100% found this document useful (1 vote)

5K views3 pagesGrinder Checklist2

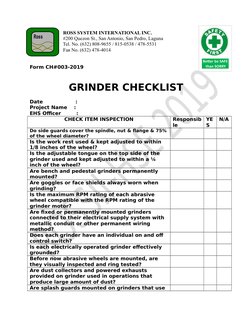

This document contains a checklist for inspecting grinders. It lists various safety items that should be checked, including ensuring guards cover the grinding wheel, work rests are properly adjusted, and goggles are worn. It also checks that grinders are properly grounded, wheels are inspected before use, and dust collection systems are used as needed. A second section provides a portable grinder inspection checklist to document the inspection of specific grinders in the company each month.

Uploaded by

jovyCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

5K views3 pagesGrinder Checklist2

This document contains a checklist for inspecting grinders. It lists various safety items that should be checked, including ensuring guards cover the grinding wheel, work rests are properly adjusted, and goggles are worn. It also checks that grinders are properly grounded, wheels are inspected before use, and dust collection systems are used as needed. A second section provides a portable grinder inspection checklist to document the inspection of specific grinders in the company each month.

Uploaded by

jovyCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd