Manufacturing Execution System (MES) Overview

t: 1890 924 155 / +353 21 4536121

f: +353 1 6335872

e: info@esp.ie

w: www.esp.ie

�What is MES

What is MES

MES is an electronic interface between personnel, equipment automation, orders, logistics, equipment and processing instructions (batch records). MES is located between the company-wide Enterprise Resource Planning system (ERP) and the process control systems. MES mediates between business administration (covering core functions such as sales and production planning or controlling) and the automation of the production process.

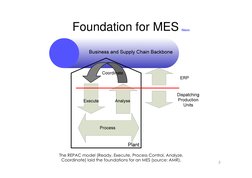

�Foundation for MES

Return

The REPAC model (Ready, Execute, Process Control, Analyze, Coordinate) laid the foundations for an MES (source: AMR).

�Vision of an MES System

Some paper? No Paper

Lights Out, Continuous Batch

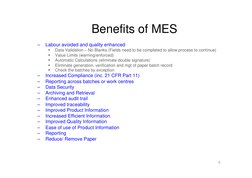

�Benefits of MES

Labour avoided and quality enhanced

Data Validation No Blanks (Fields need to be completed to allow process to continue) Value Limits (warning/enforced) Automatic Calculations (eliminate double signature) Eliminate generation, verification and mgt of paper batch record Check the batches by exception

Increased Compliance (inc. 21 CFR Part 11) Reporting across batches or work centres Data Security Archiving and Retrieval Enhanced audit trail Improved traceability Improved Product Information Increased Efficient Information Improved Quality Information Ease of use of Product Information Reporting Reduce/ Remove Paper

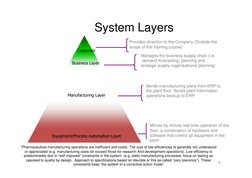

�System Layers

Corporate Business Layer Provides direction to the Company (Outside the scope of this training course) Manages the business supply chain (i.e. demand forecasting, planning and strategic supply organisational planning)

Manufacturing Layer

Sends manufacturing plans from ERP to the plant floor. Sends plant Information operations backup to ERP

Equipment/Process Automation Layer

Minute by minute real time operation of the floor, a combination of hardware and software that control all equipment in the plant

Pharmaceutical manufacturing operations are inefficient and costly. The cost of low efficiencies Is generally not understood or appreciated (e.g. manufacturing costs far exceed those for research And development operations). Low efficiency is predominately due to self imposed constraints in the system (e.g. static manufacturing processes, focus on testing as opposed to quality by design, Approach to specifications based on discrete or this so-called zero tolerance). These 6 constraints keep the system in a corrective action mode

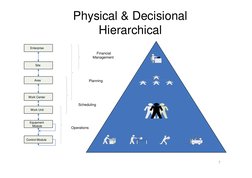

�Physical & Decisional Hierarchical

Enterprise

Financial Management

Site

Area

Planning

Work Center

Scheduling

Work Unit

Equipment Module

Operations

Control Module

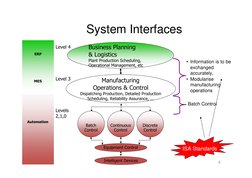

�System Interfaces

Level 4

ERP

Business Planning & Logistics

Plant Production Scheduling, Operational Management, etc

MES

Level 3

Dispatching Production, Detailed Production Scheduling, Reliability Assurance, ...

Manufacturing Operations & Control

Information is to be exchanged accurately, Modularise manufacturing operations Batch Control

Levels 2,1,0

Automation

Batch Control

Continuous Control

Discrete Control

Equipment Control Intelligent Devices

ISA Standards

8

�Key Systems Supporting Manufacturing and Quality

Business Systems

ERP MRP

Collectively involved in the planning, sales, purchase of raw materials

Manufacturing Systems

MES CAPA Laboratory Systems Chromatography Historian SDMS (Scientific Data Mgt. System) EQM (Equipment and Container Mgt) Weigh and Dispense Document Mgt.

Collectively involved in the production of the end product.

Automation Systems

PLC (Programmable Logic Controller) DCS (Distributed Control System) SCADA (Supervisory Control and Data Acquisition)

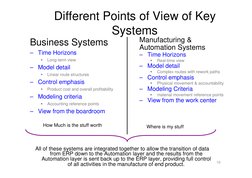

�Different Points of View of Key Systems

Business Systems

Time Horizons

Long-term view

Manufacturing & Automation Systems

Time Horizons

Real-time view

Model detail

Linear route structures

Model detail

Complex routes with rework paths

Control emphasis

Product cost and overall profitability

Control emphasis

Physical movement & accountability

Modeling Criteria

material movement reference points

Modeling criteria

Accounting reference points

View from the work center

View from the boardroom

How Much is the stuff worth Where is my stuff

All of these systems are integrated together to allow the transition of data from ERP down to the Automation layer and the results from the Automation layer is sent back up to the ERP layer, providing full control of all activities in the manufacture of end product.

