Professional Documents

Culture Documents

Penstocks Design: Mohammad A. Al Shehri Ahmad S. Al Umair Osama Al-Mubarak

Uploaded by

praveendehsarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Penstocks Design: Mohammad A. Al Shehri Ahmad S. Al Umair Osama Al-Mubarak

Uploaded by

praveendehsarCopyright:

Available Formats

Penstocks Design

Mohammad A. Al Shehri

Ahmad S. Al Umair

Osama Al-Mubarak

Project Advisor: Dr. Emad Tanbour

A Design Project Submitted in Partial Fulfillment

of the Requirements for the Course

Assessment III: Graduation Project

College of Engineering

Department of Mechanical Engineering

Statement of Purpose

To design a Penstocks that can be

manufactured using locally available

resources and manufacturing techniques.

Design the project using the SolidWorks

program.

College of Engineering

Department of Mechanical Engineering

Table of Contents

Introduction

Design GANTT Chart

Sketches

Scope of Project

Penstocks Classification

Calculations

Penstocks Prototype

College of Engineering

Department of Mechanical Engineering

Introduction

Apenstock is a sluice or gate or intake structure that

controls water flow, or an enclosed pipe that delivers water

to hydraulic turbines and sewerage systems.

Penstocks may be used where water level control, flow

isolation or diversion is required. This may include dams,

rivers and weirs, water treatment, sewage treatment, storm

water, irrigation flood control gate applications.

College of Engineering

Department of Mechanical Engineering

Design GANTT Chart

College of Engineering

Department of Mechanical Engineering

Sketches

College of Engineering

Department of Mechanical Engineering

Gate Frame will be installed on a concrete wall. It has height

of 4.17 m and width of 2.26 m.

The frame is made of steals steel.

We have installed 14 thrusts on each side of the

Frame to distribute the lode on it and provide

More strength to the starchier of the frame.

We have installed 6 pushers inside to provide

perfect selling when the gate is closed.

Frame Design

College of Engineering

Department of Mechanical Engineering

College of Engineering

Department of Mechanical Engineering

Frame Design

Frame:

THIKNES:

inner =

17.13 cm

outer=

23.13

Length:

400 cm

WIDTH:

200cm

Frame Design

Frame Dead Bolts

6 cm diameter

7 cm tall

Chamfer 0.8 cm with 45

degree

Sixfold with diameter 4.5

cm, and 4cm long

Gate: In our design the gate was 2 m X 2m and it consist of

four major parts:

a) Front wall (facing the water).

b) Back wall.

c) Supporting metal sheets.

d) Hench (Gate Holder).

e) Supporting pushing's.

Parts Design

College of Engineering

Department of Mechanical Engineering

Thickness of the

assembly of the

wall

15.6 cm

The wall will face

the water

plate thickness 1

cm

the other side of the

door

plate thickness 0.3

cm

Front Wall

It is 2x2

Thickness 1 cm

There is a rubber surrounded the front door

that will face the water, it has a width 6cm

and the thickness is 0.5cm

To prevent leakage.

From the other side of

the wall there will be

sheets to support the wall

Number of the supporting

sheets in the door

assembly

7

The sheet 14x14 cm

Thikness of the sheet 3mm Between every sheet 4 cm

To support the door and let it to handle more pressure and forces.

Gate Assembly

College of Engineering

Department of Mechanical Engineering

Back Wall

thickness 0.3 cm

Plates

There is 9 plates

In 160cm long distance, 10cm width, and

0.6cm thickness.

It has distance between each other 20cm.

To disrepute the

forces in the door

and give it the

ability to handle

high loads.

Pushing's

Triangle shape

Height 1cm

10 cm long

2 cm width

The first one is 23.7 cm from the

top of the back door

The distance between them is

60cm

The shift is 2 cm between them

To push the door to

the other side and to

prevent leakage when

it is fully closed.

