Professional Documents

Culture Documents

New Microsoft Word Document

Uploaded by

Divyang BehreOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

New Microsoft Word Document

Uploaded by

Divyang BehreCopyright:

Available Formats

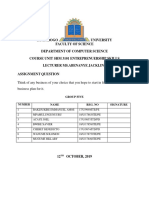

Assignment 1: Select one organisation/ sector.

Identify the organization structure(hierarchy) and come up with the scenario how supply chain management is playing a role in that sector. Assignment 2: How a material manager(QC manager) interact with the other department(eg, finance, IT, marketing etc.) of the organisation.

1 Materials Flow Systems UNIT 2 STRATEGIC ROLE OF MATERIALS MANAGEMENT Objectives At the end of this unit, you should be able to:

Define the key advantages of material management process;

Identify the scope of material management;

Describe the strategic role of material management and its interfaces; and

Discuss the possibility of material management in an organization. Structure 2.1 Introduction

2.2Objectives and Advantages of Materials Management in an Organization 2.2.1Why Integrated Materials Management? 2.2.2Advantages of Materials Management 2.2.3Scope of Materials Management 2.3Roles of Materials Management in an Organization 2.4Functional Role of Materials Management 2.5 Summary 2.6Self Assessment Questions 2.7Reference and Suggested Further Readings 2.1 INTRODUCTION The basic objectives of material management in an organisation are:

To obtain materials at the minimum price, however, this minimum price must not compromise on the quality of goods and the continuity of supply.

To minimise the inventory of an organisation without sacrificing the timely availability of materials. This frees up working capital of an organisation for other useful organisation purposes. Thus, the bottom line of any material management system is the minimisation of material procurement, storage and handling costs, without compromising quality and availability of materials. Material management procedures are strategically placed within an organisation. They have different meanings for different people. Some of the material management procedures may give more weightage to purchasing, while others may attach a lot of importance to inventory control. A good material management process may have a strong backing of quality management and quality assurances

of material purchasing and handling. This combination has a great impact on profitability and productivity as this may reduce the rejection rates of materials, thus, bringing down the overall cost of production in a well managed system. It is sometimes stated that it is the control of quality from the procurement to final distribution of the product that improves productivity and corporate image.A strong logistics system that can create a steady flow or continuum of materials flow into the production pipeline is the need of the hour. It is also claimed that such a continuum can minimise the need for material management. However, the

2Materials Management: An Overview question is how good this continuum is? And how are the quality control processes associated and linked to this continuum in an organization? Thus, the material management is an important strategic issue within an organisation. Let us discuss more about its strategic placement in the subsequent sections. 2.2 OBJECTIVES AND ADVANTAGES OF MATERIALS MANAGEMENT IN AN ORGANIZATION Materials Management has several core objectives and many secondary objectives. The core objectives of material management are:

Proper, cost effective material procurement.

Proper storage of materials so as to minimize wastages and material hold ups.

Making available the material TIMELY. A good material management system will keep up to data records of all the information generated in it, preferably using a computer-based system. In addition to these primary objectives a materials management system indirectlyfulfills many secondary objectives also. These secondary objectives are normallyrelated to the functions of a material management system. Some of these secondary objectives are:

Identifying new or better sources of supply

Development and sustenance of relationships with the vendors

Creating a standardized quality of the products

Performing the value analysis of inventory. This can be related to the cost of materials.

Creating a smooth flow of materials and information among the various sections of materials management system. The material management system works under the broad basic objectives of an organization that is maximum profit with sustained growth and research, satisfiedcustomers and staff of the organization . The material management supports thisobjective by providing support through:

Continuity of supply by maintaining a uniform flow of materials,

Reducing the costs of materials purchased and handling by using scientific techniques and electronic tools. The use of scientific tools and techniques for materials and information management,

Minimizing holdups of working capital and performing effective inventory control,

Releasing working capital by ensuring effective control over inventories,

Providing high quality at the lowest price, and

Development of better relationships with customers and suppliers. 3 Materials Flow Systems 2.2.1Why Integrated Materials Management? Some of the key functions that are undertaken during the process of material management are:

Materials Planning

Materials purchasing

Receiving of Materials

Stores

Inventory Control

Scrap and Surplus disposal A material management system integrates all these functions as a single function. But what is the need of such integration? If we do not integrate the functions as above then they can operate of their own and integration can produce suboptimal results. This is analogous to a situation when you want to make a computer hardware, you buy all the sub-systems thatare cost optimized in there own way, for example the mother board may supportfastest CPU, RAM may have maximum capacity in the same cost etc., but whenyou assemble your PC you find that all these components are not compatible toeachother.Similarly, one expects similar strains among the functions of the material management system, for example, although high procurement may reducecost but is it really justifiable keeping the inventory control function requirementsin considerations. Thus, various functions have conflicting optimizing requirements.A material management system has to bring solution within these conflicting requirements. However, since the material management system is not controlled by a single subsystem, enforcing such requirements may create a problem. Therefore, in an integrated set up, a materials manager can be made responsible for inter-relatedfunction control. S/he may be allowed to control and coordinate with a view thatensures proper balance of the conflicting objectives of the individual functions. 2.2.2Advantages of Materials Management Material management has created a niche in many organizations, which haveimplemented the integrated materials management. These organizations usuallyenjoy the following advantages:

Better accountability on part of materials as well as other departments as no

one can shift blame to others.

