0 ratings0% found this document useful (0 votes)

1K views87 pagesEil Support

Uploaded by

Sajesh S KumarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

0 ratings0% found this document useful (0 votes)

1K views87 pagesEil Support

Uploaded by

Sajesh S KumarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

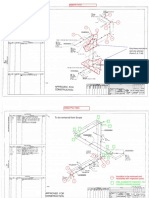

(CAD NO~7~44~601

SIDE

SEE FIG.-5 FOR

view

300_LONG

See

SIDE VIEW

2-50x10 FLAT

Fic.-5 FOR

300 LONG

oy

~ —

{G

a

MONA

WC Ww V7 see a00 1

\ 7 see nos ton Hf sappegse \ ]

SE eer SS

c ‘SEE _DETAIL-N 5 400 LONG

ee

== a == hess a

a zl aD FE Sey

== == == Hottest ER

xara Sent cde Give

IN VERTICAL) (THREE DIRECTIONAL STOP)

nos

ANCHOR ROD

oo aeLonb wb Wustn Sttucute or necuNG ewe saue as

SUITABLE THICKNESS PLATE/INCREASING THE SHOE HT.) Se sues

Se eRe Ones bo dk

BOSE, scahwoonens r02 warn

- Sloe WONG

x “ NSULATON |, ] OUT FROM |SHOE)

0], 50 i "7610 125 | 150.| 300 3 — 182

DETAIL=N 2610 178209 400 c AULA

10 THK 6S GUDE UATE [eo |

"x = 40 + ROD DIA WE

Serie

SMEGL ee

5

5

t

+ [euewt

2 RE -noE HE TST RAD OS OE Fm FT

1_| ORG NO 7-44-601 SHT 10F 1 REV)

Sa SE

wwe] Ga ro] __aLTERATON fev

CAD NO~7-44~602

Dio" [ae ae [ae [ve [20° [2a [307

Y_[138 | 174 | 182 [194 [208 [220 [242 [270

ager

PROTECTION SHIELD

0x12 FLAT

(NP)

SEE AG.-5 FOR

Ste FiG.-5 FOR

SIDE VW

ee $

“SLIDING

"HG EXISTING STEEL/SLEEPER,

PIPE RAGK (TYP)

INSULATION ‘SHOE al

Soba Ss) 7atS

See har hee sero Ee

ee iy so) se

eS aS

a —

ee nace ah

x = 40+ROD @ ENO VIEW

Sree JL

; é

3 é

le ge : E

wl lx

3 Ae/ sxx 20-5 ron | 2

eae

= a

Hee

{ies tons

r R tf ss tarsi

aad A NF one set nore

GUIDE ce

crs vemreny sx 252600 psa ar Lomo on

PASHAN, ERODE ge OE tO

acs

cnc Sine

reerer ic} nice

TPE ANCHOR

aot” Ce S06 eI WL BE aE AG =H SOE

eo sad Mars samtrwctecne fe See 2)

ARRANGEMENT FOR ‘SHOE _LENGTH

waa

‘NOTE:

PLATE same THK, 1. PROTECTION SHIELD 1S TO 9 CUT FROM UNE PIPE,

6

5

4

3 _| CuENT

2_| TTLE:-PPe SHOE FoR Wor NSUIATD CS PPE SIZE 10" TeRU 30" TPES

1 | ORG NO_7-44~602 sut 1 oF 1 [Ro

ORGINAL ISSUE 0

wane] cHKO| APPO| ALTERATION Rev

CAD NO~ 7-44-6053

4 pe

;

FOR SIDE VEW—_— ZF ge SEE _FIG.-5 FOR

500 Lone. 5 Eee Sie EW TP)

i Zak

oem Pe

[uo

SUDE.

Fons

BIPE RACK

= (RESTRAINED IN VERTICAL)

a FiG.=2

FIG. DETAIL-M sole

(HPY(ONLY FoR

200 200 igs, 5 ee 6 TT

pop, | pag

Tt a t

CF . DETAIL—M

= ow * wn (Cur FROM ONE PIPE

ht ASAve]® F'Nos" 30mm LONG)

= FOR IG 4,5 & 6 ONY

400 LONG 3

SEE FG.—5

7 WV y~ ISA_75x75x10

Lisanne 62 Hour ss eve END view

SOmm FOR, GLAWING INSULATION FOR GUIDE

PARTIAL_RESTRAINT

(THREE DIRECTIONAL STOP) 5

INSULATION] « [SHOE/CUT FROM CROSS GUIDE

Tuionness | " [rst sus size .

Up 70-75 [100] A isw8-200

76.70 125|150| 8 sve_300] FIG—6 ar 8D TH

[26 To-175|200_-cisws- #00] ANCHOR (AN ol :

prnae aa 77) baw] 3

i

Fig.—1 & SHOE TO BE WELOED TO ‘DETAIL-N’

EXISTING STRUCTURE BY INSERTING SUIDE. PLATE

SUITABLE THICKNESS PLATE/ | <

TYPE, A&S

ad5-tRod 8

-—-——--~—_ INCREASING THE SHOE HT.)

owe wwe ron sie nee Shea 8

tl TS RODS tee SEAS T= OT] aur

p00 Sor:

ARRANGEMENT FOR ROW, PIPE 1A (NCH > sofaofitols [sole woe 35

ANCHOR SHOE WELDING LENGTH OF SHOE ¥90/150/5 [40| 6 | Wiz x 35

MATERIAL SYMBOL ae[ita|2is|t76ls [So] 6 [Wie 3-40

IBOLT & NUT. ‘ASTM A 193 G7 B 16 & A 194 Gr. 4 6"| 1681290 |246|5 [es | 8 [20 x 45

}CLAMP AISI 316, 321, 347 GR-87 PLATE s 286[5 [65[e [M20 x 45

sue & shoe _Ancue suas 226 SOR TEE UP 10-460" oMly

n

5

‘

3 eae

Se ED

1_| ORG NO_7-44-603 ‘SHT 1 REV

TRON SSE nl

waoe| cw) APP ALTERATION Rev “

CAD NO~7—44-605

SEE FiG~5

FOR St Vo

Tos (nF)

=e

300 voc

fo. ve}

AS FOR EHR 20

PLATE SAME THK.

DETAL-N

(PONY FOR

FIG 4, 5 & 6

Now, PPE bat

(cur From ive re

ns Born LENG)

ISA 125175010]

Z/ prove 66 HOLE AT eveRr

CUive AISI 316, 304, 323, 347 PLATE

TSAR] 5, [SE RECTONAL STOP)

aowese |" [ne

ee ae Sora FOR CLAMPING WSULATION

75-70 125|180|-8 =

eto 17sfso0 | 6 ‘cao auDe

F

mass

sachin ; g

mn sour £0 7x

lowe SHOE ETAL WL BE SAME AS Van

JFG.—1 & SHOE TO BE WELDED TO | | 50 |

lonsine sinucrune Br insets Self Asie 50}

Suradte ‘Hees PuATe/

INCREASING THe SHOE HI). ‘ETAL

1 12 TH. €5 GUDE PUNE

Ga) we x= 40+ ROD 8

nee] é

Siok nee] i

Fano « supa] Ju [Le ]@[F [epwi] y [oor Sze

GME 1o"| 268 | 400 | 340 [10] 65] 10 [w20 x 60

Noa Be DG) ‘mip in FOR GUD P| 20250390 | 10] 75|10 Was #S

siocuexcts :

‘| 358485 [aze [10] 73]10 [W565

‘smal 16'|407[540 [400 [10] 75] 10 wos 65

1E"| 456] 590 [350| 10] 700] 10 [Wo5-¥ 65

20" 506 | 540-| 580 |10|100| 10 was 3-65

MATERIAL: NOTE:— ZerLe79] 750 630 [10] 00] 10 | wz5 3-65

BOLT & NUT:- ASTM A 193 Gr B16 & 194 Gr 4

1. FOR TEMP UP TO 400C SHOE FABRICATED

FROM 12 THK. STEi

GUE & SHOE ANGLE & FLATHIS226 STEEL PLATE FOR TEMP. ABOVE 400°C USE 10 THK. 316, 321, 347 PLATE.

6

5

4

3 _| CuENT

2_[ TITLE pre sit ron vor RSUAED ALOY?SS PB 1 We 20

1 [DRG NO_7—44—605 SHT1 OF 1

ORGINAL ISSUE 0

wane] cHKO| APPO| ALTERATION Rev

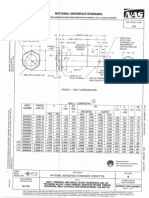

OUT SIDE DIA OF MAIN

OR BEARING PLATE

BEARING PLATE 150 WIDE

0 BE USED FOR WAINS

OVER 900 (36") DIA

22 DIA HOLE FOR

3/4” DIA BOLT.

©

BEND TO

ROD > 10

Fuar 75410 NOM.| PIPE DEVELOPED) DEVELOPED|

PIPE |0.D. | A LENGTH OF/LENGTH OF|

_ DIA. [mm BEARING | SADDLE

we) NCH PLATE

A A 20_| $08 | 235 = 80

21_| 533 | 245 = 915

Fig.— 22_| 580 | 255 = 945

‘SLIDING 23 | 584 | 260 = 950

24_| 610 | 270 = 985

: 25_| 635 | 280 = 1015

26__| 660 | 290 = 1050

ISA 85x35x5 | 27_| 680 | 295 = 1060

78 LENGTH, 28 | 711 | 305 = 1080

\ weLvep ro 29_| 737 [315 = 1120

. BEARING [PLATE cre [30] 762 [25 = 1160

31_| 787 [330 = 1170

oi 32__| 803 | 340 = 1190

33_| 838 [350 = 1220

3 34 | 864 | 360 = 1260

DETAILED DIMENSIONS AS_IN_FIG.—1 35_| 689 | 365 = 1280

CAD NO- 7-44-6086

@W.0. BOLTS AND BOLT HOLES) 3é_ | ota [ 375] 650 1300

FIG.=2 37_| 940 [405 | 990 1430

GUIDE 38_[ 6s [41s | 950 1460

a 39 | 991 [420 | 965 1470

. 40 [rors [430 968 1500

ee $6-1-20' 41__|1041 | 440 1000 1535

ree ;

ee 42_|r087 [4a_| 1020 | 1550

43 [1082 [455 | 1040__| 1580

NOM. PIPE SIZE (INCH) -

NOM. PIPE SIZE (NCH) _| 44 [ite [465 | 1065 | 1600

sywBoL a5 fas [47s [1080 | 1630

46 [1168 [480 | 1000 | 1640

a7_|re4 [490 | 11901670

481218 [500 | 1130 | 1690

NoTeS

1, USE THIS TYPE IN PREFERANCE TO TYPE~sa,

2. WHERE ROD IS WELDED TO TOP OF SUPPORTING STEEL

THE ANGLE SIZE TO BE ISA 65x4508

g

5

+

3 cuENT

2_ [uF PIPE_SADDEL FOR BARE PIPE TYPE SO & SGA

1 [ors No_7—44—606 [su 1 or 2 [Fo

ORNL SUE °

wae | enka] AP ALTERATION Rev as

SLIDING “S[gT HOLES FOR 20 BOLT

‘BTHK BEARING

750 WIDE. WELDED

TO PIPE

DETAILED DIMENSIONS:

4S FIG—1 (W.0.BOLTS)

‘ND BOLT NOLES)

10

CAD NO~ 7-44-6907

40

GUIDE_ANGLES

FOR FIG.—2 ONLY

SIDE_ELEVATION DETAIL=1 SECTION X=X

NOMINAL DIA

A R

INGHES [mm

52 | 1320 | 510 | 705

541370 | 535 | 730

60__| 1525 | sa5__| e10

66 | 1675 [635 | 885

72 | 1830 | 685 | 960

78__| 1980 [735 | 1040

ve 42135 | 7a5__ | 1120

FIG_NO ie SLIDING Se 2288_| Bea) 1.