Hinge

30.6 cm long

14.3 cm width

2 cm depth

3 cm diameter for the holes

It will be fixed to the door, to let

the pin have the ability to open

and close the door in the frame.

Screw length 225 cm

Screw nominal diameter 7 cm

Threaded length 200 cm

Power

Screw

It will be connected with the hench by a

small pin.

It will connect the pin with the gears to

open and close the door.

It will rotate inside the gear the will allow

the pin to move upward and downward .

Connector between Hinge and

Power crew

It has a six fold from the both sides.

The diameter for six folds is 4cm

Its thickness is 0.5cm

The cylindrical shape it is in the

meddle between the six folds.

It has a diameter with 3cm, and

extruded 15.6cm

It will connect

the power screw

with the hinge.

Diameter of the gear 12 cm

Thickness of the gear 4.6 cm

Number of Teeth 12

Pinion

Gear

It will rotate to move the pin

upward an downward.

It will rotate from other gear that

supported with a motor.

Diameter of the gear 12 cm

Thickness of the gear 4.6 cm

This gear is connected with

a shaft.

The shaft is connected with

a motor, the motor will rotate

the stick shaft and the gear

to rotate the other gear that

is connected with the power

screw, that will let the power

screw move, by that rotation

it will let the door open and

close.

Motor is been installed to provide the

required force to open and close the

gate.

The motion will be transferred

through two gears. One of the gears

will have a thread surface inside that

the stem will move in it, the other

gear will be attached to the motor.

The stem length is 2.25 m and has

109 rev with

An angle of 90

the motor shaft is 50 cm length and

2.5 cm

Diameter.

College of Engineering

Department of Mechanical Engineering

College of Engineering

Department of Mechanical Engineering

The stem is 2.25 m & tried is 2 m

College of Engineering

Department of Mechanical Engineering

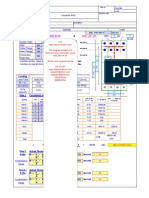

Fluid: Water

Operating force, force acting

on the door:

P=100kN P = 0.5 (F)

P = 0.5 (200)

Discharge Flow Rate:

Flow through the opening of

the weir penstock at 2m by 2m

662m/min

q = 1.73 (W) (H) (1.5)

Where:

q = discharge flow rate, m/s

W =width, m, H = height, m

q = 1.73 (2) (2) (1.5)

q = 10.4 m/sec = 662 m/min

Torque on the Drive Gear:

T = (P) (5252)/rpm

Where:

Constant = 5252

T = torque

P = power of motor, assumed at 750 Watts

= 1.00536 Hp

RPM = rotational speed, rpm

T = (1.00536) (5252)/1800

T = 2.93 ft-lbs = 0.40 m-kg

0.40 m-kg

Torque on the Driven Gear:

T = (Ft) (D2)/2

T = (4) (0.16)/2

T = 0.32 m-kg

0.32 m-kg

College of Engineering

Department of Mechanical Engineering

Hydraulic force acting on the penstock:

F = 10(H) (A)

Where:

F = force, kN

H = max. differential head, 5 m

A = door area, m

F = 10 (5) (4)

F = 200 kN

Calculations

College of Engineering

Department of Mechanical Engineering

Group Brainstorming

Gather Literatures from the web

Sketches.

Design Conceptualization

Identification of Critical

Components

Sizing and Strength Calculations

Prototyping by CAD SolidWorks

Design Approach

College of Engineering

Department of Mechanical Engineering

Reliability

Can hold resistance high force

stresses.

Light weight comparison of other

models.

