Catalog Lab

Uploaded by

Ioana PopescuTopics covered

- patents,

- user interface,

- mc6® system,

- innovation,

- modular design,

- customer service,

- electrical modules,

- work benches,

- design and colors,

- accessories

Catalog Lab

Uploaded by

Ioana PopescuTopics covered

- patents,

- user interface,

- mc6® system,

- innovation,

- modular design,

- customer service,

- electrical modules,

- work benches,

- design and colors,

- accessories

T

e

c

h

n

i

c

a

l

C

a

t

a

l

o

g

u

e

m

c

6

Technical

Catalogue mc6

1

4

5

1

0

3

0

5

K

o

n

z

e

p

t

i

o

n

u

n

d

G

e

s

t

a

l

t

u

n

g

:

B

r

o

f

r

G

e

s

t

a

l

t

u

n

g

,

I

s

n

y

i

m

A

l

l

g

u

L

a

b

o

r

WALDNER

Laboreinrichtungen GmbH & Co. KG

Haidoesch 1

88239 Wangen

Germany

Phone +49 7522 986-301

Fax +49 7522 986-418

info@waldner-lab.com

www.waldner-lab.com

Labor

Labor

The Technical Catalogue

Our latest laboratory furniture

system mc6

with its flexible

application units can be

adapted to suit changing labo-

ratory requirements.

As a modular system, it can be

used to make additions to

existing furniture or provide

new floor plan solutions

depending on the objectives.

The main components are

based on an ingenious modu-

lar system. In this way we can

provide a large number of dif-

ferent designs in every func-

tional area of the laboratory.

We are aware of the expecta-

tions placed upon us and

address these expectations

with rigorous orientation on

the needs of our customers.

Furthermore, we guarantee

first-class quality, mature,

innovative technology and

perfect service. With our laboratory furniture

system mc6

we provide a

high level of work safety,

ergonomics and economy.

It is the sum of the well

thought-out details that leads

to the perfect solution. Cus-

tomers and clients worldwide

rely on us and our service.

We are pleased to provide you

the basis for your future labo-

ratory with this technical cata-

logue.

In conjunction with the picto-

rial catalogue, you can see the

rich range of variants possible

with our laboratory furniture

system mc6

.

Contact us our specialists

will always be pleased to talk

to you.

2

3

1

Service modules

1.1 Service spine Service panels and electrical modules Add-on parts

Service modules Suspended service booms 1.2 Service wing

1.3 Service distribution terminal

Work benches

2.1 Add-on tables and supporting structures 2.2 Worktops

2.3 Mobile table 2.4 Swing 2.5 Height adjustable table 2.6 Balance table

2.7 VarioTHEK 2.8 Rack 2.9 Analysis tables Assistant Round table

Add-on plate Oval Skate Caddy 2.10 Sink work benches Laboratory sinks

Sink modules Drip cups 2.11 Mobile sinks Sink station AquaEl

Fume cupboards and exhaust devices

3.1 Bench mounted fume cupboards 3.2 Low ceiling bench mounted fume

cupboards 3.3 Low level fume cupboards 3.4 Walk-in fume cupboards

3.5 Secuflow bench mounted fume cupboards 3.6 Secuflow low volume

bench mounted fume cupboards 3.7 Bench mounted fume cupboards with

side installation 3.8 Low ceiling bench mounted fume cupboards with side

installation 3.9 Special application fume cupboards 3.10 Filter fume cupboards

3.11 Radio-isotope fume cupboards 3.12 Mobile fume cupboards 3.13 Local

exhaust devices 3.14 Monitoring and control

4

Storage space

4.1 Underbench units Underbench unit on plinth Underbench unit on castors

Suspended underbench unit Underbench unit for fume cupboards Underbench

unit for fume cupboards for the storage of solvents Underbench unit for fume

cupboards for the storage of acids and alkalis 4.2 Disposal Underbench unit for waste

disposal Waste disposal system for acids and alkalis Waste disposal system for flammable

liquids 4.3 Wall mounted cabinets 4.4 Instrument cupboards 4.5 Top-mounted

cabinets 4.6 Exhaust cabinets Pull-out cabinet Emergency cabinet Acid and alkali

cabinet Gas cylinder cabinet Solvents cabinet Supply system for flammable liquids

5

Teaching laboratories

5.1 Teacher desk 5.2 Students desk with service pillar/service module

5.3 Students desk with service module 5.4 Mobile table

6

General

6.1 Patents, brands, design patents and registered designs 6.2 Certified

safety and quality 6.3 Design and colours 6.4 From planning to the finished

laboratory 6.5 Standards and technical rules

Page 3 21

Page 23 45

Page 47 87

Page 89 115

Page 117 127

Page 129 136

3

Service modules

1.1 Service spine

Service panels and electrical modules

Add-on parts

Service modules

Suspended service booms

1.2 Service wing

1.3 Service distribution terminal

The philosophy of our mc6 fur-

niture system is to enable

changes to be made easily and

therefore to provide more

mobility in the laboratory.

Energy and service systems have

a central role.

Pipes and cables for supplies

and waste are run to the service

spine, service module, sus-

pended service boom and the

service wing. These units then

provide the services at fittings

and integrated electrical units.

Due to the modular layout and

flexible installation technology,

services and energy are always

available where they are needed.

1

4

Service modules

General

The special feature of the serv-

ice spine is its modular layout

and its logical separation from

the furniture in the laboratory.

The service spine gives the

designer freedom of choice

during the design of the labo-

ratory environment and pro-

vides the best possible options

for different designs and rapid

changes. The backbone of this

system is formed by the strong

pillar profile without grooves,

which can be combined

together with the freely selec-

table bench frames to form a

work bench against a wall or a

double-sided work bench.

The strong profile frame is per-

fectly designed for fitting dif-

ferent services and electrical

modules, reagent shelves,

instrument shelves and much

more.

The surfaces of the supporting

structure and the panels are

protected with high-grade

powder coatings. As the items

fitted to the panel can be

changed rapidly without the

need to undo bolts, laboratory

operations are hardly inter-

rupted at all.

The supply pipes, for example

for water and compressed air,

can be rapidly extended and

fitted using a quick release

coupling system. Overbench

cabinets can also be fastened

when pillar extensions are

used.

For the perfect planning of the

preparatory work on-site, we

provide planners and architects

with installation plans contain-

ing exact sizes for supply pipes

and cables as well as informa-

tion on dimensioning and flow

rates.

Flexibility and rapid upgrad-

ability

The modular design principle

enables all modules to be rap-

idly replaced or changed for

expansion. This feature signi-

fies low installation costs.

Shelves can be fitted as

required independent of modu-

lar size. Ready to plug-in elec-

trical modules are installed in

no time.

Full independence from the

work bench

As a result of the separation of

the service spine and furniture,

worktops and underbench

units can be moved or

changed without dismantling

the mechanical services and

electrical installation.

Two service spines used for

double-sided work benches

Here the double spine com-

prises two self-contained spines

that are independent of each

other. When making changes,

double bench spines can be

converted into two individual

spines set up against the wall.

Service spine

1

5

Use of electrical modules

that can be positioned as

required

Our modules only need space

where the power is required.

There is no awkward electrical

trunking with the service

spines. You can use the full

depth of the bench.

Wear-free cold/hot water

fittings

Unlike upper sections with a

grease chamber, our fittings

with ceramic sealing in the

upper section are wear-free

and maintenance-free for sig-

nificantly increased economy.

