Professional Documents

Culture Documents

Fluid Machines

Uploaded by

Vikas PoddarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fluid Machines

Uploaded by

Vikas PoddarCopyright:

Available Formats

DEPARTMENT OF MECHANICAL ENGINEERING

QUESTION BANK

SUBJECT-FLUID MACHINES

CLASS-DIPLOMA IV

th

(MECHANICAL)

UNIT-I

1-Write the Short notes on

a) Laminar Flow

b) Turblent Flow

c) Transient flow

2-Find the head lost due to friction in a pipe of diameter 300 mm and length 50 m, through which water

is flowing at a velocity of 3 m/s using

i) Darcy formula.

ii) Chezys formula for which C=60

Take Kinematic Viscosity for water=0.01 stoke.

3-Find the loss of head when a pipe of diameter 200 mm is suddenly enlarged to a diameter of 400 mm.

The rate of flow of water through the pipe is 250 liters/sec.

4-A Pipe of diameter 300 mm and length 3500 m is used for the transmission of power by water. The

total head at the inlet of pipe is 500 m. Find the maximum power available at the outlet of the pipe, If

the value of f=0.006

UNIT-II

1- A Jet of water of diameter 75 mm moving with a velocity of 25 m/s strikes a fixed plate in such a

way that the angle between the jet and plate is 60

o

.Find the force excreted by the jet on the

plate (i) in the direction normal to the plate and (ii) in the direction of the jet.

2- A nozzle of 50 mm diameter delivers a stream of water at 20 m/s perpendicular to a plate that

moves away from the jet at 5 m/s. Find;

i) The force on the plate

ii) The work done

iii) The efficiency of jet.

3- A 7.5 cm diameter jet having a velocity of 30 m/s strikes a flat plate, the normal of which is

inclined at 45

0

to the axis of jet. Find the normal pressure on the plate : (i) When the plate is

stationary, and (ii) when the plate is moving with a velocity of 15 m/s and away from the jet.Also

determine the power and efficiency of the jet when the plate is moving.

4- Derive the expression for the force and work done on the curved plate when the plate is moving

in the direction of jet.

UNIT-III

1- Explain in detail the working and construction of Pelton turbine with neat and clean sketch.

2- Write the short notes on

a) Cavitation

b) Draft Tube

c) Surge Tank.

3- A pelton wheel has a mean bucket speed of 10 meters per second with a jet of water flowing at

the rate of 700 liters/ s under a head of 30 meters. The bucket deflects the jet through an angle

of 160

0

. Calculate the power given by water to the runner and the hydraulic efficiency of the

turbine. Assume Co-efficient of viscosity as 0.98.

4- A turbine develops 500 KW power under a head of 100 meters at 200 r.p.m.What would be its

normal speed and output under a head of 81 meters?

UNIT-IV

1-Explain in detail with neat and clean sketch the design, Construction and working of centrifugal

Pump.

2-A centrifugal pump is to discharge 0.118 m

3

/s at a speed of 1450 r.p.m. against a head of 25 m.

The impeller diameter is 250 mm, its width at outlet is 50 mm and manometric efficiency is

75%.Determine the vane angle at the outlet periphery of the impeller.

3-Write the short notes on

a) Multistage Pump

b) Submersible Pump

c) Gear Pump

d) Classification of Pump and Priming.

4-The internal and external diameter of the impeller of a centrifugal pump are 200 mm and 400 mm

respectively. The Pump is running at 1200 rpm.The Vane angles of the impeller at inlet and outlet

are 20

o

and 30

0

respectively. The water enters the impeller radially and velocity of flow is constant.

Determine the work done by the impeller per unit weight of water.

UNIT-V

1- Explain in detail with neat and clean sketch the design, Construction and Working of

reciprocating Pump.

2- Write the short notes on

a) Slip

b) Air Vessel

c) Single acting and double acting reciprocating Pump.

3-A single acting reciprocating Pump, running at 50 rpm, delivers 0.01 m

3

/s of water the diameter of

piston is 200 mm and stroke length 400 mm. Determine;

i) The theoretical discharge of the Pump

ii) Coefficient of discharge

iii) Slip and Percentage slip of the pump.

4-A double acting reciprocating pump, running at 40 rpm, is discharging 1 m

3

of water per minute.

The pump has a stroke of 400 mm.The diameter of piston is 200 mm.The delivery and suction head

are 20 m and 5 m respectively. Find the slip of the pump and power required to drive the pump.

UNIT-VI

1-Explain the working principle of Hydraulic accumulator and Hydraulic intensifier with neat and

clean sketch.

2-Explain the working principle of Hydraulic Coupling and torque converter with neat and clean

sketch.

3-Explain the working Principle of Hydraulic Press with neat and clean diagram.

