Professional Documents

Culture Documents

GAIL F20S009 LLDPE for Blown Film

Uploaded by

Md Minhaj0 ratings0% found this document useful (0 votes)

9 views1 pageF20S009 is a linear low density polyethylene optimized for blown film extrusion applications like packaging films. It has excellent processability and mechanical properties like tensile strength, elongation, and impact strength. It is recommended for general purpose, heavy duty, and liquid packaging films. The document provides processing guidelines for barrel temperature, blow up ratio, die gap and regulatory/packaging information for F20S009. For technical assistance, contact GAIL Polymer Technology Centre.

Original Description:

mmm

Original Title

F20S009mmm

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentF20S009 is a linear low density polyethylene optimized for blown film extrusion applications like packaging films. It has excellent processability and mechanical properties like tensile strength, elongation, and impact strength. It is recommended for general purpose, heavy duty, and liquid packaging films. The document provides processing guidelines for barrel temperature, blow up ratio, die gap and regulatory/packaging information for F20S009. For technical assistance, contact GAIL Polymer Technology Centre.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views1 pageGAIL F20S009 LLDPE for Blown Film

Uploaded by

Md MinhajF20S009 is a linear low density polyethylene optimized for blown film extrusion applications like packaging films. It has excellent processability and mechanical properties like tensile strength, elongation, and impact strength. It is recommended for general purpose, heavy duty, and liquid packaging films. The document provides processing guidelines for barrel temperature, blow up ratio, die gap and regulatory/packaging information for F20S009. For technical assistance, contact GAIL Polymer Technology Centre.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

GAIL (India) Ltd.

(A Govt. of India Undertaking)

Petrochemicals Marketing Division

The information, data and suggestions contained herein are to the best of our knowledge accurate and reliable. It is the ultimate responsibility of the user to

ensure that the product is suited and the information is applicable to the user specific application.

Revised in Apr2008

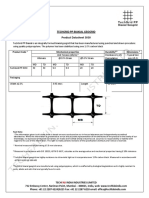

F20S009

Linear Low Density Polyethylene for Blown Film Extrusion

Application: F20S009 is optimally stabilized with antioxidants, slip additive, antiblocking agent and

processing aid.

It has excellent processability with optimum combination of mechanical, optical and sealing characteristics.

It is recommended for general purpose, heavy duty and liquid packaging in laminated / non-laminated film

applications.

Property Values* Unit Test Method

Melt Flow Index (I

2

) 0.9 gm/10min ASTM D1238

Density 0.918 gm/cc ASTM D1505

Tensile Strength @Break (MD/TD) 390/310 kg/cm

2

ASTM D882

Elongation @Break (MD/TD) 700/800 % ASTM D882

Tear Strength (MD/TD) 3.0/10 gm/mic ASTM D1922

Dart Impact Strength 3.4 gm/mic ASTM D1709

Coefficient of Friction 0.22/0.17 - ASTM D1894

(Static/Dynamic)

Haze 9 % ASTM D1003

* Typical characteristics of the product given purely as a guide. Mechanical/Optical properties were determined on 40 micron film made with 2.0mm die gap

and BUR: 2.2

Processing Guidelines:

Barrel temperature: 170 - 200

0

C

Blow up ratio: 2.0 to 2.25

Die gap: 1.8 to 2.2

Regulatory Information:

Certificate is available on request.

Packaging & Storage:

F20S009 is available in natural colour/pellet form in 25 kg strong bags made of woven fabric. The product

should be stored in dry conditions at temperature below 50

o

C and protected from UV light.

For any technical assistance contact:

GAIL Polymer Technology Centre

B-35/36, Sector-1, Noida, UP-201301, Tel: +91-0120-2549155/156, 2549310; Fax: 011-26185941

Website: www.gailonline.com

You might also like

- Feedstock Technology for Reactive Metal Injection Molding: Process, Design, and ApplicationFrom EverandFeedstock Technology for Reactive Metal Injection Molding: Process, Design, and ApplicationNo ratings yet

- F20S009Document1 pageF20S009Pratik GaikwadNo ratings yet

- F18A020UDocument1 pageF18A020UAman ChaudharyNo ratings yet

- Linear Low Density Polyethylene: Film Extrusion GradeDocument2 pagesLinear Low Density Polyethylene: Film Extrusion GradeAnugya RastogiNo ratings yet

- High density polyethylene for film extrusionDocument1 pageHigh density polyethylene for film extrusionJaydeep JainNo ratings yet

- E52A003 E52A003N: GAIL (India) LTDDocument1 pageE52A003 E52A003N: GAIL (India) LTDMd MinhajNo ratings yet

- Reliance Ldpe Heavy Duty Non Slip 0 5 Mfi J22fa002eDocument2 pagesReliance Ldpe Heavy Duty Non Slip 0 5 Mfi J22fa002eakshayNo ratings yet

- F2001A (1)Document2 pagesF2001A (1)Pratik GaikwadNo ratings yet

- Film Grades LL F2001SDocument2 pagesFilm Grades LL F2001SKool LeisureNo ratings yet

- P54 LLLDocument1 pageP54 LLLMd MinhajNo ratings yet

- Linear Low Density Polyethylene: Provisional Technical DatasheetDocument2 pagesLinear Low Density Polyethylene: Provisional Technical DatasheetMohit MohataNo ratings yet

- Flame Retardant Label Materials 7203 and 7204Document2 pagesFlame Retardant Label Materials 7203 and 7204FAH MANNo ratings yet

- 2K005E Tech Data (June.2011)Document2 pages2K005E Tech Data (June.2011)Giang TúNo ratings yet

- 2K010 Tech Data (June.2011)Document2 pages2K010 Tech Data (June.2011)Giang TúNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- Cynpol LD4001Document1 pageCynpol LD4001Gabs GabrielaNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- LLDPE Film Product Data SheetDocument2 pagesLLDPE Film Product Data SheetManufaktur Sinar JoyoboyoNo ratings yet

- Lldpe Hanwa 3120Document1 pageLldpe Hanwa 3120puipuiesperaNo ratings yet

- Lldpe Film 9030aDocument1 pageLldpe Film 9030aCasey LewisNo ratings yet

- Fortron 1120LDocument2 pagesFortron 1120LdanielNo ratings yet

- Product Sheet Petlin LD N125y - 0Document2 pagesProduct Sheet Petlin LD N125y - 0Manufaktur Sinar JoyoboyoNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- Im B120MADocument1 pageIm B120MAPrashant MalikNo ratings yet

- Low Density Polyethylene: Lamination Film ApplicationsDocument1 pageLow Density Polyethylene: Lamination Film ApplicationsMahadi Bachar MahamatNo ratings yet

- TDS Im-Atb338Document1 pageTDS Im-Atb338HD TalababuNo ratings yet

- GAIL (India) LTD.: High Density Polyethylene For OFC DuctsDocument1 pageGAIL (India) LTD.: High Density Polyethylene For OFC DuctsMd MinhajNo ratings yet

- PP Omopolimero - Borealis Hd120mo TDSDocument2 pagesPP Omopolimero - Borealis Hd120mo TDSarmandoNo ratings yet

- TDS Pe 008 Up4806hDocument2 pagesTDS Pe 008 Up4806hariefNo ratings yet

- Electroplating/Anodizing Tape: Technical Data December, 2006Document2 pagesElectroplating/Anodizing Tape: Technical Data December, 2006sanjay ukalkarNo ratings yet

- B55HM0003/B55HM0003N: GAIL (India) LTDDocument1 pageB55HM0003/B55HM0003N: GAIL (India) LTDPrateek GijjannavarNo ratings yet

- Bindex E-188 Speciality Polymer: Technical Data SheetDocument2 pagesBindex E-188 Speciality Polymer: Technical Data SheetfNo ratings yet

- POLYMER C150Y - Jan15 - New - Rev1Document2 pagesPOLYMER C150Y - Jan15 - New - Rev1W I Prayogo100% (1)

- Linear Low Density Polyethylene Injection MoldingDocument2 pagesLinear Low Density Polyethylene Injection MoldingakshayNo ratings yet

- Q2018 Series: Linear Low Density Polyethylene (LLDPE)Document2 pagesQ2018 Series: Linear Low Density Polyethylene (LLDPE)lyesNo ratings yet

- TDS Pe 200 SF5007Document2 pagesTDS Pe 200 SF5007Oktaviandri SaputraNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- 3M FT-DT8DuctTapeDocument2 pages3M FT-DT8DuctTapeElviera MphieNo ratings yet

- Product Sheet Petlin LD C150y - 0Document2 pagesProduct Sheet Petlin LD C150y - 0121221042No ratings yet

- 481 Preservation Sealing TapeDocument2 pages481 Preservation Sealing TapeSixmonNo ratings yet

- LLDPE JL210 Technical SheetDocument2 pagesLLDPE JL210 Technical SheetlyesNo ratings yet

- TDS HP740T DaelimDocument1 pageTDS HP740T Daelimbrandon abella gutierrezNo ratings yet

- Plating Masking TapDocument2 pagesPlating Masking TapkkphadnisNo ratings yet

- Q1018 Series: Linear Low Density Polyethylene (LLDPE)Document2 pagesQ1018 Series: Linear Low Density Polyethylene (LLDPE)lyesNo ratings yet

- TDS Pe 003 Uf1810s1 03Document2 pagesTDS Pe 003 Uf1810s1 03qc jrpNo ratings yet

- Rlene specificationDocument2 pagesRlene specificationjaintarunNo ratings yet

- 3M Preservation Sealing Tape 481Document6 pages3M Preservation Sealing Tape 481Mait YNo ratings yet

- At-N70 NC006 Tds-En - 071049Document2 pagesAt-N70 NC006 Tds-En - 071049Thunder StromNo ratings yet

- 24FS040 24FA040: Low Density PolyethyleneDocument1 page24FS040 24FA040: Low Density PolyethyleneMahadi Bachar MahamatNo ratings yet

