Professional Documents

Culture Documents

Manifold Design Calculations

Uploaded by

sumant.c.singh16940 ratings0% found this document useful (0 votes)

833 views5 pages1) The document calculates the pressure handling capability of a 3 valve manifold assembly's major components.

2) It analyzes the weakest points which are spindle/gland retainer, gland retainer/gland body, and gland body/main body threaded joints, as well as the gland retainer and gland body sections.

3) The calculations show that all components can withstand the required pressure of 10,000 psi with safety factors above the minimum required value of 4, demonstrating the assembly's adequate pressure handling capability.

Original Description:

ggg

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1) The document calculates the pressure handling capability of a 3 valve manifold assembly's major components.

2) It analyzes the weakest points which are spindle/gland retainer, gland retainer/gland body, and gland body/main body threaded joints, as well as the gland retainer and gland body sections.

3) The calculations show that all components can withstand the required pressure of 10,000 psi with safety factors above the minimum required value of 4, demonstrating the assembly's adequate pressure handling capability.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

833 views5 pagesManifold Design Calculations

Uploaded by

sumant.c.singh16941) The document calculates the pressure handling capability of a 3 valve manifold assembly's major components.

2) It analyzes the weakest points which are spindle/gland retainer, gland retainer/gland body, and gland body/main body threaded joints, as well as the gland retainer and gland body sections.

3) The calculations show that all components can withstand the required pressure of 10,000 psi with safety factors above the minimum required value of 4, demonstrating the assembly's adequate pressure handling capability.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 5

Design calculation to prove pressure handling capability of 3 VALVE MANIFLD!

"D#A$IN% & 3VM'('))'*+

The 3 valve manifold assembly consists of the following major parts (Refer detailed drawing No

3VM-SS--T!" #

$% &land Retainer

'% &land (ody

3% Spindle

"% )oc* N+t

,% Retainer -asher

.% /ac*ing S+pport

0% &land -asher

% /ac*ing - Teflon

/ress+re withstand capacity re1+ired of manifold

= 10,000 psi

= 10,000 psi / 2.2 x 2.54 x 2.54

= 704 Kg/cm

2

(1 Kgs = 2.2 lbs; 1 inch = 2.54 cm)

The vee-tip of the spindle closes an orifice of diameter 4mm = 0.4cm = d

o

Are o! ori!ice hole =

2orce on spindle re1+ired to withstood at $3333 /si when the valve is in closed condition

= press"re x re = 704 #g/cm

2

x 0.125$ cm

2

= %%.42 #g.

,ressure -ithstanding capability shall be chec.ed at the follo-ing threaded /oints0

1. Spindle to gland retainer threading.

2. Gland Retainer to gland Body threading.

3. Gland body to main body threading.

1) Pressure withstand capability calculation for spindle to gland

retainer threading :

Thread type M(; Thread pitch = 1.25mm = 0.125cm = &

1

Thread length = 2.0mm

No of threads = &hreding leng&h / pi&ch

d

o

2

=

(0.4)

2

= 0.125$ cm2

4 4

= 20/1.25

= 1$

Minim+m root diameter of threading = $.$47mm = 0.$$47cm = d

1

Tensile ! shear strength for material of Spindle is SS3$. is %4 #si

= %4000 psi = %4000 = 5'1% #g/cm

2

= T

2.2 x 2.54 x 2.54

(1 #g = 2.2 lbs; 1 inch = 2.54 cm)

Shear withstand area of each thread

= d

1

x &

1

= (.14 x 0.$$47 x 0.125 = 0.2$ cm

2

Shear withstand area of $. threads

= 0.2$ x 1$ = 4.1$ cm

2

= A

1

Shear withstand force capability threaded spindle

= ) x A

1

= 5'1% x 4.1$ = 24$1% Kgs

2actor of safety 4

*her +i&hs&nd !orce cpbili&, = 24$1% = 27%.42

*her +i&hs&nd !orce re-"ired %%.42

Th+s the spindle of gland retainer threading is ade1+ately rated for press+re capability re1+ired%

2) Pressure withstand capability calculation for Gland retainer

to gland body threading :

Thread type M$.; Thread pitch = 1.5mm, = 0.15cm. = t

2

Threading length = 2'mm

No threads 4 2'/1.5 = 1'.(( = 1' &hreds

Minim+m root diameter of threading = 14.(7$mm = 1.4(7$ cm = d

2

Tensile shear strength of SS3$. material = ) = 5'1% #g/cm

2

Shear withstand area of each thread 4 d

2

t

2

= (.14 x 1.4(7$ x 0.15 = 0.$77 cm

2

Shear withstand area of $3 threads

= 1' x 0.$77 = 12.%$( cm

2

.= A

2

Shear withstand force capability of above threaded joint

= ) . A

2

= 5'1% x 12.%$( = 7$12( Kg

2actor of Safety 4 7$12( = %$0

%%.42

Th+s5 this threaded joint is also ade1+ately rated for press+re capability re1+ired%

3) Pressure withstand capability calculation for gland body to main

body threading :

Thread type M$6 Thread pitch = 1.5mm = 0.15cm = t

3

Threading length = 7.5mm

No of threads 4 7.5mm / 1.5mm = 5 &hreds

Minim+m root diameter of threading 4 1$.(7$mm = 1.$(7$ cm = d

3

Tensile shear strength of SS3$. Material = ) = 5'1% Kg/cm

2

Shear withstand area of each thread

= d

3

t

3

= (.14 x 1.$(7$ x 0.15 = 0.77 cm

2

.

Shear withstand area of , threads

= 5 x 0.77 = (.%5 cm

2

. = A

3

Shear withstand force capability of above threaded joint

= T x A

3

= 5'1% . (.%5 = 227%4 Kg

2actor of safety 4 227%5 / %%.42 = 257.$7

Th+s5 this threaded joint is also ade1+ately rated for the press+re capability re1+ired%

,ressure -ithstanding capability shall also be chec.ed at

"# Section 7-7 which is the wea*est section area in the gland retainer% ( Refer 8rawing No

3VM--SS-T!'-$ #

,# Section (-( which is the wea*est section area in the gland body ( Refer 8rawing no 3VM--

SS-T!'- ' #

12 ,ressure -ithstand capability calculation for section A'A of gland retainer " Dra-ing no

3VM'))'('*34 5+

D

0

= 14.(7$ mm = 1.4(7$ cm

D

i

= % mm = 0.% cm

Tensile withstand area of this section

= ( /

0

2

0 /

i

2

)

4

= ( 1.4(7$

2

0 0.%

2

)

4

= 3.14 ( 2.066

0 0.$4

)

4

= 1.11' cm

2

= A

4

Tensile shear strength of SS3$. Material = ) = 5'1% Kg/cm

2

Tensile withstand force capability of this section

= T x A

4

= 5'1% . 1.11' = $$22 Kg

2actor of safety

= 1orce +i&hs&nd cpbili&, 2ilble = $$22 = 74.%'

1orce +i&hs&nd cpbili&, re-"ired %%.42

Th+s5 this section is ade1+ately rated for press+re capability re1+ired%

62 ,ressure -ithstands capability calculation for section 7'7 of gland body "#efer2 Dra-ing

3VM'('))'*342 +

Tensile withstand area of this section

D

0

= 1$.(7$ mm = 1.$(7$ cm

D

i

= 10.1 mm = 1.01 cm

= ( /

0

2

0 /

i

2

)

4

= ( 1.$(7$

2

0 1.01

2

)

4

= 3.14 ( 2.682

0 1.02

)

4

= 1.( cm

2

= A

5

Tensile shear strength of SS3$. material = T = 5'1% Kg/cm

2

Tensile withstand force capability of this section

= T x A

5

= 5'1% x 1.( = 7$'(.40 Kg

2actor of Safety

= 7$'(.40 = %7.00

%%.42

Th+s5 this section is ade1+ately rated for the press+re capability re1+ired%

S+mmary9 The wea*est possible points of 3 : Valve manifold assembly have been fo+nd to be

ade1+ately rated to withstand a press+re $35333 psi%

The forged steel body sections (8rawing ; 3VM--SS-T!$# are even more rated to withstand the

press+re capable and hence not chec*ed%

You might also like

- Technical Specifications of HDPE Pipes As Per Indian Standards InstituteDocument1 pageTechnical Specifications of HDPE Pipes As Per Indian Standards InstituteZacharia JohnNo ratings yet

- Pttep Painitng of Offshore FacilitiesDocument66 pagesPttep Painitng of Offshore FacilitiesSufianNo ratings yet

- Wesman Schieldrop BurnerDocument2 pagesWesman Schieldrop Burnerash617980% (5)

- Bending Machine CRC Evans Centurion 06 20Document4 pagesBending Machine CRC Evans Centurion 06 20bharathaninNo ratings yet

- Acessórios Cloro Gás - VaccupermDocument28 pagesAcessórios Cloro Gás - Vaccupermbalzac1910% (1)

- Techsonic EZ III Rev 4 092010 PDFDocument70 pagesTechsonic EZ III Rev 4 092010 PDFandresgomez10No ratings yet

- Victaulic DimensionsDocument2 pagesVictaulic DimensionsSH1961No ratings yet

- ManifoldDocument20 pagesManifoldNilesh MistryNo ratings yet

- Annular Plate RemovalDocument2 pagesAnnular Plate RemovalVishvjeet Prakash TiwariNo ratings yet

- Renderoc TGDocument2 pagesRenderoc TGMansoor Ali50% (2)

- Aws D.1.1 UtDocument1 pageAws D.1.1 UtAMIN_GOODARZI_NDTNo ratings yet

- Pipe Bends Specification PDFDocument4 pagesPipe Bends Specification PDFToniNo ratings yet

- Pneumatic Slide GateDocument7 pagesPneumatic Slide Gateemad sabriNo ratings yet

- Metal Tapered Tube Plugs: Tube Plug Sizing ChartDocument1 pageMetal Tapered Tube Plugs: Tube Plug Sizing ChartRaghavanNo ratings yet

- Weight For Bolt With Nut PDFDocument1 pageWeight For Bolt With Nut PDFRam RajaramanNo ratings yet

- Alvaer DNV2.7-3 PDFDocument23 pagesAlvaer DNV2.7-3 PDFThanhdong Do100% (1)

- Foot Valve Catalog PDFDocument4 pagesFoot Valve Catalog PDFFabio MiguelNo ratings yet

- Film Calculation Based On Pipe SizeDocument1 pageFilm Calculation Based On Pipe SizeSivalingam GovindarajanNo ratings yet

- Valve Actuator ChecklistDocument2 pagesValve Actuator Checklisthamoody_007No ratings yet

- Test & Repair Equipment Engineered Solutions Valve AcademyDocument44 pagesTest & Repair Equipment Engineered Solutions Valve AcademyBouzaida Maher100% (1)

- Kerosene Test ProcedureDocument1 pageKerosene Test ProcedureAshwani Dogra100% (1)

- Witness Joint ChecklistDocument1 pageWitness Joint ChecklistAustin J AlfredNo ratings yet

- MOV Technical Data SheetDocument6 pagesMOV Technical Data SheetBilel MahjoubNo ratings yet

- Fiberglass Coating SpecDocument3 pagesFiberglass Coating Specponnivalavans_994423100% (1)

- Installation, Operation & Maintenance Manual: Virgo Engineers LimitedDocument47 pagesInstallation, Operation & Maintenance Manual: Virgo Engineers LimitedSreenivasNo ratings yet

