0% found this document useful (0 votes)

752 views18 pagesAEi Reliability Report Example PDF

Uploaded by

T/ROXCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

752 views18 pagesAEi Reliability Report Example PDF

Uploaded by

T/ROXCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

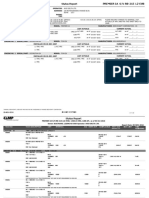

- Scope: This section outlines the scope of the analysis including a summary of the methods used and results obtained.

- Functional Description: Describes the components involved in the analysis, including passive and active devices, with technical specifications.

- Assumptions: Lists the assumptions made in the analysis process regarding environmental and operational factors.

- Quality and Reliability in the Design Process: Discusses how quality assurance and reliability were integrated into the design process of the components.

- Component Approval and Qualification: Explains partnership strategies and component approval processes to ensure product quality and reliability.

- Methods of Analysis: Describes the statistical methods and procedures used to analyze component reliability.

- Analysis Results: Presents results from the reliability analysis including failure rates and contributing factors.

- Conclusions and Recommendations: Summarizes findings and offers recommendations based on component analysis results.