STORE INVENTORY MANAGEMENT SOP

INTRODUCTION

This section covers the Store Inventory procedures of the Company.

Next to cash, inventory is very susceptible to pilferage and mismanagement.

Majority of the assets of any company is devoted into inventory so an overstocked

inventory or non-moving item can easily hurt the financials of the Company.

That’s why proper control should be implemented when managing inventory,

especially in stores where it’s harder to monitor. The procedures enumerated in

this Manual can help the Company become more effective and efficient in its

inventory management.

COVERAGE

This Simplified Standard Operating Procedure (SOP) covers the following key

areas:

1. Inventory Ordering – including ordering procedures and ordering flow.

2. Inventory Receiving – including delivery acceptance standards, inspection

procedures, and damage report.

3. Inventory Management – including computing minimum stock level,

inventory turnover, and performing daily and monthly inventory reports.

Company Name

Company Address

Contact Numbers

www.website.com

� STORE INVENTORY MANAGEMENT SOP

ORDERING INVENTORY

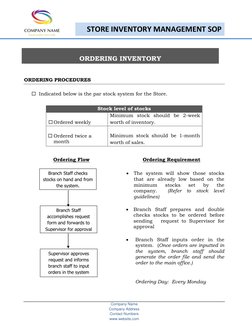

ORDERING PROCEDURES

Indicated below is the par stock system for the Store.

Stock level of stocks

Minimum stock should be 2-week

Ordered weekly worth of inventory.

Ordered twice a Minimum stock should be 1-month

month worth of sales.

Ordering Flow Ordering Requirement

Branch Staff checks The system will show those stocks

stocks on hand and from that are already low based on the

the system. minimum stocks set by the

company. (Refer to stock level

guidelines)

Branch Staff Branch Staff prepares and double

accomplishes request checks stocks to be ordered before

form and forwards to sending request to Supervisor for

Supervisor for approval

approval

Branch Staff inputs order in the

system. (Once orders are inputted in

Supervisor approves

the system, branch staff should

generate the order file and send the

request and informs

order to the main office.)

branch staff to input

orders in the system

Ordering Day: Every Monday

Company Name

Company Address

Contact Numbers

www.website.com

� STORE INVENTORY MANAGEMENT SOP

Main office receives and The Main Office will load the order

loads the order in the file and prepare the stocks.

system.

Based on the delivery lead-time, the

order will be delivered to the

branches.

Lead time to deliver: 3 days

Company Name

Company Address

Contact Numbers

www.website.com

� STORE INVENTORY MANAGEMENT SOP

INVENTORY RECEIVING

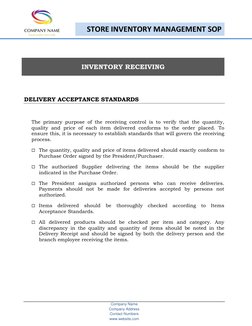

DELIVERY ACCEPTANCE STANDARDS

The primary purpose of the receiving control is to verify that the quantity,

quality and price of each item delivered conforms to the order placed. To

ensure this, it is necessary to establish standards that will govern the receiving

process.

The quantity, quality and price of items delivered should exactly conform to

Purchase Order signed by the President/Purchaser.

The authorized Supplier delivering the items should be the supplier

indicated in the Purchase Order.

The President assigns authorized persons who can receive deliveries.

Payments should not be made for deliveries accepted by persons not

authorized.

Items delivered should be thoroughly checked according to Items

Acceptance Standards.

All delivered products should be checked per item and category. Any

discrepancy in the quality and quantity of items should be noted in the

Delivery Receipt and should be signed by both the delivery person and the

branch employee receiving the items.

Company Name

Company Address

Contact Numbers

www.website.com

� STORE INVENTORY MANAGEMENT SOP

RECEIVING DELIVERIES

Receiving Flow Receiving Requirements

A delivery receipt will be

generated for every delivery The Warehouse Dept. delivers stocks

to the branch

Delivery Crew gives copy of Branch Staff receives delivery receipt

delivery receipt to

authorized Branch Staff for

the list of deliveries

Branch staff should check the

delivered stocks and ensure that

Prior to acceptance of they are complete and in good

orders, the Branch Staff condition.

must thoroughly inspect the

goods for any defects /

discrepancies Once delivered items are ok, Branch

Staff uploads the “receiving file”.

After uploading, the Branch Staff can

Branch Staff uploads the generate inventory receiving report

receiving file to receive the from the system.

stocks in the system

automatically.

Company Name

Company Address

Contact Numbers

www.website.com

� STORE INVENTORY MANAGEMENT SOP

INSPECTION PROCEDURES

Verify contents of ordered packages or boxes.

Check integrity of materials / supplies delivered. Materials / supplies

should have manufacturer’s packaging seal or tamper proof seal unbroken.

Inspect expiration dates.

Store new deliveries behind old deliveries.

