0% found this document useful (0 votes)

555 views21 pagesAssembly Line Design Final

This document discusses assembly line design. It provides details on:

- What is an assembly line and why they are used

- The types of assembly lines including single model, multi-model, and multi-variant

- The objectives of assembly line design such as minimizing work imbalance and idle time

- Methods for data collection, task grouping and assignment, and mathematical modeling to design the optimal assembly line layout

- Key performance measures to evaluate the assembly line design such as line efficiency, balance delay, and output per day.

Uploaded by

Manas RaneCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

555 views21 pagesAssembly Line Design Final

This document discusses assembly line design. It provides details on:

- What is an assembly line and why they are used

- The types of assembly lines including single model, multi-model, and multi-variant

- The objectives of assembly line design such as minimizing work imbalance and idle time

- Methods for data collection, task grouping and assignment, and mathematical modeling to design the optimal assembly line layout

- Key performance measures to evaluate the assembly line design such as line efficiency, balance delay, and output per day.

Uploaded by

Manas RaneCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Introduction: Introduces the assembly line design project including contributors and an image of the setup.

- What is an Assembly Line?: Defines what an assembly line is and explains its purpose in manufacturing for efficiency and productivity.

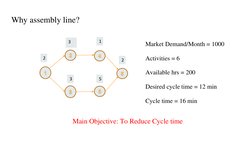

- Why Assembly Line?: Explains the purpose of the assembly line including factors like market demand and cycle time.

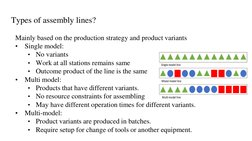

- Types of Assembly Lines: Explores different models of assembly lines such as single model, multi model, and their characteristics.

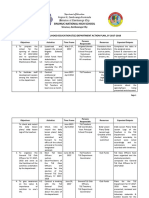

- Objectives and How to Achieve?: Discusses the objectives of assembly line optimization and methods for achieving them.

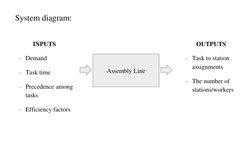

- System Diagram: Presents a system diagram showing inputs and outputs of the assembly line process.

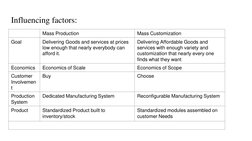

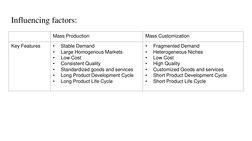

- Influencing Factors: Analyzes the factors influencing mass production and mass customization with comparisons.

- Data Collection Methods: Lists the data collection methods relevant to managing an assembly line effectively.

- Rank Positional Weights Method: Describes the technique of ranking positional weights in the distribution of work elements along a line.

- Mathematical Modeling: Presents mathematical modeling with precedence diagrams and calculations for optimizing cycle times.

- Pictorial View of Final Assembly Line: Provides a visual illustration of the finalized assembly line layout.

- Performance Measures: Evaluates line performance by metrics like efficiency, balance delay, and output ratios.

- Conclusion: Offers final thoughts on the interplay between cycle time, workstations, and output levels.

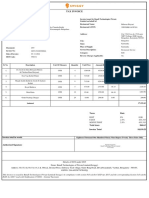

- Pizza Operations: Details an example assembly line setup for producing pizzas with task timings and flow diagram.

- Acknowledgements: Expression of thanks and acknowledgment at the end of the document.