Professional Documents

Culture Documents

Pages From 2. R215-V6 (High Pressure Separator - RevP1

Uploaded by

aleemudin86Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pages From 2. R215-V6 (High Pressure Separator - RevP1

Uploaded by

aleemudin86Copyright:

Available Formats

Saudi Aramco 2616-ENG (10/2002)

O

P

R

N

S

SAUDI ARABIAN OIL COMPANY

P

M

T

C

E

R

T

E

N

G

G

D

E

S

C

R

I

P

T

I

O

N

I

S

S

U

E

D

F

O

R

C

O

M

M

E

N

T

S

(

F

W

S

R

E

V

O

1

)

I

S

S

U

E

D

F

O

R

P

R

O

J

E

C

T

P

R

O

P

O

S

A

L

(

F

W

S

R

E

V

D

1

)

J

O

/

E

W

O

1

0

-

0

0

7

4

1

1

0

-

0

0

7

4

1

D

A

T

E

F

E

B

-

1

2

J

U

N

-

1

2

R

E

V

.

N

O

.

A

B

DISCIPLINE

ENGINEER

DRD

DATE J UN-12

PROJ ECT

ENGINEER

________________

DATE ___________

CERTIFIED

RS

DATE ___________

CONSTRUCTION

AGENCY

________________

DATE ___________

OPERATIONS

________

DATE ___________

E

D

S

D

V

E

R

I

F

I

C

A

T

I

O

N

C

O

N

T

R

O

L

N

U

M

B

E

R

B

Y

:

_

_

_

_

_

_

_

_

_

_

_

_

_

_

D

A

T

E

_

_

_

_

_

_

_

_

_

_

_

_

_

R

E

V

I

S

I

O

N

C

E

R

T

I

F

I

C

A

T

E

T

H

I

S

I

N

D

I

C

A

T

E

S

T

H

A

T

R

E

V

.

N

O

.

_

_

_

_

_

_

_

_

_

_

_

_

O

F

T

H

I

S

D

R

A

W

I

N

G

I

S

C

O

V

E

R

E

D

,

F

O

R

A

L

L

A

P

P

R

O

V

A

L

/

C

E

R

T

I

F

I

C

A

T

I

O

N

R

E

Q

U

I

R

E

M

E

N

T

S

,

B

Y

D

R

A

W

I

N

G

C

O

M

P

L

E

T

I

O

N

C

E

R

T

I

F

I

C

A

T

E

(

D

C

C

)

N

O

.

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

MECHANICAL RERATE REPORT FOR DWG.TYPE

PLANT .NO INDEX DRAWING NO. SHT. NO.

REV.

NO.

HIGH PRESSURE SEPERATOR (R215-V6) DOC

Z12 D PP-E05448

52

OF

71

B

CLEAN TRANSPORTATION FUELS PROJ ECT, RIYADH REFINERY

RIYADH, SAUDI ARABIA J O / EWO: BI-10-00741

DOC CLASS: 4 DSN: 2179

T

H

I

S

D

R

A

W

I

N

G

A

N

D

T

H

E

I

N

F

O

R

M

A

T

I

O

N

C

O

N

T

A

I

N

E

D

H

E

R

E

I

N

A

R

E

T

H

E

S

O

L

E

P

R

O

P

E

R

T

Y

O

F

S

A

U

D

I

A

R

A

M

C

O

.

N

O

R

E

P

R

O

D

U

C

T

I

O

N

I

N

F

U

L

L

O

R

I

N

P

A

R

T

S

H

A

L

L

B

E

O

B

T

A

I

N

E

D

F

R

O

M

T

H

I

S

D

O

C

U

M

E

N

T

W

I

T

H

O

U

T

T

H

E

W

R

I

T

T

E

N

C

O

N

S

E

N

T

O

F

I

T

S

O

W

N

E

R

.

APPENDIX 3 PRELIMINARY SAFETY INSTRUCTION SHEET

psi

I.D. m(ft) Nom. Thick. mm(ins SHAPE

3 mm(in)

EQUIPMENT DATA

3 mm(in)

32-SAMMSS-004

FYC-Z12-32-A039-001-001

ASME VIII DIV 2 1977 Ed, API 510 9TH Ed 2006

; CORROSION ALLOWANCE

SERVICE

SA 266 Cl 2

HGH PRESSURE SEPARATOR

HEAD I.D. m(ft.)

ORDER NO.

; CORROSION ALLOWANCE

LENGTH m(ft.)

55 BOOT

3.98

0.91

BUTT (SINGLE SIDED GROOVE) SHELL TO HEAD

HEAD FULL BUTT (DOUBLE SIDED GROOVE)

SEAMS TYPE RADIOGRAPHY EFFICIENCY E

225

O

C(

O

F)

7.62

1.67

3.98

: RATING AND FACING

1500#RTJ

1500#RTJ / RF

POSITION kPa (psi) POSITION

: THICK, MAT'L. AND

LIMITED BY :

LINING

PACKING

TRAYS

BOTH

MDMT:

0.85 / 1.0 POST WELD HEAT TREATMENT

YES (TBC)

AT TOP

SHELL STRESS

232

2904

kPa (psi)

PROTECTED BY SAFETY VALVE ON

TEST PRESSURE, at TOP

103.4 EXTERNAL PRESSURE :

S.V. SET AT

MINIMUM THICKNESS

HEADS :

PRESSURE AND TEMPERATURE 47.8

OTHER GOVERNING CONSIDERATION

SHELL SECTION tm mm(ins)

DRAWING NO.

BASED ON :

INDEX

T

H

I

S

R

E

V

I

S

I

O

N

N

O

.

I

S

C

O

V

E

R

E

D

,

F

O

R

A

L

L

A

P

P

R

O

V

A

L

R

E

V

I

E

W

F

O

R

K

E

Y

D

R

A

W

I

N

G

S

C

O

N

S

T

.

A

G

E

N

C

Y

/

D

A

T

E

D

E

S

I

G

N

C

E

R

T

I

F

I

C

A

T

I

O

N

O

P

E

R

A

T

I

O

N

S

/

D

A

T

E

C

E

R

T

I

F

I

E

D

/

D

A

T

E

RIYADH REFINERY

D

R

A

W

I

N

G

C

O

M

P

L

E

T

I

O

N

C

E

R

T

I

F

I

C

A

T

E

N

O

.

