Professional Documents

Culture Documents

Quality Management: TQM, Six Sigma, ISO

Uploaded by

Walid Gahfer0 ratings0% found this document useful (0 votes)

69 views43 pagesThis document discusses various quality management frameworks and standards including Total Quality Management (TQM), Six Sigma, ISO 9000, and the American Society for Quality (ASQ). TQM focuses on complete customer satisfaction through continuous improvement and employee involvement. Introducing TQM requires significant cultural changes in companies. ISO 9000 provides international standards for quality management systems and certification. ASQ promotes quality principles and training.

Original Description:

Original Title

Quality Management TQM

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses various quality management frameworks and standards including Total Quality Management (TQM), Six Sigma, ISO 9000, and the American Society for Quality (ASQ). TQM focuses on complete customer satisfaction through continuous improvement and employee involvement. Introducing TQM requires significant cultural changes in companies. ISO 9000 provides international standards for quality management systems and certification. ASQ promotes quality principles and training.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

69 views43 pagesQuality Management: TQM, Six Sigma, ISO

Uploaded by

Walid GahferThis document discusses various quality management frameworks and standards including Total Quality Management (TQM), Six Sigma, ISO 9000, and the American Society for Quality (ASQ). TQM focuses on complete customer satisfaction through continuous improvement and employee involvement. Introducing TQM requires significant cultural changes in companies. ISO 9000 provides international standards for quality management systems and certification. ASQ promotes quality principles and training.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 43

Quality Management

TQM, Six Sigma, ISO

Quality

• Quality is concerned with quality assurance

and process improvement in manufacturing

and service sectors (including the public

sector).

• the use of sound measurement methods,

statistical analysis and process improvement

techniques to significantly improve quality on

the shop floor and in manufacturing and

service (etc) planning.

Quality management

• Quality management is concerned with

compliance with quality standards,

certification and compliance

Total Quality Management -

TQM

• popular "quality management" concept.

• assuring product or service quality.

• business philosophy - a way of doing business.

• describes ways to managing people and business

processes to ensure complete customer

satisfaction at every stage.

• often associated with the phrase - "doing the

right things right, first time".

Main features of TQM:

• views “quality” entirely from the point of view

of “the customer”.

• All businesses have many types of customer.

• customer can be someone "internal" to the

business (e.g. a production employee working at

the end of the production line is the "customer"

of the employees involved earlier in the

production process).

Customers...

• customer can also be “external to the business”.

• ‘normal’ customers.

• When you fly with an airline you are their customer.

• When Tesco's buys products from food

manufacturers, it is a customer.

• TQM recognises that all businesses require

"processes" that enable customer requirements to be

met.

TQM focus...

• TQM focuses on the ways in which these

processes can be managed - with two key

objectives:

• 1 100% customer satisfaction

• 2 Zero defects

Importance of Customer -

Supplier Relationships - ‘Quality

Chains’

• TQM focuses on importance of relationship between

customers (internal and external) and supplier.

• These are "quality chains” which can be broken at

any point by one person or one piece of equipment not

meeting the requirements of the customer.

• Failure to meet requirements in any part of quality

chain multiplies, and failure in one part of system

creates problems elsewhere, leading to yet more failure

and problems, and so the situation is exacerbated.

Customers

• ability to meet customers’ (external and internal)

requirements is vital.

• To achieve quality throughout organisation, every person in

quality chain needs training to ask following questions about

every customer-supplier chain:

• Customers

• Who are my customers?

• What are their real needs and expectations?

• How can I measure my ability to meet their needs and

expectations?

Questions...

• Do I have the capability to meet their needs and

expectations? (If not, what must I do to improve

this capability?)

• Do I continually meet their needs and

expectations? (If not, what prevents this from

happening when the capability exists?)

• How do I monitor changes in their needs and

expectations?

Suppliers:

• Who are my internal suppliers?

• What are my true needs and expectations?

• How do I communicate my needs and

expectations to my suppliers?

• Do my suppliers have the capability to

measure and meet these needs and

expectations?

• How do I inform them of changes in my

needs and expectations?

