Professional Documents

Culture Documents

6 PO 32 Said

Uploaded by

Araby Gamal GamalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6 PO 32 Said

Uploaded by

Araby Gamal GamalCopyright:

Available Formats

Poster PO-32

LNG IMPORT TERMINALS: OFFSHORE VS ONSHORE A SITE AND CONCEPT SCREENING METHODOLOGY TERMINAUX D'IMPORTATION DE GNL: OFFSHORE OU BIEN A TERRE UNE METHODOLOGIE POUR LA SELECTION DU CONCEPT

Mike Said Joram Meijerink Shell Global Solutions International B.V.

ABSTRACT Shell Global Solutions has developed a concept screening methodology that uses a combination of commercial, permitting and technical criteria to assist business developers to decide on the most suitable offshore LNG terminal concept for a specific market. As LNG terminals are generally sited relatively close to densely populated areas permitting in these locations often proves difficult, moving developers to consider offshore solutions. These offshore alternatives include: Floating Storage Regas Units (FSRU) Offshore Gravity Based Structures (GBS) Converted LNG Carrier (submerged or external turret) Platform Based Import Terminals Whilst none of these alternatives have yet been built, they rely largely on proven technologies. Their technical novelty lies more in the way their various components are integrated into a single working system. As each system possesses different strengths and weakness, the real challenge is to determine which solution is best suited to a particular location The matching of these solutions to the complexity of the gas market requirements such as gas demand profile, send out pressure/temperature and interruptability of gas supply, when combined with local technical site factors such as metocean conditions and issues surrounding permitting procedures and stakeholder engagement, ensures this selection of the correct import terminal solution is a significant challenge. This concept-screening methodology provides a structured mechanism for combining commercial market, local site and permitting conditions to logically rank the various alternatives against their respective costs. This approach has already proven invaluable to ensure selection of the right terminal concept in an early project development phase, avoiding regret time and expenditure by focusing quickly on the right concept taking all essential multi discipline parameters into account. In addition it allows stakeholders a transparent and quantified insight into the decision making process, a vital step in todays complex permitting climate.

PO-32.1

SESSIONS CONTENTS

Poster PO-32

This paper will introduce the various offshore LNG import concepts, describe the screening methodology required and the decision making process involved to facilitate selection of these concepts. RESUME Shell Global Solutions a mis au point une nouvelle mthodologie de slection qui combine des critres commerciaux, techniques et relatifs l'obtention des permis, afin d'assister les promoteurs de projets dans leur choix du concept de terminal de GNL off shore le mieux adapt un march spcifique. Comme les terminaux GNL sont gnralement implants proximit relative de zones haute densit de population, l'obtention des permis s'avre souvent difficile, ce qui pousse les promoteurs envisager des solutions off shore. Ces alternatives off shore comprennent: les units de regazification et de stockage flottantes (Floating Storage Regas Units - FSRU) les structures poids off shore (Offshore Gravity Based Structures - GBS) les navires-citernes de GNL convertis (tourelle immerge ou en surface ou amarrage point unique) les terminaux d'importation sur plate-forme Bien qu'aucune de ces alternatives n'aient dj t construites, elles font largement appel a des technologies qui ont fait leur preuve. Leur originalit technique rside davantage dans la faon dont leurs divers composants sont intgrs dans un systme oprationnel unique. Comme chacun des systmes possde ses propres points forts et points fables, le vritable dfi consiste dterminer quelle est la solution la mieux adapt au site considr. L'adaptation de ces solutions la complexit des exigences du march du gaz, comme le profil de la demande en gaz, la pression/temprature de distribution et la possibilit d'interrompre la distribution de gaz, ainsi que les facteurs locaux et techniques lis au site, comme les conditions ocano-mtorologiques et les problmes relatifs aux procdures d'obtention des permis et l'engagement des parties prenantes, font que le choix de la solution adquate pour le terminal d'importation reprsente un srieux dfi. Cette mthodologie de slection de concept procure un dispositif structur permettant de combiner march commercial, site local et conditions d'obtention des permis afin de classifier logiquement les diverses alternatives en fonction de leurs cots respectifs. Cette approche s'est dj avre un outil inestimable pour assurer la slection du concept de terminal appropri au cours de la phase prliminaire de dveloppement de projet, vitant des pertes de temps et des dpenses en convergeant rapidement sur le concept adquat aprs avoir pris en compte tous les paramtres pluridisciplinaires essentiels. En outre, elle donne aux parties prenantes une vision transparente et quantifie du processus dcisionnel, un atout indispensable dans le contexte actuel complexe de l'obtention des permis.