- Leak Test Proce.-TankDocument7 pagesLeak Test Proce.-Tankpraveen 0064No ratings yet

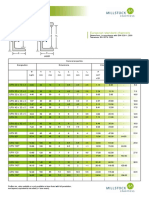

- Stainless Steel Upn Channels SectionsDocument4 pagesStainless Steel Upn Channels SectionsKriengsak RuangdechNo ratings yet

- Rationalise List Welding ConsumablesDocument19 pagesRationalise List Welding ConsumablesMayank SadaniNo ratings yet

- Electrode Consumption On Pipe WeldingDocument2 pagesElectrode Consumption On Pipe Weldinganjangandak2932100% (1)

- A223 6 44 0074Document15 pagesA223 6 44 0074mishtinilNo ratings yet

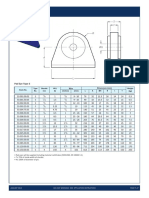

- Pad Eyes PDFDocument1 pagePad Eyes PDFPierluigiBusettoNo ratings yet

- PLUMBNESSDocument9 pagesPLUMBNESSanusaan2007No ratings yet

- Belt Conveyor Draw FinishDocument1 pageBelt Conveyor Draw FinishRizki FauziNo ratings yet

- Dry Bulk Storage Tank SpecificationDocument7 pagesDry Bulk Storage Tank SpecificationMohamed Mostafa IbrahimNo ratings yet

- Paint Quantity Estimation: Application LossDocument4 pagesPaint Quantity Estimation: Application LossChethanNo ratings yet

- Pamphlet TG-X SeriesDocument2 pagesPamphlet TG-X SeriesrajeshNo ratings yet

- Presentation Rekuluvo Counter-Flow Air Preheater Technologie" Gea-Ecoflex GMBH Dr.-Ing. Olivier BrasseurDocument29 pagesPresentation Rekuluvo Counter-Flow Air Preheater Technologie" Gea-Ecoflex GMBH Dr.-Ing. Olivier BrasseurdeepchotiNo ratings yet

- A33a PMS PDFDocument5 pagesA33a PMS PDFS.selvakumar100% (1)

- ANSI Flange Bolt & Stud ChartDocument2 pagesANSI Flange Bolt & Stud Chartkh88hmiNo ratings yet

- ITB-spc For Tape Coating For UG Piping PDFDocument15 pagesITB-spc For Tape Coating For UG Piping PDFShyam Sundar GayenNo ratings yet

- Pressure Vessel - Selection of Material and Manufacturing ProcessDocument13 pagesPressure Vessel - Selection of Material and Manufacturing Processjyoti swaroop repaka67% (3)

- Storage Tank API 650Document20 pagesStorage Tank API 650jalison07xNo ratings yet

- Structural Importance of Door Sheet StiffeningDocument39 pagesStructural Importance of Door Sheet StiffeningJassem ArbiNo ratings yet

- Lesson 0.1 - Precalculus - Math MedicDocument2 pagesLesson 0.1 - Precalculus - Math Medicfeng yanNo ratings yet

- Surface Preparation and Painting ProcedureDocument10 pagesSurface Preparation and Painting ProcedureNenad TomicNo ratings yet

- Pipe Dimensions Chart Rev Jan 2012Document1 pagePipe Dimensions Chart Rev Jan 2012eljammalNo ratings yet

- WWW .Abs Fir E.it: Vertical Foam Bladder TankDocument4 pagesWWW .Abs Fir E.it: Vertical Foam Bladder TankJorge InostrozaNo ratings yet

- ASME V (2017) 139 Table T-421Document2 pagesASME V (2017) 139 Table T-421Rupam Baruah100% (1)

- Bifold UpdatedDocument8 pagesBifold UpdatedGopinath GunasekaranNo ratings yet

- 39NiCrMo3 PDFDocument2 pages39NiCrMo3 PDFAmy GriffinNo ratings yet

- How To Calculate Hydrostatic Test Height in TanksDocument4 pagesHow To Calculate Hydrostatic Test Height in TanksEric MagnayeNo ratings yet