Main Principles of TQM

• The main principles underlying TQM are summarised

below:

• Prevention Prevention is better than cure. In the

long run, it is cheaper to stop products defects than

trying to find them

• Zero defects The ultimate aim is no (zero) defects -

or exceptionally low defect levels if a product or service

is complicated

• Getting things right first time Better not to

produce at all than produce something defective

Quality/CI/Involvement

• Quality involves everyone Quality not just concern of

production or operations department - involves everyone,

including marketing, finance and human resources

• Continuous improvement Businesses always looking

for ways to improve processes to help quality

• Employee involvement Those in production and

operations have vital role to play in spotting improvement

opportunities for quality and identifying quality problems

Introducing TQM into a

Business

• TQM not an easy concept to introduce into

businesses - particularly those not traditionally

concerned with understanding customer needs

and business processes.

• In fact - many attempts to introduce TQM fail!

• One of reasons for challenge of introducing

TQM is that it has significant implications for

the whole business.

Involvement, but...

• For example, it requires that management give

employees a say in the production processes that

they are involved in.

• In a culture of continuous improvement, workforce

views are invaluable.

• The problem is - many businesses have barriers to

involvement.

• For example, middle managers may feel that their

authority is being challenged.

Empowerment

• So "empowerment" is a crucial part of TQM.

• The key to success is to identify the management

culture before attempting to install TQM and to

take steps to change to the new required

management style.

• Since culture is not the first thing that managers

think about, this step has often been missed or

ignored with resultant failure of a TQM strategy.

TQM focus...

• TQM also focuses the business on the activities

of the business that are closest to the customer -

e.g. the production department, the employees

facing the customer.

• This can cause resentment amongst departments

that previously considered themselves ‘above’

the shop floor.

ASQ...

• The American Society for Quality (ASQ) is an

association for quality professionals.

• The organization focuses on customer satisfaction,

root cause analysis and continual improvement

• The organization teaches the importance of stable

top management support to drive continual

improvement

• They are pushing Six Sigma and ISO 9000

ASQ...

• ASQ membership steeply rose from 1984 to

1995.

• during the Total Quality Management (TQM)

movement.

• Times have changed, and the TQM movement

probably does not fit anymore,

• but the ideas generated by the quality visionaries

are timeless

ASQ focus...

• ASQ has a manufacturing focus

• It has developed programs to deploy quality in

the healthcare industry with great success.

• Other areas such as engineering, project

management, marketing and customer support

offer opportunities for ASQ

ISO 9000

• ISO 9000 is the international standard for quality

management,

• It is becoming a worldwide standard.

• December 2001: there were more than 510,616

businesses certified in 161 countries.

• The 10 industrialized nations accounted for

nearly 62% of that total

ISO 9000 certification

• Certification/registration takes place when an

independent and competent body certifies that a

product, process, service or system conforms to

specific requirements.

• With ISO 9000, registration and certification are

used interchangeably, and bodies that issue

conformity certificates are referred to as registrars

in the USA, and elsewhere as certification or

registration bodies.

ISO 9000 registration

• Since the registrar is independent of both the

organization seeking certification (the first

party) and its customers (second parties),

• the registration process is known as third-party

assessment,

• and its value is based on the proven competence

of the registrar.

Known brands...

• multinational organizations normally prefer known

brand names such as Bureau Veritas (France), Lloyd's

Register (UK), SGS (Switzerland), T¿ (Germany) or

American National Standards Institute (United States)

• smaller companies may prefer local registrar, able to

provide a more personalized service.

• organizations shopping for a registrar should consider

the following factors:

Factors in choosing a

registrar

• Price. Some registrars base their rates on the

organization size while others may charge a

daily rate.

• Location. Registrar located close to the

organization preferred to a distant registrar.

• Compatibility. Is registrar familiar with nature

of organization's business and comfortable with

its culture?

Prior to Audit

• prior to an on-site audit:

• a review of the company's quality manual to see whether

it meets requirements.

• Organisations need to ensure any issues raised by the

auditor are addressed by either changing procedures or

documents

• Preassessment. Organisation pays for practice audit.

Registrar can be directed to areas that the company

wants covered to address potential weak points.

European and US

documentation

• European documentation procedures tend to be

more elaborate, so organisations spend more, on

average, on ISO 9000 implementation than

American companies.

• Approx 3 times more…?

• For many years, the Japanese evinced little interest

in ISO 9000 registration, preferring the total

quality management (TQM) approach with a focus

on continuous improvement.

Revised ISO 9000

• ISO's revised ISO 9000: 2000 incorporated TQM

principles and is changing the thinking process.

• Intended to be applicable to all organizations,

regardless of type, size or product category.