NOTES:

1. CORROSION ALLOWANCE HAS BEEN REVISED TO 3MM FROM ORGINAL 4.8MM. NO BENEFIT FROM THIS CHANGE HAS BEEN ASSUMED TO CONTRIBUTE

TO MATERIAL PRESSURE THICKNESS, THE EXCESS HAS BEEN ASSUMED TO COVER ANY MATERIAL LOSS FROM OPERATION.

2. CALCULATED TEST PRESSURE INDICATED IS AS A RESULT OF THE RERATE TO 232C DESIGN TEMPERATURE AND MUST BE CARRIED OUT IN THE

FIELD.

BOTH 101.4 INDICATED DESIGN TEMP AND PRESSURE

: THICK AND TYPE

BASED ON INDICATED DESIGN

: NO. MAT'L. AND DRAWING NO.

: SHOP

: SIZE, HEIGHT AND MAT'L.

METHOD OF ATTACHMENT

kPa (psi) FIELD

SHELL

SPECIAL DESIGN CONSIDERATION OR

UNUSUAL CONSTRUCTION FEATURES

kPa (psi)

OPERATING LIMITS

(CHANGES TO OPERATING LIMITS REQUIRE OPERATIONS ENGINEERING APPROVAL)

14514 DESIGN PRESSURE, AT TOP

O

C(

O

F)

SHELL

INDICATED DESIGN TEMP AND PRESSURE

20030 (Note 2)

TEST PRESSURE, WIND LOAD, OR

DWG. TYPE

: RATING AND FACING

INDICATED DESIGN TEMP AND PRESSURE

SIS

220.2

BOOT

NOTE BELOW ANY SPECIAL HAZARDS, RECOMMENDATIONS, INSPECTIONS, OR TESTS THAT ARE IMPORTANT FOR THIS EQUIPMENT.

1 OF 1

PLANT NO.

A

SHT.NO. REV.NO SIS FOR

SAFETY PRECAUTIONS

CALCULATED TEST PRESSURE

O

C(

O

F)

kPa(g) (psi) @

TESTS NEW

AMB

APPLICABLE CODE AND EDITION

N/A

HEMISPERICAL

19123 HORIZ

kPa (psi)

MANWAY

NOZZLE

J

O

B

O

R

D

E

R

/

E

W

O

N

O

.

T

H

I

S

R

E

V

I

S

I

O

N

I

S

N

O

T

T

O

B

E

U

S

E

D

F

O

R

C

O

N

S

T

R

U

C

T

I

O

N

U

N

T

I

L

C

E

R

T

I

F

I

E

D

A

N

D

D

A

T

E

D

ALL

BUTT (SINGLE SIDED GROOVE)

T

H

I

S

D

R

A

W

I

N

G

A

N

D

T

H

E

I

N

F

O

R

M

A

T

I

O

N

C

O

N

T

A

I

N

E

D

H

E

R

E

I

N

A

R

E

T

H

E

S

O

L

E

P

R

O

P

E

R

T

Y

O

F

S

A

U

D

I

A

R

A

M

C

O

.

N

O

R

E

P

R

O

D

U

C

T

I

O

N

I

N

F

U

L

L

O

R

I

N

P

A

R

T

S

H

A

L

L

B

E

O

B

T

A

I

N

E

D

F

R

O

M

T

H

I

S

D

O

C

U

M

E

N

T

W

I

T

H

O

U

T

T

H

E

W

R

I

T

T

E

N

C

O

N

S

E

N

T

O

F

I

T

S

O

W

N

E

R

.

SPEC'N NO.

HORIZONTAL

1977

RU822M0008

CONCRETE LINED BOTTOM HALF OF VESSEL AND BOOT, BOTTOM NOZZLES MONEL LINED

KOBE STEEL LTD

SHELL

ASSEMBLY DRAWING

110

N/A

INSULATION

A Z12

1.0

1.0

HYDROCRACKER UNIT (Z12)

HIGH PRESSURE SEPARATOR

Nom. Thick. mm(ins)

Saudi Aramco 2694-ENG (11/2010)

SAUDI ARABIA RIYADH,

EKRD/2694-1110.XLS

R215-V6 NO.

POSITION

DESIGN SHEET NO.

HEADS

R215-V6

MANUFACTURER

SHELL SECTION

SAUDI ARABIAN OIL COMPANY

DATA AND OPERATING LIMITS SHEET - PRESSURE VESSELS

Z12-D-PP-E01204

MANUFACTURER'S SERIAL NO.

EQUIPMENT NO.

MATERIAL SPECIFICATION SA 516 Gr 70

YEAR BUILT

MATERIAL SPECIFICATION

R

E

V

I

S

I

O

N

D

E

S

C

R

I

P

T

I

O

N

D

A

T

E

R

E

V

.

N

O

.

A

N

D

C

E

R

T

I

F

I

C

A

T

I

O

N

R

E

Q

U

I

R

E

M

E

N

T

S

,

P

E

R

S

A

E

P

-

3

3

4

,

U

N

D

E

R

O

T

H

E

R

R

E

Q

U

I

R

E

D

(

S

A

U

D

I

A

R

A

M

C

O

)

R

E

Q

U

I

R

E

D

(

S

A

U

D

I

A

R

A

M

C

O

)

B

Y

/

D

A

T

E

E

N

G

G

.

/

D

A

T

E

R

E

V

I

S

I

O

N

V

A

L

I

D

A

T

I

O

N

SPOT FULL

PARTIAL FULL

YES NO

Saudi Aramco 2616-ENG (10/2002)

O

P

R

N

S

SAUDI ARABIAN OIL COMPANY

P

M

T

C

E

R

T

E

N

G

G

D

E

S

C

R

I

P

T

I

O

N

I

S

S

U

E

D

F

O

R

C

O

M

M

E

N

T

S

(

F

W

S

R

E

V

O

1

)

I

S

S

U

E

D

F

O

R

P

R

O

J

E

C

T

P

R

O

P

O

S

A

L

(

F

W

S

R

E

V

D

1

)

J

O

/

E

W

O

1

0

-

0

0

7

4

1

1

0

-

0

0

7

4

1

D

A

T

E

F

E

B

-

1

2

J

U

N

-

1

2

R

E

V

.

N

O

.