The basic structure of the

service spine based on the

example of a double work

bench with the various

elements fitted

6

Service modules

General

Service wing

Since the introduction of our

laboratory furniture system

mc6 , the term freedom in

the laboratory has been com-

pletely re-defined: Maximum

flexibility of all systems and

maximum freedom of move-

ment without interface prob-

lems provide people working in

laboratories freedom to be able

to implement their ideas.

The revolutionary service wing

supplements the new freedom

in the laboratory in a special

manner: as the central furni-

ture element in which all key

services such as mechanical,

electrical, lighting, EDP, extract

air and of course the disposal

of waste water are integrated,

our system provides a very

high-degree of flexibility.

The possibility of being able to

plug-in to the service wing,

practically anywhere, using

quick-release couplings signifies

a very high level of freedom of

movement in the laboratory.

Using the service wing simpli-

fies the entire laboratory fitting

out process including the

mechanical and electrical serv-

ices. A central feed point is

sufficient and the service wing

securely mounted to the ceil-

ing with adjustable steel bars

makes further installations,

holes in the walls and visible

suspension systems superflu-

ous. Installation costs are

reduced significantly, exten-

sions can be made without

problems without the need to

make structural changes.

With the service wing we have

created a service supply area

outside the direct working

area. All services can be rapidly

fed to the work bench without

complications.

Extraordinary flexibility in

the laboratory

All areas of the laboratory are

supplied using cross and T ele-

ments. All services are pre-

installed in the wing. In this

way we achieve a large num-

ber of possible configurations.

It is possible to dock any-

where at any time. Standard-

ised units for analysis tables

and work benches, mobile

tables, racks, mobile sink units

or mobile fume cupboards

everything can be used as

required under the wing.

Simplification of the prelimi-

nary structural planning

Complex installations for differ-

ent systems and their planning

are no longer required when

the service wing is used. The

saving in room height due to

the lack of need for a sus-

pended ceiling for improved

appearance signifies a consid-

erable saving in planning and

fitting out costs.

Easy to reach connection

quick-release couplings

When standing, the connec-

tions on the service wing

can be reached easily without

problems.

The service wing is also

easy to integrate in difficult

circumstances

The existing room architecture

and the characteristics of the

ceiling, wall and floor often

make extensive installations

more difficult. On listed build-

ings it is not even allowed to

make major changes to the his-

toric structure. Here the service

wing can be easily integrated

with minimal effort without

complications.

Perfectly planned, pre-

assembled and equipped in

the factory

The service wing system for

your laboratory is fully pre-

assembled in our factory to suit

your needs. You save assembly

time on-site and your service

wing is rapidly installed and

ready to use.

Uncomplicated to extend

and maintain

Due to its independent design

as a self-contained unit, the

service wing is almost mainte-

nance-free. Extending, upgrad-

ing and checking the system

are possible without major

effort.

1

7

The service wing with cross

element and systems and

furniture components that can

be placed below it.

4

3

2

1

5

6

7

8

9

3

2

1

4

5

6

8

7

8

Service modules

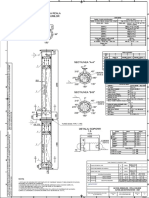

1.1 Service spine

Service spines provide fittings

and sockets, can be fitted with

supply pipes and cables and

waste pipes, and are used for

mounting a wide range of shelf

systems.

Service panels and electrical

modules can be individually

equipped and upgraded. The

powder-coated panels made of

steel sheet are clipped into the

lateral profiles on the service

spine above the worktop with-

out the need for tools.

The uprights for the service

spine can be extended in

height at any time as required,

e. g. for installing overbench

cabinets.

Layout

1 Installation com-

partment panel

2 Cantilever

3 Sanitary panel

4 Reagent shelf

(add-on part)

5 Slot panel

6 Cover panel

7 Electrical module

8 Uprights

9 Frame with

levelling screw

1 Underbench units

2 Table connection

panel

3 Row of panels

4 Instrument shelf

(add-on part)

5 Reagent shelf

(add-on part)

6 Worktop

7 Uprights

8 Frame with

levelling screw

1

9

Service spine section

Double work benches comprise

two independent uprights.

The supply and waste area runs

horizontally underneath the

worktop in the installation

area. The sanitary panels and

the electrical modules are con-

nected to the related main

pipes and cables using flexible

cables and pipes.

Bench mounted

service module section

The supply area on the bench

mounted service module runs

horizontally above the work-

top. Mechanical services and

electrical services are fitted

using the panel technology

or using a fixed panel.

1

5

6

3

m

m

W

H

9

0

0

m

m

T

h

r

o

u

g

h

-

p

u

t

3

8

3

m

m

2

4

0

m

m

355 mm

300 mm

100

4

0

m

m

1500 / 1800 mm

1

7

5

0

m

m

W

H

9

0

0

m

m

150 500 / 650 mm

675 / 825 mm

8

0

150

50 mm

25 mm

39 mm

10

Service modules

1.1 Service spine

Application examples

Double work bench with bench mounted

service module and underbench units on

plinth

Double work bench with bench mounted

service module and cantilever construction

with mobile underbench unit

Wall bench with one row of panels and 4-

leg construction with mobile underbench

unit

Double work bench with two rows of panels

and C frame construction with suspended

underbench units

Wall bench with two rows of panels and

flush sockets;

Underbench units on plinth

1

11

Double work bench with one row of panels

and splash protection;

Underbench units on plinth

S2 Wall bench with one row of panels and

C frame construction with mobile under-

bench units

Wall bench with two rows of panels and

underbench units on plinth

S2 Double work bench with one row of

panels and splash protection;

C frame construction with mobile under-

bench units and underbench units on plinth

Double work bench, with open spine

system. Electrical trunking is optional.

12

Service modules

1.1 Service spine

Service panels and electrical modules

The panels and modules are

clipped into a mounting frame

and can be arranged as

required.

The outlet valves in the panels

can be connected as required

to the main pipes using

branch pipes. The main pipes

are laid in the installation com-

partment underneath the

worktop or the cantilever.

It is possible to fit up to five

angle taps to sanitary panels

(for gas, water, vacuum, com-

pressed air or high purity gas

valves).

In addition, a sanitary panel

can be fitted with a drip cup.

Up to eight sockets for alter-

nating current or up to two

sockets for three-phase cur-

rent can be fitted to electrical

modules. Different sockets

can be combined.

As an option, the sockets can

also be supplied fitted flush

with the service spine.

The supply is provided using

an electrical module with an

interface to the electrical

supply and, on request, an

electrical module with up to

14 fuses under a cover.

Cover panels cover the areas

between sanitary panels and

electrical modules. Individually

mounted electrical modules

are always fitted with a half

height cover panel.

Behind slot panels there are

slot rails to which add-on parts

of varying height can be fitted.

Sanitary panel

with angle taps

Sanitary panel

with drip cup

Electrical module

with eight sockets for

alternating current

Electrical module with

various sockets

Electrical module with

interface to the electrical

supply and electrical module

with fuses

Cover panel with an

electrical module

Slot panel

1

13

Add-on parts

Add-on parts can be fitted at

different heights to panels

and runners with slots on the

service spine.

The following add-on parts

are available:

- Reagent shelf

- Instrument shelf

- Scaffold points

Reagent shelf

A glass plate is fastened to

two brackets using screws.

An angle behind the glass

plate is used as a stop and for

stiffening.

Bracket for reagent

shelf

The reagent shelf can be

extended using rods sup-

ported with braces at the top

or bottom. For this purpose

special brackets with a fasten-

ing feature for rods with a

diameter of 13 mm are used.