• Is a move from conformance thinking to performance

thinking.

• Old standard: presence of 20 elements was evaluated;

now it must be determined whether the processes are

effective.

ISO and Deming

• It has been recommended that companies use Dr.

W. Edwards Deming's built-in "plan-do-check-

act" cycle in the procedure

• to establish a plan and then take corrective

measures when quality results such as warranty

costs or defects exceed set objectives.

• Thus, the standard is moving organizations

toward Japanese-style continuous improvement.

Measuring customer

satisfaction

• Another requirement is measuring customer

satisfaction.

• Most US companies developing questionnaires to

assess whether customers are satisfied with

products and services.

• European registrars are wary of paperwork created

by questionnaires, and some prefer instead to

develop a set of indices to measure customer

satisfaction.

Objective evidence

• "I just need objective evidence that customers

have processes for assessing customer

satisfaction, even if it means that they just record

telephone calls made to customers,”

Cwiekowski, Great Western Registrar LLC (Phoenix)

• 90% of registered companies indicated they would

make the transition to ISO 9001: 2000 before the

December 2003 deadline.

Malcolm Baldrige National

Quality Award

• the Baldrige Program has produced a widespread

positive impact on the quality performance of

U.S. companies.

• The quality literature-- for example, J.M. Juran --

feel that the criteria used for judging the Baldrige

competition have become the leading model

defining the concepts of continuous improvement

and total quality management (TQM).

Baldrige criteria

• the Baldrige criteria are widely used by

companies nationwide to conduct self-audits,

and to develop and guide their own TQM

policies,

• whether they enter the competition or not.

• Been nearly two million requests for Baldrige

application forms and criteria.

Successful companies’ tactics

• With a focused, rapid deployment of a Six

Sigma plan, a major (US) financial services

company was able to save $75 million in

productivity benefits, reduce customer

complaints by 29% and increase stock value by

52%.

Leading companies...

• Leading companies establish internal quality

awards to promote the benchmarking function.

• For example, one company honours an

employee annually with its Quality Award.

• Recipients receive a celebration within their

organization.

Top companies

• Top companies divide benchmarking data according to

audience.

• For example, a leading telecom equipment

manufacturer separates benchmarking information into

administrative and technical categories.

• The administrative information is then posted on

internal electronic message boards, whereas the

technical information is more specifically targeted to

key stakeholders.

The quality journey...

• The great leaders of the quality revolution of the

1980s focused on improving the competitiveness

of American organizations and did all they could

to spread the word.

• Many companies start a quality journey by

latching onto a quality trend.

• Such as TQM…

Quality trends, circles, ISO, ...

• Quality trends: part of US business culture.

• But...

• Quality circles, total quality management (TQM),

• ISO, QS, Baldrige and now Six Sigma,

• have all had their day as the quality solution.

• Employees are tired of this year’s solution.

• Quality programs constantly change.

Difficult...

• Difficult to develop quality system that can

show significant results—and without significant

results, management loses support from

employees.

• This is the case with Six Sigma, as with all

previous repackaged quality programs

Quality-improvement

methods and techniques

• There are tried-and-true quality-improvement

methods and techniques

• Companies need to make them a part of the

company’s culture and stay focused on the tasks

that lead to a healthier business, not the

certificate on the wall or the colour of the belt.

Taguchi: the Loss Function.

• Quality is the gap between how good something

is and how good it possibly could be,

• and we should continually focus on narrowing

that gap.

• the state of the quality profession: is there a gap

between what quality professionals are

contributing and what they could be contributing

to their organizations ?

Quality gap...

• focus of quality movement shifted away from the

great quality visionaries.

• in their place is inappropriate level of attention to

things such as ISO

• -- marketing driven, time consuming standard doing

poor job assuring that companies meet a relatively

low quality hurdle.

• Has quality profession evolved from being change

agents to compliance officers?

