0% found this document useful (0 votes)

927 views3 pages5s Checklist

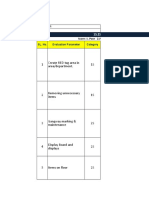

This 5S audit worksheet is used to evaluate a workstation based on the 5S methodology of sorting, setting in order, shining, standardizing, and sustaining. It contains 25 checklist items across the 5 categories to assess the workstation. The audit yields a score from 0-4 for each item and category based on adherence to 5S principles with the goal of continuous improvement. Areas of focus include eliminating unnecessary items, clearly marking storage locations, maintaining clean and organized spaces, documenting standard procedures, and sustaining the 5S system through training and review.

Uploaded by

vickram_chandu9526Copyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

927 views3 pages5s Checklist

This 5S audit worksheet is used to evaluate a workstation based on the 5S methodology of sorting, setting in order, shining, standardizing, and sustaining. It contains 25 checklist items across the 5 categories to assess the workstation. The audit yields a score from 0-4 for each item and category based on adherence to 5S principles with the goal of continuous improvement. Areas of focus include eliminating unnecessary items, clearly marking storage locations, maintaining clean and organized spaces, documenting standard procedures, and sustaining the 5S system through training and review.

Uploaded by

vickram_chandu9526Copyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd