Professional Documents

Culture Documents

Kerosene Test Procedure

Uploaded by

Ashwani DograCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kerosene Test Procedure

Uploaded by

Ashwani DograCopyright:

Available Formats

KEROSENE LEAK TEST PROCEDURE

1 1.1 1.2 2 2.1 2.1.1

SCOPE

This procedure provides details of methods to conduct leak testing using kerosene as penetrant. This procedure may be applied for non-pressure parts welds like those in air and flue gas ducts.

PROCEDURE :

PRE CLEANING Parts to be inspected should be cleaned of dirt, dust, oil, grease, scales, rust etc. prior to application of penetrant(Kerosene).The outer part on which the developer is applied shall also have the same pre cleaning requirement.

2.2 2.2.1 2.3 2.3.1 2.3.2 2.4 2.4.1 2.5 2.5.1 2.5.2 2.6 2.6.1 2.6.2 2.6.3 2.6.4 2.7 2.7.1 2.7.2 2.7.3

Penetrant Normal commercially available kerosene without suspended impurities can be used as penetrant. Penetrant application : The penetrant may be applied to the part using conventional spray pumps. The penetrant shall be allowed to be wet on the part for a period of 10 mins. Developer A concentrated solution of lime and water mixture shall be used as developer. Application of developer : The developer solution can be brushed on the other side of parts, where leak path can exist. A thin and uniform layer of developer may be applied. Allow the developer to dry by normal evaporation. Evaluation Where leak path exists, kerosene will bleed out, leading to stains on the developer applied Evaluation shall be done within 10 mins. of developer drying up.

All indications shall be treated as relevant, unless precluded by predetermined paths(Unwelded portions etc.) Where indications are concluded as relevant, the shall be subjected to repairs. Repairs Approximate location, which has given rise to a relevant indication, shall be marked. Such portions shall be ground ensuring that the leak path is removed and rewelded. Retesting shall be over a greater area than the actual area of the repair to rule out any possible adjacent leak path.

CHECKED & APPROVED BY : NAME : SIGN :

PREPARED BY : NAME : SIGN :

DATE :

DATE :

You might also like

- Pneumatic Test ProcedureDocument3 pagesPneumatic Test Procedurevijay padale50% (2)

- Apcosil 605Document1 pageApcosil 605rihtak123No ratings yet

- Condensate Recovery Meter CRM 485R: Energy Conservation - Environment - Process EfficiencyDocument6 pagesCondensate Recovery Meter CRM 485R: Energy Conservation - Environment - Process Efficiencyaftab0% (1)

- Safety ValvesDocument11 pagesSafety Valvesravindra_jivaniNo ratings yet

- Hydrostatic Test Procedure: 1. ScopeDocument5 pagesHydrostatic Test Procedure: 1. ScopeHassan SleemNo ratings yet

- كيفية حساب كمية سلك اللحام المطلوبةDocument6 pagesكيفية حساب كمية سلك اللحام المطلوبةMohamed AtefNo ratings yet

- Visit Report For Rakhoh BoilersDocument16 pagesVisit Report For Rakhoh BoilersSanket Koyate SpeedsterNo ratings yet

- Hydrotest Procedure for WHR CPP BoilersDocument12 pagesHydrotest Procedure for WHR CPP BoilersJOHnNo ratings yet

- ControlMaster Select Service ManualDocument46 pagesControlMaster Select Service ManualJoss Maykol Mundaca VasquezNo ratings yet

- Water-Tube Boilers - Part 1: General Requirement: National Standard of The People'S Republic of ChinaDocument21 pagesWater-Tube Boilers - Part 1: General Requirement: National Standard of The People'S Republic of ChinaNATTHAPONG BUNSOMPOPNo ratings yet

- Job Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptDocument13 pagesJob Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaNo ratings yet

- Radiographic Test ProcedureDocument10 pagesRadiographic Test ProcedureNoor A AlamNo ratings yet

- Fabrication Procedure for Rolling Shell PlatesDocument10 pagesFabrication Procedure for Rolling Shell PlatesMuhammad Yunus NurdinNo ratings yet

- RT ProcedureDocument12 pagesRT ProcedurePRASHANTNo ratings yet

- B.W.G. Chart PDFDocument1 pageB.W.G. Chart PDFSaqib AliNo ratings yet

- DPT Report MBBR U-BDocument15 pagesDPT Report MBBR U-BMuhammad Fitransyah Syamsuar PutraNo ratings yet

- 90 Degree V-Notch Weir Discharge TableDocument5 pages90 Degree V-Notch Weir Discharge TableLaras Murni RahayuNo ratings yet

- Motor PDFDocument1 pageMotor PDFSwapnil JoshiNo ratings yet

- Managing Corporates: Third Party InspectionDocument1 pageManaging Corporates: Third Party Inspectionrajaguru20003No ratings yet

- High Gloss Metal Polyurethane CoatingDocument2 pagesHigh Gloss Metal Polyurethane CoatingAkash BadwaikNo ratings yet