Any Questions

Taken from:

‘Quality Initiatives Increase Savings’, Quality Magazine:

http://www.qualitymag.com/CDA/ArticleInformation/news/news_item/0,6407,119529,00.html

‘About Quality’, Quality Magazine: http://www.qualitymag.com/FILES/HTML/QTY_about_us/1,6446,,00.html

‘Probing the Limits: Could Deming Have Been Wrong?’ , Quality Magazine :

http://www.qualitymag.com/qty/cda/articleinformation/features/bnp__features__item/0,,102404,00+en-uss_01dbc.html

‘Six Sigma? No Thanks’, Quality Magazine::

http://www.qualitymag.com/qty/cda/articleinformation/features/bnp__features__item/0,,99484,00+en-uss_01dbc.html

‘Probing the Limits: Wake Up ASQ!’, Quality Magazine::

http://www.qualitymag.com/qty/cda/articleinformation/features/bnp__features__item/0,,105764,00+en-uss_01dbc.html

‘ISO 9000 for a Small Planet’,

http://www.qualitymag.com/qty/cda/articleinformation/features/bnp__features__item/0,,98551,00+en-uss_01dbc.html

‘No Respect’, Quality Magazine :

http://www.qualitymag.com/qty/cda/articleinformation/features/bnp__features__item/0,,99000,00+en-uss_01dbc.html

‘Still Passionate for Quality?’, Quality Magazine :

http://www.qualitymag.com/qty/cda/articleinformation/features/bnp__features__item/0,,98570,00+en-uss_01dbc.html

tutur2u: total quality management -tqm http://www.tutor2u.net/business/production/quality_tqm.htm

You might also like

- TOS Module 4 - Total Quality ManagementDocument66 pagesTOS Module 4 - Total Quality ManagementDr. Leela M HNo ratings yet

- Unit 8 - TQMDocument37 pagesUnit 8 - TQMAshutosh SrivastavaNo ratings yet

- Unit 1: TQM-History and EvolutionDocument55 pagesUnit 1: TQM-History and EvolutionNirmal RajNo ratings yet

- Product QualityDocument17 pagesProduct QualityMalkeet SinghNo ratings yet

- Lesson 1 Overview of TQMDocument30 pagesLesson 1 Overview of TQMGlycel GayatinNo ratings yet

- Why TQMDocument58 pagesWhy TQMpazilarsp100% (1)

- Total Quality Management Presentation: Presented To Sir. Sibtay AamirDocument30 pagesTotal Quality Management Presentation: Presented To Sir. Sibtay Aamirgowthamansmba08jayam5091No ratings yet

- BSE TQM Review Material 09oct2021Document37 pagesBSE TQM Review Material 09oct2021Maria MiguelNo ratings yet

- Total Quality Management: Delivered By: Shazarel Bin Shamsudin Shazarel@uthm - Edu.myDocument21 pagesTotal Quality Management: Delivered By: Shazarel Bin Shamsudin Shazarel@uthm - Edu.myAfiq AsyrafNo ratings yet

- Topic 1 TQM ReportsDocument18 pagesTopic 1 TQM ReportsAida GanituenNo ratings yet

- UntitledDocument49 pagesUntitledChristian LagelstorferNo ratings yet

- Total Quality ManagementDocument97 pagesTotal Quality ManagementRodiemerNo ratings yet

- 01 Quality Management Concept - Lecture 01 - 05Document71 pages01 Quality Management Concept - Lecture 01 - 05OcktaNo ratings yet

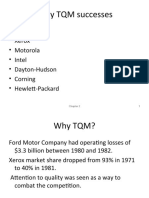

- Early TQM Successes: - Nashua - Xerox - Motorola - Intel - Dayton-Hudson - Corning - Hewlett-PackardDocument31 pagesEarly TQM Successes: - Nashua - Xerox - Motorola - Intel - Dayton-Hudson - Corning - Hewlett-Packardrocks tusharNo ratings yet

- Hbs 201 Quality Management SystemDocument12 pagesHbs 201 Quality Management SystemTawanda MahereNo ratings yet

- TQM Unit-1Document54 pagesTQM Unit-1durgapriyaNo ratings yet

- 9BS 2.4Document7 pages9BS 2.4georgianaNo ratings yet

- TQM in Service SectorDocument21 pagesTQM in Service SectorPushkar MathureNo ratings yet

- A Power Point Presentation On TQMDocument46 pagesA Power Point Presentation On TQMtafere99No ratings yet

- Experiment:-4: Topic:-Total Quality ManagementDocument21 pagesExperiment:-4: Topic:-Total Quality ManagementAniket A. MestryNo ratings yet

- TQM MidtermDocument51 pagesTQM MidtermcutierineeeNo ratings yet

- Dasar TQMDocument27 pagesDasar TQMIzzati WindaNo ratings yet

- A Report On "Introduction To Total Quality Management (TQM) "Document29 pagesA Report On "Introduction To Total Quality Management (TQM) "Madhav ShenoyNo ratings yet