96 | 2440 [01s | 1270

HOM. PIPE SIZE. 102 | 2590 | 965 | 1345

108] 2745 | 1018 | 1425

6

5

4

3 | CUENT,

2_| TITLE = PIPE SADDEL FOR BARE PIPE SZE 52° THRU 108" TYPE-S7

1 | oRG NO = 7-44~607 sut1 or 1 [REV

0

REV i

(CAD NO~ 744-628

INSERT PLATE Exé¥T

PIPE DIA

NOM. PIPE DIAL

CUT TO REQUIRED LENGTH AT SITE

(DO NOT CUT THRIUGH ELBOW OR PIPE)

10 DIA TELL TALE HOLE

SLIDING PLATE Bx®xT THK,

INSERT PLAT

i |

TIT (a TR ma

4156 FOR PIPE SIZE 2" TO 4”

‘D206 FOR PIPE SIZE 6" 1036 LBAI—H—S

= [Posmon (cue)

HEIGHT DETAILS AS PER

SIZE NO.

Type. TYPE :-L1A

SYMBOL

NOTE:

aie 2 1. FOR DIMENSIONS REFER STD. NO. 744-621

=f; EXECPT DIMENSION E.

e=0+196 [ror PIE Sze 2” 10 4”

E=D+208—TFOR PIPE SIZE 6" 10 36” |

ot

; Ms

IPosmion (CROSS GUIDE) \

HEIGHT -

SIZE_NO,_ (DETAIL AS PER

Bee OS WYRE U1) Sceeerrererrreeerrrt

POSITIOON

SYMBOL (THREE DIRECTIONAL STOP)

~( i A 7 :

POSITIOON —_N POSITIOON = S$

(CROSS GUIDE) (GUIDE)

6

5

4

3 _| CuENT

‘2_| TOTLE Uo SRR OME SS OME FOR RE 8 RSL PE SE TE

1 [ORG NO 7-44-6268 sur 1 or 1 [ RY,

ORGINAL ISSUE 0

wane] cHKO| APPO| ALTERATION Rev

CUT TO REQUIRED LENGTH AT SITE

(00 NOT CUT THRIUGH ELBOW OR PIPE)

CAD_NO~ 744-630

| isutation | 4

e INSULATION a

3 wl. 3

t ie [8 Siig 8 Ie

10 DIA TELL TALE HOLE fi dt B |e I ale

r ra | 839

BASE PLATE BxBxt : zig 10 DIA TELL TALE i “(258

3 HOLE 4 23

wsert pare exesr \ JT g |e | 8 "lg

Piers ui 8

T BASE PLATE BxBxT 7 T

| Leour x

H

) INSERT PLATE €xEx )

NOTES:

1, MATERIAL OF SUPPORT PIPE SAME AS MAN PIPE SPEC. ALL PLATES CARBON STEEL.

2. IN CASE SIZE AND/OR SCH. OF SUPPORT PIPE (D1) LISTED IN THE TABLE IS NOT AVAILABLE.

USE NEXT HIGHER SIZE AND/OR NEAREST EQUNALENT THICKNESS AVAILABLE.

HEIGHT Tee HEIGHT

SIZE_NO.

SYMBOL SYMBOL

aE 3 REX BOLT FULLY THREADE

no. | © ade | & 7 c ‘WH NUT

1 2—{ 2° sc. 40 | 150 | 150 | 10 [ow - 30x 150 Lone

aT 137

2 #—| 3° son. 40 | 200 | 200 | 10 fe] m - 30 x 150 Lone

s 205 100

3 [For] +" sen. 40 | 200 | 200 | 12 [2627] w = 39 x 175 LONG

12 267

se 300

rer] © SCH 40 | 250 | 250 | 12 -s10—] Mm — 40 x 175 LONG

a a A

6 [2X wor son. «0 | 350 | 350 | 12 | 88%] um — 40 x 200 Lone | 200

2a 615

6

5

4

3 CUENT

2__[ TITLE AOUSUALE LOW SIPPORTSUONG FOR PPE SE 2 TATED & Lh

1 [ORG NO 7-44-6350 HT 1 oF 1 _[ REY

ORIGNAL SSUE °

wave] cHko] aPPO| ALTERATION ReV

ko

D | Nom. PIPE IA

200

(wax, 1800)

=]

|_CUT_FROM_ISMB_200

SLIDE PLATE

ix150x8 THK:

INSERT PLAT

‘250x250x10 THK.

ARRANGEMENT.

SUDING)

FOR SS & ALLOY STEEL

125 | 125

SIZE_NO,

PIPE_USE_6 THK.

PLATE EQUIVALENT TO PIPE MATERIAL

{ NOM. PIPE OA

: j | | paca

feb poe

S Loe

|_CUT FROM ISMB 200

BASE PLATE,

150x150x8 THK.

INSERT PLATE.

ARRANGEMENT

TYPE=2(Fl

CAD_NO~ 7-44-6351

6

5

4

3 _| CuENT

‘2_| TITLE LOW SUPPORT SLONG & FED FOR PPE SIE 7° THRU 6° TPE —L11

1 [ORG NO 7-44-6351 sut tor 1 | RY,

ORGINAL ISSUE 0

APPO ALTERATION Rev

147177 | 95 | 582

16" | 204 | 703 | 435 | 300 | 200 | 250 | 300

18" | 229 | 122 | 400

207] 253 [136 | 546

22° | 275 [150 | 600 | 350 | 250 | 300 | 350

2a" | 304 [164 | 654

26°] 330 [177 | 700

ore ga0 thee Pere] 30° | 280 | 300 | 350

32°] 407 [210 [870 |,

36" | 456 | 246 [962 | *0° | 300 | $50 | 400

PROTECTON SHIELD

isMB_(1

} | “SuOING PLATE |

1500

4

tte)

BN fT

BxBx12 THKCS,)

CAD NO~ 744-633

inseat pure

Bxext2 THK.

8)

ARRANGEMENT TYPE = 1

(SUDING)

Tee] NOM. PIPE_DIA ls i Leave

iNCHES HE OS

ARRANGEMENT TYP% IE | SUDING PLATE

|ASRANGEMENT TPE J HEIGHT BxBxI2 THK(CS.) “be

INSERT PLATE |

‘sywBOL i Tey?

Co)

NoTes

1. PROTECTION SHIELD SHALL BE NOT

FROM LINE PIPE. TR) [aw

MAX, LOAD: 20009.

MAX. MOMENT: 600kg.M (FOR ARRANGEMENT TYPE-2 ONLY) ARRANGEMENT TYPE = 1

(FiKED)

SLIDING FIXED

6

5

4

3 | CUENT,

2_| THTLE tow SPORT ON WEED OW OR PPE SEW" TRU 36 TE US & LW

1 [ORG NO 744-635 sur tor 2 [REY

ORIGINAL ISSUE. 0

wane] cHKo| APPO| ALTERATION REV

NOMINAL Ca ce NOMINAL

PIPE DIA. 90 H PIPE DIA

DETAIL _'M i ¢ t te

aah | he

3 1

an) 5 1 +

: ay | 3) |

w I

: Liz at “W’ BOLT TYPE C4

: Elz

| ae |) “ARRANGEMENT=2

: 1 algo 1] (NOTE-1)

a)z\2) 1

VB ‘|

yy ole : 1

NY BO 1

le iga125%75x6 | |g i ISA125x75x

49] SUING PLATE 40) SLIDING

ma PLATE

‘of INSERT PLATE INSERT_PL.

4 byl 50x 150x8 5 val 150x150x8|

aye

ARRANGEMENT TYPE=1 v4 ‘ARRANGEMENT TYPE~2

(SLIDING) 7172") 60 (SLIDING)

NOMINAL D : NOMINAL

DET Me 20 DETAIL—"M" f}.—-4 .

1 i

J og i

g i

rrr i

|

! ws !

Fale} | Naas ne

ae |) ARRANGEMENT-2

8 algls| 1) (SOTE=1)

8 ' Bizz \

|" |g| I

xg Pe 1

2 1

= «the 1SA125x75x6 1 ISA125x75x6

SUONG PLATE PLAN ' LONG PLATE

TPE 4 1

: INSERT puaTe| (FOR TYPE 1&3) ' INSERT PLATE|

7150x1508 “150x150x8

ARRANGEMENT TYPE—4!

(FIXED)

Li5 =~ | ~~ g'= (FOR TYPE 1&3)

nee NOM PIE OACNGHES) Nore.

aweagewent | UE axe Loan 750Kq 1 FORBES OF BOT NE Ck RF 10 S10. 744-644

s

5

4) CuENT

5

7] TRE LOW SUPPORT SLIDING & FIXED FOR PIPE

1 SIZE 3/4” THRU 1 TYPE L15

Ee

——— Toone 744655 oo 4

CAD NO~ 7-44~635

ayn —f

| 10 THK

mPNCS

so (execs) :

A = :

ISAM ‘

SEE TABLE

EXIST. EL BASE_PLATE |

ar FOE FOUNDATION ye

ee. SIDE VIEW

1__MAX.LOAD (W)

Py

‘SIZE | MAX LOAD M A 8 c

No | (W) Kg

i 600 [er anane| 600 | 750 | 25

2 | 800 [is tions | 700 | 150 | 60

3_| 1500 [is tsii3e6 | 800 | 150_| 60

60 so |

Bey | BU

A

c

le ISAM

SEE TABLE

+ Li6 =

BASE PLATE

SaSeGT re LOCATING OMENSION

\ 5izE_NO HEIGHT

— —-— — ec,

NOTE:

EXIST. STEEL

OR _FOUNDATION

1, DO NOT USE FOR ANCHORING THE PIPE.

CAD NO- 7-44~636

6

5

4 TcueNT

3

2) me LOW SUPPORT STANCHION

1 TYPE _LI6 & LIGA

F REV

ORGNAL SUE ORE NO 7= 44-656 SHI t OF + a

MADE] CHKD APPO. ALTERATION Rev

CAD NO~ 7-44~637

NOMINAL PIPE DIA. Joey CUT TO REQUIRED LENGTH AT SITE

Ld (00 WOT CUT THROUGH ELBOW OR PPE) o1430

Lhe woe

S — * FF +]

Bae ||

x28 Po } ts

Bs

BS

a I i

Gi SE jp

insert puse (7

i ‘BxBxT (TYP)

a as! a

| \ re 10 wove

INSTALLATION. PROCEDURE

PLACE SUPPORT UNDER PIPE BEFORE CONNECTING Pir

PIPE FLANGE IS ALIGNED WITH EQUIPMENT OR VALVE

1) MATERIAL OF SUPPORT PIPE SAME AS MAIN PI

(BOTTOM OF HEX.