- Mdpe 3802Document1 pageMdpe 3802Indrajeet DodlaNo ratings yet

- TDS Pe 001 Uf1810Document2 pagesTDS Pe 001 Uf1810asrilNo ratings yet

- Techgrid PP 3030 VW 1Document1 pageTechgrid PP 3030 VW 1Ashraf KadabaNo ratings yet

- Cardia Biohybrid™ H-M01Document2 pagesCardia Biohybrid™ H-M01Xuân Giang NguyễnNo ratings yet

- HD5301AADocument2 pagesHD5301AAAnonymous K8jq6tYGNo ratings yet

- Tds DGDX 6097 Astm ButeneDocument2 pagesTds DGDX 6097 Astm ButeneLakshay UniplarNo ratings yet

- Marlex - HGX-030-SP Tech SpecDocument1 pageMarlex - HGX-030-SP Tech Specebook ebookNo ratings yet

- Topilene J700N ENDocument1 pageTopilene J700N ENJoni Sie MssNo ratings yet

- Emraan Hashmi CVDocument3 pagesEmraan Hashmi CVMd MinhajNo ratings yet

- Emraan Hashmi CVDocument3 pagesEmraan Hashmi CVMd MinhajNo ratings yet

- Fiber To The HomeDocument35 pagesFiber To The HomeABHISHEKNo ratings yet

- Vietnam Analysis (Telecom Scenario 2014)Document8 pagesVietnam Analysis (Telecom Scenario 2014)Md MinhajNo ratings yet

- arun+synopsis+after+rguhJASs+correction CompressedDocument14 pagesarun+synopsis+after+rguhJASs+correction CompressedMd MinhajNo ratings yet

- Vietnam Analysis (Telecom Scenario 2014)Document8 pagesVietnam Analysis (Telecom Scenario 2014)Md MinhajNo ratings yet

- Saumil TiwariDocument3 pagesSaumil TiwariMd MinhajNo ratings yet

- arun+synopsis+after+rguhJASs+correction CompressedDocument14 pagesarun+synopsis+after+rguhJASs+correction CompressedMd MinhajNo ratings yet

- Quality AssuranceDocument24 pagesQuality AssuranceMd MinhajNo ratings yet

- Tien Phong KryoS Demo PR enDocument3 pagesTien Phong KryoS Demo PR enMd MinhajNo ratings yet

- Passport DocsDocument1 pagePassport DocsMd MinhajNo ratings yet

- Bill of lading declaration for non-Israeli shipmentDocument1 pageBill of lading declaration for non-Israeli shipmentMd MinhajNo ratings yet

- SampleDocument3 pagesSampleMd Minhaj0% (1)

- Cleartrip Flight E-TicketDocument1 pageCleartrip Flight E-TicketMd MinhajNo ratings yet

- GAIL (India) LTD.: High Density Polyethylene For OFC DuctsDocument1 pageGAIL (India) LTD.: High Density Polyethylene For OFC DuctsMd MinhajNo ratings yet

- P54 LLLDocument1 pageP54 LLLMd MinhajNo ratings yet

- Polyolefins For Pipe and FittingsDocument2 pagesPolyolefins For Pipe and FittingsMd Minhaj100% (1)

- Reliance Industries Limited: RELENE F 46003 Blow Moulding / Blown Film GradeDocument1 pageReliance Industries Limited: RELENE F 46003 Blow Moulding / Blown Film GradeMd MinhajNo ratings yet

- Pe 45GP004Document2 pagesPe 45GP004Sumukha RNo ratings yet

- MadDocument18 pagesMadMd MinhajNo ratings yet

- SJJDFBFKSDDocument1 pageSJJDFBFKSDMd MinhajNo ratings yet

- Sale Organisation 3Document88 pagesSale Organisation 3Md MinhajNo ratings yet

- MNZBKDJFFKJDDocument1 pageMNZBKDJFFKJDMd MinhajNo ratings yet

- Career Developmenwtwtt CycleDocument1 pageCareer Developmenwtwtt CycleMd MinhajNo ratings yet

- Big Data: The Future of Progression, Competition, and ProductivityDocument5 pagesBig Data: The Future of Progression, Competition, and ProductivityMd MinhajNo ratings yet

- PE ApplicationsDocument4 pagesPE ApplicationsMd MinhajNo ratings yet

- RPT Format & GuidelinesDocument4 pagesRPT Format & GuidelinesMd MinhajNo ratings yet

- Telecom Power Systems: Renewables, Efficiency & MonitoringDocument23 pagesTelecom Power Systems: Renewables, Efficiency & MonitoringMd MinhajNo ratings yet

- University of Chicago Press Fall 2009 CatalogueFrom EverandUniversity of Chicago Press Fall 2009 CatalogueRating: 5 out of 5 stars5/5 (1)

- University of Chicago Press Fall 2009 Distributed TitlesFrom EverandUniversity of Chicago Press Fall 2009 Distributed TitlesRating: 1 out of 5 stars1/5 (1)