The rods are fixed in the holes

in the brackets using clamping

screws. Braces can be clamped

to the rods, the braces are fas-

tened to the slots in the serv-

ice spine using hooks and

increase the load capacity of

the rods.

Instrument shelf

A panel is fastened to two

brackets from below using

countersunk screws. An angle

behind the panel is used as a

stop and for stiffening. The

panel is supported underneath

or on top using braces.

Scaffold points

Scaffold points are used for

fitting a rod with a diameter

of 13 mm. The rod is fixed by

turning the knob on the scaf-

fold point by a quarter of a

turn.

Reagent shelf

Bracket with

hole for rod

Reagent shelf

with brace underneath

Reagent shelf

with brace on top

Bracket for reagent

shelf

Instrument shelf

with brace underneath

Instrument shelf

with brace on top

Scaffold points

14

Service modules

Service modules

1.1 Service spine

Service modules are used for

the provision of electrical and

mechanical services at the

laboratory workstation. They

are fastened to the raw ceil-

ing using a ceiling anchor.

The sanitary panels and elec-

trical modules fastened to the

uprights can be positioned on

both sides and can be

equipped as required.

Suspended service booms are

used for the provision of elec-

trical and mechanical services

at the laboratory workstation.

The modular spines are fas-

tened to the raw ceiling. The

sanitary panels and electrical

modules fastened between

the uprights can be posi-

tioned on both sides and can

be equipped as required.

Suspended

service booms

1

15

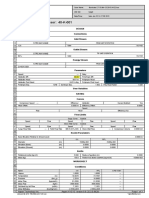

Technical data

Service spine

Widths (mm)

Height (mm)

Depths, single-sided with table (mm)

Depths, double-sided with table (mm)

Working heights (mm)

Pillar extension (mm)

Pillar extension for suspended cabinet

with height of 540 mm (mm)

Pillar extension for suspended cabinet

with height of 720 mm (mm)

Pillar extension up to

the ceiling (mm)

Height S2 panel

for working height of 900 mm (mm)

600, 900, 1200,

1500, 1800

1745

750, 900

1500, 1800

720, 900

960

515

695

1725

280

Dimension of the panels

Width, panel (mm)

Width, slot panel (mm)

Height, panel (mm)

300

300, 75

180, 360

Dimension of the electrical modules

Width, electrical module (mm)

Height, electrical module (mm)

300

180

Bench mounted service module

Widths (mm)

Height (mm)

Working heights (mm)

Opening

for working height of 720 mm (mm)

Opening

for working height of 900 mm (mm)

900, 1200,

1500, 1800

1563

720, 900

563

383

Reagent shelf

Widths (mm)

Depth (mm)

Load carrying capacity

600, 900, 1200,

1500, 1800

150

20 kg

Instrument shelf

Widths (mm)

Depth (mm)

Load carrying capacity

600, 900, 1200,

1500, 1800

300

30 kg

Scaffold points

Diameter of the hole for rods (mm)

Load carrying capacity in conjunction

with reagent shelf without brace

Load carrying capacity in conjunction

with reagent shelf with brace

13

5 kg

20 kg

Service module

Width (mm)

Length of the uprights (mm)

300

adjusted to suit

customer needs

Width, panel (mm)

Heights, panel (mm)

300

180, 360

Dimension of the electrical modules

Width, electrical module (mm)

Height, electrical module (mm)

300

180

Suspended service boom

Widths (mm)

Length of the uprights (mm)

600, 900, 1200,

1500, 1800

adjusted to suit

customer needs

Dimension of the panels

Width, panel (mm)

Height, panel (mm)

300

180

Dimension of the electrical modules

Width, electrical module (mm)

Height, electrical module (mm)

300

180

Dimension of the panels

1

1

2

3

4

5

6

8

3

2

5

6

7

4

700 mm

2

1

1

m

m

100 mm 300 mm 300 mm

520 mm 90 mm 90 mm

1

16

Service modules

1.2 Service wing

The service wing provides

services and waste facilities at

the laboratory workstation.

The service wing support is

fastened underneath the lab-

oratory ceiling, independent

of modular size. To avoid

vibrations, the support is

braced in the longitudinal and

transverse directions.

Different fittings or electrical

modules can be fitted to the

Layout

Components of

the service wing

1 Cover panel

2 Wing element

3 Electrical module

4 Support

5 Front cover

6 Workplace light

7 Fittings

8 Alsident exhaust

(optional)

underside of the elements on

both sides.

Due to the modular layout, the

services and energy supplies in

the laboratory can be varied as

required during the design of

the laboratory space and can

also be upgraded at any time.

Cross section

through the

service wing

1 Support

2 Indirect room

lighting

3 Service duct

4 Workplace lighting

and possibility for

extract air spigot

5 Electrical supply

area

6 Mechanical

services supply and

waste area

Section

1

17

Service wing elements

Feed element

T-element

Wing element

Cross element

Design variants

Mechanical

services

Electrical

Lighting

Ventilation

Dust protection

A very wide range of supply services such as flammable gas,

technical gases, pure gas, vacuum, compressed air, water in

a very wide range of quality stages

Waste pipes for waste water

Electrical supply for alternating current and three-phase current

Fuse modules

Workplace lighting

- Indirect room lighting

Alsident exhaust

Extract air spigot for mobile fume cupboard AeroEm

Plate valves for room ventilation

Cover over the spacing elements from above

18

Service modules

1.2 Service wing

Service wing elements

Feed element

The supply pipes are fed

through the wall at the height

of the service wing using a feed

element. As an alternative to

the feed element, the supply

pipes can be fed through a

service duct from the ceiling to

the service wing. In this case

the isolating valves are outside

the service wing.

Easy access to the isolation

valves and pipes in the service

wing is provided by opening

the feed element.

Mechanical services supply

and waste facilities directly

at the service wing

The fittings (angle taps, high

purity gas valves or quick

release outlets) supply the labo-

ratory workstation with flam-

mable gas, technical gases,

pure gases, vacuum or com-

pressed air and water.

The pipes from, e. g., service

distribution terminals (see sec-

tion 1.3) or mobile sinks (see

section 2.11) are connected to

quick release outlets.

Wing element

with angle taps

Wing element with

high purity gas valve

Quick release outlets for

gas, water, waste water

Feed element

Open

1

19

Dimension of the elements

Length, feed element (mm)

Lengths, wing elements (mm)

Lengths, T elements (mm)

Lengths, cross elements (mm)

Width (mm)

Height (incl. dust cover) (mm)

600

600, 900, 1200,

1500

1500

1500

700

210

Dimensions panels and modules

Length (mm)

Width (mm)

300

180

Dimensions of the workplace lights/cover panels

Lengths (mm)

Width (mm)

600, 900,

1200, 1500

100

Electrical supply directly at

the service wing

Up to eight sockets for alter-

nating current or up to two

sockets for three-phase cur-

rent can be fitted to electrical

modules.

Connections, e. g., for tele-

phones, monitors, data or

loudspeakers can also be

installed on electrical modules.

Extract air removal directly

at the service wing

Extract air spigots can be fitted

to the underside of the service

wing between the two halves

of the wing.

The spigots are connected to

the central exhaust system

using an extract air duct.

It is possible to connect, e. g.

the ducts from mobile fume

cupboards AeroEm (see section

3.12) or specific Alsident

exhausts (see section 3.13).