PO-32.2

SESSIONS CONTENTS

Poster PO-32

Cet article prsente les diffrents concepts d'importation de GNL off shore et dcrit la mthodologie de slection requise et le processus dcisionnel entrant en jeu pour faciliter la slection de ces concepts, tout en soulignant certains des dfis techniques fondamentaux qui restent surmonter pour la russite de l'introduction sur le march de ces alternatives off shore. INTRODUCTION Natural gas is rapidly being adopted as the fuel of choice for the 21st Century. Readily transported in the form of LNG, market demand for this product across the world is growing fast. Demand for LNG, is typically located near major population centres leading to a growing tension between the desire for its beneficial qualities (clean, relatively inexpensive and easily distributed) and a persistent public perception of LNG as a dangerous product. The public at large generally wish to enjoy the benefits of this product but without exposure to its perceived hazards - The so-called NIMBY attitude The key drivers influencing the successfully implementation of any LNG import terminal are numerous, complex and varied whilst at the same time, advances in technology are offering a wider choice of options for the method of importation using both onshore and offshore technology. Regardless of which of these options is finally selected all are capital intensive and time consuming, and as the picture becomes increasingly complex, business developers are looking for ways to bring some structure to the decision making process, thereby increasing the chances that they will back the right concept from day one. Shell Global Solutions International (SGSI) with the assistance of Shell Transport and Shipping Co (STASCO) have developed such a tailor made process, details of which are presented in this paper. CHOICE OF LNG IMPORT TECHNOLOGIES The last 2-3 years has seen a rapid expansion in the range of alternative methods for importing LNG. The conventional onshore method using either sheltered or exposed berth terminals has been joined by credible offshore options developed from successful applications in the oil and gas industry. These offshore LNG alternatives include; Floating Storage Regas Units (FSRU) Converted LNG Carriers (submerged or external turret type mooring). Offshore Gravity Based Structures (GBS) Platform Based Import Terminals

Whilst to date, none of these offshore alternatives have been built, most are under serious consideration by the leading LNG industry players in a variety of locations around the world, with several in advanced stages of design and permit application. As each alternative offers a unique blend of strengths and weakness it is no longer obvious which of these offshore solutions offers the most compelling case for development. Brief descriptions of the offshore alternatives are given below on the assumption the reader is familiar with the details of conventional and exposed berth import terminals.

PO-32.3

SESSIONS CONTENTS

Poster PO-32

OFFSHORE TERMINAL CONCEPTS Floating, Storage and Regasification Concept A Floating Storage and Regasification Unit (FSRU) LNG import terminal concept comprises of a purpose built permanently moored FSRU with several LNG carriers shuttling between the export facility and the import site. The FSRU barge is typically between 350 to 400 metres long by up to 70 metres wide and normally does not have a propulsion system. (It will be towed from the shipyard and installed at its operational site.) Figure 1 - Artist Illustration of FSRU The FSRU consists of a double-hulled barge designed using normal shipbuilding designs and standards and can be constructed in a wide range of conventional ship yards worldwide (although typically these are based in Far East). The LNG storage system is based on standard designs for ship cargo containment systems; using spherical tanks, membrane or prismatic freestanding tanks. (Storage capacity can range from around 200,000 m3 to in excess of 500,000 m3 as required) The regasification facilities are located on the main deck of the barge and are typically tailored to suit the specified gas send-out conditions. Power generation for barge services are normally provided by gas turbines with dual fuel diesel engines as back up (sized according to the requirements of the regas equipment). Accommodation is generally located at the stern (unlike in the artists impression shown above) so as to provide the maximum distance between the turret and accommodation unit). A key advantage of the FSRU concept is that it can be moored in a wide range of water depths. In shallow waters (approximately 20 to 30 metres), a jacket based, soft yoke system can be used, in greater water depths a catenary based, turret mooring system can be employed. Both of these systems are weather-vaning, allowing the FSRU barges heading to rotate according to the vector of the local environmental forces. LNG offloading is typically achieved using a modified version of conventional hard arm LNG loading arms. In this so called side by side configuration the LNG carrier is moored alongside the FSRU with both vessels weather vaning around the FSRUs turret mooring. This system is limited to a relatively benign range of environmental conditions governed principally by the combined relative motion of the two vessels and the operational limit of the tugs used to assist berthing operations. In the event the FSRU is required to be located in harsher metocean conditions then use of an alternative offloading technology called Stern to Bow or Tandem configuration can be made. Whilst this tandem technology is still considered developmental several leading industry equipment suppliers are actively progressing it.