- Manual Ultrasonic Testing ProcedureDocument17 pagesManual Ultrasonic Testing Procedurebaskaran ayyapparaj100% (2)

- Method Statement - RT Lorad + CRTDocument4 pagesMethod Statement - RT Lorad + CRTMohdHuzairiRusli100% (4)

- 1888 03Document36 pages1888 03Laura MarquezNo ratings yet

- Report of Ultrasonic Flaw Detection Test of Weld JointDocument1 pageReport of Ultrasonic Flaw Detection Test of Weld Jointkevin desai100% (1)

- Belt Watch PDFDocument5 pagesBelt Watch PDFkalaiNo ratings yet

- GIC Pressure GaugeDocument2 pagesGIC Pressure GaugeSUSOVAN BISWASNo ratings yet

- SPM Make Portable Vib 15 PDFDocument2 pagesSPM Make Portable Vib 15 PDFSSAC PVT.LTD.100% (1)

- Vertical Foam Bladder Tank Technical SpecsDocument4 pagesVertical Foam Bladder Tank Technical SpecsJorge InostrozaNo ratings yet

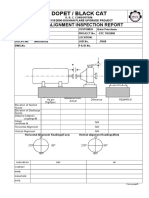

- Dopet / Black Cat: Pump Alignment Inspection ReportDocument1 pageDopet / Black Cat: Pump Alignment Inspection ReportMangalraj MadasamyNo ratings yet

- Mesuring Tape HE - mt.001Document2 pagesMesuring Tape HE - mt.001Chethan Nagaraju KumbarNo ratings yet

- Reverse Dial-Indicator-Alignment-Procedure PDFDocument4 pagesReverse Dial-Indicator-Alignment-Procedure PDFamirthraj74No ratings yet

- Procedure Demonstration RecordDocument5 pagesProcedure Demonstration RecordSantanu SahaNo ratings yet

- Bag House Filter Commissioning ReportDocument10 pagesBag House Filter Commissioning ReportArif Febrianto0% (1)

- Installation and Maintenance Manual: Forbes Marshall Safety Relief ValveDocument20 pagesInstallation and Maintenance Manual: Forbes Marshall Safety Relief ValveMona UpretiNo ratings yet

- All about steam boiler hydrostatic testingDocument2 pagesAll about steam boiler hydrostatic testingRoland NicolasNo ratings yet

- ACHE - Installation, Erection, Start Up & Commissioning Check ListDocument2 pagesACHE - Installation, Erection, Start Up & Commissioning Check Listrahim_335162856100% (1)

- Is 6044 1 2000Document13 pagesIs 6044 1 2000Subhradeb PramanikNo ratings yet

- Status of power plant equipment testing June 2022Document2 pagesStatus of power plant equipment testing June 2022SureshYarlagaddaNo ratings yet

- Sa 516 GR 70Document2 pagesSa 516 GR 70Idil FitriNo ratings yet

- Pressure drop calculations for item no. 8402 A/BDocument1 pagePressure drop calculations for item no. 8402 A/BKailas Nimbalkar0% (1)

- Screw Conveyors Pre Commissioning ITPDocument9 pagesScrew Conveyors Pre Commissioning ITPdidi sudiartoNo ratings yet

- Job Procedure For Puncture/Floatation/Rain Water Accumulation TestDocument4 pagesJob Procedure For Puncture/Floatation/Rain Water Accumulation Testfaisal jasim100% (1)

- Belt Conveyor Design DrawingDocument1 pageBelt Conveyor Design DrawingRizki FauziNo ratings yet

- Method Statement For Dye Penetrant Test For Storage TanksDocument5 pagesMethod Statement For Dye Penetrant Test For Storage Tanksmecmacho100% (3)

- Mpi Report SampleDocument6 pagesMpi Report SampleGowrisanthosh PalikaNo ratings yet

- DP Test ProcedureDocument8 pagesDP Test ProcedureAjith KumarNo ratings yet

- Pttep Painitng of Offshore FacilitiesDocument66 pagesPttep Painitng of Offshore FacilitiesSufianNo ratings yet

- FORMULA (Coating)Document4 pagesFORMULA (Coating)Ravindra S. JivaniNo ratings yet

- PARATHERM 600 HEAT RESISTING FINISHDocument2 pagesPARATHERM 600 HEAT RESISTING FINISHyarth880% (1)

- SOP For Operation and Cleaning of Conveyer BeltDocument2 pagesSOP For Operation and Cleaning of Conveyer BeltSudheer Nair100% (1)

- Dye Penetration Inspection Report SampleDocument2 pagesDye Penetration Inspection Report Samplehafizi salimanNo ratings yet

- Ultrasonic Testing Procedure GuideDocument8 pagesUltrasonic Testing Procedure GuideShailendra GhaisasNo ratings yet

- Sect 6 Priority Panel (K01-11-036) ManualDocument68 pagesSect 6 Priority Panel (K01-11-036) ManualJose Luis Jimenez InfanteNo ratings yet