A

B

DISCIPLINE

ENGINEER

DRD

DATE J UN-12

PROJ ECT

ENGINEER

________________

DATE ___________

CERTIFIED

RS

DATE ___________

CONSTRUCTION

AGENCY

________________

DATE ___________

OPERATIONS

________

DATE ___________

E

D

S

D

V

E

R

I

F

I

C

A

T

I

O

N

C

O

N

T

R

O

L

N

U

M

B

E

R

B

Y

:

_

_

_

_

_

_

_

_

_

_

_

_

_

_

D

A

T

E

_

_

_

_

_

_

_

_

_

_

_

_

_

R

E

V

I

S

I

O

N

C

E

R

T

I

F

I

C

A

T

E

T

H

I

S

I

N

D

I

C

A

T

E

S

T

H

A

T

R

E

V

.

N

O

.

_

_

_

_

_

_

_

_

_

_

_

_

O

F

T

H

I

S

D

R

A

W

I

N

G

I

S

C

O

V

E

R

E

D

,

F

O

R

A

L

L

A

P

P

R

O

V

A

L

/

C

E

R

T

I

F

I

C

A

T

I

O

N

R

E

Q

U

I

R

E

M

E

N

T

S

,

B

Y

D

R

A

W

I

N

G

C

O

M

P

L

E

T

I

O

N

C

E

R

T

I

F

I

C

A

T

E

(

D

C

C

)

N

O

.

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

MECHANICAL RERATE REPORT FOR DWG.TYPE

PLANT .NO INDEX DRAWING NO. SHT. NO.

REV.

NO.

HIGH PRESSURE SEPERATOR (R215-V6) DOC

Z12 D PP-E05448

54

OF

71

B

CLEAN TRANSPORTATION FUELS PROJ ECT, RIYADH REFINERY

RIYADH, SAUDI ARABIA J O / EWO: BI-10-00741

DOC CLASS: 4 DSN: 2179

T

H

I

S

D

R

A

W

I

N

G

A

N

D

T

H

E

I

N

F

O

R

M

A

T

I

O

N

C

O

N

T

A

I

N

E

D

H

E

R

E

I

N

A

R

E

T

H

E

S

O

L

E

P

R

O

P

E

R

T

Y

O

F

S

A

U

D

I

A

R

A

M

C

O

.

N

O

R

E

P

R

O

D

U

C

T

I

O

N

I

N

F

U

L

L

O

R

I

N

P

A

R

T

S

H

A

L

L

B

E

O

B

T

A

I

N

E

D

F

R

O

M

T

H

I

S

D

O

C

U

M

E

N

T

W

I

T

H

O

U

T

T

H

E

W

R

I

T

T

E

N

C

O

N

S

E

N

T

O

F

I

T

S

O

W

N

E

R

.

APPENDIX 4 EXTRACTS FROM ASME II D MATERIAL PROPERTIES

Saudi Aramco 2616-ENG (10/2002)

O

P

R

N

S

SAUDI ARABIAN OIL COMPANY

P

M

T

C

E

R

T

E

N

G

G

D

E

S

C

R

I

P

T

I

O

N

I

S

S

U

E

D

F

O

R

C

O

M

M

E

N

T

S

(

F

W

S

R

E

V

O

1

)

I

S

S

U

E

D

F

O

R

P

R

O

J

E

C

T

P

R

O

P

O

S

A

L

(

F

W

S

R

E

V

D

1

)

J

O

/

E

W

O

1

0

-

0

0

7

4

1

1

0

-

0

0

7

4

1

D

A

T

E

F

E

B

-

1

2

J

U

N

-

1

2

R

E

V

.

N

O

.

A

B

DISCIPLINE

ENGINEER

DRD

DATE J UN-12

PROJ ECT

ENGINEER

________________

DATE ___________

CERTIFIED

RS

DATE ___________

CONSTRUCTION

AGENCY

________________

DATE ___________

OPERATIONS

________

DATE ___________

E

D

S

D

V

E

R

I

F

I

C

A

T

I

O

N

C

O

N

T

R

O

L

N

U

M

B

E

R

B

Y

:

_

_

_

_

_

_

_

_

_

_

_

_

_

_

D

A

T

E

_

_

_

_

_

_

_

_

_

_

_

_

_

R

E

V

I

S

I

O

N

C

E

R

T

I

F

I

C

A

T

E

T

H

I

S

I

N

D

I

C

A

T

E

S

T

H

A

T

R

E

V

.

N

O

.

_

_

_

_

_

_

_

_

_

_

_

_

O

F

T

H

I

S

D

R

A

W

I

N

G

I

S

C

O

V

E

R

E

D

,

F

O

R

A

L

L

A

P

P

R

O

V

A

L

/

C

E

R

T

I

F

I

C

A

T

I

O

N

R

E

Q

U

I

R

E

M

E

N

T

S

,

B

Y

D

R

A

W

I

N

G

C

O

M

P

L

E

T

I

O

N

C

E

R

T

I

F

I

C

A

T

E

(

D

C

C

)

N

O

.

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

MECHANICAL RERATE REPORT FOR DWG.TYPE

PLANT .NO INDEX DRAWING NO. SHT. NO.

REV.

NO.

HIGH PRESSURE SEPERATOR (R215-V6) DOC

Z12 D PP-E05448

59

OF

71

B

CLEAN TRANSPORTATION FUELS PROJ ECT, RIYADH REFINERY

RIYADH, SAUDI ARABIA J O / EWO: BI-10-00741

DOC CLASS: 4 DSN: 2179

T

H

I

S

D

R

A

W

I

N

G

A

N

D

T

H

E

I

N

F

O

R

M

A

T

I

O

N

C

O

N

T

A

I

N

E

D

H

E

R

E

I

N

A

R

E

T

H

E

S

O

L

E

P

R

O

P

E

R

T

Y

O

F

S

A

U

D

I

A

R

A

M

C

O

.

N

O

R

E

P

R

O

D

U

C

T

I

O

N

I

N

F

U

L

L

O

R

I

N

P

A

R

T

S

H

A

L

L

B

E

O

B

T

A

I

N

E

D

F

R

O

M

T

H

I

S

D

O

C

U

M

E

N

T

W

I

T

H

O

U

T

T

H

E

W

R

I

T

T

E

N

C

O

N

S

E

N

T

O

F

I

T

S

O

W

N

E

R

.