Proper storage of products received:

a. FIFO policy

b. No overloading in shelves.

c. Proper temperature maintained.

Update or create new records.

Company Name

Company Address

Contact Numbers

www.website.com

� STORE INVENTORY MANAGEMENT SOP

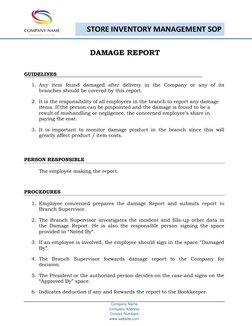

DAMAGE REPORT

GUIDELINES

1. Any item found damaged after delivery in the Company or any of its

branches should be covered by this report.

2. It is the responsibility of all employees in the branch to report any damage

items. If the person can be pinpointed and the damage is found to be a

result of mishandling or negligence, the concerned employee’s share in

paying the cost.

3. It is important to monitor damage product in the branch since this will

greatly affect product / item costs.

PERSON RESPONSIBLE

The employee making the report.

PROCEDURES

1. Employee concerned prepares the damage Report and submits report to

Branch Supervisor.

2. The Branch Supervisor investigates the incident and fills-up other data in

the Damage Report. He is also the responsible person signing the space

provided in “Noted By”.

3. If an employee is involved, the employee should sign in the space “Damaged

By”.

4. The Branch Supervisor forwards damage report to the Company for

decision.

5. The President or the authorized person decides on the case and signs on the

“Approved By” space.

6. Indicates deduction if any and forwards the report to the Bookkeeper.

Company Name

Company Address

Contact Numbers

www.website.com

� STORE INVENTORY MANAGEMENT SOP

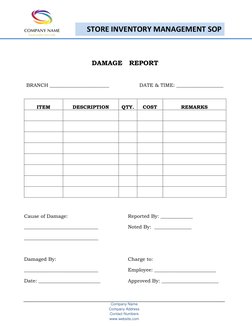

DAMAGE REPORT

BRANCH ________________________ DATE & TIME: ___________________

ITEM DESCRIPTION QTY. COST REMARKS

Cause of Damage: Reported By: _____________

______________________________ Noted By: _______________

______________________________

Damaged By: Charge to:

______________________________ Employee: _________________________

Date: _________________________ Approved By: _______________________

Company Name

Company Address

Contact Numbers

www.website.com

� STORE INVENTORY MANAGEMENT SOP

INVENTORY MANAGEMENT

Inventories include tangible products / supplies owned by the Company.

POLICIES

The Company and its branches are to undertake required inventory for proper

accounting and stock monitoring of its raw materials and supplies. Inventory is

undertaken by the branch staff with the supervisor.

Monthly and yearly inventory taking are to be headed by the Bookkeeper-

Accountant and the Branch Supervisor. They are assisted by the branch

staff.

For every loss, damaged product, a report shall be prepared and a copy will

be furnished to the President for his/her decision as to whether to charge it

to the company or to the employee concerned.

Minimum stock level / Ordering Quantity for each inventory item shall be

clearly decided upon by the President at the start of its operation.

Any other existing system of reports, forms, and procedures implemented in

the Branch should be in compliance with the Company Policy.

Company Name

Company Address

Contact Numbers

www.website.com

� STORE INVENTORY MANAGEMENT SOP

GUIDELINES

Items / products and other supplies is purchased from the Authorized

Suppliers and sold for a profit. To keep a profitable business, all products must

be available at all times for customer purchase.

Inventory Management involves:

Performing a “stock count”

All stocks must be accounted for. Everything that comes in and goes

out must be recorded.

Maintaining proper inventory records

Stock Card

Simple index cards

Kept for each item in stock

Determining when to re-order

Re-order when inventory reaches the minimum stock level

Terminology

Minimum stock - Amount of stock required to support branch

operations until additional supplies are received

Lead time – Time between placing an order and receiving it

Maximum usage – number of item/products sold in a given time

period

Company Name

Company Address

Contact Numbers

www.website.com

� STORE INVENTORY MANAGEMENT SOP

Calculating Minimum Stock Level

Minimum Stock Level = Maximum lead time in weeks

X Maximum Usage

EXAMPLE:

Maximum lead time = 2 weeks

Maximum usage/wk = 3 packs

Minimum stock level = 2 x 3 = 6 packs

When only 6 packs are left, place an order

Determining how much to re-order

Establish proper full stock level. Re-order to reach that level.

Never order more than your storage space can hold.

Never order more supplies than you can use before they expire.

Consider maximum usage plus minimum stock level.

Consider delivery time and costs when placing orders.

Placing orders properly

Inspecting delivery of new orders

Ensuring proper storage of inventory

Keep in a clean, organized, and locked storeroom / cabinet.

Store according to manufacturer’s instructions.

Place in well ventilated room.

Company Name

Company Address

Contact Numbers

www.website.com

� STORE INVENTORY MANAGEMENT SOP

Store away from direct sunlight.

Place items on shelves.

STORAGE GUIDELINES (to follow)

Currently, stocks are stored by type, e.g. all ink systems are grouped together

by model.

IAYC is still developing a warehousing or storage standards.

PRODUCTS – STOCK LEVEL

2 weeks Min. stock

Items par stock level for

level re-ordering

Bottled Inks

Epson:

Black

Cyan

Magenta

Yellow

Light Cyan

Light Magenta

Canon:

Black

Cyan

Magenta

Yellow

Brother:

Company Name

Company Address

Contact Numbers

www.website.com

� STORE INVENTORY MANAGEMENT SOP

Black

Cyan

Magenta

Yellow

Compatible Ink Cartridges:

73n Compatible K

73n Compatible C

73n Compatible M

73n Compatible Y

LC 38 Compatible K

LC 38 Compatible C

LC 38 Compatible M

LC 38 Compatible Y

Printer Package:

Canon IP2770 (Single

Function)

Canon MP287 (Multi Function)

Brother MFC-J3220 (Multi

Function)

4 in 1

Company Name

Company Address

Contact Numbers

www.website.com

� STORE INVENTORY MANAGEMENT SOP

INVENTORY TURNOVER

Inventory turnover measures the time inventory is used over a certain

period of time. Products and supplies bought at the start of the month

should be used within the month. Turnover means usage of inventory

products for sale in the branch. When inventory is not readily used, it

results to the following:

Items stocked for long period result to damage. Damage products

increases product cost since purchases are not converted to sales.

Cash is tied up to inventory.

Labor cost increases due to employees maintaining storage.

Excessive inventory requires space and rentals. This does not

maximize space usage.

Unwarranted opportunities for theft.

This ratio reveals how well inventory is managed. It is important because

the more times inventory can be turned over a given operating cycle, the

greater the profit. The Inventory Turnover Ratio is calculated as follows:

Inventory Turnover Ratio = Net Sales / Average Inventory at Cost

FREQUENCY

As stated above, Inventory taking at the branch is done on a daily, monthly,

and yearly basis.

Refer to the above policies on the persons in charge of inventory taking and

Company Name

Company Address

Contact Numbers

www.website.com

� STORE INVENTORY MANAGEMENT SOP

its authorized signatories.

The year-end inventory taking is necessary for government reportorial

requirements and year-end Company Report.

Company Name

Company Address

Contact Numbers

www.website.com

� STORE INVENTORY MANAGEMENT SOP

DAILY INVENTORY REPORT

PURPOSE

To monitor daily movement of the following:

Products and items in the cabinet.

Products and items in the counter area.

COPY DISTRIBUTON

1st copy (Bookkeeper-Accountant)

2nd copy Branch File Copy

PERSON RESPONSIBLE

Assigned employee

PROCEDURES

1. Branch Staff is responsible of preparing this report.

2. Branch Staff updates the inventory in the computerize inventory system.

3. Branch Staff conducts actual count of items using the scan bar code.

4. Forward this report to Supervisor.

5. Forward to Bookkeeper or Company office

Company Name

Company Address

Contact Numbers

www.website.com

� STORE INVENTORY MANAGEMENT SOP

DAILY INVENTORY REPORT

BRANCH DATE & TIME:

__________________________ ___________________

MIN. DIFF.

ITEM DESCRIPTION QTY. REMARKS

STOCK

Prepared By: Approved By:

______________________________ ________________________________

Date: _________________________ Date: _______________________

Company Name

Company Address

Contact Numbers

www.website.com

� STORE INVENTORY MANAGEMENT SOP

MONTHLY INVENTORY REPORT

COPY DISTRIBUTION

1st copy (Bookkeeper-Accountant)

2nd copy Branch File Copy

PERSON RESPONSIBLE

Branch Staff and Bookkeeper

PROCEDURES

1. Branch Supervisor and Bookkeeper are the persons responsible for the

Monthly Inventory Report.

2. Under the caption “ITEM”, list the items subject to monthly count.

3. In the column “ENDING INVENTORY” indicate the remaining quantity of

stocks at the end of the month. Based on Daily Inventory Tracking or

stock card.

4. For all areas stated above, “PHYSICAL / ACTUAL COUNT” means the

verified or physical count of stocks at the end of the month as witnessed

by the Accountant/Bookkeeper.

5. “VARIANCE” means the difference between the “ENDING INVENTORY”

(per record) and the “PHYSICAL / ACTUAL COUNT”.

6. Report to be certified by the Bookkeeper.

Company Name

Company Address

Contact Numbers

www.website.com

� STORE INVENTORY MANAGEMENT SOP

MONTHLY INVENTORY REPORT

BRANCH DATE & TIME:

_________________________ ___________________

ENDING ACTUAL VARIANCE

ITEM DESCRIPTION REMARKS

INV. INV.

Prepared By: Approved By:

______________________________ ________________________________

Date: _________________________ Date: _______________________

Company Name

Company Address

Contact Numbers

www.website.com