- Y Strainer CatalogDocument21 pagesY Strainer CatalogIrfan FahmiNo ratings yet

- KMT Aqua-Dyne Master Catalog PDFDocument36 pagesKMT Aqua-Dyne Master Catalog PDFMark1025No ratings yet

- Kaukan Oil Cooler Instruction HandbookDocument14 pagesKaukan Oil Cooler Instruction HandbooksunhuynhNo ratings yet

- Manifold Design CalculationsDocument5 pagesManifold Design Calculationsyadagiri marojuNo ratings yet

- PNV HS 8 MF Design CalculationsDocument5 pagesPNV HS 8 MF Design Calculationssumant.c.singh1694No ratings yet

- Compression Members Problems - PDFDocument15 pagesCompression Members Problems - PDFNIKHIL BANDWALNo ratings yet

- Unit 5Document31 pagesUnit 5Nirina ArimananaNo ratings yet

- 17 Padeye - Spreadsheet Rev ADocument12 pages17 Padeye - Spreadsheet Rev Aoluomo1No ratings yet

- Calculation of Screw JackDocument20 pagesCalculation of Screw JackVenu Gopal RaoNo ratings yet

- BillPayReceiptTataDocomo September 2016Document1 pageBillPayReceiptTataDocomo September 2016sumant.c.singh1694No ratings yet

- Taxi Receipt Template 04Document1 pageTaxi Receipt Template 04sumant.c.singh1694No ratings yet

- Solar Energy Section 5 AppendixDocument16 pagesSolar Energy Section 5 Appendixsumant.c.singh1694No ratings yet

- Final Audit Neelam UnmannedDocument98 pagesFinal Audit Neelam Unmannedsumant.c.singh1694No ratings yet

- Alumni Information Form: (Please Send Score Card of Exam)Document1 pageAlumni Information Form: (Please Send Score Card of Exam)sumant.c.singh1694No ratings yet

- Technip PCVDocument1 pageTechnip PCVsumant.c.singh1694No ratings yet

- DS 21 M 0012 - 0Document13 pagesDS 21 M 0012 - 0sumant.c.singh1694No ratings yet

- Gas GroupsDocument1 pageGas Groupssumant.c.singh1694No ratings yet

- Cable Schedule Heater 1Document1 pageCable Schedule Heater 1sumant.c.singh1694No ratings yet

- DS 21 M 0018 - 0Document13 pagesDS 21 M 0018 - 0sumant.c.singh1694No ratings yet

- On-Line Recharge ReceiptDocument1 pageOn-Line Recharge Receiptsumant.c.singh1694No ratings yet

- Ex Register ExampleDocument26 pagesEx Register Examplesumant.c.singh1694No ratings yet

- MSS SP 99Document11 pagesMSS SP 99sumant.c.singh1694No ratings yet

- PNV HS 8 MF Design CalculationsDocument5 pagesPNV HS 8 MF Design Calculationssumant.c.singh1694No ratings yet

- List of StandardsDocument3 pagesList of Standardssumant.c.singh1694No ratings yet

- Basics Ferrule Paper Metallurgy 9 07Document6 pagesBasics Ferrule Paper Metallurgy 9 07sumant.c.singh1694No ratings yet

- Index of API CodesDocument3 pagesIndex of API Codessumant.c.singh1694No ratings yet

- Basics Ferrule Paper Metallurgy 9 07Document6 pagesBasics Ferrule Paper Metallurgy 9 07sumant.c.singh1694No ratings yet

- HS FNT02 00000080aec - DDocument4 pagesHS FNT02 00000080aec - DMarcoNo ratings yet