You might also like

- State Bank of IndiaDocument1 pageState Bank of IndiaVikas PoddarNo ratings yet

- Effect of EGR On Diesel EngineDocument17 pagesEffect of EGR On Diesel EngineVikas PoddarNo ratings yet

- Lovely Professional University, Punjab: Internal Combustion Engines V. Ganesan, Pub.-Tata Mcgraw-HillDocument10 pagesLovely Professional University, Punjab: Internal Combustion Engines V. Ganesan, Pub.-Tata Mcgraw-HillVikas PoddarNo ratings yet

- By-Vikas Kumar Reg-11MEE0038Document9 pagesBy-Vikas Kumar Reg-11MEE0038Vikas PoddarNo ratings yet

- Travelers' Health: Water Treatment MethodsDocument6 pagesTravelers' Health: Water Treatment MethodsVikas PoddarNo ratings yet

- Vibrating Table: Project PresentationDocument28 pagesVibrating Table: Project PresentationVikas PoddarNo ratings yet

- The Ketan Parekh ScamDocument7 pagesThe Ketan Parekh ScamVikas PoddarNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- ENG Franz Zotlöterer 2c2Document10 pagesENG Franz Zotlöterer 2c2Frank FacebNo ratings yet

- Epic For CNG Stations in Rlic and Mic: PROJECT/CONTRACT NO: 4091/GC18104500 Contract TitleDocument19 pagesEpic For CNG Stations in Rlic and Mic: PROJECT/CONTRACT NO: 4091/GC18104500 Contract TitleVedran KosanovicNo ratings yet

- Trailer Brake Valves: RE 66 137/05.11 Replaces: RE 66 137/11.08Document16 pagesTrailer Brake Valves: RE 66 137/05.11 Replaces: RE 66 137/11.08houssem houssemNo ratings yet

- Supersonic Jet Impingement On A Flat PlateDocument16 pagesSupersonic Jet Impingement On A Flat PlateShadaan KhanNo ratings yet

- Sizing Control ValvesDocument70 pagesSizing Control ValvesAriyandi Yuda PraharaNo ratings yet

- Lift Pump CalculationDocument10 pagesLift Pump CalculationMaxmore KarumamupiyoNo ratings yet

- Theory & Design For Mechanical Measurements Laboratory ME 435L Lab ManualDocument29 pagesTheory & Design For Mechanical Measurements Laboratory ME 435L Lab ManualJoseph ZeaiterNo ratings yet

- Clariflocculator: Description Unit Input Calculated Range Value Value 54000 Mim M 492 M MDocument6 pagesClariflocculator: Description Unit Input Calculated Range Value Value 54000 Mim M 492 M MAnonymous EKxXjqyVHNo ratings yet

- GATE 2014: General Instructions During Examination: Common Data Button That Appears On The ScreenDocument17 pagesGATE 2014: General Instructions During Examination: Common Data Button That Appears On The ScreenRobin ParmarNo ratings yet

- Performance Investigation of T-Shaped Micromixer WDocument9 pagesPerformance Investigation of T-Shaped Micromixer WVinu DNo ratings yet

- Chiksan Drawings 1Document1 pageChiksan Drawings 1Nasrien KadirNo ratings yet

- Pipeline Surge CalcDocument8 pagesPipeline Surge CalcBassem BalghouthiNo ratings yet

- Chapter 2 Pressure Transient Analysis in Drawdown and BuildupDocument52 pagesChapter 2 Pressure Transient Analysis in Drawdown and BuildupJhon Jaime RomeroNo ratings yet

- Aeroelastic GallopingDocument17 pagesAeroelastic GallopingMalika NavaratnaNo ratings yet

- Wieght of ANSI Schedule Water: (Reference Only)Document12 pagesWieght of ANSI Schedule Water: (Reference Only)கோகுல் இராNo ratings yet

- Potential Flow PDFDocument8 pagesPotential Flow PDFAsal MortazaviNo ratings yet

- Mass TransferDocument58 pagesMass TransferShai Sta Catalina100% (1)

- 06 - D155 - Hyd Fan CircuitDocument12 pages06 - D155 - Hyd Fan CircuitMichael Davenport100% (2)

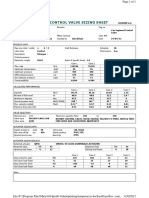

- Control Valve Sizing SheetDocument1 pageControl Valve Sizing SheetCecep AtmegaNo ratings yet

- Some Notes On Aircraft and Spacecraft Stability and Control: Michael Carley, M.j.carley@bath - Ac.ukDocument115 pagesSome Notes On Aircraft and Spacecraft Stability and Control: Michael Carley, M.j.carley@bath - Ac.ukMohammad Reza Madadi100% (1)

- Ducts Design For Air CondidtioningDocument10 pagesDucts Design For Air CondidtioningramNo ratings yet

- Aerodynamic Analysis of Dimple Effect On Aircraft Wing With Cover Page v2Document5 pagesAerodynamic Analysis of Dimple Effect On Aircraft Wing With Cover Page v2UNITED CADDNo ratings yet

- Cooling Tower EditoidDocument33 pagesCooling Tower EditoidJabber Reyes AmborNo ratings yet

- Exercise 4 Effects of ControlsDocument58 pagesExercise 4 Effects of Controlss raman100% (1)

- 01 Introduction To CFDDocument52 pages01 Introduction To CFDaadhithyarajasekaranNo ratings yet

- Fluid Flow Through Rock Joints The Effect of Surface RoughnessDocument11 pagesFluid Flow Through Rock Joints The Effect of Surface RoughnessFeiyang WangNo ratings yet

- HVAC Chilled Water Distribution SchemesDocument56 pagesHVAC Chilled Water Distribution SchemesJenson Joy100% (5)

- The Molecular Model: Phase SpaceDocument29 pagesThe Molecular Model: Phase SpaceLu LibinNo ratings yet

- Hydraulic System Failure CausesDocument2 pagesHydraulic System Failure CausesManuel CespedesNo ratings yet