Professional Documents

Culture Documents

Micro Structural Analysis

Uploaded by

Alexandre BonnassieuxOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Micro Structural Analysis

Uploaded by

Alexandre BonnassieuxCopyright:

Available Formats

ENG ME306 Professor Harold Park

Microstructural Analysis by X-Ray and S.E.M.

Section C4, February 7th, 2012

Bonnassieux, Alexandre, Pierre U03371989

Bonnassieux |1

1 Introduction

The purpose of this lab is to introduce the basics of x-ray diffraction, the process of scanning electron microscopy, and the analysis that can be done with these procedures.

2 Theory

2.1 X-Ray Diffraction

Similarly to the way that an optical grating diffracts light beams, the repetition of group of atoms that exists throughout a crystal forms a three-dimensional grating which can diffract a beam of xrays. A beam of x-rays aimed at a specific structure will show a finger print of the structure with its diffracted rays. In crystals, the pictures formed by the x-ray diffractions can help in determining the spacing of the lattices contained inside the structure, as well as space groups, and positions of atoms in the unit cell. Diffraction will also indicate the orientation of a single crystal, the preferred orientation in a polycrystalline specimen, the dimensions of the unit cell, and measurements of residual and applied stress. X-ray diffraction can also provide information concerning the effect on the lattice of plastic deformation, mechanism, of deposition, crystallization, transformation, age hardening and precipitation, and the constitution of organic and inorganic systems. The underlying principle for all x-ray diffraction application is Braggs Law. Given a parallel set of planes of atoms which repeat through a crystal (spaced at intervals of d), the condition for the x-rays reflection from these planes is (1) Where is the wavelength of the x-rays, n the order of the reflection, and the angle of incidence of the beam on the planes .

2.2 Scanning Electron Microscope

Typical microscopes use a visible light wave source, in comparison to a scanning electron microscope (SEM), which uses a source of electrons. An electron accelerated towards a conductive sample will knock another electron off of the atoms on that surface. These ejected electrons from the samples surface are picked up by a detector. The electron beam used by the microscope scans across the sample and the detector is able to transfer the information to a screen. The main advantage of an SEM is that it had a much greater depth of focus compared to traditional optical microscopes. This allows for much larger areas to be in focus at the same time. Another advantage of such a machine is the production of high resolution images, leading to quality images at very high magnifications. An SEM can achieve magnifications of 10,000X whilst maintaining a

Bonnassieux |2 relatively good quality focused image, which an optical microscope generally does not go above 1000X magnification.

3 Methods

3.1 X-Ray Diffraction

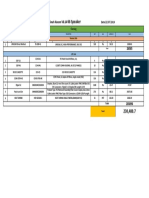

During the lab demo, an x-ray diffraction machine was visited, but not used. The machine is fairly simple to operate, using a computer to start the process after placing the sample into the correct place on the machine, which is housed behind safety glass. After the machine is run, the data is displayed directly on the nearby computer, where closer analysis can be made. The reflection rules of xray diffraction for common structures are as follows

Table 1

Bonnassieux |3

3.2 Scanning Electron Microscope

We were not able to use the SEM in the main demonstration of the lab, as the machines are used by faculty and other researchers to perform experiments and obtain information on microstructure for various samples. The following is a general diagram of the workings of a standard SEM:

Figure 1

4 Results

The results of x-ray diffraction and SEM imaging were given in the lab report, but were not actually performed by the lab group. Some examples of images of fracture surfaces of tensile bars produced by the scanning electron microscope are

Bonnassieux |4

The results of the x-ray diffraction are in forms of graphs, and are attached in appendix I-IV.

5 Analysis

Question One

The basis for x-ray diffraction is governed by Braggs Law (equation 1). A diagram of x-ray diffraction usually looks like the following where it is easy to see why we only get peaks at certain values of theta

Bonnassieux |5

Figure 2 Two parallel incident rays (1 and 2) make an angle theta with the planes of the crystal. A reflected beam with maximum intensity will only result if the waves reflected are in phase. This will only happen is the difference in path lengths is an integer number of wavelength. This only happens at certain angles that the beams are reflected from the crystal structure as the machine moves around the sample. This constructive interference will be determined by the unit cells dimensions. Using the reflection rules of x-ray diffraction, we can see how the angle values of the reflection relate to the crystal structure of the sample. Braggs law can be manipulated to give (for a cubic unit cell) So that the measured value of can be related to the cell parameters and the distance between atomic layers in a crystal, so that the crystal structure can be described.

Question Two

Identifying materials from x-ray diffraction graphs is the very important in understanding the functioning of this process.