- GRP - PM.QA.02A - Prosedur Magnetic Test (AWS) - Rev.01Document14 pagesGRP - PM.QA.02A - Prosedur Magnetic Test (AWS) - Rev.01Riyan to100% (1)

- Holiday Detector SK22436Document1 pageHoliday Detector SK22436Mohammad ShamimNo ratings yet

- Cp12 Pps 3274c Me Ds 001 Data Sheet Hvac Sunyaragi Rev.0Document1 pageCp12 Pps 3274c Me Ds 001 Data Sheet Hvac Sunyaragi Rev.0Triana Rosma Fikriyati DinaNo ratings yet

- Waste Combustors With Energy Recovery: ASME PTC 34-2007Document3 pagesWaste Combustors With Energy Recovery: ASME PTC 34-2007Md Naim HossainNo ratings yet

- WIweld10 Dye Penetrant Examination Rev 00Document3 pagesWIweld10 Dye Penetrant Examination Rev 00Gautam KumarNo ratings yet

- Liquid Dye Penetrant Test Inspection Sample ProcedureDocument8 pagesLiquid Dye Penetrant Test Inspection Sample Procedureم.ذكى فضل ذكىNo ratings yet

- Procedure For LPT TestDocument4 pagesProcedure For LPT Testdyke_enggNo ratings yet

- Casting and Forging DiscontinuitiesDocument25 pagesCasting and Forging DiscontinuitiesAshwani Dogra100% (1)

- Electrode SheetDocument6 pagesElectrode SheetAshwani Dogra100% (2)

- Material Chemical CompositionDocument37 pagesMaterial Chemical CompositionAshwani Dogra100% (1)

- Generator AuxiliariesDocument37 pagesGenerator AuxiliariesAshwani Dogra100% (1)

- Principle of Substation DesignDocument9 pagesPrinciple of Substation DesignAshwani DograNo ratings yet

- Generator Hydrogen CoolingDocument31 pagesGenerator Hydrogen CoolingAshwani Dogra67% (3)

- Xcitation System in ElectricalDocument34 pagesXcitation System in ElectricalAshwani DograNo ratings yet

- Busbar, Connectors and ClampsDocument12 pagesBusbar, Connectors and ClampsAshwani Dogra100% (1)

- Circuit BreakerDocument64 pagesCircuit BreakerAshwani Dogra100% (1)

- Introduction To Sub StationsDocument3 pagesIntroduction To Sub StationsAshwani DograNo ratings yet

- Feed Water Deaeration in Thermal Power PlantDocument46 pagesFeed Water Deaeration in Thermal Power PlantAshwani Dogra100% (2)

- 13.0 Set of Question For E-ProcurementsDocument2 pages13.0 Set of Question For E-ProcurementsAshwani DograNo ratings yet

- Air Preheater in Thermal Power Plant Problem N SolDocument25 pagesAir Preheater in Thermal Power Plant Problem N SolAshwani Dogra100% (2)

- Design of Earthing System For HVDocument22 pagesDesign of Earthing System For HVAshwani Dogra100% (1)

- Introduction To Supercritical TechnologyDocument7 pagesIntroduction To Supercritical TechnologyAshwani DograNo ratings yet

- Badarpur Thermal Power SatationDocument132 pagesBadarpur Thermal Power Satationdiwakar_npti100% (2)

- Non Destructive TestingDocument39 pagesNon Destructive TestingAshwani DograNo ratings yet

- Set of Questions Risk ManagementDocument2 pagesSet of Questions Risk ManagementAshwani Dogra100% (1)

- Power Plant Commissioning PDFDocument274 pagesPower Plant Commissioning PDFLaholDelveca89% (27)

- Coal to electricity process diagram and instrumentationDocument36 pagesCoal to electricity process diagram and instrumentationAshwani Dogra100% (1)

- Fire Fighting Systems in Power StationsDocument68 pagesFire Fighting Systems in Power StationsAshwani Dogra100% (1)

- Safety Work PermitDocument36 pagesSafety Work PermitAshwani Dogra100% (1)

- EP Com Business ProcurementDocument104 pagesEP Com Business ProcurementAshwani DograNo ratings yet

- Coal to electricity process diagram and instrumentationDocument36 pagesCoal to electricity process diagram and instrumentationAshwani Dogra100% (1)

- Presentation On NTPC Inspection ServicesDocument34 pagesPresentation On NTPC Inspection ServicesAshwani Dogra100% (3)

- Introduction To Industrial Safety and Accident PreventionDocument42 pagesIntroduction To Industrial Safety and Accident PreventionAshwani DograNo ratings yet

- Different Cycles in Gas Turbine & Steam TurbineDocument18 pagesDifferent Cycles in Gas Turbine & Steam TurbineAshwani DograNo ratings yet

- Transmission Line PresentationDocument55 pagesTransmission Line PresentationAshwani Dogra88% (8)

- Safe Practices in Material HandlingDocument65 pagesSafe Practices in Material HandlingAshwani DograNo ratings yet

- Fire Fighting Systems in Power StationsDocument68 pagesFire Fighting Systems in Power StationsAshwani Dogra100% (1)