Low production cost

Low maintenance

Positives

College of Engineering

Department of Mechanical Engineering

Stress Analyses

Motor and Gear Mechanism

College of Engineering

Department of Mechanical Engineering

College of Engineering

Department of Mechanical Engineering

Video clip

Thank you

College of Engineering

Department of Mechanical Engineering

You might also like

- Pipeline Design for Water EngineersFrom EverandPipeline Design for Water EngineersRating: 5 out of 5 stars5/5 (1)

- Section 9.0 - CulvertsDocument11 pagesSection 9.0 - CulvertsOMANAKUTTAN100% (1)

- Design Considerations For GatesDocument1 pageDesign Considerations For GatesBehçet Serdal Canbaz0% (1)

- Penstock DesignDocument28 pagesPenstock Designriz2010100% (6)

- Penstock ManualDocument159 pagesPenstock Manualstudent_bl95% (21)

- Design of Penstock: Reference Code:IS 11639 (Part 2)Document4 pagesDesign of Penstock: Reference Code:IS 11639 (Part 2)sunchitk100% (3)

- Trash Rack CalculationDocument8 pagesTrash Rack Calculationsumit67% (3)

- 3D Hydro Mechanical (Gates)Document52 pages3D Hydro Mechanical (Gates)api-19871259100% (2)

- Gate Design ProcedureDocument42 pagesGate Design ProcedureNoppadol Ariyakrua92% (13)

- Trash RackDocument10 pagesTrash RackBalu MNo ratings yet

- Considerations in Radial Gate Design ICOLDDocument27 pagesConsiderations in Radial Gate Design ICOLDkamal167100% (1)

- Training On Hydraulic Gates (Document4 pagesTraining On Hydraulic Gates (sanbarunNo ratings yet

- Design of PenstockDocument25 pagesDesign of PenstockSalman Shuja100% (1)

- 1 Steel Penstock: 1.1 Location and ArrangementDocument7 pages1 Steel Penstock: 1.1 Location and ArrangementDangol RupeshNo ratings yet

- HydromechanicalDocument31 pagesHydromechanicalJennifer HudsonNo ratings yet

- Bifurcation CalculationDocument7 pagesBifurcation CalculationIMJ JNo ratings yet

- Vetical Dam Hoist MechanismDocument38 pagesVetical Dam Hoist Mechanismkrishnan_selvaNo ratings yet

- Trashrack DesignDocument4 pagesTrashrack DesignpicottNo ratings yet

- Hydraulics and Design of TrashrackDocument25 pagesHydraulics and Design of TrashracksapkotamonishNo ratings yet

- Trashrack DesignDocument12 pagesTrashrack DesignAnonymous b9DIaPTq6BNo ratings yet

- Is 4622 2003Document27 pagesIs 4622 2003Apurba Haldar100% (1)

- Sickle PlateDocument24 pagesSickle PlateanjnaNo ratings yet

- Structural Design of Penstock Indian StandardDocument24 pagesStructural Design of Penstock Indian StandardPEJU0007100% (2)

- Penstock CaalculationDocument3 pagesPenstock CaalculationGertjan DuniceriNo ratings yet

- Penstock Embedded DesignDocument6 pagesPenstock Embedded Designgrahazen50% (2)

- Vol IIDocument74 pagesVol IIBhaskar ReddyNo ratings yet

- Radial Gate Design ProcedureDocument2 pagesRadial Gate Design ProcedureSangyt Karna100% (2)

- Buried Steel Penstock Second EditionDocument96 pagesBuried Steel Penstock Second EditionGabriel Espinal100% (1)

- Design Computation Penstock 3Document26 pagesDesign Computation Penstock 3Roland TagufaNo ratings yet

- Wye BranchesDocument8 pagesWye BranchesbarukomkssNo ratings yet

- Penstock FormulaDocument9 pagesPenstock FormulaGertjan DuniceriNo ratings yet

- A New Improved Formula For Calculating Trashrack LossesDocument8 pagesA New Improved Formula For Calculating Trashrack LossesNikom KraitudNo ratings yet

- Is 11388 (2012) - Recommendations For Design of Trash Racks For IntakesDocument12 pagesIs 11388 (2012) - Recommendations For Design of Trash Racks For Intakeskshitj100% (2)

- Penstock Branch DesignDocument38 pagesPenstock Branch DesignIfnu Setyadi100% (7)