HEAD TO GROUND

SMOOTH)

INGE,

SPEC, ALL PLATES

CARBON STEEL,

TO_EQUIPMENT TURN ADJUSTABLE NUT UP UNTIL

2) IN CASE SIZE AND OR SCH. OF SUPPORT PIFE (D1) LISTED IN THE TABLE IS NOT AVAILABLE USE NEXT

HIGHER SiZE AND OR NEAREST EQUIPMENT THICKNESS AVAILABLE,

3) IN CASE OF HIS MORE THAN 1000, RASE

HT OR CONCRETE PEDASTAL TO SUIT.

4) USE THiS OETAL AS SOUD SUPPORT FOR LNE WHEN VERTICAL THERMAL EXP. 1S NOT PRESENT, THE MOST

GOVMON USE SHOULD TO END SUCTION PUMP

D1 HEX. BOLT FULLY

No} © | oae-n/® [t | ¢ |reeoowmenow| HK | P|

2 5 70. a 150 110 is

1 |B Frscnao [200 [10 FT weryertao vone Ff TL

300 “70 2609023

7 ST esc TT jens ow [2

25 ; 3 —| 1}

3 fe] arscnao | sso | 12 [2x52] wer/s'a7s vous [S091 e538

te er soa—| tao | 23.

eT; 55 Sof 280-97

‘ 16" B’scH.40 | 400 2 410 M=1"x175. LONG 350 230 27

5 18° B"SCH.40 | 400 12 454 350 230 27

a S50 5 soo | 790

6 [BT roscnao] 450 | 12 [ST warigiz00 vos F 22 T eTs

li7-1-H Li7A -1- 1H

nee re

sue 40, woos SHE Ho se.

seo, eos

a

5

4 | CuENT

3

2 | IME ADJUSTABLE LOW SUPPORT WITH 4—BOLTS

1 FOR PIPE SIZE 2"THRU 24" TYPE L17_& L17A

ye

=a aF 15g NO 7= 44-637 SH 10 3

waoe| ono APPO ALTERATION fev

CAD NO 7-44-6368

DIA

A {00 Nor cur THROUGH e180 2

NOMINAL PIPE DIA. | De | ‘OR PIPE)

NOMINAL PIP%

TACK WELD !

Lock NUT =

108 TEEL TALE

HOLE

BY GENERAL INSERT Puate|

cmt ExExt (1)

a

Tee,

SIZE No. weiget eicet

SHie0L 0.

INSTALLATION PROCEDURE: PLACE SUPPORT UNDER PIPE BEFORE CONNECTING PIPE TO EQUIPMENT TURN

ADJUSTABLE NUT UP UNTIL PIPE FLANGE IS ALIGNED WITH EQUIPMENT OR VALVE FLANGE.

1) MATERIAL OF SUPPORT PIPE SAME AS MAIN PIPE SPEC. ALL PLATES CARBON STEEL.

2) IN CASE SIZE AND OR SCH. OF SUPPORT PIPE (D1) LISTED IN THE TABLE IS NOT AVAILABLE, USE NEXT

HIGHER SiZE AND OR NEAREST EQUIPMENT THICKNESS AVAILABLE,

3) USE THIS SUPPORT IN PREFERANCE TO TYPE L10 & L1OA,

4) USE THIS DETAL AS SOLID SUPPORT FOR LINES WHEN VERTICAL THERMAL EAP. IS NOT PRESENT, THE MOST

COMMON USE TO END SUCTION PUMP.

Size] Di TEX. BOLT FULLY

No | ° |(wore-2| 8 | E | T | C_|rieeioeo wm wo wun] X | %

+

+ P2ssenao [is0]s70] 10 FT -sortso wxe

| 100] 40

I 7

2 ee tescnao [ooo [220 [10 F187 1 y-son180 Lone

a 205

3 [ior e'scx.40 |200|220] 12 [262] w-sox175 tons | | 46

127 287 150

4 LE erscu.4o | 250] 270] 12 [382

ier PSH 416 | y-42175 tons | [50

5_| 18° fe'scH.40 |300) 320/12 | 454

a 354

{rorson.40| 350] 370 483 iG

6 Le orscuad] 12 | 24 w-4sx200 Lone |180] 56

6

5

4 Teuenr

3

7] TE ADJUSTABLE LOW SUPPORT FOR BARE &

< INSULATED SIZE 2” THRU 24" TYPE L18 & L18A

= PREY,

AE 9 TORE NO 7= 44-638 SHT_1 0} a

wave] cro] aPPO ALTERATION ReV

CAD NO~ 7-44-63

CUT TO REQUIRED LENGTH AT SITE 4

(00 NOT CUT THROUGH ELBOW 8

OR PPE) za

Z

+t

7 rT

= Lock wut ee —, | ——{uacrine gor} ——— Lock NUT

\ DETAIL ‘A’ FREE TO MOVE

Y

y

BASE PLATE a

SEE DETAL ox SEE DETAL ‘A

10

BY GENERAL INSERT PLATe|

ore ExExT (TYP)

|

[tiga -1 —

Tee Tee

SIMBOL _5:7E No. HEIGHT smeo, SIZE N HeiGHT

INSTALLATION PROCEDURE: PLACE SUPPORT UNDER PIPE BEFORE CONNECTING PIPE TO EQUIPMENT. TURN

ADJUSTABLE NUT UP UNTIL PIPE FLANGE IS ALIGNED WITH EQUIPMENT OR FLANGE.

| NOTE: FLANGE.

1) MATERIAL OF SUPPORT PIPE SAME AS MAIN PIPE SPEC. ALL PLATES CARBON STEEL.

2) IN CASE SIZE AND/OR SCH. OF SUPPORT PIPE (01) LISTED IN THE TABLE IS NOT AVAILABLE, USE NEXT

HIGHER SIZE AND/OR NEAREST EQUIPMENT THICKNESS AVAILABLE,

3) USE THIS SUPPORT IN PREFERANCE TO TYPE L10 & L1OA.

4) USE THIS DETAIL AS SOLID SUPPORT FOR LINES WHEN VERTICAL THERMAL EAP. IS NOT PRESENT, THE MOST

COMMON USE SHOULD TO END SUCTION PUMP.

SIZE] D1 HEX, BOLT FULLY

NO (NOTE-2) BielT C__|rareaven wrt two nur] X [oe |o1e

7,

1 scr.ao [eo [170] 10 LT y-sox150 Lone

ug 100| 40 | 70

2 rscu.4o [110 [220 [10 L1SZT ysox150 Lone

205

3 le'scH.40 |125]220| 12 [2262] w-sex175 tons | | 45 | 90

287 150

388

+ soko | 190] 270] 12 [388

w-42x175 tons | | 50 | 100

5 j'sc.40 [240|s20| 12 | 454

354

6 o"scH.49] 298] 370] 12 [| S24) y—4ax200 tons |160| 56 | 110

6

5

4) CuENT

3

2 ‘TITLE ADJUSTABLE LOW SUPPORT FOR BARE AND.

1 INSULATED SIZE_2” THRU 24" TYPE 19 & L194

=p REY,

Onn BE 3 TORE NO 7= 44-639 SHT_1 0} a

wave] cro] aPPO ALTERATION Rev

NOM. PIPE DIA. NOM. PIPE DIA.

> by

f

: ° ; !

cnn

CAD NO~ 744-644

JEXISTING EXISTING|

j STEEL STEEL

E

GUIDE FIXED.

ARRANGEMENT TYP! ARRANGEMENT. TYPI

(1/2" To 24") (1/72" To 1 1/2")

D 0.0. “U" CLAMP

(mm) ef s| a] F

1/2” 21 65 30 | 50 6 24

3/4" 27 70 36 | 50 6 30

1" 33 75 45 | 55 8 37

1/2" 48 90 60 | 55 8 52

2" 60 105 | 72 60 8 64

3 89 145 | 106 | 80 | 12 94

c4—-2-0D 4” 114 [170] 130|[ 80 | 12 | 119

6" 168 | 240 | 190 | 100 | 16 | 173

TYPE NOM. PIPE DIA. 8" 219 | 290 | 242 | 100 | 16 | 226

(INCH) 10” | 273 | 345 | 296 | 100 | 16 | 280

ARRGT. TYPE 12” 324 420 | 351 | 130 | 20 | 331

FIXED 14” 356 _| 450 | 382 | 130 | 20 | 362

16" 408 | 500 | 435 | 130 | 20 | 414

18" 457_ | 565 | 490 | 140 | 24 | 465

20” 508 | 620 | 540 | 140 | 24 | 515

24" 610 | 720] 645 | 140 | 24 | 620

é

5

+

3 CUENT

2 | TITLE U-BOLT FOR BARE PIPE SIZE 1/2" THRU 24” TYPE-C4

1 [ors No 7—44-644 [st 1 or 1 | RVQ

ORGRAL BIE °

wave] cro] aPPO ALTERATION ReV

CAD NO~ 7~44~645 (SHEET 1 OF 2)

D PLR ESE ee ie ae ee ae [a a Te

Rar fe 30 Pas | a7 [se fara | 337 [162 [178 [203 | 220 | 256 275 [305

‘a__[30_|-40-[-50 | s0-| 50 | 100] 150 | 200 | 200 [200 | 200 | 200 [300 |300 | 300

& [160 }160-[ 60 [160 [ 165 | 165 [200 [220 [230 [230 [275 1270 [300 [795 [290

8

e

< ' 5

* 2!

Lt 20}|, 110 J 120

FOR PIPE 1” THRU 6”

i (rote=ty [Ne } 0d

Lo j 9]; Nomina, + 7

i f See . f i PIPE DIA.

| | i i LL

fei ae #3

° LL a) >

2] i —!

oust STE ost Con

INSULATED PIPE

PROTECTION SHLD

@woTe=2)

cs = REF. LEVEL NOIr=

e 1. FOR PPE STE UP To 6" AL. PLATE MATERAL SIL BE EQUNALENT

ree NOW PIPE DA To PPE MATERAL. FOR PRE SZE 8° AND ABOVE PLATE MATERIAL

squgot INCHES) SHALL BE CARBON STEEL FOR TEMP UP TO 400 AND EQUNALENT

suo. TO PIPE MATERIAL FOR TEMP ABOVE 400°C

2. PROTECTION SHIELD CUT FROM UNE. PISE

é

5

4 | CuENT

3

5] TE SUPPORT LUG, SLIDING FOR BARE/INSULATED

2 PIPE SIZE 1” THRU 24" TYPE C5 & COA

= rey

Onn BE [DRE NO 744-645 aro A

wave] cro] aPPO ALTERATION Rev

CAD_NO~ 744-646

D rele se) ele] eile elie] | or oe lee

R_[ a] 2 | 30] «5 | 57] a4] s10| 137] 162 | 176 | 203 | 229 | 254 | 279 | 308

~_[ 30 | 40 | 60 | 60 | 60 | 100,| 130,| 200 | 200 | 200 | 200 | 200 | 300 | 300 | 300

@ [190 | +90 | 190 | 190 [180 | 180 280 | 280 | 260 | 280 | 275 | 270 | 300 | 296 | 230

c ul | t4| | te} 16[ re] te] 20] 20] 20 20] 20] 20] 20

E o[ of of of 7[ e| 9] e| 1] 10] 10] 10] 10] 10] 10

BOLT Swe] wi2 x 40 wid x 45 [wie x50 wie x 60

SLOTTED MOLE

SLOTIED HoLe 8

Po 755

J) bal ,

Ta 7U

HED

=

v _|20] #5 | 7s

FOR PIPE 1” THRU 6” FOR PIPE _8” THRU 24”

ke hou, pot

NOM. PIPE DIA to Tek. PUNE 1 Opec

(NOTE=1) f j

| j JE

le —

1 1 fo

oP oR

(6S = )_ rer eve

Tee ~ INSULATED PIPE

nee__ NOM. PIPE OA

‘SYMBOL (INCH)

NOTE:~

1. FOR PIPE SIZE UP TO 6" ALL PLATE MATERIAL SHALL BE EQUIVALENT TO PIPE MATERIAL. FOR PIPE SIZE 8° AND|

ABOVE PLATE MATERIAL SHALL BE CARBON STEEL FOR TEMP. UP TO 400°C AND EQUIVALENT TO PIPE MATERIAL

FOR TEMP, ABOVE 400°C.