Wing element with

extract air spigots

Wing element

with electrical

modules

Technical data

Alsident exhaust on

the extract air spigot

3

2

1

4

20

Service modules

1.3 Service distribution terminal

In combination with the serv-

ice wing as a supply and

waste disposal system, the

service distribution terminal

enables services and electrical

supplies to be drawn directly

at the workplace. The service

distribution terminal is

clamped to worktops or steel

support frames using a

clamping system.

Layout

Components of a

service distribution

terminal

1 Service distribution

terminal with

sanitary panel

2 Service distribution

terminal with

electrical module

3 Clamping system

4 Service beam

The service distribution termi-

nal is supplied using the service

wing. Services and the electri-

cal supply are provided using

flexible pipes and cables that

are connected to the service

distribution terminal.

The pipes and cables are con-

nected to the service wing

using quick release outlets and

plugs.

A very wide range of mechani-

cal services such as flammable

gas, technical gases, pure

gases, vacuum, compressed air

can be provided.

Design variants

Up to three angle taps or high

purity gas valves are fitted to

the sanitary panel.

Up to eight sockets for alter-

nating current or up to two

sockets for three-phase current

can be fitted to the electrical

panel. Different sockets can be

combined.

The pipes and cables between

the service distribution terminal

and the service wing are fed to

the service beam and bundled

with two straps. In addition, a

steel rope on the service beam

is used to provide strain relief

for the pipes and cables.

The service distribution termi-

nal can be fastened horizon-

tally, e.g. to a worktop or ver-

tically to a steel frame, e. g. to

the rack (see section 2.8) .

1

21

Examples of the design variants

Service distribution termi-

nal with angle taps

Service distribution terminal

with high purity gas valves

Service distribution terminal

with 8 sockets for alternating

current

Service distribution termi-

nal with different sockets

Fastening two service distri-

bution terminals one above

the other

Vertical fastening of the

service distribution terminal

Horizontal fastening of the

service distribution terminal

Dimension service distribution terminal

Width (mm)

Height of a service distribution

terminal (mm)

Height of two service distribution

terminals (mm)

Depth (mm)

Clamping range for the fastening (mm)

300

205

410

125.5

10 to 90

23

Work benches

2.1 Add-on tables and supporting structures

2.2 Worktops

2.3 Mobile table

2.4 Swing

2.5 Height adjustable table

2.6 Balance table

2.7 VarioTHEK

2.8 Rack

2.9 Analysis tables

Assistant

Round table

Add-on plate

Oval

Skate

Caddy

2.10 Sink work benches

Laboratory sinks

Sink modules

Drip cups

2.11 Mobile sinks

Sink station

AquaEl

Work benches have a special

significance in our laboratory

furniture system: due to the

separation of the supply of serv-

ices and furniture in the system,

add-on table and mobile tables

are used to a greater degree.

The different types and versions

of all our work benches are

designed as mobile laboratory

modules and are equipped with

varying supporting structures

and individual board materials.

Our benches feature a high

level of stability combined with

an attractive design.

2

24

Work benches

General

Benches in the laboratory

area mean numerous possible

applications.

In a wider sense, benches

comprise supporting struc-

tures, the frames, which are

optimally designed to suit the

purpose.

All Waldner bench frames

have one feature in common:

WIG-welded from precision

rectangular tube, our benches

will withstand maximum

loads. Welded joints are

ground very clean on all our

products you will not find

open ends of tubes with plas-

tic caps in the floor area on

our products. We even weld

here. Optimally protected

against external effects by the

high-grade powder coating,

our frames have flawless sta-

bility and appearance.

The same applies to the sur-

faces on the worktops. Here

you have all options to suit

the working environment and

requirements. Items of equip-

ment, e.g. monitors, often

clutter the work surface on

the benches.

We have searched for better

solutions for positioning these

items. The Waldner solution is

called the Rack. You will be

amazed as to the possible

uses of this rack and that of

its mobility.

The documentation and analy-

sis of the results of work on

the PC are particularly pleas-

ant using our analysis tables.

Useful accessories such as the

assistant, add-on plate and

rack are ideally matched to

these requirements.

Bench frames for different

needs

C frame, 4-leg and cantilever

bench frames form the basis

for our work benches. The

frames are defined by their

shape to suit requirements

and the application.

The 4-leg steel support

frame

provides a high level of stabil-

ity for add-on tables, mobile

tables and analysis tables for

working sitting or standing.

Underbench cupboards can be

mobile or suspended and

moved independent of modu-

lar size. Sitting niches are

therefore possible anywhere.

The frames are fitted with

height adjustable feet.

2

25

C frame steel support

frames

are extremely steady and can

be loaded with 200 kg/m

2

.

They carry suspended under-

bench units without problems

and provide users a large

amount of knee and legroom.

The height is adjusted using

fully integrated adjusting

strips.

The cantilever frame

provides the greatest legroom

and lightest visual impact. It is

fitted to service spines or

directly to walls via its can-

tilever bracket design.

The multi-talent, the rack

is used primarily for fitting

items of equipment and has

a load carrying capacity of

150 kg.

The heights of shelves can be

adjusted as required in 45 mm

increments.

The shelves are available made

of either melamine coated

particleboard or powder-

coated perforated steel plate.

The shelves can be fitted with

a tilt of up to 15 without

tools. The extendable shelves

mounted on caged ball-bear-

ings and with 60 kg maximum

load can be pulled out to 2/3

of their depth. The castors

enable the rack to be moved

quickly.

Further refined accessories

The skate as a castor-mounted

base unit for your PC, the

caddy as a trolley for the

printer, add-on plate, assistant

and round table are only a few

examples of useful accessories

in the laboratory environment.

Our modular sinks

Available in various installa-

tion variants, the sink module

impresses with its height of

950 mm, which facilitates

fatigue-free work. Sink and

module are manufactured as

one unit without joints.

Our sink and drip modules are

manufactured from self-sup-

porting, acid proof technical

ceramic material. The sup-

porting structure is formed by

underbench cupboards with

plinth.

26

The worktops for the laboratory benches are

mounted on height adjustable bench frames

(4-leg, C frame or cantilever frame) or directly

on underbench units with plinth.

The complete WIG-welded sides and supports

are made of precision rectangular steel tube.

Supports are bolted to the frame such that

underbench units can be suspended in the

bench frame or pushed underneath on

castors.

Work benches

2.1 Add-on tables and supporting structures

Supporting structures

Add-on tables with H frame

Material frame and supports (mm)

Powder coating

Load capacity

Working heights (mm)

Frame heights 4-leg (mm)

Frame depths 4-leg (mm)

Standard lengths (mm)

The individual H frame has adjustable levelling feet made of steel each with a plastic

plate.

Levelling: - 5 to +25 mm with key projection.

ST 50/25/2

Layer thickness 80

200 kg/m

2

720, 900

690, 870

552, 702, 852

600, 900, 1200, 1500, 1800

Variant

Levelling covered by tube sleeve

Two-part installation compartment cover that can be slid to the side for

standard length frame 600 to 1800 mm in front of a service spine

Add-on tables with C frame

Material frame and supports (mm)

Powder coating

Load capacity

Working heights (mm)

Frame heights C frame (mm)

Frame depths C frame (mm)

Standard lengths (mm)

C frames can be individually adjusted in height and have two levelling screws in the

bottom steel brackets with a continuous pressure pad.

ST 50/25/2

Layer thickness 80

200 kg/m

2

720 or 900

690, 870

552, 702

600, 900, 1200, 1500, 1800

Variant

Two-part installation compartment cover that can be slid to the side for

standard length frame 600 to 1800 mm in front of a service spine

2

27

Add-on table with cantilever frame

Material frame and supports (mm)

Powder coating

Load capacity

Working heights (mm)

Frame heights (mm)

Frame depths (mm)

for wall fastening

Standard lengths (mm)

Fastening to the service spine or to the wall adapter using clamp strap.