PO-32.4

SESSIONS CONTENTS

Poster PO-32

Converted LNG Carrier Concept As an alternative to the Floating Storage Regas Unit (FSRU) it is possible for a virtual LNG terminal to be created using the LNG carriers themselves. This so called Energy Bridge or Converted LNG carrier scheme as initially proposed by El Paso makes use of the LNG carriers as storage vessels, directly regassifying the LNG using additional bow/deck mounted regas equipment. This scheme has several attractive qualities, most appealing of which is the high operability offered by the internal turret mooring system. Using a submerged turret system it is possible for the LNG carrier to approach and safely connect to a sub sea buoy in up to Hs 5.5 m waves. Once connected the mooring system can safely withstand even North Sea storm conditions (The APL STL system has been successfully deployed in the Offshore Oil and Gas sector in the North Sea region for many years)

Source: APL Website

Figure 2 - Illustration of APL Submerged Turret Loading System After connection, the carrier can send out gas via a conventional gas swivel down a flexible gas riser to a pre installed PLEM and subsea gas export line. Using the currently envisaged regas equipment, it will typically take up to 6 days to regas the standard cargo parcel of 140,000 m3 of LNG. It is also possible to create a hybrid version of an FSRU by equipping an existing carrier with a weather-vaning external mooring turret, bow mounted process deck, upgraded power and utility systems and midship mounted LNG loading arms. A carrier converted in such a manner can be used in a very similar fashion to the conventional FSRU described above albeit with a reduced buffer capacity. Offshore Gravity Based Structures (GBS) A GBS LNG import facility is based around either a concrete or steel rectangular caisson (or several caissons) located on the seabed and is totally self-supportive with respect to its operation, utilities and power generation. A GBS integrates the basic functions of an LNG import terminal in one single structure:

PO-32.5

SESSIONS CONTENTS

Poster PO-32

It provides a berth and unloading facilities for the LNG shuttle carriers It contains the space for LNG storage It houses the regasification, utility and sendout equipment on its deck

Additionally, the GBS provides protection of the LNG carrier against excessive waves and current during the offloading and berthing operations.

Source: Shell G&P Website

Figure 3 - Typical LNG import Gravity Base Structure (GBS) The GBS typically requires a location in modest water-depths, since the larger the water depth, the higher the structure needs to be and the higher the costs. The minimum required water depth for a GBS is typically 14 - 15 meters, governed by the depth required for an LNG carrier to be able to approach and berth to the terminal. Typical overall dimensions of a GBS with 250,000 m3 LNG storage capacity, located in 15 meters of water, are approximately 340m long by 60m wide by 40m high. Located on top of the GBS deck, along with all the regasification equipment and utilities, will also be the accommodation, flare and a heli-deck, in line with governing safety requirements for offshore structures. Direct Regas Concept A further alternative option for importing LNG exists in the form of direct regas facilities. This option also makes use of the LNG carriers as storage vessels but this time instead of placing limited regas facilities onboard each carrier as is the case with the converted carrier scheme, here one large regas plant is located on an offshore platform. The carriers will still be required to remain in berth for a longer period than the normal 24 hour offloading period (hence incurring additional demurrage costs) but if the regas capacity can be made high enough this additional duration can be limited to around 12 hours.