2. PROTECTION SHIELD CUT FROM LINE PIPE.

a

5

‘

rc

2 TT ST RB RGD ESET

1 [ors no _7-aa-eus [suri or 2 [RV

TREN ESE 0

wade] cana] PPO ALTERATION Rev

CAD NO~ 7-44-65

a1

(SPACER PLATE)

H GC

=e

>|

°

ul v

a

ol

®

\ t =| ALL SHARP CORNERS.

TO BE ROUNDED OFF

MACHINE BOLTS d2 x S

NOM. PIPE DIA. IN. INCHES. (SEE NOTE-2)

VAX. DIMENSIONS BOLT &

p frond la] eleo]refe|t]c ful a [Hu] | Nurs

(NB) gxs

1/2" 22| 35| 35 | 156/85

3/4" 27[ 40] 40 [168/90

) 450 35] 45] 45[776[95 | 6 | 35 | 18] 1/2"| 15] 9 | M12 x 50

1172" 50 50] 50] 201/115

oa 62| 60] 55221130 |

x 92| 80] 75|295|180 50 | 25] 3/4"

F] 800 Fis -eoasTsistisol 1° 30] 15 | M16 x 75

oa 170] 125 |720| 415 [215 -|

3) 1950 foottealisslaas]oso] 12 100 | 40|1 1/2") 50] 18 | M24 x 85

10" I276| 190185 | 565|290

14 [358] 230225 | 645] 330

16" l410| 270265 [725|370

18” l460| 290 [285 | 805 | 400 :

Sor] 3000 eee tSteestaso| 1 [140 | 60 |1 1/27 38] 24 |mso x 120

24" | 4500 __[613|370|365|975[480| 20 [140 | 65 [1 1/2] 40| 50 [M36 x 140

NOTES:— 1. FOR CS PIPE MATERIAL SHALL 8E AS FOLLOWS:

THE CLAMP SHALL BE FABRICATED FROM C.S. PLATE, BOLTS IS:1367

CLASS 10.9 & NUTS IS:1367 CLASS 12

INCASE OF SS/ALLOY STEEL PIPE MATERIAL SHALL BE AS FOLLOWS:

CLAMP PLATE AIS! 316, 321 OR 347. & BOLTS & NUTS ‘ASTM’

A-193 GR BI6 & A-194 GR 4.

2. WHERE EVER THE PIPE CLAMPS ARE SUBJECTED TO VIBRATION AN

ADDITIONAL CHECK NUT WILL BE USED. BOLT/STUD BOLT LENGTH

SHALL BE SUITABLY INCREASED TO ACCOMODATE THE CHECK NUT.

6

5

4

3 _| CuENT

2. TITLE PFE GAN FOR WGUATD OS PPE SUE I/F TRU 26 THERCTO

1_ | 0RG No := 7-44-650 sat tor 1 [RV

ORGINAL ISSUE 0

wane] cHKO| APPO| ALTERATION Rev

x

d, USE_SINGLE_BOLT_ARRANGEMENT

FOR 4” AND BELOW ON BOTH HOLES

USE DOUBLE BOLT_ ARRANGEMENT,

FOR 6° AND LARGER ON BOTH HOLES

CAD NO~ 7~44~651

‘LTHICK GUSSET PLATE FOR 15 Le

y SPRING

h Ei

dads | ES

f Tt t

z a , «||

a] 2 BASE R

Ps (NOTE=2)

PRET x Ty Ja tele |]e |r leo «| c | 4 Peewee

SIZE 0.0. [oou Sze (INCHES) FRE:

vv [ss | 3 | 164] 124] 75 | eol|s | 60 | 35 | 2| %«% | 25

63 | 3 | 198) 138] 75 zfs [a | | 35| | Sox% | a

0 | 6 | 240| 170 90 30 | 10 | 12 70 | 40 | 25 | %x% | 2s

80 | 6 | 270| 200] 90 45 | 10 | 12] 70 | 40 | 2 | %x% | 25

0 | 6 | 294] 224] 90 s7 | 10 | 12[ 70 | 40 | 25 | %x% | 2s

113] 10 | 400] 310] 115 70 | 65 | 12 | 14 | 90 | 50] 40 | %x% | 40

113] 10 | 452[ 352[ 115] too] 111] 12 | 14 | 90 | 50 | 40 | %x% | 40

140] 10 | sos] 405[ 115] 125] 135] 20 | 22 | 120| 65 | 45 | % «% | 50

140| 12 | s56| 466| 115] 145] 163] 20 | 22 | 130] 70 | 45 | % *% | 50

140[ 12 | saa| 496] 115] 165] 175] 20 | 22 | 130] 70 | «5 | % ~%5 | 50

140] 12 | 642] 567| 115] 190] 206] 20 | 22 | 130] 70 | 45 | % x% | 50

140] 12 | 690] 600] 115] 215] 230] 20 | 22 | 130] 70 | 45 | % x% | 50

z0"| 150] 12 | 742| 642| 115] 240] 256| 22 | 24 | 140| 65 | 50 | 4ex% | 65

2a"| 150] 12 | 844| 745] 115] 290] 307] 22 | 24 | 140| 05 | 50 | %ex% | 65

NOTE:

1. SPRING COIL DETALS ARE ONLY FOR INDICATIVE, EQUNALENT

C1 SPRING COIL MAY BE USED BASED ON AVALABLLY.

2, BASE PLATE NOT REQUIRED FOR INSTAUATON ON STEEL VEMBERS, USE

Tee NOM _PIPE_DIA WELDNG STUDS WHENEVER WEVBERS ARE NOT ALLOWED TO BE ORLLNG|

(INGRES) 3. TIBER STRESS’ OF SPRINGS COLS=562¢ Kq/Cm? (80,000!/ln?).

4 MODULUS OF ELASTCITY=0.96x10? Kg/Cm? (12.6K1020/ln).

6

5

4 CuENT

3

7] TRE PIPE HOLD DOWN CLAMP FOR BARE

<—{PULSATING PIPE SIZE_1” THRU 24” TYPE C11

7 REY,

AE 3 RE NO 7= 44-65; SHO} 0

wave] cHko] aPPO| ALTERATION ReV

BOLT SIZE WiaaS | wiexS0 MT6xEO)

D 7 = i ae [ae |e" 20" [oa

R 7 45. 162 [178 [203 [220 [254 [305

A 30 50 200 | 200 | 200 | 200 | 300 | 300

c 14 16. 23 [2s [eo | 32 32] 32

= fo 0. jo [10 [10 [70 | 70 [70

Fh 10 25_[ 25 [20 [15 [40 [35

SLOTTED HOLE

150

CAD NO~ 7-44~653,

FOR PIPE_1” THRU 6” FOR PIPE 8” THRU 24”

10 THK PL 10 THK PL -

(NoTe=1) (NoTe=1) “™\

\ 2

noua, | —— {oma

PIPE OW g ! '

gl qo : |

8 8 : :

‘| 8 4 ! ;

« wet | Hl : |

x > :

6 jt \ ft

PROTECTION SHLD}

REF. LeveL Wore=2)

13 ——?--D NOTE:

1. FOR PPE STE UP To 6" AL. PLATE MATERAL SIL BE EQUNALENT

NOM PIPE DIA. TO PIPE MATERIAL. FOR PIPE SIZE 8° AND ABOVE PLATE MATERIAL

WCHES) ‘SHALL BE CARBON STEEL FOR TEMP UP TO 400°C AND EQUIVALENT

Dre CUP LENGTH ‘TO PIPE MATERIAL FOR TEMP ABOVE 400°C.

‘SYUBOL 2. PROTECTION SHIELD CUT FROM LINE PIPE.

é

5

4) CuENT

3

5] THE SUPPORT LUG (SINGLE) FIXED FOR BARE AND

: INSULATED PIPE SIZE 1” THRU 24” TYPE C13

aR,

AE 9 ORE NO 7= 44-653, SHIT OF 1 A

wave] cro] aPPO ALTERATION Rev 25.

a 7 a

i7_[24 [30 [4557 | 34 [110 [137 | 162 | 178 | 203 [29 [254 [305

“3x0 |-40|"s0-|-50_|-8o| 100 150 | 200 | 200 [200 [200-2001 300 1300

FL10 [10 [10 [10 [10 [10 [2s [25 [25 [25 [20 [1s [45 [45

2|>|=\0)

p 8 pF

0 MN,

400 MAX.

CAD NO~ 7-44-54

FOR PIPE 1” THRU 6” FOR PIPE 8” THRU 24”

re woes

vom —_\ hhowna,

PIPE DI a 4 we

qs el { i |

2] 7 2 H ’

J o | { i 1

a im |

x 1 & Hi :

s ¢ :

5 ji \

fer .oven (wote=2)

ci4 --G--D NOTE:=

NOM PIPE _D\A. TO PIPE MATERIAL. FOR PIPE SIZE 8” AND ABOVE PLATE MATERIAL

WCHES) ‘SHALL BE CARBON STEEL FOR TEMP. UP TO 400°C AND EQUIVALENT

TYPE CUP LENGTH ‘TO PIPE MATERIAL FOR TEMP. ABOVE 400°C.

‘SYMBOL 2. PROTECTION SHIELD CUT FROM LINE PIPE.

