Professional Documents

Culture Documents

Maintain Ability

Uploaded by

Fausto ReyesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maintain Ability

Uploaded by

Fausto ReyesCopyright:

Available Formats

1

1

Introduction to Maintainability

The concept of maintainability encompasses:

An operational measure of effectiveness

A characteristic of design

An engineering specialty that supports design

A cost driver

A planned activity in each stage of product life-cycle

2

Introduction (cont)

Maintainability - is the ability of an item to be maintained; this

ability stems from the aggregate of all design features which

promote serviceability.

Maintenance - is a series of actions of appropriate character

(content, timing, quality) to restore or retain an item in an

operational state.

Contrast:

Reliability is time to failure, probability of no failure

Maintainability is time to diagnose and repair a fail ure or time

to prevent future failure

2

3

Maintainability is Inherently a Probabilistic

Measure

Detection, diagnosis, repair, check-out all involve uncertainty

Human skill and learning are involved

Differences due to individuals

Differences due to experience

Consider other definitions of maintainability:

The probability that:

Item will be restored to operational status in T hours

Maintenance will not be required more than X times per time

period

Maintenance cost will not exceed $Z per time period

4

Maintainability in the System

Life-Cycle

The Maintainability Plan is developed during conceptual

design, reviewed internally and by customer, and includes:

Functions to be performed (p.391-393)

Standards/ Procedures/ models to be used

Schedule

Documents/ Reports

Organization, responsibilities, interfaces within your

company and with customer, supplier

3

5

Maintainability in the System Life-Cycle

The Systems Engineering Plan has a major section devoted

to integration of the engineering specialties into the design

process. The SE is responsible for assuring adequate

participation, influence, visibility, etc. is granted to

maintainability, and others.

6

Qualitative Maintainability Measures

Especially important early in design when limited data exist

Examples:

Skill level reduction

Ease of access

Simplicity of task

Identification, markings, coding

Standardization

Safety during maintenance

Clearly written, easy to follow instructions

Ease of fault isolation

4

7

Qualitative Maintainability Measures(cont)

Some ways these get incorporated into design

Management emphasis

Experienced maintenance chiefs on each team

Checklists (see handout)

Degree to which quantitative measures/ models are

sensitive to these

8

Quantitative Measures of Maintainability

Maintenance Elapsed-Time Factors

Mean Corrective Maintenance Time

(MTTR)

Mean Preventative Maintenance Time

Median Corrective Maintenance Time

Median Preventative Maintenance Time

Mean Active Maintenance Time

ct

M

pt

M

ct

M

~

pt

M

~

M

5

9

Quantitative Measures of Maintainability

Maintenance Labor-Hour Factors

Maintenance labor-hours per operating cycle

Maintenance labor-hours per cycle

Maintenance labor-hours per month

Maintenance labor-hours per maintenance action

Maintenance Frequency Factors

Meantime between maintenance = MTBM

Unscheduled (corrective) and Scheduled ( preventive)

Meantime between replacement = MTBR

10

Maintainability Function

Definition: Let T = Repair Time Random Variable. The

Maintainability Function M(t) is defined by M(t) = P(Tt)

Example: Suppose T is exponential with repair rate .

Mean time to repair:

1

MTTR

MTTR

t

t

e e t M

1 1 ) (

6

11

Other Distributions Used

Normal - Simple, remove and plug in.

Lognormal - complex repair; multiplicative degradation

model.

Weibull - Variety of situationsmost versatile. A

generalization of the exponential, which has constant

failure rate. Often used for worst linkor first of many

flaws to produce a failure.

12

Properties of Weibull Distribution

Invented in 1951; tried to create

Set, , controls shape of h(t),

Then,

Adjoin a third shift parameter 0, which shifts left

endpoint of range of distribution:[j+]. Require >0

0 , ) ( t at t h

b

H t ( )

( )

t

( )

1

t

) (

) (

dt

t dH

t h

F t e e e

Ht

t

( ) ,

( )

_

,

1 1 1

1

t

=1 is exponential

7

13

Properties of Weibull Distribution(cont)

Final Result

h t

t

F t e

MTTR or MTBF

t y e dy M

t

t y

( )

( )

( )

( )

ln

( )

( )

+ ( ) +

( ) +

( )

_

,

_

,

1

1

0

1

1

1

1

2

R(t) e

-

t -

-

14

How Controls Shape of h(t) For Weibull

Distribution

This is a handout

8

15

Weibull Closure Property

Recall for n exponential-life components with rates

and a series system

If a series system has:

n independent parts, each Weibull with the same

n

,..., ,

2 1

s i

i

n

1

n

n

1

,...,

1

,

1

2

2

1

1

The respective characteristic lives

16

Weibull Closure Property(cont)

Then

System Lifetime Distribution is Weibull with shape

parameter

and,

s i

i

n

s i

i

n

_

,

_

,

1

1

1

1

9

17

Example

5 Hoses in an Engine Cooling System have =1.8,

Respective 1= 95, 2= 110, 3=130, 4=130, 5=150

months, then

O

s

+ + +

_

,

+

_

,

1

95

1

110

1

130

1

150

48 6

39 6

43 2

1 8 1 8 1 8 1 8

1

1 8

. . . .

.

.

.

.

months

R 48.6(ln2) months

MTBF 48.6 1

1

1.8

1

1.8

18

Properties of Lognormal Distribution

Definition - X is lognormal with range space (0, + ),

parameters and IFF Y= ln X, is normal with parameters

and

Mode of X at

Median of X at

Mean of X at

Variation of X is

2

y y

e x

y

u

e x

2

2

1

y y

e

x

x

e e

y y y 2

2 1

2 2

( )

+

10

19

Properties of Lognormal Distribution (cont)

Properties

1.

2. If Xj, j=1,,n are lognormal and independent,

then the geometric mean is lognormal

If X lognormal X lognormal

1 y1 2 y2

, , ,

y y 1

2

2

2

( ) ( )

2 1 2 1

X * X then W t; independen X , X and

( )

2

2

2

1 2 y1

, with lognormal is

y y y

+ +

( )

2

,

y y

x

j

j

n n

_

,

1

1

y

y

n

,

2

_

,

20

Example 1 pp.395-398

Assumes normal

Takes , s to be ,. Is this ok ?

Whats wrong with equation 14.1 ?

X

11

21

Example 2

Suppose n Components in series, each exponential with I failure

rate for component I; Let Mcti= time to repair system when ith

component fails. Then for system is estimated

by (14.2)

If there are of type i in the system, then use:

MTTR M

ct

M

X M

ct

i cti

i

n

i

i

n

1

1

M

n M

n

ct

i i cti

i

n

i i

i

n

1

1

Repair time/unit time

System failure/unit time

Repair time

per failure

n

i

22

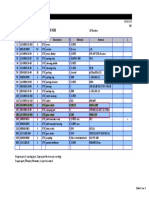

Example 2 (cont)

i n . *10 hrs M (hr) Repair Time per 10 hr

Assemblies Components n M

1 4 10 .1 4.0

2 6 5 .2 6.0

3 2 8 1.0 16.0

4 1 15 .8 7.5

5 5 12 .5 30.5

161 63.5

MTTR

63.5

161

i i

3

cti

3

i i cti

0 394 . hours

12

23

Mean Preventative Maintenance Time

Includes

Inspection

Servicing, Cleaning

Replacements

Calibration

Overhaul

M

fpt M

fpt

pt

i pti

i

n

i

i

n

( )(

( )

)

1

1

Where fpti = frequency of the ith

preventive maintenance

action

Mpti = elapsed time for

ith preventive maintenance

action

24

Median (Active) Corrective Maintenance

Time

For sample of size n on Mct for one component

For m classes of corrective maintenance on system, with

respective failure rates i

ln

M e

ct

M

cti

i

n

n

1

]

1

1

1

1

1

1

ln

M e

ct

M

i cti

i

m

i

i

m

1

]

1

1

1

1

1

1

1

Note: It is possible to do the

computations using log10

versus 10 versus e

x x

13

25

Median (Active) Preventative Maintenance

Time

ln

M e

pt

fpt M

fpt

i pti

i

n

i

i

n

( )

( )

1

]

1

1

1

1

1

1

1

26

Mean (Active) Maintenance Time

= Overall Corrective Maintenance Rate

fpt = Preventive Maintenace Rate

fpt

M fpt M

M

pt ct

+

+

i

fpt

i

14

27

Maximum(Active) Corrective Maintenance

Time

M e

M

n

Z

cti

i

n

y

max

ln

1

]

1

1

1

1

1

1

Where;

y y

cti

cti

S

M

M

n

n

( )

( )

[ ]

2

2

2

1

ln

ln

28

Other Maintenance Elapsed-Time Measures

Logistics delay time (LDT), waiting for

facility, equipment

Spare part

Tool

Transport

Administrative delay time (ADT)

Organizational (people, paper, priorities, etc)

Non-physical

15

29

Other Maintenance Elapsed-Time

Measures(cont)

Maintenance Downtime (MDT)

MDT = +LDT+ADT

where i= frequency of respective action/ delay

M

3 2 1

3 2 1

+ +

+ +

T D A T D L M

T D M

30

Maintenance Labor Hour Factors

Together with skill levels and their day rates, these factors

determine labor cost of maintenance and number in each

skill level per maintenance facility

MLH/OH

MLH/cycle

MLH/month

MLH/MA

16

31

Maintenance Labor Hour Factors(cont)