PO-32.6

SESSIONS CONTENTS

Poster PO-32

However, in order for this scheme to work the gas grid has to be able to absorb large amounts of gas in a short period, in addition to the market allowing for an interrupted supply of gas. Alternatively, some sort of gas storage system must be provided.

Accommodation

Pressure and regas facilities

Utilities

Offloading platform

50m

Mooring dolphin

LNG carrier

Figure 4 - Indicative configuration for direct regas facility using offshore platforms Direct regas as a concept is by no means applicable everywhere as it requires some very specific local characteristics to be in place but this in itself serves to emphasise the point that when considering these alternatives careful assessment of all existing local conditions is vital to match the optimum solution to each location. EXPLORING THE OPTIONS Range of Potential Locations When considering importing LNG into a specific market, a wide range of possible locations can present themselves. These options could include either land-based terminals using breakwaters for protection or, depending on the local metocean conditions, perhaps an exposed berth jetty. Alternatively they could be located in shallow water, using a GBS, although this depth restriction usually means the GBS is located closer to the land and hence more visible from the beach. By way of contrast they can often be located using floating technology further offshore, which although usually in deeper water and requiring longer subsea pipelines at extra cost, will be significantly less visible. Clearly each of these possible sites and concepts present a different blend of characteristics that will influence to a greater or lesser degree the overall likely success of the project. Each alternative also has an associated cost and schedule for completion. Defining The Boundary Conditions In order to ensure this range of sites are compared fairly however, it is important to first set some boundary conditions. This is a set of parameters that represent the required functionality as defined by the business that all the concepts should be able to meet, irrespective of the technical solution selected, these would typically include:

PO-32.7

SESSIONS CONTENTS

Poster PO-32

LNG storage volume Gas delivery profile Gas send out rate Gas send out pressure and temperature Interruptability of gas supply

Date of first gas Size of LNG delivery carrier Location of LNG supply point.

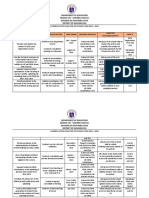

In addition to these boundary conditions the following base line data is required in order to build up an initial picture of the range of possible sites and concepts; Metocean data including; o Wind statistics/Wave statistics/Water temperature, salinity data/Tide and current data/Fog statistics/Ice statistics/Precipitation data/Air Quality data. Admiralty Charts showing bathymetry, shipping lanes, buoys and obstructions, etc Site Soil and Sediment data Seismic data Technical Data on LNG Delivery Carriers Shipping Density Statistics Relevant Exclusion Zones Existing Relevant Infrastructure (Existing pipelines, platforms, harbours, etc) A desktop analysis of all of this data should allow a long list of potential sites and concepts to be drawn up by a team of experts for presentation to the main study team at a kick off workshop of the site and concept selection process. KEY DECISION MAKING CRITERIA In order to make sense of each sites competing characteristics, SGSI have introduced the concept of Technical and Permitting Confidence factors. These factors express a relative measure of the likelihood of each concept successfully being technically realised and being granted permit approval within target time frame as specified in the functional requirements. Table 1 Example Technical and Permitting Decision Making Criteria

Criteria T01 T02 T03 T04 T05 T06 T07 T08 T09 T10 T11 T12 T13 T14 T15 T16 T17a T18 T19 Type

Technical

Criteria Type P01 P02 P03 P04 P05 P06 P07 P08 P09 P10 P11 P12 P13 P14 P15 P16 P17 P18 P19 P20 P21 P22

Permitting

MetOcean and Operability Shipping access Turn around times Construction Codes Construction Schedule Constructability Safety and Security of Operation Use of Proven Technology Expandibility of Design Required Site Preparations Method of Power Generation Method of Regas Proximity to Navigational/ Marine areas Water temperature (inside vs outside LIS) Water quality Soil Conditions Pipeline Route Feasibiltiy Pipeline Performance Non interuptibility of Gas Supply