- Din 7977Document1 pageDin 7977zorghi1No ratings yet

- 14972178-CL44444444RM-Claas Lexion 405 410 415 420 430 440 450 460 Repair ManualDocument953 pages14972178-CL44444444RM-Claas Lexion 405 410 415 420 430 440 450 460 Repair ManualOleg Kuryan100% (6)

- EN3301 SK-Standard KatalogversionDocument10 pagesEN3301 SK-Standard KatalogversionDimitrios KonstantopoulosNo ratings yet

- DESIGN OF SWAGING MACHINE NewDocument41 pagesDESIGN OF SWAGING MACHINE NewBenjamin Peter100% (2)

- KC-SEF214 Rivet Nuts Catalogue - ENGLISH - Jan 2018 Screen File - 1Document56 pagesKC-SEF214 Rivet Nuts Catalogue - ENGLISH - Jan 2018 Screen File - 1gunallNo ratings yet

- (Ebook) System - Pro Engineer TutorialDocument287 pages(Ebook) System - Pro Engineer Tutorialapi-3714448100% (6)

- Is 1367 Bolt TestingDocument2 pagesIs 1367 Bolt TestingLakshmi NarayananNo ratings yet

- Microsoft Word - Fitter QuestionDocument6 pagesMicrosoft Word - Fitter QuestionVikashKumarNo ratings yet

- Eaton® Quick Disconnect Couplings Master CatalogDocument152 pagesEaton® Quick Disconnect Couplings Master CatalogMarvin Nta DgzNo ratings yet

- BS 00084-2007Document66 pagesBS 00084-2007jjdNo ratings yet

- MS51959DDocument4 pagesMS51959DbaluchiifNo ratings yet

- Overhead Transmission Lines Spacers: - Svenska KraftnätDocument20 pagesOverhead Transmission Lines Spacers: - Svenska KraftnätKy TaNo ratings yet

- Mcqs FitterDocument64 pagesMcqs FitterdaasapNo ratings yet

- Fitter ToolsDocument7 pagesFitter ToolsSainadhReddy100% (1)

- Asme B1.10MDocument28 pagesAsme B1.10MGANESH100% (1)

- Jennmar Hard Rock CatalogueDocument96 pagesJennmar Hard Rock CatalogueAntonio RamosNo ratings yet

- Tyco Ty-B PDFDocument8 pagesTyco Ty-B PDFJorge ValenciaNo ratings yet

- Ac 193Document46 pagesAc 193Tiago Castelani100% (1)

- Ward Domestic Pipe Fittings US CatalogDocument81 pagesWard Domestic Pipe Fittings US CatalogMustafa AlweshahiNo ratings yet

- Design and Stress Analysis of Screw Press Oil Expeller: © JUL 2019 - IRE Journals - Volume 3 Issue 1 - ISSN: 2456-8880Document4 pagesDesign and Stress Analysis of Screw Press Oil Expeller: © JUL 2019 - IRE Journals - Volume 3 Issue 1 - ISSN: 2456-8880natyNo ratings yet

- Norma Metrica Iso DinDocument1 pageNorma Metrica Iso DinProyectos IngemetzaNo ratings yet

- UnionsDocument3 pagesUnionsdaburto2No ratings yet

- SAAE1Document15 pagesSAAE1Roberto Carlos Díaz GalavizNo ratings yet

- Installation Ring Gear Installation ManualDocument31 pagesInstallation Ring Gear Installation Manualscott100% (1)

- BS1881-207 1992Document19 pagesBS1881-207 1992suranga100% (1)

- NPT, Nps & - ThreadsDocument3 pagesNPT, Nps & - ThreadsklashincoviskyNo ratings yet

- 5278 Manual - Mini Metal LatheDocument26 pages5278 Manual - Mini Metal Latheredneckrepairs50% (2)

- Operation Manual: Whirligig®Document12 pagesOperation Manual: Whirligig®Richard VachonNo ratings yet

- Technology of Machine Tools: GagesDocument24 pagesTechnology of Machine Tools: GagesAnibal DazaNo ratings yet