Grillage AnalogyDocument9 pagesAlternative Forms of Two Lane T-Beam Bridge Superstructure - Study by Grillage AnalogyAnkur SrivastavaNo ratings yet

- Design Rules For Aerodynamic Effects On BridgesDocument46 pagesDesign Rules For Aerodynamic Effects On BridgesAnkush KumarNo ratings yet

- The Design of Integral BridgesDocument27 pagesThe Design of Integral BridgesBridgy mcbridgeNo ratings yet

- Design of A Composite Road Bridge With High Strength SteelDocument6 pagesDesign of A Composite Road Bridge With High Strength SteelJoão Rocha de LimaNo ratings yet

- Shear Capacity of Circular Concrete SectionsDocument14 pagesShear Capacity of Circular Concrete Sectionspatricklim1982No ratings yet

- Recent Integral BridgesDocument54 pagesRecent Integral Bridgeskunjal_radiaNo ratings yet

- Curved Girder BridgeDocument69 pagesCurved Girder BridgeBurakku RōzuNo ratings yet

- IMPLICATION OF IRC 112 ON RCC BRIDGE DESIGNDocument8 pagesIMPLICATION OF IRC 112 ON RCC BRIDGE DESIGNkrunalNo ratings yet

- Structural Bridge Design Example Manual - New Zealand & AustraliaDocument388 pagesStructural Bridge Design Example Manual - New Zealand & AustraliaEric Villenas0% (1)

- Prestressed Concrete Bridge SuperstructuresDocument18 pagesPrestressed Concrete Bridge SuperstructuresVashdev100% (1)

- Box Girder - Bridge - Sci PDFDocument58 pagesBox Girder - Bridge - Sci PDFTarun Kant GoyalNo ratings yet

- PC Cable-Stayed Bridge Construction Stage AnalysisDocument28 pagesPC Cable-Stayed Bridge Construction Stage AnalysisEncik BadrulNo ratings yet

- M54 Unit 10 Skew Deck & Intergral BridgesDocument25 pagesM54 Unit 10 Skew Deck & Intergral BridgesPhilip YapNo ratings yet

- Steel Truss Bridge 3D Modeling and AnalysisDocument61 pagesSteel Truss Bridge 3D Modeling and Analysisvaibhav dahiwalkar100% (1)

- Design of Slender Reinforced Concrete Bridge Columns Considering The Interaction Between ColumnsDocument10 pagesDesign of Slender Reinforced Concrete Bridge Columns Considering The Interaction Between ColumnsTeo Peng Keat100% (1)

- Prestress Bridge Design PDFDocument79 pagesPrestress Bridge Design PDFdsam123No ratings yet

- T-Roff Girder DesignDocument41 pagesT-Roff Girder Designlinda100% (1)

- Losses in Prestress-Friction, Anchorage SlipDocument16 pagesLosses in Prestress-Friction, Anchorage SlipSravanthi MeharNo ratings yet

- Wood-Armer Principle IRJETDocument7 pagesWood-Armer Principle IRJETRishikesh MajumdarNo ratings yet

- Substructures - Solutions - MidasbridgeDocument14 pagesSubstructures - Solutions - Midasbridgechao liuNo ratings yet

- Bridge Design Diaphragms Ch11notes - PDFDocument74 pagesBridge Design Diaphragms Ch11notes - PDFfraantoine100% (2)

- LFD Vs LRFD PDFDocument3 pagesLFD Vs LRFD PDFYuriMamaniNo ratings yet

- Integral Abutment and Jointless BridgesDocument343 pagesIntegral Abutment and Jointless BridgesJc Wong100% (3)

- Cable Supported Bridges: Concept and DesignFrom EverandCable Supported Bridges: Concept and DesignRating: 5 out of 5 stars5/5 (1)

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesFrom EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesNo ratings yet

- Bridging the Strait: The Story of The Confederation Bridge ProjectFrom EverandBridging the Strait: The Story of The Confederation Bridge ProjectRating: 5 out of 5 stars5/5 (2)

- BDM Example 6 - 20180101Document23 pagesBDM Example 6 - 20180101mustafurade1No ratings yet

- Shear Wall - BS8110-97-007Document4 pagesShear Wall - BS8110-97-007Kavin TamNo ratings yet

- Design Parameters of Steel SMF Connections - Adan - 08 22 11 PDFDocument12 pagesDesign Parameters of Steel SMF Connections - Adan - 08 22 11 PDFkalinggacitraNo ratings yet

- Short Span Bridges-PciDocument78 pagesShort Span Bridges-Pcipetre_filipov100% (1)

- 100'x30' 4U4S (Taunggyi)Document18 pages100'x30' 4U4S (Taunggyi)R Kar HeinNo ratings yet