- 5 Quality ManagementDocument33 pages5 Quality ManagementSheryl Lorenzo100% (1)

- Chapter 9Document33 pagesChapter 9Denise BaterinaNo ratings yet

- TQM&EDocument41 pagesTQM&Emelaku solomonNo ratings yet

- Total Quality Management-1Document18 pagesTotal Quality Management-1Karthik KeyanNo ratings yet

- TQM Class 1-5 PeriodsDocument68 pagesTQM Class 1-5 Periodsaditya v s sNo ratings yet

- Definition: Total Quality ManagementDocument30 pagesDefinition: Total Quality ManagementnalinijevalNo ratings yet

- Total Quality ManagementDocument3 pagesTotal Quality ManagementAyush GargNo ratings yet

- TQM With Quality Circle and Quality AssuranceDocument47 pagesTQM With Quality Circle and Quality AssurancePraneela80% (5)

- TQM and Six SigmaDocument38 pagesTQM and Six SigmaNik SyarihanNo ratings yet

- Introduction PrinciplesDocument31 pagesIntroduction PrinciplesrajmehaNo ratings yet

- Operations Manager: - Deliver A Quality Product/service ToDocument23 pagesOperations Manager: - Deliver A Quality Product/service ToakshaynnaikNo ratings yet

- Unit - 1Document55 pagesUnit - 1Puneeth RajNo ratings yet

- TQM ReportDocument22 pagesTQM ReportMarco LacapNo ratings yet

- Total Quality MGTDocument16 pagesTotal Quality MGTduncanNo ratings yet

- 3 TotalQualityManagementDocument59 pages3 TotalQualityManagementPrateek HosamaniNo ratings yet

- Lect#9Document33 pagesLect#9Sadam Mangnejo0% (1)

- TQM Student PPT - MBADocument77 pagesTQM Student PPT - MBASameer Patil100% (7)

- CH 2 Quality ManagementDocument101 pagesCH 2 Quality Managementmoyo josephNo ratings yet

- TQM QA Unit1Document9 pagesTQM QA Unit1akhshayamNo ratings yet

- Operation ManagementDocument129 pagesOperation ManagementVishwanath SN100% (1)

- L2 Total Quality Management PhilosophiesDocument32 pagesL2 Total Quality Management Philosophiesdaniel.lim7725No ratings yet

- Lean Training Presentation PDFDocument160 pagesLean Training Presentation PDFjrobinson81783No ratings yet

- Total Quality Management: Unit - VIDocument16 pagesTotal Quality Management: Unit - VIA SNo ratings yet

- MGT Concepts and Practices Assignment: Department of Management (Mba)Document119 pagesMGT Concepts and Practices Assignment: Department of Management (Mba)mekuNo ratings yet

- Chapter 4Document25 pagesChapter 4SALIM HUSAYN AMBEEYAH ALOUKILINo ratings yet

- Systems & Performance Improvement Methodology PDFDocument32 pagesSystems & Performance Improvement Methodology PDFsalanziNo ratings yet

- TQM Uniabuja Second ClassDocument48 pagesTQM Uniabuja Second ClassOge AdibeliNo ratings yet

- TQM - HeteroDocument114 pagesTQM - HeteroKartik Muppirisetty0% (1)

- 5.3 Lean Production & Quality ManagementDocument33 pages5.3 Lean Production & Quality ManagementMagdalena NeuschitzerNo ratings yet

- Lecture 5 - Service QualityDocument25 pagesLecture 5 - Service QualityAndhykeYuniawatiNo ratings yet

- Strategic Quality ManagementDocument27 pagesStrategic Quality Managementsuresh84123100% (2)

- World Class Manufacturing: Session 2 Quality Systems: ISO 9000-2000, ISO 14000, Frame Work For BusinessDocument8 pagesWorld Class Manufacturing: Session 2 Quality Systems: ISO 9000-2000, ISO 14000, Frame Work For BusinessPrashant KadamNo ratings yet

- Quality Management System and ISODocument15 pagesQuality Management System and ISODana Goan100% (1)

- Project Mission - Is: Sales and DistributionDocument43 pagesProject Mission - Is: Sales and Distributionsudha243191100% (1)