10

�Overview Functionality of ERP, MES, Automation

ERP

Supply Chain

Enterprise Resource Planning

Inventory Management MRP Asset Management Financial Management

Warehouse Management Equipment/ Container Management Central Recipe & Configuration Management

Scheduling & Planning LIMS /SPC Weighing & Dispensing (Electronic) Batch Record Data Historian Equipment Control

Console Controller Corrective And Preventive Action Tracking

Personnel Qualification & Training

MES

Document Management CAPA

Material Tracking (Genealogy)

Reporting/ Information

Automation

PLC/Intelligent Device

SCADA

DCS

Console Controller

PLC/Intelligent Device

including system integration

11

�IT View of System Landscape

ERP

Level 4

Business Process Information Network

ERP, APO, Logistics Systems

MES

Level 3

Operations Information Network

MES, LIMS, WMS, CMM Systems

Level 2

Automation

HMI, SCADA, Batch Systems

Automation Network

PLC, DCS, Packaged Systems

Discrete & Process Device Communication Networks

Level 1

I/O, Devices, Sensors

12

�Typical MES Architecture

13

�Modules/Benefits of MES

Typical Modules of an MES System EBR/MBR Weigh & Dispense Warehouse Mgt Material Flow Control Equipment & container Mgt Finite Scheduling

14

�Standard MES Functionality

Manufacturing Order (ERP)

Work Order (MES)

SFO1

SFO2

SFO3

SFO4

SFO5

15

�Material Mgt Within Production Controlled by MES

Blending Compression Coating

Electronic control of all materials in production (Order and Stock)

16

�Visual Production Status/Tracking

Sign off clean sheet

Line clearance

Tablet filler set-up

labeller

Checkweigher

Vision system

Take first retain sample

production

17

�Automatic Recording of Daily balance checks in EQM

Paper Log Book Paperless EQM

18

�Automatic Complete Check of Room and Setup Parts

Paper BMR Paperless EBR

Plausibility Check Electronic Signature Check by System

19

�Packaging Line Batch Details

Product: Tablet 800mg Market; IE/ UK Batch No: 123 Exp date: SEP 2006

20

�Barcode Identification and Scanning

Room and equipment Pack room 1 Checkweigher Bottle unscrambler Auto cartoner Vision system GMP No.

F-05 CW-001 BUS-001 CRT-001 PVS-003

Verified By

Room F-05

BUS-001

CW-001

CRT-001

PVS-003

21

�Barcode Identification and Scanning

Scanned

Room and equipment Pack room 1 Checkweigher Bottle unscrambler Auto cartoner Vision system Set-up checks GMP No.

F05 CW-001 BUS-001 CRT-001 PVS-003

Verified By

Not Necessary

variables

John Smith 30 Sep 05 Verified by:______________________________Date:___________________________________

22

th

�Automatic Calculation of water to add for Granulation

Paper BMR Paperless EBR

23

�Automatic Downloading of setpoints to control equipment (e.g. Granulator PLC)

Paper BMR Paperless EBR

MES

Control Network

Granulator

Blender

Coaters

Presses

24

�Execute EBR for Electronic Batch Recording

Steering of RSBatch execution by using EBR and monitor batch execution. Real-time process and data presentation using RSVIEW and process control using RSBatch.

25

�Execute EBR for Electronic Batch Recording

Return

Create Batch Report

Analyse, review and approve batch report for real-time Release

26

�Standards & Best Practises

(and FDA Current Initiatives)

Regulation/Compliance 21 CFR Part 11 (Electronic Records & Signature)

Validation of Systems Copies of records Protection of records Limitations on access Computer Time stamped records Operational system checks (permission of sequencing) Authority checks Use of devices for determination of checks Qualified personnel Adherence to written policies Use of appropriate control Control for open systems EBRs (unique and attached to the executed record) Periodic testing of controls

Standards/ Best Practises PAT

Reduction of cycle times Less batch failures Faster batch release time Improved management change control Reduced start-up time Improved speed of deployment

GAMP4 EMEA (European Medicines Agency) ISPE (International Society of

Pharmaceutical Engineers)

Lean Manufacturing S95 standard S88 standard

FDA (Food and Drug Administration) IMB (Irish Medicine Board) Annex (11 & 15)

27

�Future Requirements & Standards

Competitive markets is forcing the need to have accurate,timely information on which to make business decisions. The data already exists on the manufacturing floor. The issue is accessing the data and turning that into useful information. The need is to leverage standards to help move forward.

28

�Any Questions?

t: 1890 924 155 / +353 21 4536121

f: +353 1 6335872

e: info@esp.ie

w: www.esp.ie