Part A

To identify the materials that are represented by the charts (found in appendix I-IV), it is necessary to use Braggs Law. Solving for the lattice spacing, Braggs Law becomes

Bonnassieux |6 Since the angle scale is in 2-theta, we must divide these angles by 2 when plugging them into this equation. The charts given in the lab (found in appendix V-VIII) give the wavelength of the radiation that was used (1.540598nm) which is used for . We also assume that n=1. For the first graph, the locations of the peaks were found, and then manipulated using the formula above to find the spacing of the crystal structure Radiation (nm) Peak Number Peak Location (2) d (A) 1.540598 1 35 2.56 2 38 2.366 3 40 2.25 4 53 1.726 5 64 1.454 6 71 1.326 7 76 1.251 8 77 1.237 9 82 1.174 10 87 1.119 Table 2: Scan #1 Results Comparing the results obtained for the spacing of the sample with the charts that were given in the lab, we can see the Scan#1 fits best with the Titanium, in appendix V. Similarly, scan #2,3,4 can also be manipulated to find the spacing of the materials that were analyzed using x-ray diffraction. Radiation (nm) Peak Number Peak Location (2) d (A) 1.540598 1 43.5 2.079 2 51 1.789 3 74.5 1.27 Table 3: Scan #2 Results Radiation (nm) Peak Number Peak Location (2) d (A) 1.540598 1 38.35 2.236 2 44.5 2.034 3 65 1.434 4 78 1.224 5 83.5 1.157 Table 4: Scan #3 Results Radiation (nm) Peak Number Peak Location (2) d (A) 1.540598 1 44 2.065 2 65 1.434 3 83.5 1.157

Bonnassieux |7 Table 5: Scan #4 Results

From the data obtained in the tables above, comparing these values to the charts enables us to identify the unknown materials. The material used in Scan#2 is Austenite (Fe,C, appendix VI), Scan#3 is Aluminum (appendix VII), and Scan#4 is Iron (Fe, appendix VIII).

Part B

The crystal planes (hkl) associated with each peak can be identified for each scan using the charts provided and tables 2-5 Radiation (nm) Peak Number Peak Location (2) d (A) (hkl) 1.540598 1 35 2.56 100 2 38 2.366 200 3 40 2.25 101 4 53 1.726 102 5 64 1.454 110 6 71 1.326 103 7 76 1.251 200 8 77 1.237 112 9 82 1.174 400 10 87 1.119 202 Table 6: Scan #1 Results with crystal planes Radiation (nm) Peak Number Peak Location (2) d (A) (hkl) 1.540598 1 43.5 2.079 111 2 51 1.789 200 3 74.5 1.27 220 Table 7: Scan #2 Results with crystal planes Radiation (nm) Peak Number Peak Location (2) d (A) (hkl) 1.540598 1 38.35 2.236 111 2 44.5 2.034 200 3 65 1.434 220 4 78 1.224 311 5 83.5 1.157 222 Table 8: Scan #3 Results with crystal planes Radiation (nm) Peak Number Peak Location (2) d (A) (hkl) 1.540598 1 44 2.065 110 2 65 1.434 200 3 83.5 1.157 211

Bonnassieux |8 Table 9: Scan #3 Results with crystal planes

Part C

The crystal structures can be determined with the help of the reflection rules of x-ray diffraction found in table 1 and the charts given. Scan#1 Titanium, has a hexagonal crystal structure. Scan#2 is Austenite and has a face-centered cubic crystal, Scan#3 is Aluminum and has a face-centered cubic crystal structure, and Scan#4 is Iron and has a Body-centered cubic crystal structure.

Question Three

Optical microscopes must have a perfectly flat surface to get a food focused image at high magnifications, which proves to be challenging when trying to magnify small samples with this method. The limitation of light microscopes, and the reason why we cannot use a light microscope to look at the microstructure at very high magnifications is because of its use of light. Since the device magnifies the light reflected on an object, the limit of the magnification is found in the wave length of the light that is used. Therefore, with an optical microscope, it is not possible to magnify objects that are smaller than the shortest wavelength of visible light (around 400 nanometers) since the object cannot reflect the visual light due to its size and will consequently be virtually invisible to the microscope.

6 Conclusion

The objectives of the lab were clearly completed, and I know feel that I have a basic knowledge of x-ray diffraction as well as the working of a scanning electron microscope. The results of x-ray diffraction were used to identify the unknown metals that were tested, and the crystal planes and structure associated with those samples. Although the S.E.M. was not actually used during the lab, we received a good theoretical and visual explanation (using video) of the working of the machine.