APPENDIX 5 FWS STANDARD MINIMUM NOZZLE LOADS

Extract from FWS Standard Nozzle Loads for 1500# Process Nozzles

F

x

F

y

F

z

M

x

M

y

M

z

Nozzle Size (inch), D = 4 4.0 4.0 5.6 1.9 1.9 2.6

10 10.8 10.8 15.2 11.3 11.3 15.9

12 13.5 13.5 19.2 16.4 16.4 23.3

16 19.4 19.4 27.6 29.4 29.4 41.4

Direct Loads (kN) Moment Loads (kNm)

Saudi Aramco 2616-ENG (10/2002)

O

P

R

N

S

SAUDI ARABIAN OIL COMPANY

P

M

T

C

E

R

T

E

N

G

G

D

E

S

C

R

I

P

T

I

O

N

I

S

S

U

E

D

F

O

R

C

O

M

M

E

N

T

S

(

F

W

S

R

E

V

O

1

)

I

S

S

U

E

D

F

O

R

P

R

O

J

E

C

T

P

R

O

P

O

S

A

L

(

F

W

S

R

E

V

D

1

)

J

O

/

E

W

O

1

0

-

0

0

7

4

1

1

0

-

0

0

7

4

1

D

A

T

E

F

E

B

-

1

2

J

U

N

-

1

2

R

E

V

.

N

O

.

A

B

DISCIPLINE

ENGINEER

DRD

DATE J UN-12

PROJ ECT

ENGINEER

________________

DATE ___________

CERTIFIED

RS

DATE ___________

CONSTRUCTION

AGENCY

________________

DATE ___________

OPERATIONS

________

DATE ___________

E

D

S

D

V

E

R

I

F

I

C

A

T

I

O

N

C

O

N

T

R

O

L

N

U

M

B

E

R

B

Y

:

_

_

_

_

_

_

_

_

_

_

_

_

_

_

D

A

T

E

_

_

_

_

_

_

_

_

_

_

_

_

_

R

E

V

I

S

I

O

N

C

E

R

T

I

F

I

C

A

T

E

T

H

I

S

I

N

D

I

C

A

T

E

S

T

H

A

T

R

E

V

.

N

O

.

_

_

_

_

_

_

_

_

_

_

_

_

O

F

T

H

I

S

D

R

A

W

I

N

G

I

S

C

O

V

E

R

E

D

,

F

O

R

A

L

L

A

P

P

R

O

V

A

L

/

C

E

R

T

I

F

I

C

A

T

I

O

N

R

E

Q

U

I

R

E

M

E

N

T

S

,

B

Y

D

R

A

W

I

N

G

C

O

M

P

L

E

T

I

O

N

C

E

R

T

I

F

I

C

A

T

E

(

D

C

C

)

N

O

.

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

MECHANICAL RERATE REPORT FOR DWG.TYPE

PLANT .NO INDEX DRAWING NO. SHT. NO.

REV.

NO.

HIGH PRESSURE SEPERATOR (R215-V6) DOC

Z12 D PP-E05448

61

OF

71

B

CLEAN TRANSPORTATION FUELS PROJ ECT, RIYADH REFINERY

RIYADH, SAUDI ARABIA J O / EWO: BI-10-00741

DOC CLASS: 4 DSN: 2179

T

H

I

S

D

R

A

W

I

N

G

A

N

D

T

H

E

I

N

F

O

R

M

A

T

I

O

N

C

O

N

T

A

I

N

E

D

H

E

R

E

I

N

A

R

E

T

H

E

S

O

L

E

P

R

O

P

E

R

T

Y

O

F

S

A

U

D

I

A

R

A

M

C

O

.

N

O

R

E

P

R

O

D

U

C

T

I

O

N

I

N

F

U

L

L

O

R

I

N

P

A

R

T

S

H

A

L

L

B

E

O

B

T

A

I

N

E

D

F

R

O

M

T

H

I

S

D

O

C

U

M

E

N

T

W

I

T

H

O

U

T

T

H

E

W

R

I

T

T

E

N

C

O

N

S

E

N

T

O

F

I

T

S

O

W

N

E

R

.

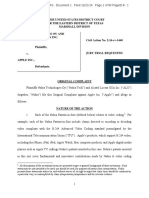

APPENDIX 6 INSPECTION REPORTS

RIYADH REFINERY DEPARTMENT

ENGINEERING DIVISION

INSPECTION UNIT

2009, TRS INSPECTION FINAL REPORT

2009

Field Insp. Supervisor:

M. Banammahl M.RALAL

4.8mm

177 .C

03/23/2009

Plant No.:

2-12

Date prepared:

Locationl Area:

G-H drocracker

Date Inspected:

110/2009

Unit Supervisor:

Yahya, Kh Ii

Corrosion Allowance

Design Press.

Design Temp.

Claddingl Lining

E ui ment data:

Material

Report No.: INSP G/021/09

Equipment No. & Service:

215-V-6 Se arator

Reasonfor Inspection:

TRS, March/Februa

P&E Inspector:

Greg Jolley API #5184

Thick.

Inspection summary:

A full internal and external visual inspection was performed per API-510 and Aramco

guidelines, during the February 2009 plant wide T&1. A scaffold was erected for full

access. The bottom half is concrete lined. Civil required minimal repairs. The top half

was grit blasted for WFMP on the welds with no relevant indications. A new demister

was installed. The top unlined portion of the vessel has mild corrosion .030" (. nOmm)

shell and .060" (1.54mm) nozzles. Corrosion in the manway RTJ "0" ring will require

repairs next scheduled T&1.

Observations:

There was 3" of product sludge found in the bottom prior to cleaning. The vertical wall

demister was removed and replaced with like kind 316ss, double wired down and

visually accepted. The support ring was securely attached by to the shell with no visible

cracking or corrosion noted. This demister was moderately fouled with scale and

product. Previous process changes eliminated the use of the outlet gas demister. A full

scaffold was erected for access. The bottom half is concrete lined with minor repairs.

The boot section was also lined. Minor repairs were required (see civil for iining issues).

The top half had a scattered thin hard scale. Corrosion in the top half is generally .030"

(.770mm) with isolated pitting in the middle top section to .040" (.1OOmm). The welds are

in the same condition as the adjacent base metal with no visual defects. Nozzles were

clear and free of obstruction. General corrosion in the nozzles 10 was .040" (.700mm)

and isolated pitting in the top nozzles to .060" (.150mm). The inlet distributor was clear

with no corrosion. The slots were full thickness. There were 2 of the 3 hold down

bolts/nuts missing. These were replaced with like kind and accepted. The liquid outlet

stand pipe was intact and secure with no corrosion or erosion. The bottom outlet nozzle

was flushed free of any loose hardware and debris. The top gas outlet nozzle (12") and

manway RTJ "0" rings and seats were PT tested and had no corrosion. The top manway

and cover has moderate corrosion on the RTJ "0" ring seating surface and is

738

Only head material

SA 516 Gr. 70.