Pipeline connections (RoW) Shipping Operations Impact Conflicts with Shipping activities Local Content Perception of safety (to Population) Abandonment Technical Maturity Proximity to people Compatible landuse Visual Impact Noise Impacts Air Emissions Water emissions Schedule (EIS duration) Ecology/Dredging/Footprint Marine Ecology Area occupation Sediment Quality CZMA (NY vs CT) State vs Federal waters (USGC vs FERC) Site Control Fiscal boundaries

PO-32.8

SESSIONS CONTENTS

Poster PO-32

Each of these confidence factors is built up from a series of decision-making criteria. Table 1 lists some typical criteria that might be considered. It should be made clear that only criteria that differentiate between sites, should be considered as the overall objective of the analysis is to determine which combination of site and concept is considered more favourable than its neighbour. The Technical Confidence factors focus on those aspects of the concept that are inherent to a concepts technical feasibility. For example choice of vaporiser equipment or required level of site preparation. Both these aspects will be quite different for say an FSRU compared to a land based conventional terminal and can therefore be used to differentiate between the sites. The Permitting Confidence factors are those aspects of each site and concept which relate to its likelihood of being successfully granted permit approval. Factors such as the proximity of the facility to population centres or the level of noise emissions can have a significant impact of the likelihood of a particular site being grant permit approval over another. SGSI DECISION MAKING PROCESS The exercise to compare and contrast all of these various competing criteria is clearly not trivial and typically requires expertise from across a range of disciplines to ensure a convincing final assessment. SGSI has found the most efficient way forward is to adopt an integrated approach, building discipline-focused study teams e.g.; Technical Team (Expertise in Import Terminals, Process, Safety, Shipping, Costing, etc) Pipeline Team (Expertise in subsea pipelines, booster stations, pipeline shorecrossings, pressures temperatures, etc) Environmental Team (Expertise in environmental impact assessments) Stakeholder Team (Expertise in stakeholder management) Legal Team Marketing Team Management Team It is strongly recommended that the leaders of these teams are involved in the entire decision making process to ensure a high level of buy in to the final outcome.

PO-32.9

SESSIONS CONTENTS

Poster PO-32

Site and Concept Screening Methodology The SGSI site and concept selection process uses the following 5-stage program aimed at ensuring the right people, armed with the necessary information reach a common decision in an open and transparent fashion. Kick-off Work Shop Scouting Trip Data Gathering Final Site Evaluation Workshop Workshop Results

Shell Global Solutions

Site and Concept Selection Methodology

Integrated Team Approach

Technical Pipeline Legal HSE Marketing Stakeholder

Kick-Off Workshop Scouting Trip Data Gathering

4m on th

s ty pic a

Final Workshop

l

Workshop Results

Figure 5 - Site & Concept Selection Process The process offers a further key benefit that it captures all considered alternatives and documents the reasons for their rejection. This information will play an important role during subsequent stakeholder engagement by offering clear justification and track record on how the proposed solution was reached. Kick-off Site and Concept Selection Workshop As the first step in the process, the kick off workshop performs the following roles; Presents the alternative import Import Terminal Concepts terminal concepts Offshore Gravity Based Structure (GBS) Sets the study boundary conditions Floating Storage Regas Unit (FSRU) Introduces the decision-making process Converted LNG Carrier (Energy Bridge) Identifies the key decision making Platform Based Import Terminals criteria Conventional LNG Import Terminals Identifies missing information and Exposed Berth LNG Terminals assigns responsibility for collection Agrees the terminal Site Long List The main purpose of this kick off workshop is to bring all the participants to a similar level of awareness of the alternatives available, to create the study teams as identified above and introduce the long list of potential sites and concepts for further study. This can usually be accomplished in a one-day workshop. Scouting Trip Stage 2 of the process requires the study teams to gain an accurate insight into the local conditions in the area of interest. This dedicated scouting trip forms a vital part of the overall data gathering process as there is no substitute for first hand knowledge. In order to maximise the effectiveness of the final assessment workshop it is advised that only persons involved in the entire process should attend the scouting trip. The scouting trip has the following key objectives;

PO-32.10

SESSIONS CONTENTS

Poster PO-32

Allow the study team to experience first hand the local conditions. Gain appreciation of local stakeholder issues. Reduce long list of possible sites by inspection to a short list of the most promising sites Document reasons for long list site rejections.

