0% found this document useful (0 votes)

1K views5 pagesEquipment Cleaning Validation Protocol

This document outlines a validation protocol for cleaning manufacturing equipment used in the production of liquid antiseptics. It describes the objective to demonstrate that cleaning procedures can reduce residue levels to prevent contamination. The worst-case product was identified based on toxicity and solubility criteria. Sampling plans and acceptance criteria for visual inspection, microbiological testing, and non-specific analytical tests are defined. The protocol also addresses equipment descriptions, responsibilities, cleaning procedures, and studies for dirty and clean equipment hold times.

Uploaded by

QACopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views5 pagesEquipment Cleaning Validation Protocol

This document outlines a validation protocol for cleaning manufacturing equipment used in the production of liquid antiseptics. It describes the objective to demonstrate that cleaning procedures can reduce residue levels to prevent contamination. The worst-case product was identified based on toxicity and solubility criteria. Sampling plans and acceptance criteria for visual inspection, microbiological testing, and non-specific analytical tests are defined. The protocol also addresses equipment descriptions, responsibilities, cleaning procedures, and studies for dirty and clean equipment hold times.

Uploaded by

QACopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

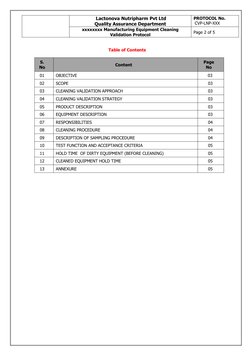

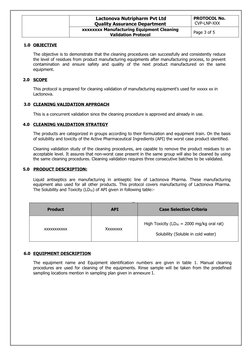

- Cleaning Validation Strategy: Explains the strategic plan used to validate cleaning procedures, emphasizing different cleaning agents and their effectiveness.

- Objective: Defines the purpose and expected outcomes of the equipment cleaning validation protocol.

- Cleaning Validation Approach: Outlines the strategies and procedures to perform cleaning validation effectively.

- Scope: Describes the extent and boundaries within which the validation will be conducted.

- Product Description: Details the product involved in the validation process, including specifications and physical properties.

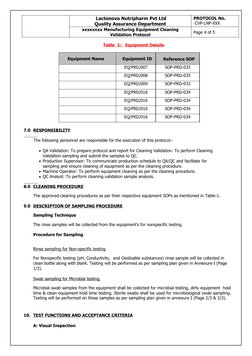

- Equipment Description: Describes the equipment that will undergo the cleaning validation to ensure compatibility.

- Description of Sampling Procedure: Specifies the methods and techniques used for sampling during the validation process.

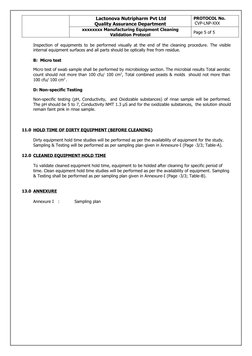

- Test Function and Acceptance Criteria: Details the testing requirements and criteria for acceptable outcomes in the cleaning process validation.

- Responsibility: Lists the personnel responsible for carrying out various tasks in the validation protocol.

- Cleaned Equipment Hold Time: Specifies the duration equipment can remain in a clean state while maintaining validation standards.

- Hold Time of Dirty Equipment (Before Cleaning): Defines the maximum allowed time for equipment to remain uncleaned while still expecting successful validation.

- Annexure: Includes supplementary materials and documentation relevant to the validation protocol processes.