Shell, boot, nozzles

SA 266 Cl2

148 kg/cm

2

recommended to weld build up and machine next scheduled T&1. The top half of the

shell welds were grit blasted for WFMP with no relevant indications reported. This vessel

is fit for continued service until the next T&1.

Refractory lining:

The bottom half is concrete lined with minor repairs. The boot section was also lined.

Minor repairs were done and accepted by civil inspector.

RepairsIT ests:

1. Minor concrete lining repairs were made per the civil recommendations.

2. UT scanning the bottom external performed on the shell with no issues reported.

3. UT thickness was performed with no measureable wall loss noted.

4. WFMP was performed on the top welds after grit blasting with no indications

noted.

5. A new vertical wall demister was installed.

6. The top gas outlet was lifted and the RTJ "0" ring and seats PT tested with no

indications or corrosion

Future Recommendations:

1. Open, clean and Inspect during the next scheduled T&I,March 2013

2. Flush with firewater to remove sludge

3. Build full scaffold for access to the top head

4. Grit blast the top section welds for WFMP(grit blasting was performed this T&I

because wire brushing would not remove the hard scale)

5. Flush outlet piping after all work is completed, break outside flange and gap

minimum 30mm to flush loose nuts and bolts

6. Weld build up the manway gasket surfaces and machine (both head and cover)

due to corrosion on the seats.

7. Install new demister pads

8. Remove support rings on gas outlet nozzle for inspection and NOT.

9. Open water boot and offer for inspection.

10. Remove bottom insulation for UT

11. Straight beam scan to check thickness under cement lining.

12. Provide 110/220 power cable for WFMPI

cc:

Area (G) foremen

T&I Supervisor

Equipment File

739

T

M

i

n

B

a

s

e

S

u

r

v

e

y

D

a

t

e

L

a

s

t

D

a

t

e

S

u

r

v

e

y

L

o

n

g

R

a

t

e

N

e

a

r

R

a

t

e

R

e

m

L

i

f

e

N

e

x

t

T

m

I

D

a

t

e

C

o

r

r

.

C

I

a

s

T

m

i

n

0

4

/

0

1

/

2

0

1

2

O

S

I

S

t

r

a

i

g

h

t

L

i

n

e

A

n

a

l

y

s

i

s

R

e

p

o

r

t

(

R

e

p

o

r

t

i

n

M

i

l

l

i

m

e

t

e

r

s

)

R

I

Y

A

D

H

R

E

F

I

N

E

R

Y

O

p

e

r

a

t

i

n

g

A

r

e

a

:

T

M

L

m

m

m

m

m

m

m

m

N

e

a

r

1

D

a

t

e

S

u

r

v

e

y

m

m

N

e

a

r

2

D

a

t

e

S

u

r

v

e

y

N

e

a

r

3

D

a

t

e

S

u

r

v

e

y

N

e

a

r

D

a

t

e

S

u

r

v

e

y

m

m

D

e

s

c

r

i

p

t

i

o

n

P

I

a

n

t

:

Z

1

2

-

I

S

O

M

A

X

U

N

I

T

2

2

1

5

-

V

6

C

i

r

c

u

i

t

:

1

0

6

.

0

0

0

9

/

2

0

/

1

9

8

0

0

3

/

2

1

/

2

0

1

2

0

.

1

0

0

.

0

0

3

1

.

5

8

0

3

/

2

1

/

2

0

1

7

3

1

1

1

2

.

0

0

1

0

9

.

0

0

0

9

/

2

0

/

1

9

9

7

1

0

9

.

5

0

0

6

/

2

0

/

2

0

0

5

1

0

9

.

0

0

0

2

/

2

0

/

2

0

0

9

1

0

9

.

0

0

1

6

"

N

o

z

z

l

e

6

4

.

8

0

0

9

/

2

0

/

1

9

8

0

0

3

/

2

1

/

2

0

1

2

0

.

0

5

0

.

0

0

2

7

.

7

8

0

3

/

2

1

/

2

0

1

7

3

2

6

8

.

0

0

6

6

.

3

0

0

9

/

2

0

/

1

9

9

7

6

6

.

5

0

0

6

/

2

0

/

2

0

0

5

6

6

.

3

0

0

2

/

2

0

/

2

0

0

9

6

6

.

3

0

2

0

"

N

o

z

z

l

e

2

7

.

9

0

0

9

/

2

0

/

1

9

8

0

0

3

/

2

1

/

2

0

1

2

0

.

0

6

0

.

4

5

2

.

4

2

0

9

/

2

1

/

2

0

1

2

0

3

3

1

.

0

0

2

9

.

0

0

0

9

/

2

0

/

1

9

9

7

3

0

.

8

0

0

6

/

2

0

/

2

0

0

5

3

0

.

7

0

0

2

/

2

0

/

2

0

0

9

3

0

.

4

0

4

"

N

o

z

z

l

e

2

7

.

9

0

0

9

/

2

0

/

1

9

8

0

0

3

/

2

1

/

2

0

1

2

0

.

0

5

0

.

1

9

8

.

2

5

0

3

/

2

1

/

2

0

1

3

1

4

3

1

.

0

0

2

9

.

5

0

0

9

/

2

0

/

1

9

9

7

3

0

.

5

0

0

6

/

2

0

/

2

0

0

5

3

0

.

1

0

0

2

/

2

0

/

2

0

0

9

3

0

.

1

0

4

"

N

o

z

z

l

e

2

7

.

9

0

0

9

/

2

0

/

1

9

8

0

0

3

/

2

1

/

2

0

1

2

0

.

0

3

0

.

0

0

9

2

.

0

0

0

3

/

2

1

/

2

0

1

7

3

5

3

1

.

0

0

3

0

.

2

0

0

9

/

2

0

/

1

9

9

7

3

0

.

5

0

0

6

/

2

0

/

2

0

0

5

3

0

.

2

0

0

2

/

2

0

/

2

0

0

9

3

0

.

2

0

2

"

N

o

z

z

l

e

2

2

.

9

0

0

9

/

2

0

/

1

9

8

0

0

3

/

2

1

/

2

0

1

2

0

.

0

6

0

.

0

0

5

7

.

9

0

0

3

/

2

1

/

2

0

1

7

3

6

2

8

.

0

0

2

6

.