Bonnassieux |9 Sources: http://web.pdx.edu/~pmoeck/phy381/Topic5a-XRD.pdf

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Preview: Gradient Based Histogram Equalization of Thermal Infrared ImagesDocument24 pagesPreview: Gradient Based Histogram Equalization of Thermal Infrared ImagesNguyễn DũngNo ratings yet

- LED Uniform Illumination Using Double Linear Fresnel Lenses For Energy SavingDocument15 pagesLED Uniform Illumination Using Double Linear Fresnel Lenses For Energy SavingAlexOO7No ratings yet

- Geology 40 SyllabusDocument2 pagesGeology 40 SyllabusMimiNo ratings yet

- Test Planner AakashDocument3 pagesTest Planner AakashthekiddiedreamsNo ratings yet

- Contact Lens Parameter GuideDocument5 pagesContact Lens Parameter GuideYogapriya SNo ratings yet

- Basic Printing Ed 2Document4 pagesBasic Printing Ed 2rlambrecNo ratings yet

- 4 1081739710235148289-2 PDFDocument228 pages4 1081739710235148289-2 PDFNiloy Basak100% (1)

- Espectro ElectromagneticoDocument18 pagesEspectro ElectromagneticoEnrique CabreraNo ratings yet

- Izmir High Technology Institute-Spectra 300 TEM - QUO-142586-W7Y2 R0Document34 pagesIzmir High Technology Institute-Spectra 300 TEM - QUO-142586-W7Y2 R0Sedat AkkurtNo ratings yet

- P C F I: Hotonic Rystal Iber NterfacingDocument11 pagesP C F I: Hotonic Rystal Iber NterfacingNadia F Mohammad Al-RoshdeeNo ratings yet

- Product Description (V100R002 03)Document151 pagesProduct Description (V100R002 03)ghallabalsadehNo ratings yet

- OCR Physics A: Optical Fibres: Path DifferencesDocument2 pagesOCR Physics A: Optical Fibres: Path DifferencessciencedocsmanNo ratings yet

- PhotoSign PDFDocument2 pagesPhotoSign PDFMotiur RahmanNo ratings yet

- THE Electromagnetic Spectrum: Unit 2, Module 2 Kiziah F. GranilDocument10 pagesTHE Electromagnetic Spectrum: Unit 2, Module 2 Kiziah F. GranilHannah Joy DulayNo ratings yet

- Benjamin Optical Unconscious Conty PDFDocument15 pagesBenjamin Optical Unconscious Conty PDFDana KiosaNo ratings yet

- 8573-4 2019 (E)Document34 pages8573-4 2019 (E)carolina quiroga50% (2)

- Macro Photography Short GuideDocument29 pagesMacro Photography Short GuideGwenetteSinclair100% (2)

- 66 Speaker: Project Name: Madinah Haram V0.14Document1 page66 Speaker: Project Name: Madinah Haram V0.14mohamed ghazyNo ratings yet

- EE-SV3 Series: Photomicrosensor (Transmissive)Document2 pagesEE-SV3 Series: Photomicrosensor (Transmissive)hüseyin vururNo ratings yet

- RoyalZProduction Music Video GuideDocument60 pagesRoyalZProduction Music Video GuideDamien GauranandaNo ratings yet

- FiO Final Program 2011Document132 pagesFiO Final Program 2011Sathish KumarNo ratings yet

- Telescope: Physics NotesDocument1 pageTelescope: Physics NotesIlias AchhabNo ratings yet

- S&IOT Mid-1 QBDocument3 pagesS&IOT Mid-1 QBMᴀɴɪ TᴇᴊᴀNo ratings yet

- Ch. 8-Passive Components PDFDocument77 pagesCh. 8-Passive Components PDFאליNo ratings yet

- E1951 137950-1Document7 pagesE1951 137950-1Sarvesh Mishra100% (1)

- Color 1 Color 2 Color 3: HEX RGB HSB Cmyk HEX RGB HSB Cmyk HEX RGB HSB CmykDocument8 pagesColor 1 Color 2 Color 3: HEX RGB HSB Cmyk HEX RGB HSB Cmyk HEX RGB HSB CmykMr. FerreiraNo ratings yet

- P6 IB10 Physics Holiday HomeworkDocument4 pagesP6 IB10 Physics Holiday HomeworkRyan LiNo ratings yet

- ExposureLesson 1Document52 pagesExposureLesson 1Govindarajan BangaruNo ratings yet

- Vertical Aerial PhotographsDocument27 pagesVertical Aerial PhotographshandokoNo ratings yet

- Science 3 Detailed Lesson PlanDocument5 pagesScience 3 Detailed Lesson PlanCathlynDucutNo ratings yet