The individual cantilever frames have adjustable levelling feet made of steel each

with a plastic plate. Levelling: - 5 to +25 mm with key projection.

ST 50/25/2

Layer thickness 80

200 kg/m

2

720 bzw. 900

690, 870

661, 811

Wall adapter ST 50/25/2

WH 720 mm length 572 mm

WH 900 mm length 752 mm

600, 900, 1200, 1500, 1800

Variant

Levelling covered by tube sleeve

Two-part installation compartment cover that can be slid to the side for

standard length frame 600 to 1800 mm

Notes on underbench units:

Moveable underbench units for the working heights 720 and 900 mm can be

pushed in.

Notes on fastening:

The cantilever frame can only be used in conjunction with a service spine or

fixed to a strong wall.

The welded tube construction is not self-supporting and must be firmly

joined to the service spine or the wall.

28

Work benches

2.2 Worktops

Worktops for wall benches without service spine

or for free-standing benches

The laboratory worktops are either mounted

on bench frames (4-leg, C frame or cantilever

frame) or directly on underbench units with

plinth.

The following dimensions are available

Worktop widths (mm)

Worktop depths (mm)

600, 900, 1200, 1500, 1800

600, 750, 900

Material worktop

Melamine resin coating on base

material

Particleboard, self-supporting*

Polypropylene coating on

particleboard base*

Solid grade laminate without

increased edge*

Stainless steel on particleboard base*

Tiles on coated plywood board*

Technical ceramic material

self-supporting

Technical ceramic material -

compound worktop on structural

element

Epoxy resin self-supporting

Glass (safety glass ESG)

* Work surfaces also available by the

metre. Maximum length that can be

supplied 3600 mm

Grooved upstand edging strip made

of plastic

Wall sealing strip

Installation ventilation grid

750x100 mm

Flush edge profile

Marine edging

Installation ventilation grid

750x100 mm

Flush stainless steel edge

Marine edging

Marine edging on two

or three sides

Profiled plastic end cap

Marine edging on two

or three sides

Marine edging

Profiled plastic end cap

Without marine edge

Marine edging on two or three sides

Marine edging

Material increased edge: Epoxy resin

Marine edging on two or three sides

Marine edging

Variants

2

29

Worktops for wall benches and

double work benches in front of a service spine

The laboratory worktops are either mounted

on bench frames (4-leg, C frame or cantilever

frame) or directly on underbench units with

plinth.

The following dimensions are available

Worktop widths (mm) 600, 900, 1200, 1500, 1800

Wall bench

Module depth 750 mm

Module depth 900 mm

Worktop depth (mm)

675

825

Double work bench

Module depth 1500 mm

Module depth 1800 mm

Worktop depth per side (mm)

675

825

Material worktop

Melamine resin coating on base

material

Particleboard, self-supporting*

Polypropylene coating on

particleboard base*

Solid grade laminate without

increased edge*

Stainless steel on particleboard base*

Tiles on coated plywood board*

Technical ceramic material

self-supporting

Technical ceramic material -

compound worktop on structural

element

Epoxy resin self-supporting

Glass (safety glass ESG)

* Work surfaces also available by the metre. Maximum length that can be

supplied 3600 mm

Flush edge profile

Marine edging

Flush stainless steel edge

Marine edging

Marine edging on two

or three sides

Profiled plastic end cap

Marine edging on two

or three sides

Marine edging

Profiled plastic end cap

Without marine edge

Marine edging on two or three sides

Marine edging

Material increased edge: Epoxy resin

Marine edging on two or three sides

Marine edging

Variants

30

Critical substances

Damaging

substances

Advantage

Disadvantage

Use

Weight

Total thickness

- Acids with concentration > 10%

- Concentrated hydrochloric acids

- Nitric acids

- Heated sulphuric acid

- Resistance to moisture

- Flat

- Easy to dispose of

- Low coating thickness

- Wet room

- Benches with medium stress

26.4 kg/m

2

19 mm

Critical substances

Damaging

substances

Advantage

Disadvantage

Use

Weight

Total thickness

- Acids with concentration > 10%

- Concentrated hydrochloric acids

- Nitric acid

- Heated sulphuric acid

- Flat

- Joints sensitive to moisture

- Medium chemical resistance

- Mobile tables, add-on tables, window

benches

- Instrument benches and laboratory

benches in the dry area

- Cannot be used in the moist or wet

area

19.6 kg/m

2

30 mm

Melamine resin/postformed Polypropylene

Critical substances

Damaging

substances

Advantage

Disadvantage

Use

Weight

Total thickness

- Hydrocarbons

- Citric acid

- Oxalic acid

- Carbon tetrachloride

- Diesel oil

- Ozone

- Concentrated nitric acid

- Chloroform

- Petrol

- Benzol

- No joints

- Flat

- Light

- High chemical resistance to acids and

many solvents

- Easy to dispose of

- Less glass breakage

- Soft surface sensitive to scratches

- Sensitive to heat

- Areas with high chemical resistance

- Working with hydrofluoric acid

- Area in which the lack of joints is

important

- Radio-isotope area

20.3 kg/m

2

30 mm and 7 mm increased edge

Tiles

Critical substances

Damaging

substances

Advantage

Disadvantage

Use

Weight

Total thickness

- None

- Hydrofluoric acid

- Flat

- High resistance to chemicals

- Tops have gaps with low resistance

to chemicals

- Gaps difficult to clean and difficult

to decontaminate

- Laboratory benches of all types that

are subjected to chemicals

30 kg/m

2

30 mm and 7 mm increased edge

Work benches

2.2 Worktops

Properties of the worktops

Solid grade laminate

2

31

Epoxy resin

Critical substances

Damaging

substances

Advantage

Disadvantage

Use

Weight

Total thickness

- Various solvents

- Diluted acids

- Hydrofluoric acid

- Concentrated, warm mineral acids

- No joints

- Flat

- Solid panel

- High mechanical loading possible

- Easy to dispose of

- Surface sensitive to scratches

- Sensitive to concentrated acids

- Laboratory workstation of all type

32 kg/m

2

19 mm and 7 mm increased edge

Stainless steel

Critical substances

Damaging

substances

Advantage

Disadvantage

Use

Weight

Total thickness

- Cadmium

- Lactic acid

- Oxalic acid

- Compounds containing chlorine

and bromine

- Formic acid

- Sulphuric acid

- No joints

- High resistance to solvents

- High temperature resistance

- Sensitive to halogens and their

compounds

- For maximum loads in the area of

decontamination and moisture

resistance as well as solvent resistance

- Biology

- Microbiology

- Pharmacy

- Radio-isotope area

- Pathology

27.5 kg/m

2

30 mm and 7 mm increased edge

Technical ceramic material

Critical substances

Damaging

substances

Advantage

Disadvantage

Use

Weight

Total thickness

- None

- Hydrofluoric acid

- Best chemical resistance

- Mechanically stable

- Easy to dispose of

- Evenness tolerances due to firing process

- Thermodynamic stress limited

- Areas with very high chemical and

mechanical stress

56 kg/m

2

26 mm and 7 mm increased edge

Glass

Critical substances

Damaging

substances

Advantage

Disadvantage

Use

Weight

Total thickness

- None

- Hydrofluoric acid

- Flat

- High resistance to chemicals

- Sensitive to knocks at corners and

edges

- Laboratory benches of all types subject

to large amounts of chemicals

38 kg/m

2

30 mm

Stoneware compound worktop

Critical substances

Damaging

substances

Advantage

Disadvantage

Use

Weight

Total thickness

- None

- Hydrofluoric acid

- Flat

- Lighter than technical ceramic material

- Best chemical resistance

- Easy to dispose of

- Thermodynamic stress limited

- Areas with very high chemical stress

40 kg/m

2

30 mm and 7 mm increased edge

made of epoxy resin

32

Work benches

2.3 Mobile table

Mobile table

The rectangular worktop on our mobile tables

is fitted to a seamless WIG-welded precision

rectangular steel tube frame with four heavy

duty castors. The two front castors are

equipped with a full fixing device that simulta-

neously locks castors and steering axle.