3

5

4) CuENT

5

2] TE SUPPORT LUG (SINGLE) SLIDING FOR BARE AND

2S SSID BRE SUE ISTH et ie ct

ae

vase en aero] areeaon tev 25

CAD NO~ 7-44~655

( 4

Bolt 2

See \ ; 3

L

CLAMP

CLAMP

DEV. LENGTH ALLOW LOAD

of RL Al By HI] LY] E | ao ET ge | BOLT St

Ys} 15 | 35 | 20 | 30 | 30 | 3 | 12 160

4 10x45

1” | 19 | 43 | 20 | 37 | 30 | 3 | 12 190

T 450

26 | 52 | 20 [62 | 40 | 4 | 14 | 230

12x50

32 | 58 | 23 [64 | 50 | + | 14 | 260

47 | 60 [30 [04 | oo] 6 | 1a | 360

850 16x60

eo | 90 | 30 [112] | 6 | te | 430

a7 |123 | 35 [173] 80 | 6 | 22 | 610

1350 20%70

113 | 160 [40 [226 | 80 | 8 | 22 | 750

140 | 190 | 40 | 260 | 100 | 10 | 27 | 800

106 | 220 | 40 | 331] 100 | 10 | 27 | 1030 1990 25x75

181 | 230 | 50 [362 [100] 10 | 27 | 1110

16" | 202 | 270 [ 50 | 414 | 120 | 12 | 30 | 1280 2600 20x70

18° | 233 | 200 [ 60 | 465 | 140 | 14 | 33 | 1410

30x95

20" | 250 | 320 [ 60 [615 | 140 | 14 | 33 | 1550 3600

22" | 263 | 340 | 65 | 567 | 140 | 14 | 30 | 1670 sextt0

24” | 310 | 370 [ 65 [670 | 140 | 14 | 30 | 1810

[cis-—D

Tee NOM. PIPE DIA

INCHES)

é

5

4 Teuenr

3

>] mE PIPE U—CLAMP FOR BARE

2 PIPE SIZE_1/2" THRU 24” TYPE C15

LRT

AE 9 ORE NO 7= 44-655. Sato A

wave] cro] aPPO ALTERATION Rev

CAD NO 7-44~656

yc

=] |

i +

o

°

| 6

NOM. PIPE DIA IN INCHES

dx s (SEE NOTE-4)

ALL_SHARP_ CORNER‘

TO BE ROUND OF}

\ MACHINE BOLTS (CS PIPE)/STUDS (ALLOY/SS PIPE)

dx st (NOTE-2)

WAX DIMENSIONS BOLT & | st

LOAD

> Jue |e lefelrir|olm |e |e | SUS, |Nove-2]

22 | 35 | 35 | 106

27 40| 40 | 116

aso [3545] 45/126] 6 | 35 | 18 | 15 | 6 | wiz x 50] 65

1 50 | 50 | 50 | 136

6260] 55 | 151

92 | 80 | 75 | 191 .

800 Tie] -aoy as [22s] 10| 80 | 25 | 30 | 15 |wre x 70 | 100

o 170 | 125 | 120 | 325

12] 4 30 | 18 |w24 x as | 125

87 195° [322 [160 [155 | 395 go} 4° x

70” 276 | 190 | 185 | 465

127 327 | 220 | 215 | 525

122600 | 22242204 218 | $25! 46 120 | 45 | 35 | 18 |m27 x 110] 150

16" 410 [270 | 265 | 625

18°] 5000 [460| 290 | 285 [695] 6 |140 | 50 | 35 | 25 [M30 x 110] 160

20 511 | 320 | 315 | 755

24" [4500 | 613 | 370 | 365 | 865| 20 [140 | 55 | 35 | 30 [M35 x 130] 160

NOTES:—

1, FOR C.S. PIPE

MATERIAL SHALL BE AS FOLLOWS

CLAMP PLATE C.S. BOLTS IS 1367 CLASS 10.9 & NUTS IS 1367 CLASS 12

IN THE CASE OF ALLOY/SS PIPE USE CORBON STEEL PLATES (IS 2002)

FOR CLAMPS STUDS & BOLTS TO BE USED MATERIAL A 193 & 7/A 194—2H

2. IN CASE OF ALLOY/SS PIPE USE s1 LONG STUD BOLTS.

IN THE CASE OF SS PIPES USE ASBESTOS PACKING BETWEEN PIPE & CLAMP.

CLAMPS ARE SUBJECTED TO VIBRATION AN

4. WHERE EVER THE PIPE

ADDITIONAL CHECK NUT WILL BE USED. BOLT/STUO BOLT LENGTH

SHALL BE SUITABLY INCREASED

TO ACCOMODATE THE CHECK NUT.

6

5

4

3 _| CuENT

2__| TITLE: PPE CLAP FOR BARE PPE SIZE 1/2" THRU 26" TYPE ~c16

1_[ ORG NO :— 744-656 sHT tor 1 | REV

ORGINAL ISSUE 0

wane] cHKO| APPO| ALTERATION Rev

CAD NO- 7~44~661

zq bart

3 al TURNBUCKLE,

ag i (it REF. DETAIL “O" OF 7—44—663

iat (SH! 1 OF 2)

aI Lit

4 Pr

Z Sh HANGER R00

9) REF. DETAIL 'P’ OF 7—44-663

= (SH. 1 OF 2)

PIPE_CLAMP TYPE _C1

< TYPE C1 FOR DETAIL

! REF. STD. 7-44-641

D = NOM. PIPE DIA IN INCHES

MAX,

p | ALLOWED.

LOAD (Kg) | 9 A c s

1/2" 35

3/4" 40

7] aso | 12 48] 48] 75

iz 50

2" 60

+ 50 en)

4" 800 16 90 | 50 85

6” 125

a" 1200 20 160 60 95

10" 1 22 190

12] 1800 220 | 60 | 105 NOM. PIPE SIZE_IN INCHES

14” 230

16” 2100 25 [270 | 75 | 115

18” 290

20" 320

34" 2800 28 F379] 75 | 130

BARE PIPE

6

5

+

3 | CuENT

2 [ie “SFE A PRE OF RT ASUNS PBT

1 | DRG NO :- 7-44-661 SHT 1 OF 2 | REV

ORGRAL BIE °

wave] cro] aPPO ALTERATION Rev

EXISTING STEEL

EYE ROD C.S.

FOR DETAILS REF.

SHT. 2 OF 2

PIPE_CLAMP TYPE C1

~ SID, 744-64

D = NOM. PIPE DIA IN (INCHES)

CAD NO~ 7-44~662

MAX.

ALLOWED

D e}ale

LOAD (Kg) H2-L =D

1/2" 35

3/4 38 TYPE

T) 450 | 12 424 45 LENGTH

17 50

2 55 NOM. PIPE SIZE IN

x” 75

#| 800 | 76 | 90| 50

= 125: SYMBOL

ge] 1200 | 20 [a5] 60

10" 190)

72] 1500 | 22 f5q] 60

147 230 NOTE:—

te] 2100 | 25 [270] 75 1. LENGTH OF EYE ROD = (L + C)-A

18” 290

20" 320

Jar] 2800 | 28 P5Q4 75

BARE PIPE

6

5

4

3 | CUENT,

2 [ime Ty re OE

1 [ORG NO :— 744-662 SH i oF 2 [REV

ORIGNAL SSUE °

wave] cHko] aPPO| ALTERATION ReV

‘Emm

DETAIL ‘x 2

EXISTING STEEL 2 once en

4k z 40

c

pa CU UR a

3| “gg DETAIL NT N a ai

41(R00 DA) es The

4 | a LEFT HAND ici naNo |

ia |} wns THREAD THREAD | ~—DETAIL ‘0’

let TuRWaUCKLE)

Sle — fj|__tancer roo THREAD ROD DIA

ae DETAIL i ) a

fi I

wu CLAMP TYPE ct S :

FOR DETAIL u

SID. 746-641

DETAIL ‘e"

| (HANGER ROD)

at 6

HANGER ROD

>| | Popes oeacr

UTU rir CL

N 100 uP To 8”

we (0 FOR 10" THRU 24"

O = NOM, PIPE DIA IN INCHES DETAILN (BEAM BRACKET)

a BEAM BRACKET HANGER ROD TURNSUCKLE

p | A | ALtoweD| a1

LODE (Kg) mM] t|n]urls | e2) pr )c}u]«

172", 35

3/87|_40

490 | 12 | 45] 6 | 60] 170| 75] 14 | 130] 100] 14 | 2° | ss

woo [76 [eo [8 | 75] 190] 100] 18 | 150] 10] 18 | | 8s

1200 | 20] 90] 8 | 115] 210/120] 22 | 160] 120] 27 | 2" | 53

1800 | 22 |100 | ro | 125 | 220) 138 | 24 | 180] 130] 26 | 2" | 53

2100 | 25 |120 | 2 | 130| 230) 150 | 27 | 200] 140] 27 | 2° | 53

2800 | 28 |150 | 14 | 150| 250/ 165 | 50 | 210] 150] 30 | 3" | 70

Tee NOM, PIPE_SIZE BARE PIPE

(IN INCHES)

LeNGTH SYMBOL

é

5

2 +

& 3 CUENT

3 2 [me ER ee

‘ [ors No 7—a4-663 [ST we,

2 ORIGINAL ISSUE oO

| waoe| cuKo] aPPo ALTERATION ev s

EXISTING STEEL

BEAM BRACKET

REF. DETAIL — N

OF 744-663,

TURNBUCKL:

REF. DETAL — 0

OF 744-663

HANGER_ROD

NOM. PIPE DIA IN INCHES

REF. DETAL

OF 744-663

PIPE CLAMP TYPE-C3

FOR DETAIL Ri

STD. 744-643,

TPE

LencrH

NOM. PIPE SIZE

(IN INCHES)

SYMBOL

= PIR RAGE RIOR, TO NSU ADS PPE SIE

ORG NO 7—44~665 SH

Tie Sine hee ion

Blol-|wfufa fala

CAD NO~ 7-44-65

CAD NO 7-44-6866

3 41 (ROD DA)

at i)

Ron DAY

+ EYE_ROD WELDED EVE EYE ROD

(CARBON STE

PIPE CLAMP TYPE C3

FOR DETAIL REF -

< 51D. 7=44-643)

2

EYE ROD

MAX. EYE ROD

p | aowen | a fc

LODE (Kg) ai | s | a2

D = NOM. PIPE DIA IN (INCHES)

a 110

3a 115;

1 450 v0] 45 | 12 | 75 | 14

7a 140

z 155

z 185

= 18

4 00 | 205 | 50 | 16 | a5 a)

e 240 —

Fr] 1200 fag] 60 | 20 | 95 | 27

10" 315

a] 1800 Page] 60 | 22 | 105

16 355 0

te" | 2100 © [ses] 75 | 25 | 115 NOM. PIPE SIZE IN (INCH!

18" 425 0

= 38 SYMBOL

20" 455

pe] 2800 Foe] 75 | 28 | 130 Sp

NOTE:

LENGTH OF EYE ROD = (L +c) — A

6

5

4

3 | CUENT,

2 [ice = SIE RRL PRR OF RRO TE AE Sar

1 _[oRG NO 7-44-66 suri oF 1 [Ro

ORIGNAL SSUE °

wave] cHko] aPPO| ALTERATION REV al

gt (ROD DIA)

1 (ROD_DIA.

7 exe op weep eve

PIPE CLAMP _TY%

FOR DETAIL REF.

<| STD. 744-650

2

EYE ROD

0 = NOM. PIPE OWA IN (INCHES)

MAX.

p | AoweD | a fic EYE ROD

ai | s | a2

85

90

i) 9 | 45 | 12 | 75 | 4

1172" 115

z= 130

S00 HY 50 | te | 05 | 10

e 100

& 215

Fr] 1850 Faso 75 | 258 | 9 | 27

10" 290

Se

1a" 350 NOM. PIPE SIZE

16" 370 (INCHES)

18" 400 Y

20" 3000 430] 15 | 32 J 115 | 35 SYMBOL

2a | 4500 | 480 [120 | 36 [iso | 39

NOTE:—

1. LENGTH OF EYE ROD = (L +c) -A

AD NO~ 744-667

6

5

4

3 CUENT

PIPE BARGER -SUPPDR:

2 [ime PPE Pe

1_| DRG NO 7—44~667

ORGNAL BILE °

wave] cako] APPO| ALTERATION ReV 25)

CAD NO 7-44-68

é EYE_ROD_FOR

oo ORY DETAIL REF.