- Sluice Gates - Slide Gates - PenstocksDocument28 pagesSluice Gates - Slide Gates - Penstocksnazar750100% (2)

- 4.10 - Desilting Basin - Flushing Sluice Gate and HydraulicDocument4 pages4.10 - Desilting Basin - Flushing Sluice Gate and Hydraulicsrigirisetty208No ratings yet

- Structural Design of PenstockDocument28 pagesStructural Design of PenstockApichartj Jusuay67% (3)

- Water Power Penstocks Hydrodynamic Pressures Due To Earthquakes Oct 2005Document5 pagesWater Power Penstocks Hydrodynamic Pressures Due To Earthquakes Oct 2005Bagheri HessamNo ratings yet

- Design of Hydraulic GateDocument20 pagesDesign of Hydraulic GateTarunPatra100% (1)

- Manual On Design Fabrication Erection & Maintenance of Steel PenstockDocument167 pagesManual On Design Fabrication Erection & Maintenance of Steel Penstockrajeevakumar100% (38)

- Steel Penstocks - 4 Exposed PenstocksDocument40 pagesSteel Penstocks - 4 Exposed Penstocksjulio83% (6)

- Hydro Dynamic ForcesDocument34 pagesHydro Dynamic Forcesvikasgahlyan100% (1)

- Penstock Thickness CalculationDocument2 pagesPenstock Thickness Calculationrakesh1987_careers100% (6)

- Ecway Technologies: Design and Fabrication of Cyclone Seperator Using Vane PumpDocument9 pagesEcway Technologies: Design and Fabrication of Cyclone Seperator Using Vane Pumpieee4mybusinessonly100% (1)

- Complete Model ReportDocument22 pagesComplete Model ReportHari Krishna K.C.No ratings yet

- The Design of Langqi Min River Bridge, Fuzhou, China: Min Zhang Tianbo Wan Yingliang WangDocument6 pagesThe Design of Langqi Min River Bridge, Fuzhou, China: Min Zhang Tianbo Wan Yingliang WangmasteriragaNo ratings yet

- Training ReportDocument23 pagesTraining ReportAnurag ChaudharyNo ratings yet

- Training Report ElectricalDocument73 pagesTraining Report ElectricalAkash KumarNo ratings yet

- Cad DrawingDocument53 pagesCad DrawingAvish Gunnuck100% (3)

- Design and FabricationDocument21 pagesDesign and FabricationMurugesh VenkatesanNo ratings yet

- 14 MarksDocument4 pages14 MarksmohanNo ratings yet

- Engineering Process Education Presentation in Orange White Simple StyleDocument10 pagesEngineering Process Education Presentation in Orange White Simple Stylejan arligueNo ratings yet

- MCQ in Machine Design Part 1 - ME Board ExamDocument16 pagesMCQ in Machine Design Part 1 - ME Board ExamRobert V. AbrasaldoNo ratings yet

- Iecep GeasDocument9 pagesIecep GeaswengNo ratings yet

- ReportDocument7 pagesReportKartikey PathakNo ratings yet

- Eto NaDocument6 pagesEto NaAiman Padilla AbreuNo ratings yet

- Cat2 PapersDocument5 pagesCat2 Paperssujalvrm21No ratings yet

- Dr. Akant Singh: Under The Guidance ofDocument20 pagesDr. Akant Singh: Under The Guidance ofnitendra kumarNo ratings yet

- Sample Master ThesisDocument56 pagesSample Master ThesisAnirudh SreerajNo ratings yet

- Comparative Study On Composite Stub Column: Nternational Ournal of Nnovative Esearch in Cience, Ngineering and EchnologyDocument6 pagesComparative Study On Composite Stub Column: Nternational Ournal of Nnovative Esearch in Cience, Ngineering and EchnologySyed Abdul RawoofNo ratings yet