Material worktop

Melamine resin coating on structural

element, self-supporting

Polypropylene coating on

particleboard base

Solid grade laminate

Stainless steel on particleboard base

Tiles on coated plywood board

Technical ceramic material

self-supporting

Technical ceramic material - compound

worktop on structural element

Epoxy resin self-supporting

Glass (safety glass ESG)

Marine edging

Marine edging

Marine edging

Marine edging

Marine edging;

Material increased edge: Epoxy resin

Marine edging

Mobile table

Working heights (mm)

Widths (mm)

Depths (mm)

Load capacity

720, 900

1200, 1500

750, 900

150 kg/m

2

Variants

Shelf fitted to bottom of frame

Suspended underbench units

Underbench units fitted onto bottom shelf

Edges and increased edge

2

33

Swing

2.4 Swing

The curved worktop on the Swing sits on a

4-leg frame. In combination with the Swing

two tables of different depth can be joined

together.

Material worktop

Melamine

Melamine with beech finish

Glass (safety glass ESG)

3mm polypropylene edge, 4-sides

3mm ABS edge, 4-sides

Edges

Swing

Working heights (mm)

Widths (mm)

Depths (mm)

Load capacity

720, 900

1200, 1500

600 / 750

675 / 825

750 / 900

200 kg/m

2

1

2

3

1

2

34

Work benches

2.5 Height adjustable table

Height adjustable table

The working height of the height adjustable

C-frame tables can be infinitely varied

between sitting working height (720 mm) and

standing working height (900 mm) using an

electric motor or a crank.

Material worktop

Melamine

Postformed

Melamine with beech finish

3mm polypropylene edge, 4-sides

3mm polypropylene edge on side and

rear

3mm ABS edge, 4-sides

Edges

Height adjustable table

Working height (mm)

Width (mm)

Depth (mm)

Load capacity

720 to 900

1500

750

70 kg/m

2

Height adjustable

table with electric

motor

1 Switch for electric

motor

2 Electric motor

3 Bench frame with

height adjustment

Height adjustable

table with crank

1 Crank

2 Bench frame with

height adjustment

2

35

Balance table

The balance table is used for analytical balances

and other sensitive measuring equipment.

A heavy slab of concrete is specially mounted

on a supporting construction.

The supporting construction for the slab is

vibration isolated from the outer worktop.

Material worktop

Melamine

Postformed

3mm polypropylene edge, 4-sides

3mm polypropylene edge on side and

rear

Edges

Balance table

Working height (mm)

Width (mm)

Depths (mm)

Width of the balance slab (mm)

Depth of the balance slab (mm)

Weight of the balance slab

Total weight of the balance table

720

900

750, 900

400

450

65 kg

120 kg

2.6 Balance table

36

Work benches

2.7 VarioTHEK

VarioTHEK

The VarioTHEK provides the ideal workplace

for laboratories as well as preparation rooms

for teaching and research.

This item can be variably equipped and is

supplied ready to plug into the service wing.

A waste water pump is integrated in the

underbench unit.

VarioTHEK

Working height (mm)

Width (mm)

Length (mm)

Height incl. castors (mm)

Worktop

Lighting

Electrical supply

Mechanical services supply

Weight

Fold down analysis table

Working height 720 mm

Suspended underbench units

900

825

1900

1920

Melamine resin with or without raised

drip cup arranged in the middle of the

bench

Variant

Stoneware compound worktop.

Integrated in the services transition

above the working area

Integrated in service modules on

request

Integrated in service panels for various

water, gases, pure and high purity

gases on request

Approx. 250 kg

Work surface beech finish

Various variants on request

2

37

Rack

Ideally suited for fitting items of equipment,

our rack is available with or without castors.

For analysis workplaces the rack is equipped

with the secretaire worktop.

Rack

Widths (mm)

Height (mm)

Depth (mm)

Widths, shelves (mm)

Depths, fixed shelves (mm)

Depths, extendable shelves (mm)

Load carrying capacity per shelf

Lad carrying capacity, total

Shelves

850, 1150

1746

677

800, 1100

440, 730

440

50 kg

150 kg

4 pieces

Material: coated OSB panels

Height adjustable in increments

of 45 mm

Optional

Powder-coated perforated plate

2.8 Rack

Analysis workplace secretaire

Widths (mm)

Depth (mm)

Load carrying capacity

800, 1100

900

50 kg/m

2

Material worktop secretaire

Melamine, colour grey

Melamine with beech finish

3 mm polypropylene edge, 4-sides

3 mm ABS edge, 4-sides

Edges

38

Work benches

2.9 Analysis tables

Assistant

The analysis workplace assistant is an addi-

tional swivelling table for 900 mm high and

750 mm deep add-on tables with 4-leg frame.

In the extended position the swivelling table

provides an additional, quarter circle shaped

work surface with a working height of

720 mm.

Assistant

Working height (mm)

Width (mm)

Depth (mm)

Load capacity

Worktop

720

695

672

30 kg/m

2

Melamine, colour grey or beech finish

The round table can be fitted to 4-leg add-on

tables.

It comprises a round worktop with a cut-out

and table leg.

Round table

Round table

Working heights (mm)

Diameter (mm)

Load capacity

Worktop

720, 900

1200

50 kg/m

2

Melamine, colour grey or beech finish

2

39

Add-on plate

The analysis workplace add-on plate is used as

an extra work surface for worktops (without

dished edges). It is fastened with an easy fixing

from below. The analysis workplace add-on

plate can be fitted to any mobile table or

mobile table without tools.

Oval

The analysis workplace oval provides an addi-

tional work surface at the front of the service

spine with double benches. The curved

worktop is fastened to the bench using two

supporting bearers fastened to the uprights

on the service spine.

Add-on plate

Width (mm)

Depth (mm)

Load capacity

Worktop

750

300

20 kg/m

2

Melamine, colour white

Thickness 19 mm

Oval

Working heights (mm)

Widths (mm)

Depth (mm)

Load capacity

Worktop

720, 900

1500, 1800

450

30 kg/m

2

Melamine, colour grey or beech finish

40

Skate

Work benches

2.9 Analysis tables

As a mobile unit the skate is used for the PC

tower at the analysis workplace. It comprises a

beech finish panel and a perforated plate side

wall.

The PC tower is fastened using a holding

strap.

Caddy

As a moveable printer table, the caddy is used

at the PC analysis workplace.

Skate

Width (mm)

Height (mm)

Depth (mm)

Base

215

467

450

Melamine resin with beech finish

Thickness 19 mm

Caddy

Width (mm)

Height (mm)

Depth (mm)

Top work surface

450

400

500

Melamine resin with beech finish

Thickness 30 mm

2

41

Laboratory sinks

Laboratory sinks are permanently installed

parts of the laboratory furniture and are

placed either against a wall or a service spine.