After the scouting trip, once the short list has been established, the base case solutions for each alternative can be defined to ensure all teams have a clear understanding of the key features of each alternative and to form a sound and clear basis for the cost and schedule estimates. Data Gathering Phase This part of the overall process is where the ultimate success of the final workshops conclusions is determined. Effort expended in this phase of the study pays big dividends in the final selection workshop. During the kick off workshop, each of the study teams were charged with obtaining the necessary location specific information relevant to ensuring an informed ranking of each of the sites can be made in the final workshop. This phase is split into the following two parts; Gathering data and performing cost and schedule estimates for each alternative Preparation of Criteria Scorecards

It is important to note that information should be gathered on only those criteria that really differentiate between the sites. If necessary a rationalisation of the criteria should be performed as some may have become redundant following the reduction of the sites to the short list. Cost estimates for each short listed site and concept are prepared in advance of the final workshop. Table 2 Example Criterion Scorecard To help maximize the effectiveness of the final workshop, each of the teams are asked to create scorecards for each of the defined criteria using the paired comparison table as illustrated in Table 2.

Criterion Scorecard T06: Constructability

Water Depths Site 1 (GBS) Factor 1 About the same 2 Prefer 3 Strongly Prefer Site 10a (FSRU) H Description Score Points h3 a: 11 18% h3 b: 0 0% h3 c: 10 17% h3 d: 4 7% h3 e: 9 15% h3 f: 3 5% h3 g: 2 3% h: 21 35% H Total 60 100% Site 6a (GBS) Site 4a ( DW GBS

Site 5 (GBS)

Site 7 (GBS)

Site 8 (GBS) F a2 f2 c2 d1 e2 F

Sites

Site 1 (GBS) Site 4a ( DW GBS) Site 5 (GBS) Site 6a (GBS) Site 7 (GBS) Site 8 (GBS) Onshore Site 10a (FSRU)

Once the table is complete, all the points for each site are counted, e.g. for Site 7 (GBS) the scores are (e3+e2+e2+e2+e2 = score 9). This score is then expressed as a percentage of the total so that a maximum of 100 points can be received on every criterion.

15 30 17 20 15 20 na 25

B C A a3 a1 B c3 C

D a2 d2 c2 D

E a1 e3 c1 e2 E

G a2 g2 c2 d1 e2 f1 G

This percentage is then used directly as the sites point score for each criterion in the main evaluation spreadsheet. These processes are fairly laborious and so are recommended to be performed in advance and presented by each team leader during the final workshop providing an opportunity for the rest of the team to contribute/challenge and agree these scores.

PO-32.11

SESSIONS CONTENTS

Onshore

Poster PO-32

Final Site and Concept Evaluation Workshop The final site & concept evaluation workshop allows the key decision makers to come together to view all the gather data in a structured and logical process leading to collective buy-in into a robust conclusion. However before the final rankings can be assessed the individual decision making criteria need to be weighted.

Initial Criteria Weighting Factors

So far the site and concept selection process has treated all the differentiating criteria as the same. Such an approach is not valid as certain criteria can be clearly defined as more important than others and hence should be weighted accordingly. Consensus for the magnitude of each weighting factor for each criterion can be established in open session by mapping the criteria on the weighting factor matrix as shown in the example figure 4.6 below. The weighting factor for each criterion is based on the following three considerations: First and foremost, the perceived importance of the considered criterion versus the other criteria. This is the most obvious consideration for determining weighting criteria.