2

0

0

9

/

2

0

/

1

9

9

7

2

6

.

5

0

0

6

/

2

0

/

2

0

0

5

2

6

.

2

0

0

2

/

2

0

/

2

0

0

9

2

6

.

2

0

2

"

N

o

z

z

l

e

8

8

.

9

0

0

9

/

2

0

/

1

9

8

0

0

3

/

2

1

/

2

0

1

2

0

.

0

6

0

.

0

0

3

3

.

3

3

0

3

/

2

1

/

2

0

1

7

3

7

9

3

.

0

0

9

1

.

0

0

0

9

/

2

0

/

1

9

9

7

9

2

.

5

0

0

6

/

2

0

/

2

0

0

5

9

2

.

1

0

0

2

/

2

0

/

2

0

0

9

9

1

.

0

0

0

3

/

0

6

/

2

0

1

0

9

1

1

2

"

N

o

z

z

l

e

7

4

.

8

0

0

9

/

2

0

/

1

9

8

0

0

2

/

2

0

/

2

0

0

9

0

.

0

4

0

.

0

8

3

7

.

8

1

0

2

/

2

0

/

2

0

1

4

3

8

7

9

.

0

0

7

7

.

9

0

0

9

/

2

0

/

1

9

9

7

7

8

.

5

0

0

6

/

2

0

/

2

0

0

5

7

8

.

2

0

1

0

"

N

o

z

z

l

e

2

3

.

8

0

0

9

/

2

0

/

1

9

8

0

0

3

/

2

1

/

2

0

1

2

0

.

0

4

0

.

0

0

4

0

.

9

1

0

3

/

2

1

/

2

0

1

7

3

9

2

7

.

0

0

2

5

.

6

0

0

9

/

2

0

/

1

9

9

7

2

6

.

4

0

0

6

/

2

0

/

2

0

0

5

2

6

.

0

0

0

2

/

2

0

/

2

0

0

9

2

5

.

7

0

0

6

/

2

7

/

2

0

1

1

2

5

.

6

2

"

N

o

z

z

l

e

2

3

.

8

0

0

9

/

2

0

/

1

9

8

0

0

3

/

2

1

/

2

0

1

2

0

.

0

4

0

.

1

0

2

1

.

6

5

0

3

/

2

1

/

2

0

1

7

3

1

0

2

7

.

0

0

2

5

.

9

0

0

9

/

2

0

/

1

9

9

7

2

6

.

4

0

0

6

/

2

0

/

2

0

0

5

2

6

.

4

0

0

2

/

2

0

/

2

0

0

9

2

6

.

2

0

2

"

N

o

z

z

l

e

2

2

.

9

0

0

9

/

2

0

/

1

9

8

0

0

3

/

2

1

/

2

0

1

2

0

.

0

4

0

.

0

3

7

6

.

3

2

0

3

/

2

1

/

2

0

1

7

3

1

1

2

7

.

0

0

2

5

.

8

0

0

9

/

2

0

/

1

9

9

7

2

6

.

4

0

0

6

/

2

0

/

2

0

0

5

2

6

.

1

0

0

2

/

2

0

/

2

0

0

9

2

5

.

9

0

2

"

N

o

z

z

l

e

5

3

.

9

0

0

9

/

2

0

/

1

9

8

0

0

3

/

2

1

/

2

0

1

2

0

.

0

4

0

.

1

4

2

0

.

5

9

0

3

/

2

1

/

2

0

1

7

3

1

2

5

8

.

0

0

5

6

.

7

0

0

9

/

2

0

/

1

9

9

7

5

7

.

1

0

0

6

/

2

0

/

2

0

0

5

5

6

.

9

0

0

2

/

2

0

/

2

0

0

9

5

6

.

8

0

0

6

/

2

7

/

2

0

1

1

5

6

.

8

4

"

N

o

z

z

l

e

1

7

.

7

0

0

9

/

2

0

/

1

9

8

0

0

3

/

2

1

/

2

0

1

2

0

.

0

4

0

.

0

0

6

5

.

9

1

0

3

/

2

1

/

2

0

1

7

3

1

3

2

2

.

0

0

2

0

.

6

0

0

9

/

2

0

/

1

9

9

7

2

1

.

6

0

0

6

/

2

0

/

2

0

0

5

2

0

.

6

0

0

3

/

0

6

/

2

0

1

0

2

0

.

6

0

1

1

/

2

"

N

o

z

z

l

e

1

0

5

.

2

0

0

9

/

2

0

/

1

9

8

0

0

3

/

2

1

/

2

0

1

2

0

.

0

6

0

.

0

0

6

5

.

0

0

0

3

/

2

1

/

2

0

1

7

3

1

4

1

1

1

.

0

0

1

0

9

.

1

0

0

9

/

2

0

/

1

9

9

7

1

0

9

.

5

0

0

6

/

2

0

/

2

0

0

5

1

0

9

.

1

0

0

2

/

2

0

/

2

0

0

9

1

0

9

.

1

0

H

E

A

D

2

2

0

.

2

0

0

9

/

2

0

/

1

9

8

0

0

6

/

2

7

/

2

0

1

1

0

.

1

4

0

.

0

0

3

4

.

2

7

0

6

/

2

7

/

2

0

1

6

3

1

5

2

2

9

.

5

0

2

2

5

.

1

0

0

9

/

2

0

/

1

9

9

7

2

2

8

.

0

0

0

6

/

2

0

/

2

0

0

5

2

2

6

.

1

0

0

2

/

2

0

/

2

0

0

9

2

2

5

.

1

0

S

H

E

L

L

2

2

0

.

2

0

0

9

/

2

0

/

1

9

8

0

0

3

/

2

1

/

2

0

1

2

0

.

1

3

0

.

0

0

3

9

.

1

0

0

3

/

2

1

/

2

0

1

7

3

1

6

2

2

9

.

6

0

2

2

5

.

4

0

0

9

/

2

0

/

1

9

9

7

2

2

7

.

0

0

0

6

/

2

0

/

2

0

0

5

2

2

5

.

4

0

0

2

/

2

0

/

2

0

0

9

2

2

5

.

4

0

S

H

E

L

L

2

2

0

.

2

0

0

9

/

2

0

/

1

9

8

0

0

3

/

2

1

/

2

0

1

2

0

.

0

5

0

.

0

0

1

4

1

.

1

8

0

3

/

2

1

/

2

0

1

7

3

1

7

2

2

9

.

0

0

2

2

7

.