The sinks can be fitted to the service spine

along the laboratory bench or as end sink units

on double work benches.

The sinks can be manufactured from

polypropylene, stainless steel, epoxy resin or

technical ceramic material. On worktops made

of technical ceramic material and polypropy-

lene, the sinks are fitted from below. On work-

tops with tiles, or made of epoxy resin or

melamine, the sinks are inserted from above.

As standard underbench units with hinged

doors and plinths are used.

2.10 Sink work benches

Material worktop

Technical ceramic material

Tiles*

Melamine resin*

Melamine resin*

Polypropylene*

Stainless steel*

Technical ceramic material

Compound worktop

Epoxy resin

* Work surfaces also available by the metre.

Technical ceramic material

Technical ceramic material

Polypropylene

Stainless steel

Polypropylene

Stainless steel

Technical ceramic material

Epoxy resin

Options

Wide range of different versions

for water bench mounted service

outlets

Eye shower

Draining rack

The following dimensions are available for worktops

Widths (mm)

Depths (mm)

900, 1200, 1500, 1800

600, 675, 750, 825, 900

500 x 400 x 250 (W x D x H) and

400 x 400 x 250 (W x D x H)

460 x 360 x 330 (W x D x H) and

360 x 360 x 330 (W x D x H)

500 x 400 x 250 (W x D x H) and

400 x 400 x 250 (W x D x H)

500 x 400 x 250 (W x D x H) and

340 x 370 x 160 (W x D x H)

500 x 400 x 235 (W x D x H) and

400 x 400 x 235 (W x D x H)

500 x 400 x 250 (W x D x H)

510 x 360 x 265 (W x D x H) and

360 x 360 x 265 (W x D x H)

457 x 381 x 279 (W x D x H) and

406 x 406 x 190 (W x D x H)

On request

On request

On request or see Internet

accessories catalogue

Sinks bonded to the worktop

from below using silicon and also

secured with steel straps

Sinks fitted flush with worktop

and also secured with steel straps

Sinks with beading fitted in the

worktop from above

Sinks with beading fitted in the

worktop from above

Sinks fitted in the worktop from

below and welded

Sinks welded flush with worktop

Sinks fitted flush with worktop

Sinks fitted flush with worktop

Material sinks Sink dimensions i. L. (mm) Type of installation

42

Sink modules

Work benches

2.10 Sink work benches

Sink modules are primarily used as end sink

units on double work benches but can also be

fitted along the laboratory bench.

The sink module and the adjacent work

surfaces on the end sink unit are made of

glazed, acid-proof technical ceramic material.

A polypropylene splash bench runs along the

entire width behind the sink module and the

adjacent work surfaces.

As standard underbench units with hinged

doors and plinths are used.

Sink modules for head sink unit

Head sink unit standard width 1500 mm

Width (mm)

Depth (mm)

600

710

Head sink unit standard width 1800 mm

Width (mm)

Depth (mm)

900

710

Adjacent work surface left and right for standard width 1500 and 1800 mm

Width (mm)

Depth (mm)

450

670

Sink height (mm)

Thickness of the splash protection

panel (mm)

made of grey polypropylene

300

10

Sink modules for service spine and as sink to stand against walls

Sink module in front of service spine with depth 750 mm

Widths (mm)

Depth (mm)

Sink module in front of service spine with depth 900 mm

Widths (mm)

Depth (mm)

Sink module as sinks to stand against walls

Widths (mm)

Depth (mm)

Sink height (mm)

600, 900

710

600, 900

860

600, 900

785, 935

300

2

43

Drip cups

Drip cups are integrated in the service spine

or fitted in the worktop.

Material drip cups

Polypropylene

Technical ceramic material

270 x 82 x 113 (W x D x H)

260 x 82 x 108 (W x D x H)

Sink dimensions i. L. (mm)

Drip cups for service spines

Drip cups for fitting in worktop

Material worktop

Melamine resin;

Polypropylene

Polypropylene

Technical ceramic material;

Tiles

Melamine resin

Stainless steel

Epoxy resin

Technical ceramic material

Compound worktop

Variants:

various different versions for water fittings on request

Polypropylene

Polypropylene

Technical ceramic material

Stainless steel

Stainless steel

Epoxy resin

Technical ceramic material

Material drip wastes Sink dimensions i. L. (mm)

255 x 105 x 150 (W x D x H)

255 x 105 x 140 (W x D x H)

250 x 95 x 112 (W x D x H)

240 x 80 x 120 (W x D x H)

240 x 80 x 120 (W x D x H)

246 x 95 x 180 (W x D x H)

245 x 95 x 150 (W x D x H)

Type of installation

Sinks with beading fitted in the

worktop from above

Sinks fitted to the worktop from

below and welded

Sinks with beading fitted in the

worktop from above

Sinks with beading fitted

in the worktop from above

Sinks welded flush with worktop

Sinks fitted flush with worktop

Sinks with beading fitted flush in

the worktop from above

44

Sink station

Work benches

2.11 Mobile sinks

Mobile sinks with castors supplement

the variable configuration of the laboratory

in conjunction with the service wing.

The mobile sinks are connected to the Waldner

service wing or teachers desk using flexible

pipes.

A pump removes the waste water via the

service wing.

Sink station

Material worktop and sink

Optional

Polypropylene

Boiler (not for standard width 600 mm)

Widths (mm)

Depth (mm)

Height, underbench unit

incl. castors (mm)

Widths, sinks (mm)

Depth, sinks (mm)

Height, sinks (mm)

Load carrying capacity per castor

Height, castor (mm)

600, 900, 1200

600

900

400, 500

400

300

70 kg

80

Lengths, feed and waste pipes (mm)

Lengths, power connecting cables (mm)

2500

2500

2

45

The ready to plug-in compact system for the

supply and disposal of water can be used on

mobile or fixed laboratory benches and

connected to the Waldner service wing using

flexible pipes.

A pump removes the waste water via the

service wing.

AquaEl

AquaEl

Material housing and sink Epoxy resin

Width (mm)

Depth (mm)

Height (mm)

Weight (incl. pipes)

304

500

480

11 kg

Lengths, feed and waste pipes (mm)

Lengths, power connecting cables (mm)

2500

2500

47

Fume cupboards and exhaust devices

3.1 Bench mounted fume cupboards

3.2 Low ceiling bench mounted fume cupboards

3.3 Low level fume cupboards

3.4 Walk-in fume cupboards

3.5 Secuflow low volume bench mounted fume cupboards

3.6 Secuflow low ceiling bench mounted fume cupboard

3.7 Bench mounted fume cupboards with side panels

3.8 Low ceiling bench mounted fume cupboards

with side panels

3.9 Special application fume cupboards

3.10 Filter fume cupboards

3.11 Radio-isotope fume cupboards

3.12 Mobile fume cupboards

3.13 Local exhaust ventilation

3.14 Monitoring and control

The requirements on laboratory

fume cupboards in relation to

work safety, ease of use and

economy have significantly

increased, not least due to the

new EN 14175.

Waldner fume cupboards, irre-

spective of the type, provide

highly innovative technology

for every type of laboratory,

and that way beyond the levels

required in the standards.

3

48

Fume cupboards and exhaust devices

General

Fume cupboards are a key ele-

ment in laboratories. All work

during which gases, fumes,

particles or liquids are handled

in dangerous quantities and

concentrations must be per-

formed in fume cupboards.