744-672

ff PIPE_CLAMP TYPE-C16

FOR DETAIL RE

« STD. 744-656

D = NOM. PIPE DIA IN INCHES

MAX.

p | auoweo | g falc

LODE (Kg)

a7 35

3/e 40

TF] 450 yo [45 | a5

Tae 50

z 65

S100 16 224 60

+ 2 He — lL — 0

= 120 —

Fy] 1950 2 ase] 75

10" 185 Tee

12 215

NGTH

ta] 2600 28 oe] 80

18" 265 NOMPIPE SIZE

18" 285 (INCHES)

=| 3000 30 115

201 315 SYMBOL

24" | 4500 36_[ 365 [120

NOTE:—

1. LENGTH OF EYE ROD = (L +6) - A

6

5

4

3 | CUENT

PIPE-HENGER SUPPORT FOR EAR:

2 [me Pipe tp iu 24° Trea

1 [DRG NO 7-44—668 ‘SHT 1 REV

ORIGNAL SSUE °

wave] cHko] aPPO| ALTERATION REV 25

CAD _NO~ 744-868

@ mm

EXISTING STEEL F pe

40

WE

DETAIL ‘x’ IX corcs ar

BEAM BRACKET _—

DETAIL “N |__| x

a1(R00 OW

i Z|

RIGHT_HAND al

ti THREAD a] Lert nano

&] THREAD

an 6) TURNBUCKLE |

4| es nt DETAIL aI DETAIL_‘o"

zz (TURNGUGKLE)

= EET HAND.

ea OT THREAD ¢ dt

= HANGER_ROD Rou Di

{1 DETAIL “P’ 1 Fs

— FHC cue ree-cis | 3 3

FOR DETAL rer. | &| L

S10. 744-658 | |

2 2 DETAIL ‘P’

—f 4} (HANGER ROD)

F ‘ 2

>| | +4) nave w00

1 ro} REF. DETAIL-P

N 100 UP To 8"

tn 7 .

DETAL ‘Ny 130 FOR 10" TR 2

0 = NOM. PIPE DIA IN INCHES (BEAN BRACKET)

MAX.

5 ne BEAM BRACKET | HANGER ROD TURNBUCKLE

A |voap (ko)| 41] mM] t | N | ur] s | a2] wz] r ic | ais

| 35

3/47|_40

TT 48] 450 | 12 | 60 | 6 | 60] 120) 75| 14 | 130] 100] 15 | 2 | 53

TZ] 50

2160

S| 80

Free] 800 | 16 | 80 | 8 | 75| 150| 100] 18 | 150] 110] 15 | 2° | 53

7] 125

StHe4 1980 | 25 [120 | 12 | 130| 220| 120 | 27 | 200] 140] 15 | 2" | 53

To" [190

12" [220

Ta tssn] 2600 | 28 |130 10 | 250] 138 | 30 | 210] 150] 20] 3° | 78

16" 270

18" [230 ; .

F182 3000 | 30 |140 | 16 | 160] 270/ 150 | 33 | 240] 170] 20 | 3° | 78

2a"[370 | 4500 | 36 [150 [18 | 180 | 2901 165 | 30 | 280 [2001 20 | 3" | 78

4-1-0

rec] NOM. PIPE_SIZE

LENGTH (IN INCHES)

SYMBOL

6

5

4

3 | CUENT,

2__| TITLE PPE WNOER SUPPORT FOR BNE PPE SUE 1/7 WRU 20" NRE 8

1 [DRG NO 7-44-69 [sai REV9|

ORIGNAL SSUE °

wave] cHko] aPPO| ALTERATION ReV 30

m BEAM BRACKET

REF. DETAIL-N

OF 744-669

'URNBUCKLE

REF. DETAL-O

OF 7-44-6869

HANGER_ROD

REF. DETAL-P

OF 7-44-669

CLAMPS TYPE=C10

FOR OETAIL REF.

<| STD. 7-44-650

D = NOM. PIPE DIA IN INCH

CAD _NO~ 744-670

"Owe

aul

D d|a

LOAD (Kal

77 35

ve 30 HiO-L-D

T] aso | 12 [95 ree]

Taz 15 7

2 130 cl

= 180 NOW. PPE SZE

=] 200 | 16 ee (WINCHES)

e 215

2 syMpoL

S190 | 25 [2 SYMBOL

io" 230

i= 320

12} 2600 | 28 [322

ie 370

187 00

1871 3000 | 30 [492

24 | 450036 480

g

5

+

3 | cueNt

| TUE PPE NG PRT FOR ASU OS FRE SEE 7 TR 2 PE HO

[BR no 7=#4-870 Tsar tor 1 [0

ORNL SUE °

waoe| nko) APO ALTERATION Rev 30

CAD NO~ 744-672

61 (R00 014

; wuts

| dit 2 NO:

Ty

' t

_|| [41 coo ow. _|| [41 coo ow

EYE ROD

pipe cue WELDED OYE eve noo

| cyeE-c12

FOR DETAL

ft Eee Fees an

- 2

EYE ROD

WAX.

p |[atuowen| a] c EYE ROD

LOAD(xGS)| als |

1/2" 110

3/40" 115)

+ D = NOM. PIPE DIA. IN INCHES. 7" 450 [420] 45 | 12 | 75] 14

1/2" 140

2' 155,

3 800 185) 50 16 | 100} 18

4” 205

&" yas0 [242} 75) 95 | 120 27

wiz to 8 275;

10” 315

TYPE NOM. PIPE DIA. 12" 345,

(INCH) 14" 2600 355 80 28 | 135 | 30

LENGTH ie a8

o 3000 115, 30 | 150 | 33

SYMBOL 20 $5

24" 4500 505 |120 | 36 | 165} 39

NoTE:—

1. L LENGTH OF EYE ROD=(L+C)-A

pi

5

*

3 [oun

‘2 TITLE PPE AANGR SUPORT OR NSU ALOYSS PPE STE 1/2" RU WE 2

1 [orc no 744-672 [sur or 1 [®%o

CRNA BOE °

wade] cana] PPO ALTERATION REV

TOAD Kgs. * i

Fes] 480° | 7 4 |b

e 1950 | 115,

8"1 185 ROO DIA (a) x

= (2600 130 PEA

7 | ‘MATERIAL EQUIRALENT \.

16" [308 3 TO PIPE SPEC

18" | 330} 4

20°] 339] “00° | 18° es a o [aleleclele la

24"| 410] 4500 | 180 ge &| 30 4

Go 5 70 1

g 120 [100 | 30 | 27 4

EAT TANG THREAD

SHIELLD oe ath

REQUIRED ON ore, ALL MATERIALS ARE CS ¥

q He

CAD NO~7-44-675

> Palelel@|e lr |e |e four aul

aS

wet L230] 8} [50] 75] 105] 0} 13x80

CENT (now 2 OR [sre [16 [0 |r0 [re [30 [75] 105] e0| 161110

eo era" | 25 [4012 [27 [40 | 751 115{100] 24x120

SYMBOL SS

honazrarae| 20 [as [16 [30 [45 | 75|120|100] z7s140

we'20" | 30/50 16 [33 [50 [foo] 160/100] soxrs0

za [36 [60 20 [se [60 hoo| 160/150] 36180

z

5

‘

3 | GuENt

2 TILE wa SFO FE NE ESET WA

1_| DRG NO 744-675 SHT 1 OF 1 REV,

Sana SSE nl

waoe| enna arr ALTERATION Rev

ect] 3 ‘ -

Sieg TIL 4

a © AY

o | x | tiie go oa as || .

Pes) 450 MaTeRAL_cOUNALENT

3 [00 10 PIPE SPEC

8 i24T io50 | ap~ beta

a [185] e 1

io" [217 8} Lock nur sya eee eee

12" 1287) 5500 |} petmen . = 76 | 106

14" [253 g —} ao 82] | 4

16” | 308) BOLT @d 3x 3 185 |25 18 10 114} 189

= # [100 170 152] 209

= 332) 3000 6" 220 ‘ 229| 313

20" [339 120 2

2a" [410] 4500 e| 7° |aa0|50| °”|14| [305 | a1

10" | sg [300 ser] sie

12" | °° [60 457] 619

% a 30

4 400 | 40 333] 711

200

16" |7°° [aso 610] 813

Now PIE DA Nos rele

13" | [20 686] 915

“| 260 3

20" |**° [560 |s0 762 [1016

JOMINAL PIPE DIA. IN| INCHES 24° [280 [620| [39[22ho| era|iais

NOTE:-ALL MATERIALS ARE IN GS.

UNLESS OTHERWISE NOTED. @d1_NUT WELDED IN POSITION

o | ale] clele |r] e |e feo asx

NOM. PIPE DIA, z 12| 30] 8] 14 |30| 75|105| a0] 12x60

(cH) 37.4" | 16 | 40 | 10 | 18 |30 | 75/105] 80] 16x110

SYMBOL e8"_| 25 | 40 [12 [27 [35 | 75] 115]100] 24x120

ho*.12".147,16"| 28 | 45 |16 [30 | 45 | 75] 120| 100] 274140

1a"20" | 30 [50 |16 [33 |50 [100] 150] 100] sox160

CAD NO~7-44-676

2 36 [60 |20 [38 [60 [100] 160130 36x180

6

5

4

3 _| CuENT

2_| TITLE PPE WE SUPPORT FOR BARE WO AGUAED PPE STE THRU 26° TPE

1 [ORG NO 744-676 SHI OF Re

ORGINAL ISSUE 0

wane] cHKO| APPO| ALTERATION Rev

CAD NO~ 7-44~637

NOMINAL PIPE DIA. Joey CUT TO REQUIRED LENGTH AT SITE

Ld (00 WOT CUT THROUGH ELBOW OR PPE) o1430

Lhe woe 5

S — * FF +]

Bae ||

x28 Po } ts

Bs

BS

a I i

Gi SE jp

INSERT PLATE / i

i ‘x8xT (TYP)

a as! = -

| \ re 10 wove |

INSTALLATION. PROCEDURE

PLACE SUPPORT UNDER PIPE BEFORE CONN

PIPE FLANGE IS ALIGNED WITH EQUIPMENT OF

1) MATERIAL OF SUPPORT PIPE SAME AS MAIN PI

(BOTTOM OF HEX.

HEAD TO GROUND

SMOOTH)

IECTING PIPE TO EQUIPMENT TURN ADJUSTABLE NUT UP UNTIL

IR VALVE. FLANGE,

SPEC, ALL PLATES

CARBON STEEL,

2) IN CASE SIZE AND OR SCH. OF SUPPORT PIFE (D1) LISTED IN THE TABLE IS NOT AVAILABLE USE NEXT

HIGHER SIZE AND OR NEAREST EQUIPMENT THI

3) IN CASE OF HIS MORE THAN 1000, RASE

4) USE THIS DETAL AS SOLID SUPPORT FOR LINE WHEN VERTICAL THERMAL EAP,

COMMON USE SHOULD TO END SUCTION PUMP

(CKNESS AVAILABLE.