- Reading Workshop: Inferring From Context: Uziel Lobo GrandettDocument8 pagesReading Workshop: Inferring From Context: Uziel Lobo GrandettLeyza Fernanda Zuluaga LopezNo ratings yet

- Histustan Case Study SolDocument7 pagesHistustan Case Study SolYuvi ChauhanNo ratings yet

- Project Plant Pals Operations & Training Plan: February 15thDocument3 pagesProject Plant Pals Operations & Training Plan: February 15thCharlie Goyal83% (6)

- BMC Workshop ExamplesDocument8 pagesBMC Workshop ExamplesBibhu R. TuladharNo ratings yet

- Inventory Management Improvement TechniquesDocument62 pagesInventory Management Improvement TechniquesNadia Fernandes100% (1)

- The Manager of The 21st CenturyDocument35 pagesThe Manager of The 21st CenturySheni Snaptu100% (1)

- Five (5) Basic Methods of Moving Conventional Goods A. TransportationDocument5 pagesFive (5) Basic Methods of Moving Conventional Goods A. TransportationHelen AligsaoNo ratings yet

- Supply Chain Management Case of Cisco Sy PDFDocument14 pagesSupply Chain Management Case of Cisco Sy PDFTortogtoh DarisurenNo ratings yet

- Database Management Systems PS Gill PDFDocument309 pagesDatabase Management Systems PS Gill PDFAyush Malik0% (1)

- History & Evolution of Supply Chain ManagemantDocument41 pagesHistory & Evolution of Supply Chain ManagemantGreeshma100% (7)

- PO Vol1 LegislativeenactmentsDocument182 pagesPO Vol1 LegislativeenactmentsSANATHNo ratings yet

- Implementation in Automotive IndustriesDocument2 pagesImplementation in Automotive IndustriesMuhammad FaisalNo ratings yet

- SOPDocument17 pagesSOPJinal K Shah0% (1)

- Angga Putra Aditya PurchasingDocument7 pagesAngga Putra Aditya PurchasingsatugarisbackofficeNo ratings yet

- Practice of Direct Material ConsumedDocument4 pagesPractice of Direct Material Consumedi200051 Muhammad HassaanNo ratings yet

- Pillar 7 Office TPMDocument9 pagesPillar 7 Office TPMapumu sexbombyaNo ratings yet

- VP Director Global Logistics Operations in Austin TX Resume William Doug DolanDocument3 pagesVP Director Global Logistics Operations in Austin TX Resume William Doug DolanWilliamDougDolanNo ratings yet

- The Order Fulfillment Process ModelDocument13 pagesThe Order Fulfillment Process Modelyuvaraj_che85No ratings yet

- Olm612s - Unit 4 PDFDocument54 pagesOlm612s - Unit 4 PDFAndile NtuliNo ratings yet

- Procurement and Manufacturing: Mcgraw-Hill/IrwinDocument26 pagesProcurement and Manufacturing: Mcgraw-Hill/IrwinSharath ChandraNo ratings yet

- Accounting Information Systems,: 6 Edition James A. HallDocument51 pagesAccounting Information Systems,: 6 Edition James A. HallNeil Carlo Antonio DeytiquezNo ratings yet

- CaseStudy ConAgra Foods Integrated LogDocument1 pageCaseStudy ConAgra Foods Integrated LogDavid BriggsNo ratings yet

- Case QuestionsDocument4 pagesCase QuestionsShilpaNo ratings yet

- A Study On Scope of E-Retailing in India: B. Voc. - Retail and Logistics ManagementDocument73 pagesA Study On Scope of E-Retailing in India: B. Voc. - Retail and Logistics ManagementDHARMENDER YADAVNo ratings yet

- Duran Report Brand CommunicationDocument11 pagesDuran Report Brand CommunicationMorgan RobertNo ratings yet

- Steering Clear of Inventory Potholes: Industry Value Chain StrategiesDocument4 pagesSteering Clear of Inventory Potholes: Industry Value Chain StrategiesVijay HanagandiNo ratings yet

- Oscm Test BankDocument594 pagesOscm Test BankTrang VânNo ratings yet

- Accounting For Raw MaterialsDocument12 pagesAccounting For Raw MaterialsKarl Wilson GonzalesNo ratings yet

- DOH Administrative Order No 2020 0037Document17 pagesDOH Administrative Order No 2020 0037John Philip TiongcoNo ratings yet