Our fume cupboards, irrespec-

tive of the type and version,

ensure maximum safety, excel-

lent ergonomics and maximum

economy.

During the development of our

fume cupboards, many years of

design know-how are accom-

panied by scientific findings

our designs are not based on

the example of others. Numer-

ous patents demonstrate our

technical lead. All Waldner

fume cupboards of course

comply with the requirements

of EN 14175.

As an important part of the

overall laboratory ventilation

scheme, our fume cupboards

can be integrated into the

building ventilation concept.

The fact that our Secuflow

fume cupboard technology

also reduces the overall costs

for the ventilation system is a

commercial advantage that

cannot be ignored and that is

made possible by the inte-

grated supportive flow technol-

ogy. You will find further infor-

mation on this topic at

www.waldner-lab.com.

Our in-house certified test

laboratory for fume cup-

board measurements

Previously the effectiveness of

fume cupboards was defined

by the extract volume flow

rates. With the re-publication

of DIN 12924 Part 1 in 1991, a

limit for the leakage of test gas

was defined instead. In this

way it was intended to facili-

tate innovations, particularly in

relation to energy saving via a

reduction in the extract volume

flow rates.

Our test facility, which had

already been in existence for

many years and that had been

setup for studies on fluid

mechanics and the optimisa-

tion of fume cupboards, was as

a result expanded to form a

test laboratory for ventilation

engineering tests according to

DIN 12924 Part 1 in 1991. Over

the last somewhat more than

10 years, over 150 different

types of fume cupboard have

been type tested in this test

facility.

On the publication of EN

14175 we setup our new test

laboratory for fume cup-

boards. The latest technical

equipment and the GS certifi-

cation via TV Product Service

GmbH guarantee the best

measurement results in rela-

tion to accuracy and repro-

ducibility.

In two independent test cham-

bers it is possible to independ-

ently test two fume cupboards

in parallel due to the duplica-

tion of equipment.

3

49

We test fume cupboards to

the old standards DIN, BS

(UK), and AFNOR (France), as

well as to the new European

EN 14175 that will replace the

previous national standards.

Furthermore, we can also per-

form measurements according

to ASHRAE 110/1995 as are

often required by customers

based in the USA.

Anybody who designs, builds

and tests fume cupboards has

a major responsibility. Not

least to the staff in the labora-

tory whose health depends on

the safe and reliable operation

of the fume cupboards.

Beyond our ISO 9001:2000

certification and the GS mark-

ing for our entire product

range, we have closed the

loop in relation to fume cup-

board tests and had our new

test laboratory tested and cer-

tified by TV Product Service

GmbH according to the Ger-

man law on equipment safety

(Gertesicherheitsgesetz). As a

result the first certified test

laboratory for fume cupboards

in Europe is in Wangen im All-

gu. Visitors are welcome at

any time.

Safety via the patented

intake airflow profile on

the front edge of the fume

cupboard worktop

It prevents turbulence that

could carry pollutant emissions

in the direction of the user in

the laboratory.

Air flowing into the fume cup-

board is guided via the airfoil-

like profile geometry (with low

turbulence over the worktop)

to the rear panel low level

extraction which ensures the

safe removal of heavy gases,

e.g. solvent fumes.

The technology in the new Waldner test laboratory:

Two independent ventilation systems incl. cooling and

heating for supply air and extract air with a flow rate of

2,500 m

3

/h each

Input air either via ceiling ventilation or supply air outlets

of varying design

Pressure and air quantity conditions in the test chamber

variably adjustable using high resolution ventilation control

technology

Temperature conditions variably adjustable, from isother-

mal to the simulation of various temperature gradients in

the chamber

Reference air exchange rate determination according to

DIN 1952 and VDI 2080

Calibrated test gas control

Transducers with electronic data acquisition

Data analysis and documentation using PC software

Clear view of all processes in

the workspace

The high level glazed panel

enables the experimental

equipment and processes to

be clearly seen.

We offer the best possible

utilisation of the working

width The slender, patented

fume cupboard side posts,

only 25 mm wide, provide the

maximum workspace width

and due to their special shape

ensure that there is little tur-

bulence in the intake air.

50

The removable panels with

perimeter extraction in the

fume cupboard rear panel

provide maximum grouping

of services

In this way we ensure that

mechanical and electrical serv-

ices can be quickly and eco-

nomically changed or

upgraded.

For more safety and

economy

Maximum user safety is pro-

vided by our toothed belt sash

mounting along with signifi-

cantly reduced maintenance

effort. The stainless steel rein-

forced toothed belts also pro-

vide the supply of electrical

power and signals to the

photo-electric barrier in the

moving sash.

Endurance tests with more

than 200,000 load cycles ver-

ify that this mounting is at

least ten-times more resistant

to load changes compared to

a conventional steel rope

mounting.

The track mechanism also

provides additional safety

In the unlikely case that both

sash mountings fail, the sash

is stopped in fractions of a

second.

All functions at a glance

The control switch and dis-

plays integrated into the fume

cupboard side posts provide

information on the operational

state of the fume cupboard at

the ideal eye height.

Sash handle with aero-

dynamic design the air frows

into the workspace when the

sash is opened and pollutant

emissions due to the opening

sash are prevented. The bal-

anced and free-moving sash

mechanism including the

release for the sash stop can

be operated with one hand.

The motion detector

The sash is closed automati-

cally if there is nobody work-

ing at the fume cupboard.

The photo-electric barrier

stops the closing process if

there are objects protruding

from inside the workspace.

Cost saving due to exten-

sive pre-assembly

The factory pre-assembly and

testing of our fume cupboards

enable them to be very quickly

installed on-site.

Due to the easy to maintain

design, all components are

quick and easy to access when

required.

During installation, servicing

and maintenance, our trained

installation and service person-

nel ensure that everything

goes smoothly and quickly.

Fume cupboards and exhaust devices

General

3

51

The best for equipment

and variability

Along with the convenient

basic equipment, our fume

cupboards provide a wide

range of variable equipment

options.

Depending on the application,

the worktop is made of tech-

nical ceramic material, tiles,

epoxy resin, polypropylene or

stainless steel, and is quick

and easy to replace.

Our fume cupboards have a

self-supporting structure. You

can install under the fume

cupboard, plinth mounted,

mobile or metal solvent

cabinets.

The integrated service panels

installed in the rear panel are

quick to replace, in addition

the sink module integrated

into the rear panel provides

more freedom in the use of

the work surface.

All control elements for our

fume cupboards are designed

for ease of use along with the

maximum possible safety for

the user.

5

4

3

2

1

6

7

8

9

10

11

52

Bench mounted fume cup-

boards according to EN 14175

prevent fumes, aerosols and

dusts escaping into the labora-

tory in dangerous quantities or

concentrations.

The following substances are

not approved for use in bench-

mounted fume cupboards:

Radioactive substances

Microorganisms

Genotype modified substances

Bench mounted fume cup-

boards are not suitable for pulp-

ing works. This instruction also

applies to bench mounted fume

cupboards with ceramic liner.

Fume cupboards and exhaust devices

3.1 Bench mounted fume cupboards

Fume cupboard EN 14175

1 Sash handle

2 Worktop

3 Display and

operating device

4 Upper sash

window

5 Fascia panel

6 Extract-air

manifold

7 Baffle with

integrated service

panels

8 Vertical sash

9 Glazed side panel

10 Cable through-

put

11 Service module

1200 1500 1800 mm 900 mm

W

H

9

0

0

m

m

E

x

t

r

a

c

t

a

i

r

c

o

n

n

e

c

t

i