4

0

0

9

/

2

0

/

1

9

9

7

2

2

8

.

4

0

0

6

/

2

0

/

2

0

0

5

2

2

8

.

2

0

0

2

/

2

0

/

2

0

0

9

2

2

7

.

4

0

0

6

/

2

7

/

2

0

1

1

2

2

7

.

4

S

H

E

L

L

2

2

0

.

2

0

0

9

/

2

0

/

1

9

8

0

0

3

/

2

1

/

2

0

1

2

0

.

0

9

0

.

0

0

6

5

.

2

2

0

3

/

2

1

/

2

0

1

7

3

1

8

2

2

9

.

1

0

2

2

6

.

2

0

0

9

/

2

0

/

1

9

9

7

2

2

7

.

5

0

0

6

/

2

0

/

2

0

0

5

2

2

6

.

7

0

0

3

/

0

6

/

2

0

1

0

2

2

6

.

2

0

S

H

E

L

L

1

0

5

.

2

0

0

9

/

2

0

/

1

9

8

0

0

3

/

2

1

/

2

0

1

2

0

.

0

6

0

.

1

5

6

8

.

0

3

0

3

/

2

1

/

2

0

1

7

3

1

9

1

1

7

.

0

0

1

1

5

.

2

0

0

9

/

2

0

/

1

9

9

7

1

1

6

.

7

0

0

6

/

2

0

/

2

0

0

5

1

1

5

.

9

0

0

3

/

0

6

/

2

0

1

0

1

1

5

.

5

0

H

E

A

D

1

"

*

"

=

F

I

a

g

T

m

i

n

s

e

t

a

t

0

Saudi Aramco 2616-ENG (10/2002)

O

P

R

N

S

SAUDI ARABIAN OIL COMPANY

P

M

T

C

E

R

T

E

N

G

G

D

E

S

C

R

I

P

T

I

O

N

I

S

S

U

E

D

F

O

R

C

O

M

M

E

N

T

S

(

F

W

S

R

E

V

O

1

)

I

S

S

U

E

D

F

O

R

P

R

O

J

E

C

T

P

R

O

P

O

S

A

L

(

F

W

S

R

E

V

D

1

)

J

O

/

E

W

O

1

0

-

0

0

7

4

1

1

0

-

0

0

7

4

1

D

A

T

E

F

E

B

-

1

2

J

U

N

-

1

2

R

E

V

.

N

O

.

A

B

DISCIPLINE

ENGINEER

DRD

DATE J UN-12

PROJ ECT

ENGINEER

________________

DATE ___________

CERTIFIED

RS

DATE ___________

CONSTRUCTION

AGENCY

________________

DATE ___________

OPERATIONS

________

DATE ___________

E

D

S

D

V

E

R

I

F

I

C

A

T

I

O

N

C

O

N

T

R

O

L

N

U

M

B

E

R

B

Y

:

_

_

_

_

_

_

_

_

_

_

_

_

_

_

D

A

T

E

_

_

_

_

_

_

_

_

_

_

_

_

_

R

E

V

I

S

I

O

N

C

E

R

T

I

F

I

C

A

T

E

T

H

I

S

I

N

D

I

C

A

T

E

S

T

H

A

T

R

E

V

.

N

O

.

_

_

_

_

_

_

_

_

_

_

_

_

O

F

T

H

I

S

D

R

A

W

I

N

G

I

S

C

O

V

E

R

E

D

,

F

O

R

A

L

L

A

P

P

R

O

V

A

L

/

C

E

R

T

I

F

I

C

A

T

I

O

N

R

E

Q

U

I

R

E

M

E

N

T

S

,

B

Y

D

R

A

W

I

N

G

C

O

M

P

L

E

T

I

O

N

C

E

R

T

I

F

I

C

A

T

E

(

D

C

C

)

N

O

.

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

MECHANICAL RERATE REPORT FOR DWG.TYPE

PLANT .NO INDEX DRAWING NO. SHT. NO.

REV.

NO.

HIGH PRESSURE SEPERATOR (R215-V6) DOC

Z12 D PP-E05448

65

OF

71

B

CLEAN TRANSPORTATION FUELS PROJ ECT, RIYADH REFINERY

RIYADH, SAUDI ARABIA J O / EWO: BI-10-00741

DOC CLASS: 4 DSN: 2179

T

H

I

S

D

R

A

W

I

N

G

A

N

D

T

H

E

I

N

F

O

R

M

A

T

I

O

N

C

O

N

T

A

I

N

E

D

H

E

R

E

I

N

A

R

E

T

H

E

S

O

L

E

P

R

O

P

E

R

T

Y

O

F

S

A

U

D

I

A

R

A

M

C

O

.

N

O

R

E

P

R

O

D

U

C

T

I

O

N

I

N

F

U

L

L

O

R

I

N

P

A

R

T

S

H

A

L

L

B

E

O

B

T

A

I

N

E

D

F

R

O

M

T

H

I

S

D

O

C

U

M

E

N

T

W

I

T

H

O

U

T

T

H

E

W

R

I

T

T

E

N

C

O

N

S

E

N

T

O

F

I

T

S

O

W

N

E

R

.

APPENDIX 7 PVELITE OUTPUT (FOR VALIDATION ONLY)

You might also like

- A 325M - 00Document5 pagesA 325M - 00aleemudin86No ratings yet

- A 36A36M00aDocument3 pagesA 36A36M00aaleemudin86No ratings yet

- Gmail - Loading Table For 3772 PDFDocument2 pagesGmail - Loading Table For 3772 PDFaleemudin86No ratings yet

- Schedule 2017-NCNDT PDFDocument2 pagesSchedule 2017-NCNDT PDFaleemudin86No ratings yet

- 1.TWI Enrolment Form From Rev 21 PDFDocument4 pages1.TWI Enrolment Form From Rev 21 PDFAkhtarcmti1342No ratings yet

- 16 - Titanium AlloysDocument2 pages16 - Titanium Alloysaleemudin86No ratings yet

- API-580, RBI, QB+ans-2 PDFDocument3 pagesAPI-580, RBI, QB+ans-2 PDFaleemudin86No ratings yet

- A 1011 A 1011M - 00Document6 pagesA 1011 A 1011M - 00aleemudin86No ratings yet

- SSPC Pci Study GuideDocument158 pagesSSPC Pci Study Guidekerons100% (22)

- API-580, RBI, QB+ans-2 PDFDocument3 pagesAPI-580, RBI, QB+ans-2 PDFaleemudin86No ratings yet