- Design and Analysis of Pre Stressed I Girders by Midas Civil SoftwareDocument7 pagesDesign and Analysis of Pre Stressed I Girders by Midas Civil SoftwareEditor IJTSRDNo ratings yet

- C EngrNB Antiquated Stuart Sept08 PDFDocument4 pagesC EngrNB Antiquated Stuart Sept08 PDFJason PowellNo ratings yet

- Fundamentals of Bridge Design Note (Repaired)Document73 pagesFundamentals of Bridge Design Note (Repaired)Awoke Aschale75% (4)

- Faculty - Civil Engineering - 2022 - Session 1 - Degree - Ecs416Document4 pagesFaculty - Civil Engineering - 2022 - Session 1 - Degree - Ecs416Sarah ZulaikhaNo ratings yet

- 7 - The Influence of Nails and Plasterboard On The Racking Resistance of Stud WallsDocument10 pages7 - The Influence of Nails and Plasterboard On The Racking Resistance of Stud WallsJulian TumielewiczNo ratings yet

- Nonlinear Analysis of Flanged RC Beams Using 3D FEMDocument15 pagesNonlinear Analysis of Flanged RC Beams Using 3D FEMCivil EngsNo ratings yet

- Boq6 PDFDocument7 pagesBoq6 PDFmd. shaju ahamedNo ratings yet

- Method Statement For Pipe Culvert Anil SahabDocument2 pagesMethod Statement For Pipe Culvert Anil SahabAsad AshfaqNo ratings yet

- Prefab Building Elements For Affordable Housing.Document41 pagesPrefab Building Elements For Affordable Housing.shrikant100% (7)

- The Pushover Analysis, Explained in Its SimplicityDocument13 pagesThe Pushover Analysis, Explained in Its SimplicityAnonymous O404LiV4CNo ratings yet

- Reinforced Concrete Continuous Beam Analysis and Design (ACI 318-14) PDFDocument44 pagesReinforced Concrete Continuous Beam Analysis and Design (ACI 318-14) PDFsteveNo ratings yet

- QLD TMR Design Criteria For Bridges and Other StructuresDocument215 pagesQLD TMR Design Criteria For Bridges and Other Structuresyyanan1118No ratings yet

- Method For Slope Failure ProtectionDocument5 pagesMethod For Slope Failure ProtectionMar Maslan100% (4)

- Load balancing beam capacityDocument13 pagesLoad balancing beam capacityLexi BarcelonNo ratings yet

- Reinforcing BarsDocument3 pagesReinforcing BarsSabre D. ButitoNo ratings yet

- Simply Supported Secondary Composite BeamDocument11 pagesSimply Supported Secondary Composite BeamgeorgeispasoiuNo ratings yet

- Msar MHT Pa Ic Zn1 TC Fwi DWG STR 0401 Msar MHT Pa Ic Zn1 TC Fwi DWG STR 0401Document1 pageMsar MHT Pa Ic Zn1 TC Fwi DWG STR 0401 Msar MHT Pa Ic Zn1 TC Fwi DWG STR 0401柔道—Ibn MasudNo ratings yet

- Department of Public Works and Highways: Region VDocument11 pagesDepartment of Public Works and Highways: Region VMarianne Jocel CostacioNo ratings yet

- Load Distribution Calculation by One Way SlabDocument9 pagesLoad Distribution Calculation by One Way Slabmona vermaNo ratings yet

- Table 6-10 Values of For Joint Strength Calculation: ConcreteDocument1 pageTable 6-10 Values of For Joint Strength Calculation: ConcreteJansen SjaklifNo ratings yet

- Delivery Note Mir Concrete Products LTD: 59 TongiDocument1 pageDelivery Note Mir Concrete Products LTD: 59 TongiQC Department Mir Concrete Products LimitedNo ratings yet

- 1.0 Earthquake Load Combination: Strength DesignDocument4 pages1.0 Earthquake Load Combination: Strength DesignAtienza ArjayNo ratings yet

- PM WBS Construction Schedule PDFDocument10 pagesPM WBS Construction Schedule PDFXozanNo ratings yet

- Spun PileDocument7 pagesSpun Pileمحمد فيذول100% (2)

- Design of Flat Slab with Reinforcement DetailsDocument8 pagesDesign of Flat Slab with Reinforcement DetailsMeganathan Mega100% (1)

- Design codes, safety and behavior of RC structuresDocument23 pagesDesign codes, safety and behavior of RC structuresAhmad Faraz JuttNo ratings yet

- Concrete Durability Requirements for Long-Term PerformanceDocument2 pagesConcrete Durability Requirements for Long-Term PerformanceShahab SadeghpourNo ratings yet