As materials management is handled by single authority, it can result in better coordination, as it becomes the central point for any material related problems.

Materials management department makes sure that better quality material is supplied timely to the requesting departments. This can result in better performance of the organization.

A materials management system is typically controlled through an information system, thus, can help in taking decisions related to material in the organization.

One indirect advantage of material management is that good quality materialdevelops the ethical and moral standard in an organization. However, pleasenote there is no study on this issue.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Vocabulary Words in Araling Panlipunan Grade 7Document3 pagesVocabulary Words in Araling Panlipunan Grade 7Sonia50% (2)

- ISO 14001 2015 Checklist 13 August 2018Document1 pageISO 14001 2015 Checklist 13 August 2018Belajar K3LNo ratings yet

- CV2Document6 pagesCV2teclarteeNo ratings yet

- The Ultimate Meeting Guide - How To Run A Meeting Like A ProDocument21 pagesThe Ultimate Meeting Guide - How To Run A Meeting Like A ProAca ChchNo ratings yet

- New Iphone, Old AbusesDocument10 pagesNew Iphone, Old AbusesYi Yi Debby100% (2)

- Mago V SunDocument8 pagesMago V SunMatthew Evan EstevesNo ratings yet

- Comparison of Mission Statements Mission Accomplished Bicon Shanta BiotechDocument32 pagesComparison of Mission Statements Mission Accomplished Bicon Shanta BiotechRachael SookramNo ratings yet

- Observation Commercial Banks PDFDocument52 pagesObservation Commercial Banks PDFyash_dalal123No ratings yet

- Legendary MarketerDocument5 pagesLegendary MarketerSonia FodorNo ratings yet

- Chapter 19 Cost Behavior and CVP AnalysisDocument2 pagesChapter 19 Cost Behavior and CVP AnalysisJohn Carlos DoringoNo ratings yet

- Kyambogo University Business Plan for Buildmax Hardware CenterDocument51 pagesKyambogo University Business Plan for Buildmax Hardware CenterEmma AmosNo ratings yet

- Organic Line For REVLON (Marketing Plan)Document15 pagesOrganic Line For REVLON (Marketing Plan)Beenish Fateh100% (3)

- IPE Prospectus 2014-16: PGDM, PGDM-RM, PGDM-BIF, PGDM-IB, PGDM-HRM & Exe PGDM ProgramsDocument28 pagesIPE Prospectus 2014-16: PGDM, PGDM-RM, PGDM-BIF, PGDM-IB, PGDM-HRM & Exe PGDM ProgramsyashNo ratings yet

- Form - 03 17 July 2019Document2 pagesForm - 03 17 July 2019muhammad ihtishamNo ratings yet

- Merchandising Operations IncomeDocument46 pagesMerchandising Operations IncomeSina RahimiNo ratings yet

- Life-Cycle Cost Analysis in Pavement DesignDocument1 pageLife-Cycle Cost Analysis in Pavement DesignSergio McNo ratings yet

- High Performance OrganizationsDocument25 pagesHigh Performance OrganizationsRamakrishnanNo ratings yet

- Business Organization and Management - IntroductionDocument17 pagesBusiness Organization and Management - Introductiondynamo vj75% (4)

- Basic Banking Tools and VocabularyDocument1 pageBasic Banking Tools and Vocabularyperrine11No ratings yet

- Digital Marketing PresentationDocument16 pagesDigital Marketing PresentationAreeb NarkarNo ratings yet

- Bralirwa Report 2011 High ResolutionDocument88 pagesBralirwa Report 2011 High ResolutionbseawellNo ratings yet

- CaseDocument2 pagesCaseAman Dheer KapoorNo ratings yet

- Credit Risk Management of Pubali Bank LimitedDocument11 pagesCredit Risk Management of Pubali Bank Limitedsweet-smileNo ratings yet

- Customs Unions and Free Trade AreasDocument6 pagesCustoms Unions and Free Trade AreasÖzer AksoyNo ratings yet

- Marketing Defined Explained Applied 2nd Edition Levens Test BankDocument22 pagesMarketing Defined Explained Applied 2nd Edition Levens Test Bankrubyhinesqhw0qb100% (26)

- Registered Nurse Annual Performance ReviewDocument7 pagesRegistered Nurse Annual Performance Reviewhkthriller1No ratings yet

- Assign 2 Management AccountingDocument10 pagesAssign 2 Management AccountingRamin Mostamer ZiaNo ratings yet

- OutsourcingDocument24 pagesOutsourcingihabkarinaNo ratings yet

- 2 Market ProblemDocument30 pages2 Market ProblemAnalizaViloriaNo ratings yet

- Cips November 2014 Examination TimetableDocument1 pageCips November 2014 Examination TimetableajayikayodeNo ratings yet