- New Doc 2017-09-18 17.22.13.1Document1 pageNew Doc 2017-09-18 17.22.13.1aleemudin86No ratings yet

- Gmail - Expatriates JobDocument1 pageGmail - Expatriates Jobaleemudin86No ratings yet

- API 510 Pressure Vessel Inspector CertificationDocument6 pagesAPI 510 Pressure Vessel Inspector CertificationvkumaranNo ratings yet

- API 510 Pressure Vessel Inspector CertificationDocument6 pagesAPI 510 Pressure Vessel Inspector CertificationvkumaranNo ratings yet

- PCN 123Document23 pagesPCN 123aleemudin86No ratings yet

- PCN 123Document23 pagesPCN 123aleemudin86No ratings yet

- PCN 123Document23 pagesPCN 123aleemudin86No ratings yet

- Unfiled Notes12Document2 pagesUnfiled Notes12aleemudin86No ratings yet

- PCN 123Document23 pagesPCN 123aleemudin86No ratings yet

- 0276-03 Nozzle Fit Up ReportDocument1 page0276-03 Nozzle Fit Up Reportaleemudin86No ratings yet

- Above GroundDocument14 pagesAbove Groundaleemudin86No ratings yet

- Above GroundDocument2 pagesAbove Groundaleemudin86No ratings yet

- 1KW GermanDocument1 page1KW Germanaleemudin86No ratings yet

- Above GroundDocument14 pagesAbove Groundaleemudin86No ratings yet

- NothingDocument1 pageNothingaleemudin86No ratings yet

- 12 Samss 007 PDFDocument30 pages12 Samss 007 PDFMohammadAseef100% (1)

- Reap EarDocument2 pagesReap Earmushtaq khan niaziNo ratings yet

- StandardsDocument5 pagesStandardsaleemudin86No ratings yet

- 12 Samss 007 PDFDocument30 pages12 Samss 007 PDFMohammadAseef100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Radio Connection ParametersDocument2 pagesRadio Connection ParametersManas Kumar MohapatraNo ratings yet

- Is 398 - 5Document12 pagesIs 398 - 5Gnanavel GNo ratings yet

- Journal Bearing ClearanceDocument2 pagesJournal Bearing ClearanceLookman FajarNo ratings yet

- Drive Lines, Differentials, and Power TrainsDocument44 pagesDrive Lines, Differentials, and Power TrainsAnonymous QiMB2lBCJLNo ratings yet

- T Rec G.8265.1 201407 I!!pdf eDocument32 pagesT Rec G.8265.1 201407 I!!pdf eRoger ParsonsNo ratings yet

- Wikimedia ArchitectureDocument32 pagesWikimedia Architectureanon-656305100% (12)

- Metric Conversion GuideDocument36 pagesMetric Conversion GuideAmmar A. Ali100% (2)

- Is - 919-Part 2Document46 pagesIs - 919-Part 2mmkattaNo ratings yet

- Porsche Academy Training - Vehicle Quick Reference MY2007-08Document36 pagesPorsche Academy Training - Vehicle Quick Reference MY2007-08Michele Colombo100% (4)

- TV LG LCD 32LG30 UD Chassis LA85DDocument35 pagesTV LG LCD 32LG30 UD Chassis LA85DIvan Leonardo Acevedo GalanNo ratings yet

- Syllabus Energy Policy - 2020 CUNYDocument7 pagesSyllabus Energy Policy - 2020 CUNYMitchNo ratings yet

- Mobile services bill detailsDocument14 pagesMobile services bill detailsVikas K JainNo ratings yet

- Edition Section Question Answer Q1 9th 3.1.6 - 5.6.1.1Document6 pagesEdition Section Question Answer Q1 9th 3.1.6 - 5.6.1.1Ainura SakpireyevaNo ratings yet

- 1 CFAP Syllabus Summer 2021Document17 pages1 CFAP Syllabus Summer 2021minhaj farooquiNo ratings yet

- TP0027-9 Masterload Gantry PDFDocument104 pagesTP0027-9 Masterload Gantry PDFtmaail698150% (2)

- Fllamable LiquiedesDocument10 pagesFllamable LiquiedesSid GeeNo ratings yet

- ValveDocument2 pagesValveRamKS80No ratings yet

- Nokia Technologies & Alcatel-Lucent USA Vs Apple Inc Case 01440Document85 pagesNokia Technologies & Alcatel-Lucent USA Vs Apple Inc Case 01440Jack PurcherNo ratings yet

- AWS B2.1-22-015 - 2002 SWPS GTAW of of Aluminum (MPS-22 To MPS-22), 18 Through 10 Gauge PDFDocument17 pagesAWS B2.1-22-015 - 2002 SWPS GTAW of of Aluminum (MPS-22 To MPS-22), 18 Through 10 Gauge PDFPamella Sandoval50% (2)

- LG HVAC 2011 Full CatalogDocument72 pagesLG HVAC 2011 Full Cataloge-ComfortUSANo ratings yet

- DDC-GF ADocument1 pageDDC-GF Amuhammad robbyNo ratings yet

- EMC VAPP Installation GUIDEDocument56 pagesEMC VAPP Installation GUIDENoureddine OussouNo ratings yet

- SCP 8Document3 pagesSCP 8Abe Sam ThomasNo ratings yet

- Yingli Solar PANDA YL270C 30b Data Sheet 1 PDFDocument2 pagesYingli Solar PANDA YL270C 30b Data Sheet 1 PDFCourtney MillerNo ratings yet

- Aci 352r - 02 PDFDocument37 pagesAci 352r - 02 PDFDYGA GramajoNo ratings yet

- Co-Bcch Cell (Gbss16.0 01)Document105 pagesCo-Bcch Cell (Gbss16.0 01)ermleeNo ratings yet

- EOI Notice No 6)Document5 pagesEOI Notice No 6)Chandeshwor ShahNo ratings yet

- Understanding Transformer PolarityDocument3 pagesUnderstanding Transformer PolarityVENKATESAN R100% (1)

- LEITI Head of Secretariat - Vacancy NoticeDocument3 pagesLEITI Head of Secretariat - Vacancy NoticeLiberiaEITINo ratings yet

- Charging For Mobile All IP Telecommunications Wireless Communications and Mobile ComputingDocument301 pagesCharging For Mobile All IP Telecommunications Wireless Communications and Mobile ComputingAlbana Gashi0% (1)