1.

Introduction:

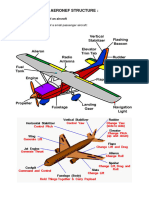

The Technological process being designed is for a Rib of an aircraft wing. Ribs are generally

the forming elements of the structure of a wing. They are attached to the main spar of the wing

and are repeated at frequent intervals. They form the skeletal part of the wing. Ribs are usually

used to incorporate the airfoil shape of the wing and the skin adopts this shape.

Technological operations of assembly are a set of procedures being performed by a worker or

automatically on the successive installation of assembly units in space their locking and

connecting to each other according to the drawing or the technical conditions of the production

instruction. The technological process of installation is a combination of procedures on installing

or arranging on the assembly units (on the panel, unit, compartment, aggregate) of the aircraft

and helicopter airframe the objects of equipment, instruments, power plants (PP), landing gear,

control linkages electrical equipment communications (ESE), hydropneumatic systems, control

systems and other functionally autonomous blocks with their following fixing to the elements

of the load-carrying scheme of the airframe.

�2. Sequence of Assembling:

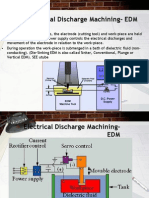

a) The manufacturing of the parts by different methods: machining, sheet forming and die

forging, casting; electrochemical and electrophysical methods, etc. The main groups of

the aircraft and helicopter parts are: outer skins; shells; stringers; ribs, frames and

longerons parts; monolithic panels; attachment fittings and joining elements; parts of

pipelines, landing gear, control systems, etc.

b) The assembly of units and panels: frames, ribs, spar, etc. The main method is a jointed

parts into units, are: riveting, welding, gluing soldering, bolted and screwed joints.

�3. METHOD OF ASSEMBLING:

The assembly with basing on the reference holes is contained in fulfillment setting of the

assembly units in correct relative position by means of registration of the special reference holes

(AH, CFH, BFH, AFH) on the basic parts, units, sections or on the assembly devices fixtures

with following their stiff connection by the dummy fasteners.

The employment of the holes as assembling bases demands no only of the basic holes correct

position into space, but and their specific position as regards to the parts contours. The parts

including into assembling complete as well as the devices base-fixing elements can be by the

carriers of the reference holes.

Depending on this two principle assembly schemes are possible:

1. The assembly by base-holes, situated on the parts or units, which assume as the bearing ones

and on them are installed all structure elements registering the proper holes (the assembly by AH

and by BFH).

2. The assembly by base-holes, situated on the special base-fixing units of the assembly device.

Such base-fixing units serve for setting and fixing of the assembling parts (the assembly by

CFH).

The generalized term adjusting-fixing holes (AFH) is accepted for all categories of abovementioned holes, as all reference holes are intended for right setting and fixing of the assembly

units in given position.

The classification of assembly methods by AFH is shown in figure.

�The assembly in a device with basing on an external surface of a skin should be applied at

assembly of a design with complex configuration of outlines, the small rigidity and with the high

requirements to accuracy of the aerodynamic forms. Especially it concerns assembly of wings

and their parts, when the transversal framework is joined with a skin through compensators and

the wing is dismembered into the panels.

The assembly by assembling holes (AH) received the widespread for manufacture of the flat

form and simple curvature units and panels. In this method mutual position of the assembled

parts is determined by coincidence of the coordinated AH, which in advance are done with the

help of the coordinated templates. The basing on the AH is possible at assembly of the A and H

framework and skin parts as well as of the product inner equipment objects, when a demanded

accuracy of the assembly not exceeds by 1,5 mm.

The assembly by AH considerably concedes by accuracy of the forms and sizes to the previous

methods, but on the assumption of qualitative coordination of a working storing rigging for

copying of AH on assembled parts, in particular at volumetric coordination of the templates for

drilling (TCC), it can be applied as to flat units (such as spars, frames, ribs), so and for

volumetric frame units and panels of unary curvature. This method of assembly allows to lower

the cost price and labor input of the AMW, to refuse from devices. The method is applied with

success for any types of manufacture.

The assembly by coordinate-fixing holes (CFH). The preferable field of application this

method of assembly are products, in the structure of which there are the stiff parts of

framework (ribs, frames, spars) with 83 holes which are accepted as basic holes. These CFH are

done into stiff

parts and on the fixtures beforehand and then install and fix of the framework parts coinciding

the CFH with the help of technological class pins. The CFH are disposed on the flat surfaces and

can be given.

The assembly by CFH is applied for sections of unary curvature and of double unique and

reversed curvature and also for compartments formed by cylindrical, elliptical and conical

surfaces. Such assembly simplifies a design of jigs and essentially improves the economic

indexes of the AMW, but it can be used for aggregates with the prearranged accuracy

on outlines not below 1,82,5 mm.

�The assembly by base-fixing holes (BFH).

At this assembly method one or a few of the most stiff units of section (aggregate or

compartment) structure are accepted as basic ones and they are installed in the prearranged

position into the assembling device. The installation on the basic units of supplied units and parts

fulfill by BFH of the base unit, coinciding the corresponding BFH on the installed units and parts

(see fig. 5.4). The BFH are placed on planes and outlines of the connected assembly units. On the

fig. 5.4 a wing torsion box is assembled by BFH; here the longerons, into struts of which

drilled the BFH for ribs, were chosen as the main base units. The panels are based by BFH too.

The errors of outlines and the ribs contours will depend on the errors of the longerons basing into

device and the errors of the ribs and panels basing by BFH. The assembly by BFH ensures the

reduction of an assembly cost and the possibility to use the jigs of simplified structures.