HT OR CONCRETE PEDASTAL TO SUIT.

IS NOT PRESENT, THE MOST

TURN ADJUSTING NUT UNTIL ELBOW FLANGE IS ALIGNED.

D1 HEX. BOLT FULLY

No} © | ocw-n/® [t | ¢ |rweoowmenow| HK | P|

FP e'sc90 7 : Tso|—10—| 5

1 Pesaran] 200 | 10 Fits] wevetoo wore 950} 90} 15

| $sei.a0~| 300-1 157 ; 250—|—T90| 22

2 [ety seras TOPE] 3/50 one | ge9— aoa

25 ; 3 —| 1}

3 fe] asco | sso | 12 [2x52] wer/s'a7s wove [S091 a5} 38

te er soa—| tao | 23.

eT; 55 Sof 280-97

‘ 16" B’scH.40 | 400 2 410 M=1"x175. LONG 350 230 27

5 18° B"SCH.40 | 400 12 454 350 230 27

a S50 5 soo | 790

6 [BT roscnao] 450 | 12 [ST warigiz00 vos F 22 T eTs

li7-1-H Li7A -1- 1H

nee re

sue 40, woos SHE Ho se.

seo, eos

a

5

4 | CuENT

3

2 | IME ADJUSTABLE LOW SUPPORT WITH 4—BOLTS

1 FOR PIPE SIZE 2"THRU 24" TYPE L17_& L17A

ye

=a aF 15g NO 7= 44-637 SH 10 3

waoe| ono APPO ALTERATION fev

9}

CAD NO~ 744-681

CLEARANCE

yo CLEARANCE jy

cups Furwisuen| TSP = T E79 4

Wik vesse, [>

° OETAL-N,

55 PLATE WELDED =P

7 TO" CHANNEL "

U-CLAMP TYPE C15 <2

NJ FOR DETAIL. REFER A

STD 744-655 "

>

v DTATR

+S a 2” | so| 30

Reto ' 3 | 60] 45

REE. LEVEL ! 4 | 80] 50

Pay +t : 6” | 100] 85

SL. 4! ee

sit DETAIL—M

aH

Xisa soxeoxg © NOM. PIPE 1 MATERIAL

208-6HOLES,

SOS EQUIVALET TO PIPE MATERIAL

50 LONG wax. 700

Win 400

L

a E 8

"

BTET EB] eee woe, ¢ —4.

Tyee «< "

LENGTH NOM. PIPE DIA

(INCH) ae

HOLES

SYMBOL

o[¢,e],o[et

1. THIS SUPPORT CAN BE USED FOR 2" [14 [116| 25 | 116

ALLOY/SS. PIPE FOR TEMP UP TO 400%C ¥ Te 1180] 30 | 220

2. MATERIAL FOR BOLTS _1S:1367 CLASS # | 18 11801 30 | 240

10.9 NUTS 1S:1367 CLASS 12. ~

6" | 22 [250] 35 | 320

DETAIL _— N

MAX. LOAD 2000 Kg.

6

5

4

3 | CUENT,

2__| TITLE BRET VION GAIN LO SPORT FOR BRE PPE STE? T&T Bl

1 [oRG NO 744-681 SHT1 REV

ORIGNAL SSUE °

wave] cHko] aPPO| ALTERATION ReV

“AN

sie \

SHOE TYPE SI FOR DETAL

REFER STANDARD

744-601

DETAL-N

IsMc175 og B

8%

curs elewsueo

5-HOLES 209 FOR

BOLTS WTEx50 LONG

5_CLEARENCE

(TYP)

NOM, PIPE DA,

ISA_80x80x8—10016

WELDED ON SHOE

alt.

SEX Isa f0xs008

nos-suoies Hall

FOR MiB BOLTS

50 LONG | wax, 700

MIN #00

—4I

TO, 13 GAP 175 \

|

3 [Pate

740

(SA 40x40x6

DETAL = N

Say

BZ — C—O] rer Lever

1, FOR INSULATION THICKNESS UP To 75

CAD NO~ 744-682

nee “ 00, FOR INSULATION THICKNESS:

LENGTH NOM. PIPE DIA 76 10125 H=150

a 2, MATERIAL FOR BOLTS 'S:1367 CLASS 10.9

4 NUTS |S:1387 CLASS 12.

SYMBOL MAX. LOAD 2000kg

6

5

4

3 _| CuENT

2__[ TITLE BRACKET ON VERTICAL COLUMN LOAD SUPPORT FOR INSULATED

1 [ORG NO 744-682 sur tort | RY,

ORGINAL ISSUE 0

wane] cHKO| APPO| ALTERATION Rev

A SHOE TYE $1 FoR ETAL

SPER SIE Soa BT

o&

be

se, \ octaL=

1 isMe_175

a

saves soe ro0

4;

5

55] |z0 i

1 |

Be

wx

Sat

be]

(INCH) 76 TO 125 H=150

4 NUTS |S:1387 CLASS 12.

CAD NO~ 744-683

6

5

4

3 _| CuENT

2_| TITLE BRACKET ON VERTICAL COLUMN VERTICAL GUIDE FOR INSULATED Pi

1 [ORG NO 744-683 sat iors | RY,

ORGINAL ISSUE 0

wane] cHKO| APPO| ALTERATION Rev

CAD NO~ 744-684

6 THK.

ETAL vou peony D4 Sele

80x {TP

SA 80x80x6 ) 45,85

+t t support

a Bee

+a OA

'

cus runwsied | :

WH WESSEL /

'

. < B

{ar NoTE=1

Ni 2! os. 208 Hoes | 8'| 4° SCH 40 | 510

FIELD WELD ATER fF FOR wie Bouts | 1o"| 6” scH. 40 | 337

ASSENBLE U 50 LONG iz"| 6 sch. 40 | 362

OeTAL-M

(SUPPORT PPE MATSIME AS UNE PPE)

0 _NOM. PIPE OW.

REF. DETAL-N T

—1t—

2x8 NOS, 208 HOLES FOR ISA 80x00x8

Wa’ BOLTS 50 LONG

Ji

dss oe

65| : * or} Rk jc

vd : T | 110 | 230

? iswe_175 1o"| 137 _| 340

3 ia 12] 162 _| 340

noossesbai7s|, = i DETAL = W.

g

WESSEL OD. a PROTECTION SHIELD NOTE 2

win.soo max. 800 | UNINSULATED

[WN S00-wax- B00 INSULATED

—4 MaTERAL:~

BOLTS |S:1367 CLASS 10.9

NUT IS:1367 CLASS 12

NOTE:

1. INCASE SIZE AND/OR SCH.

OF SUPPORT PIPE (4) LISTED

LENGTH «< of ma IN THE TABLE IS NOT AVAILABLE

eLsto fer USE NEXT HIGHER SIZE AND/

NOM. PIPE_OW OR NEAREST EQUIVALENT

Ray 1o"| 665 _| 665 THICKNESS. AVAILABLE,

12| 715715

SYMBOL 2. PROTECTION SHIELD SHALL

BE CUT FROM LINE PIPE.

F : 44-85-1003

et tolg MAX. LOAD 3000 kg

6

5

4

3_| CuENT

| TITLE Bo EW SO EH AD SF TE

1 [ORG NO 744-684 su tor 2 [RV

ORGNAL SUE °

waoe| cHko] APPO| ALTERATION REV

CAD NO- 744-686

6 THK.

WELD

NOM, PIPE DAY D_ 1 WELDEDZ

ISA 80x80x6

ak

oy

|cups_FuRNisHED|

WITH VESSEL é

N | nore-2 | ©

. to"] 6" sch. 40 | 337

! 4 12"| 6" scu. 40 | 362

NY | ye - 14"|_ 6" sou. 40 | 376

as 16"| 6" sch. 40 | 403

FIELD WELB A =] 6" sci

‘ASSEMBLE se"| 6" sch. 40 | 429

2.NOS. 208 HOLES) DETAL =

FOR Mi6 BOLTS

50 LONG

REF._LEVEL

NOM. PIPE DIA,

+H ETA 717

2x10NOS. 206 HOLES FOR

NT6. BOLTS 50 LONG

jj 4 HOU, Tee

ISA 80x80x8

“a ie] a7 0

12*| 162 | 540

16"|_ 203 [440

18"| 229 | 440

LUNINSULATED PROTECTION SHIELO

INSULATED NOTE tT

Isve_175.

NOTE:

1, PROTECTION SHEE

BE CUT FROM LINE PIPE,

D SHALL

Be — C—O ]_ rer even D

py ala 2. INCASE SIZE AND/OR

. - SCH. OF SUPPORT PIPE (4)

nee « 1o"|_675_| 675 USTED INTHE TABLE IS NOT

LENGTH NOM. PIPE OA 12] 725 | 725 AVAILABLE USE NEXT HIGHER

GNcAY 7 SIZE AND/OR NEAREST

va] 755_| 755 EQUIVALENT THICKNESS.

SYMBOL se} eos] aos AVAILABLE.

= 3. MATERIAL FOR. BOLTS

ve"| aes | 655 IS:1367 CLASS NO-9

REF : 44-85-1003 NUTS 1S:1367 CLASS 12.

CLIP No.10

MAX. LOAD 5,000

6

5

4

3 _| CuENT

‘2_| TITLE a0 YD uM SOR BASED PES EF

1 [ORG NO _7-44-686 su tor2 [Rg

ORGINAL ISSUE 0

wane] cHKO| APPO| ALTERATION Rev

nN

a

CUP_FURNISHED

Wit VESSEL

5 CLEARANCE

Pt

155

154 125x75x10

+, 2-18 # HOLES FOR

iE | | cusp mye c15, FoR

M16 BOLTS x50 LONG DETALS REF. STANDARD

qetanes5

. NOM. PIPE DIA

158. [|_| ances)

MIN, 400 KJ

—+t WAX. 700

o lala

* | se] 25

x | ao] 30

4 | 90] 30

CAD NO~ 744-691

eo | 125 | 35

a)

REF_LEVEL NOTE:

TE ” 1, MATERIAL FOR BOLTS 1S:1367 CLASS 10.9 &

LENGTH NOM. PIPE DIA NUTS 18:1367 CLASS 12.