Any of above can be expressed as average over all

subsystems

Can apply to corrective, preventive, pr total active

Can apply to total maintenance downtime

Conceptually, want to select skill levels and maintenance

difficulty to minimize maintenance costs

32

Maintenance Frequency Factors

Meantime Between Maintenance (MTBM)

MTBMu is approximately MTBF, the

reliability factor, although in general

MTBF MTBMu

s u

MTBM MTBM

MTBM

1 1

1

+

17

33

Maintenance Frequency Factors(cont)

Meantime Between Replacement (MTBR)

A part, component, or a subsystem must be replaced by

a spare part from inventory. Major link between

maintenance actions and logistics support system

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Smith KJ Student Mathematics Handbook and Integral Table ForDocument328 pagesSmith KJ Student Mathematics Handbook and Integral Table ForStrahinja DonicNo ratings yet

- 65 ActsDocument178 pages65 ActsComprachosNo ratings yet

- Daygame by Todd Valentine NotesDocument8 pagesDaygame by Todd Valentine NotesAdnanHassan100% (7)

- AIC - AirROCT35 - Spare Parts ManualDocument153 pagesAIC - AirROCT35 - Spare Parts ManualMuhammad Arqam Al Ajam67% (3)

- Foundation Design LectureDocument59 pagesFoundation Design LectureJamaica MarambaNo ratings yet

- Good Practices in Tray DesignDocument7 pagesGood Practices in Tray Designmehul10941100% (2)

- XYZprint User Manual en V1 1003Document25 pagesXYZprint User Manual en V1 1003reza rizaldiNo ratings yet

- Cho Gsas - Harvard 0084L 11462Document503 pagesCho Gsas - Harvard 0084L 11462Claudemiro costaNo ratings yet

- Solids Separation Study Guide: Wisconsin Department of Natural Resources Wastewater Operator CertificationDocument44 pagesSolids Separation Study Guide: Wisconsin Department of Natural Resources Wastewater Operator CertificationkharismaaakNo ratings yet

- Vegetable Rates - 02-01-2021Document454 pagesVegetable Rates - 02-01-2021Saurabh RajputNo ratings yet

- Instructor: DR - Ashok Kaushal: Orthogonal ViewsDocument49 pagesInstructor: DR - Ashok Kaushal: Orthogonal ViewsKristi GjokaNo ratings yet

- AssignmentDocument13 pagesAssignmentSwakshar DebNo ratings yet

- Fo Transfer ProcedureDocument8 pagesFo Transfer ProcedureadityasahayNo ratings yet

- Radiation Formula SheetDocument5 pagesRadiation Formula SheetJakeJosephNo ratings yet

- Brainedema 160314142234Document39 pagesBrainedema 160314142234Lulu LuwiiNo ratings yet

- Tyba S4 Syntax PDFDocument107 pagesTyba S4 Syntax PDFIndahNo ratings yet

- DoomsdayDocument29 pagesDoomsdayAsmita RoyNo ratings yet

- Ceu Guidance Problematic Bleeding Hormonal ContraceptionDocument28 pagesCeu Guidance Problematic Bleeding Hormonal Contraceptionmarina_shawkyNo ratings yet

- Bsi MD Ivdr Conformity Assessment Routes Booklet Uk enDocument15 pagesBsi MD Ivdr Conformity Assessment Routes Booklet Uk enGuillaumeNo ratings yet

- Excretory Products and Their EliminationDocument13 pagesExcretory Products and Their Eliminationaravind kishanNo ratings yet

- Hazel Rhs Horticulture Level 2 Essay 1Document24 pagesHazel Rhs Horticulture Level 2 Essay 1hazeldwyerNo ratings yet

- UntitledDocument413 pagesUntitledjgj38j90No ratings yet

- Load Distribution Flow Chart For Bridge DesignDocument1 pageLoad Distribution Flow Chart For Bridge DesignBunkun15No ratings yet

- Industrial Revolution OutlineDocument8 pagesIndustrial Revolution OutlineGeraldine GuarinNo ratings yet

- Etl 213-1208.10 enDocument1 pageEtl 213-1208.10 enhossamNo ratings yet

- NDT Matrix 12-99-90-1710 - Rev.2 PDFDocument2 pagesNDT Matrix 12-99-90-1710 - Rev.2 PDFEPC NCCNo ratings yet

- E Numbers Are Number Codes ForDocument3 pagesE Numbers Are Number Codes ForaradhyaNo ratings yet

- ForewordDocument96 pagesForewordkkcmNo ratings yet

- Feasibility Study On The Seaweed Kappaphycus Alvarezii Cultivation Site in Indari Waters ofDocument9 pagesFeasibility Study On The Seaweed Kappaphycus Alvarezii Cultivation Site in Indari Waters ofUsman MadubunNo ratings yet

- Ora Laboratory Manual: Section 1 Section 1Document36 pagesOra Laboratory Manual: Section 1 Section 1Ahmed IsmailNo ratings yet