Criteria Prioritisation

P21 Site control - LT

Weighting 2.5 1.5

Weighting 1.0 0.5

Impact/ Consequence

P15 Dredging/ jetty impacts - ET P16 Marine ecology - ET P17 Area footprint/ excl. zone - ET T16 Soil/ sediment conditions - ET

P05 Safety & security - ST P10 Visual impact - ET P19 CZMA - LT T07 Safety and security - TT

P04 Local content - ST P08 Proximity to population - ET P09 Compatible landuse - ET P12 Air emissions - ET T06 Constructability - TT T18 Pipeline performance - PT P06 Abandonment - ST P07 Technology maturity T01 Operability - TT T04 Construction codes - TT T08 Use of Proven technology - TT T09 Expandability of design - TT T15 Water quality - ET

P01 Pipeline connections - PT P02 Shipping Impact - ST P03 Conflicts with fishing - ST P11 Noise impact - ET T17a Pipeline route feasibility - PT P18 Sediment quality - ET

Likelihood of occurrence

Figure 6 - Example of weighting factor matrix

Secondly, the quality of the data that has been obtained. Thirdly, the proven differentiation between sites/ concepts on the considered criterion, based on the obtained data. E.G. if after investigation it turns out that all sites/ concepts score equal on this criterion, the criterion can either be dropped or the weighting factor scored relatively low. WORKSHOP RESULTS The separate scorecards for both the technical and permitting criteria can now be combined with the criteria weighting factors using a spreadsheet based evaluation tool developed by SGSI to build up a picture of the relative rankings between the various sites and concepts.

PO-32.12

SESSIONS CONTENTS

Poster PO-32

This evaluation tool ranks each site according to its cumulative Technical Confidence Factor, Permitting Confidence factor and its relative cost. Examples of typical results are displayed in the following graphs;

Permitting Vs Technical

1.00

140%

Permitting Confidence Factor Vs Cost

0.90

120%

Technical Confidence Factor

0.80

0.70

0.60

GBS 1 - 15 m GBS 4a - 30 m GBS 5 - 17 m GBS 6a - 20 m GBS 7 - 15 m GBS 8 - 20 m Onshore FSRU 10a FSRU 4a

100%

80%

60%

40%

GBS 1 GBS 4a GBS 5 GBS 6a GBS 7 GBS 8 Onshore FSRU 10a FSRU 4a

0.50

20%

0.40

0% 0.00

0.30 0.00

Cost ($ mill)

0.10

0.20

0.30

0.40

0.50

0.60

0.70

0.80

0.90

1.00

0.10

0.20

0.30

0.40

0.50

0.60

0.70

0.80

0.90

1.00

Permitting Confidence Factor

Permitting Confidence Factor

Figure 7 Example Plots of Technical and Permitting Factors Against Cost Using these graphs, clear trends regarding the relative ranking between the various sites can be determined. By factoring in the dollar cost of each option the price for increased technical or permitting confidence can begin to be appreciated. The final graph presents all this information on one graph with the preferred solution being that option that can place all three measures into the target preferred area. In the example shown, an FSRU located at site 4a would appear to offer the best overall compromise between technical feasibility, likelihood of successful permitting and overall project development cost.

Technical Confidence Factor Vs Cost

140% 1.00 Preferred area 0.90 120% 0.80 0.70 GBS 1 GBS 4a GBS 5 GBS 6a GBS 7 GBS 8 Onshore FSRU 10a FSRU 4a 105% Confidence factor 0.60 0.50 0.40 115% 0.30 0.20 120% 20% 0.10 0.00

G BS FS R U FS R U G BS

Ranking sites

95%

100%

100%

Cost ($ mill)

110%

60%

40%

125%

Sh or eh am G BS G BS G BS G BS 10 a 4a 6a 4a 1 5 7 8

0% 0.30

0.40

0.50

0.60

0.70

0.80

0.90

1.00

Technical Confidence Factor

Sites

Figure 8 Example of Final Site and Concept Selection Summary Graphs Using this screening process in combination with their unique expert knowledge and experience, Shell Global Solutions and STASCO have assisted several clients through this complex process, helping to avoid unnecessary regret time and expenditure by identifying early in the design process the most effective import terminal site and concept for any given location in a transparent and convincing fashion.