- 219 420401 12 PavementConnector (PCC) ForBridgeApproachSlabDocument1 page219 420401 12 PavementConnector (PCC) ForBridgeApproachSlabMes RubenNo ratings yet

- Trans Tech: PublicationsDocument48 pagesTrans Tech: PublicationsSulochana KannanNo ratings yet

- Kyrgyz State Technical University Named After I.razzakovDocument17 pagesKyrgyz State Technical University Named After I.razzakovSaleem IqbalNo ratings yet

- INM8521Document43 pagesINM8521heka2006No ratings yet

- Hyundai Air Circuit BreakerDocument2 pagesHyundai Air Circuit BreakerRoberto Alejandro Richards ValverdeNo ratings yet

- Process Industry Practices VesselsDocument73 pagesProcess Industry Practices Vesselssumedh444No ratings yet

- Floor SystemDocument14 pagesFloor SystemCJ Ong100% (1)

- 11 Steel Connection Design As Per AISC 23052014Document2 pages11 Steel Connection Design As Per AISC 23052014Ahmad Badsha Quadri67% (3)

- Commissioning Your Data Center Electrical SystemDocument39 pagesCommissioning Your Data Center Electrical SystemKhaya Khoya100% (1)

- Mud BrickDocument3 pagesMud Brickabc50% (2)

- Anna University:: Chennai - 600 025: Office of The Controller of ExaminationsDocument4 pagesAnna University:: Chennai - 600 025: Office of The Controller of ExaminationsAarthi JNo ratings yet

- Aw Hook-Simulationxpress Study-1Document11 pagesAw Hook-Simulationxpress Study-1api-267794206No ratings yet

- Climbing FormworkDocument5 pagesClimbing Formworksanjeev2812No ratings yet

- Gate 1533Document7 pagesGate 1533Darshit D RajNo ratings yet

- Improving The Safety Culture in The Organization by Implementing Behaviour Based Safety (BBS)Document12 pagesImproving The Safety Culture in The Organization by Implementing Behaviour Based Safety (BBS)IJRASETPublicationsNo ratings yet

- List of Long Lead Items Rev C 11 Oct 2016Document2 pagesList of Long Lead Items Rev C 11 Oct 2016Shafiullah KhanNo ratings yet

- Especificaciones Tecnicas Scorbot ER-14Document2 pagesEspecificaciones Tecnicas Scorbot ER-14sebastian_alvarez_7No ratings yet

- Assessment of Dead Load Deflection of Bailey Bridges in BangladeshDocument5 pagesAssessment of Dead Load Deflection of Bailey Bridges in Bangladeshalpegambarli100% (1)

- 3300 SyllabusDocument5 pages3300 SyllabusLong PhamNo ratings yet

- DesignDocument5 pagesDesignfafiNo ratings yet

- Structural Health Monitoring: Course OutcomesDocument2 pagesStructural Health Monitoring: Course OutcomesprakashNo ratings yet

- 5 Superstructure FormworkDocument71 pages5 Superstructure FormworkAngel Marie PestanoNo ratings yet

- Railway Reservation SystemDocument20 pagesRailway Reservation SystemChand Kishor Prasad100% (1)

- Guide To Elemental Cost Estimating 2013Document114 pagesGuide To Elemental Cost Estimating 2013Hisbullah Kalanther Lebbe100% (1)

- 5 SoftwareTestingStrategiesDocument47 pages5 SoftwareTestingStrategiesSandy CyrusNo ratings yet

- Pengenalan JambatanDocument80 pagesPengenalan Jambatansanusi69100% (1)

- TECHNICAL NOTE 011 Lateral Loads On Falsework - Is Cross-Bracing Really Not Required at All PDFDocument2 pagesTECHNICAL NOTE 011 Lateral Loads On Falsework - Is Cross-Bracing Really Not Required at All PDFmyduyen75No ratings yet

- Strengthening Existing SteelworkDocument4 pagesStrengthening Existing SteelworkFourHorsemen100% (1)