PO-32.13

SESSIONS CONTENTS

Cost

80%

Permitting Technical Cost

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Module 5 Data Collection Presentation and AnalysisDocument63 pagesModule 5 Data Collection Presentation and AnalysisAngel Vera CastardoNo ratings yet

- Engineering Management (Final Exam)Document2 pagesEngineering Management (Final Exam)Efryl Ann de GuzmanNo ratings yet

- Epidemiologi DialipidemiaDocument5 pagesEpidemiologi DialipidemianurfitrizuhurhurNo ratings yet

- Fake PDFDocument2 pagesFake PDFJessicaNo ratings yet

- ICSI-Admit-Card (1) - 230531 - 163936Document17 pagesICSI-Admit-Card (1) - 230531 - 163936SanjayNo ratings yet

- Job Description For QAQC EngineerDocument2 pagesJob Description For QAQC EngineerSafriza ZaidiNo ratings yet

- Lab Session 7: Load Flow Analysis Ofa Power System Using Gauss Seidel Method in MatlabDocument7 pagesLab Session 7: Load Flow Analysis Ofa Power System Using Gauss Seidel Method in MatlabHayat AnsariNo ratings yet

- Action Plan Lis 2021-2022Document3 pagesAction Plan Lis 2021-2022Vervie BingalogNo ratings yet

- Zelio Control RM35UA13MWDocument3 pagesZelio Control RM35UA13MWSerban NicolaeNo ratings yet

- Building New Boxes WorkbookDocument8 pagesBuilding New Boxes Workbookakhileshkm786No ratings yet

- Channel Tables1Document17 pagesChannel Tables1erajayagrawalNo ratings yet

- 1.1. Evolution of Cloud ComputingDocument31 pages1.1. Evolution of Cloud Computing19epci022 Prem Kumaar RNo ratings yet

- Agricultural Economics 1916Document932 pagesAgricultural Economics 1916OceanNo ratings yet

- Engine Diesel PerfomanceDocument32 pagesEngine Diesel PerfomancerizalNo ratings yet

- General Financial RulesDocument9 pagesGeneral Financial RulesmskNo ratings yet

- Bajaj Allianz InsuranceDocument93 pagesBajaj Allianz InsuranceswatiNo ratings yet

- HealthInsuranceCertificate-Group CPGDHAB303500662021Document2 pagesHealthInsuranceCertificate-Group CPGDHAB303500662021Ruban JebaduraiNo ratings yet

- Low Cost Building ConstructionDocument15 pagesLow Cost Building ConstructionAtta RehmanNo ratings yet

- PFI High Flow Series Single Cartridge Filter Housing For CleaningDocument2 pagesPFI High Flow Series Single Cartridge Filter Housing For Cleaningbennypartono407No ratings yet

- Allan ToddDocument28 pagesAllan ToddBilly SorianoNo ratings yet

- Doterra Enrollment Kits 2016 NewDocument3 pagesDoterra Enrollment Kits 2016 Newapi-261515449No ratings yet

- Multispan LC 2046 Length Counter PDFDocument2 pagesMultispan LC 2046 Length Counter PDFvinod kumarNo ratings yet

- Section 8 Illustrations and Parts List: Sullair CorporationDocument1 pageSection 8 Illustrations and Parts List: Sullair CorporationBisma MasoodNo ratings yet

- CodebreakerDocument3 pagesCodebreakerwarrenNo ratings yet

- Uppsc Ae GSDocument18 pagesUppsc Ae GSFUN TUBENo ratings yet

- Sample Annual BudgetDocument4 pagesSample Annual BudgetMary Ann B. GabucanNo ratings yet

- Astm E53 98Document1 pageAstm E53 98park991018No ratings yet

- 2021S-EPM 1163 - Day-11-Unit-8 ProcMgmt-AODADocument13 pages2021S-EPM 1163 - Day-11-Unit-8 ProcMgmt-AODAehsan ershadNo ratings yet

- RevisionHistory APFIFF33 To V219Document12 pagesRevisionHistory APFIFF33 To V219younesNo ratings yet

- Catalog Celule Siemens 8DJHDocument80 pagesCatalog Celule Siemens 8DJHAlexandru HalauNo ratings yet