(INCH)

SYMBOL

6

5

4

3_| CuENT

(2 | TITLE ET OF VTE CL VON GME FR WE PE SUE TE 8

1 [ORG NO 7-44-691 sut tor 2 | REY,

ORIGINAL ISSUE oO

MADE] CHKD} APPO| ALTERATION REV

CAD_NO~ 744-692

ISA 80x80x6

ISA_40x40x6

Ae.

| oo im y .

| ~

| cues ruausuen |

Simievesse.

d ch o fc ft

N BY A a) zoel a | 6

AFTER ASSEMBLY > fio" 70 2ef 125 | 12

etal

(ou, PIPE_O1A PETAL

DETAL=N

D a] 8

2 [200

Fp 2s] 2

tI | 297

A 6 284 16

al | a —— & ‘310

4 8 | Yau ior [357

; tou ' 12 382

ia | 398

HouEs te] 425] 18

ISA 125x75010 eas

20° [ara

8 24" ‘525

or

1. USE TYPE B11A FOR BARE AND 83 FOR IN SULATED

PIPE UP TO 6" SIZE IN PREFERENCE TO THIS TYPE

MATERIAL FOR BOLTS IS:1367 CLASS 10.9 &

wee NUTS I8:1367 CLASS 12

LENGTH <

NOM. PIPE DIA 44-85-1003

(NCH) cywpoL CLIP NO.16

6

5

4

3 _| CuENT

‘2 TTL avo Yoana GD ORBE wO ASUED ES ESE WT 8

1 [ORG NO 744-692 sut tort [Rg

ORGINAL ISSUE 0

wane] cHKO| APPO| ALTERATION Rev

g PIPE SHOE

z pepe hee Tea Ee Ee

FA » PROTECTION SHIELD [pjie2 ia2|210(2z0|234[250) 2621272 beo|

a OETAL-M [c[s02|332|360|370|384|400|412|426 |438|

0°. a

oe

yess J MATERIAL SAME AS

on { pre sece

t | 10 b 10

* | REF LeveL

sa 15MC_150

1 A|_150 UPTO 5”

__I 000 250 FOR 8" & ABOVE

(NOTE 1)

ARRGT TYPE=1

(WAX. LOAD 1000%9)

EXISTING STEEL

(nP)

LeveL

\ISMc_150

REF, LEVEL

15Mc 150

150_UPTO 5"

250 FOR 8” ABOVE

(NOTE 1)

ARRGT TYPE-3

wax

LOAD 1500K9)

REF. LEVEL

\ i5Me_150

i i L & | 150 vero 6”

yx 1000 "250° FOR 8" & ABOVE [Tia 000 250 FOR 8” &

(Wore 1) ABOVE (NOTE 1)

ARRGT_IYPE—3.

(WAX. [OAD 250Ka)

ISA 100x108 4

nant:

CASE BY CASE. L 0/2+80

MAX 1000 r (NOTE 7)

A

DIA(INCH)

B42 —2—L) REF LEVEL |

wnt : |

ARRGT TYPE « iri ;

vc

i

$

é

1_| DRG NO 7-44-742 SHT 1 OF 1 REV,

CAD NO= 744-743

> c

RE

ie

Tle io

ALTERNATIVE ae ak

ARG :

(Nore=2) ® ®

REF. LEVEL 3 REF_LEVEL + + 3

z

L

1 ARRGT TYPE = 2 2509 wax.

RE ia SE | 1

gt TS 5

R nee teva,

&. 2©@ ero |—€B- le © -@-

{ , j ]

t x 500 c [a

J250kg MAX L WARK. 1500 1

r ‘MAX, 2000 ~

. 25089 MAX

ARRGT TYPE — 3 ARRGT TYPE — 4

1 L

= Jape WAX OO

HI, ETS *

| | soocwax.) rT Te ae

! q g —— E

ef ser 5

L

WK TOOT

ARRGT TYPE~5

NOTE: ry

1. FABRICATE FROM ISA 80x80x8 t

UNLESS OTHERWISE NOTEt ey + >

2, THE aTTaCHEMENT oF suPbortiNe =f -—hwar“Tor

staf |

EXISTING ke |} x

Fi | REF LEVEL

B43—3—HL—x ] RE! : suc 26 + \1s0 one

TE LOCATION ARRGT TYPE-7 ALTERNATIVE_ARRANGEMENT (TYP)

ARRGT TYPE. HEIGHT/LENGTH MAX LOAD 750kg PETAL M

(APPUCABLE TO ALL ARRGT TYPE)

é

5

+

3 CUENT

2 [TE PPE SUPPORT BRACKETS

1_| ORG NO 744-743 SHT1 REV

ORGRAL BIE °

wave] cro] aPPO ALTERATION ReV

‘BOO{MAK)

From ppe

Breces Tea THAN

8

(FABRICATION

(WAXY (WAX)

CAD NO= 744-744

ISA =100x100%10

ISA =100x100%10

ARRANGEMENT TYPE-1 ARRANGEMENT TYPE-2

(FOR UNBALANCED LOAD) (FOR UNBALANCED LOAD)

WAX

o ALLOWABLE

LOAD Kgs.

8 0/2 ° 30

OO(MAK) + =

b 4 140

e 700

oa 2000

10"

THRU 4000

a

\

ISA_~100x100x10

B44—65—D

ARRANGEMENT TYPE—3

(FOR UNBALANCED LOAD) Pe NOM. PIPE D/A (INCH)

LENGTH

6

5

4

3 | CUENT,

2__| TITLE PIPE SUPPORT BRAGKET FROM PIPE 3 THRU 24” TPE B44

1 [ORG NO 7-44-744 SHT 1 REY,

ORIGINAL ISSUE. 0

wave] cHko] aPPO| ALTERATION REV

Smm_CLEARANCE

o

NOW, PPE DA

NOMINAL PIPE

OIAMETRE

‘FLAT

‘SEE TABLE

CAD NO~ 7~44~751

A A

FOR SIZE_UPTO 10” FOR SIZE_12” THRU 24”

GI--D

sua. Tyee NOM PIPE_DIA(NCHES

Do A ® | FLAT SIZE | ANGLE SIZE

vi 26

Ye

>

=

nc 6 | 40x65 --

iV

+

WA

$

33

.

10 | sox10 --

14” 10 65x12 75x75x10

ie

20” 10 75x12 90x90x10

24"

NOTE

Tz PROTECTION SHIELD 1S TO BE CUT FROM LNE PIPE.

g

5

4) CuENT

3

7 | TLE GUIDE SUPPORT FOR BARE PIPE

< SIZE 1/2" THRU 24” TYPE Gl

: = TRE

— + pag NO 7= 44-75 Sito al

waoe| nko) APO ALTERATION Rev

CAD NO~ 7-44~-752

NOMPIPE DIA

3 CLEAR

ROO(TYP)

FOR SIZES UP TO 4”

FIELD WELD

Pye

NOM.PIPE DIA.

Nett —A- Arai —e

FOR SIZES 6” THRU 24” ‘OR SIZES 6" THRU 24”

G2A=-0

Tee NOM PIPE _DIA(NGHES) Tee NOM PIPE DIA(INGHES)

sweat sao

oD H | @ MATERIAL

2" & sMauer| 40 | 6 FLAT 80x10

sto4" | 70 | 6 FLAT 80x10

eto 8" | 130 | 6 | 2 Nos ISA 50x50x6

10" 10 18" | 230 | 10 | 2 Nos ISA 75x75x10

20" to 24” | 350 | 10 | 2 Nos ISA 90x90x10

‘NOTE:=

1. GUIDE ANGLES SHOULD BE SUTABLY TRIMMED WHEREVER

IT OBSTRUCTS WITH ADJOINING GUIDE ANGLES.

6

5

4 CuENT

2 Lar GUE SUPPORT FOR SIRE FE

: SiZE_1/2" THRU 24" TYPE G2 & G2A

AE ORE NO 744-752 sur or | Ro}

wave] cHko] aPPO| ALTERATION ReV

CAD NO~ 7-44~753,

= soxine

~ | 15)

dt tefl = :

a E Ps

i sons

2

som Brora

cRoss ouide

2” THRU 12”

a scot

sim f=, ol

i sons

af

Ju

soma cs pure tromu cs pute sors son

CROSS GUIDE

2” THRU

a

reel] bow pt on

DISTANCE BETWEEN INCHES)

an oe

se MRNETON seo SL 9 cUT Pw UNE ae

j

:

4) CuENT

2 ae GROSS BIDE FE

: Bo oe ne

ORIGINAL ISSUE 0 DRG NO 7—44-753 ‘SHT REV |

eo we

CAD NO~ 7-44~754

5. oo 1 [pie ie po Le

1

cam 150 200 250

x

BY FIELD

a .

fi

[ IsMB. i

SEE TABLE 4

a i

g i

a4 i

2 ol '

FOR PIPE 2” THRU 12”

x

BY FIELD

-—|—..—.- —.— | —.. —_

3 aoe i

ise i

SEE TABLE 4

3 :

a :

5 q }

5 :

3 3

FOR PIPE 14” THRU 24”

|G4——D

8 NOM PIPE OUJINCHES)

sme.

g

5

4) CuENT

3

7] ME CROSS GUIDE FOR BARE PIPE SIZE

2 2"THRU_24"1YPE_G4 (FOR OFFSITE)

wey,

=o EE 1 [ong NO 7= 44-754 sito al

waoe| nko) APO ALTERATION Rev

CAD NO~ 7-44~755

o eee [i [6 8 [20

1

caw 150 200 250

x

BY FIELD

[ i

SEE TABLE 4

3 1

2 1

2 J '

+ :

x PROTECTION SHIELD

BY FIELO CUT FROM LINE PIPE

||

. a + n 20" n

4 Set it ii

|,_isMe i

See TABLE

8 :

5 J i

5 2 :

2 :

G5 —-D

Te} |LNOM PIPE DIA.INCHES) |

seo,

6

5

4 | CuENT

3

7] ME ANCHOR FOR BARE PIPE 2” THRU

: 24” (FOR OFFSITE) TYPE G5

mE

ORGWAL SUE LORS NO 744-755 SHT_O

wave} cro] APP ALTERATION REV

CAD NO 744-781

Sam

[seRINc box to

Iree-1 j

FORCE_FIT

existing ae WAX,

fsvee g* | |p| x | allow, DETAIL x’

Sil= ale LOAD kg

ble | ee 0 | Norm 2

row wo gh ges] [# q a

fread ——~Lejx) Sieg) [e125 | 105 aI g, re

F a] 160 gl x

fuanauowe (Sef 3] Pete 3 &

erat 5 3 = r

8) fiz" 220 2

ert Hany “TE 3} P24 2600 a 8

eae &} [re 230

acer roo |! =| [is"| 270 ~

TAIL 18°] 290 LEFT_HAND cc |_ pice nano

. | 3000 THREAD TAREAD

tHE 20"| 320 DETAR ‘o*

»| | 2eLsz2 14500 0 = NOM. PIPE DA IN INCHES

i D c| aifa2] iz] Fr [c

< clump TwPE-c16 2 15 [12 | 2" [130100 | 33

| FOR OETA REF. ai 15 | 16 | 2*}150 [100 | 53

STD. 744-656 oe 15 | 25 [2* [200 [140 | 53

TO" 12" 1816" [20 | 28 [3"[210]150| 78

1%, 20° [20 | 30 | 3*| 240/170] 78

FIXTURE TYPE“A 2a 20 | 36 [3 | 280|200] 78

G Lert Hana a

5 THREAD | —_[ (ROD OA), |

5 8 gq 2 sy

g zg 2 So ¢g DETAIL _‘P*

jz 5 EF of o D = NOM. PIPE OWA IN INCHES

2% sl sf &) FE D s|ala

23 ou al gg = 712 [14

ge 8 Sf at Ss cru as [16 [18

Tis [25_[27

T= SHI = AS L= 0 130 268 | 30

150] 3035

SYMBOL Tose be

NOTES:

1. ALL MATERIALS ARE C.S. UNLESS OTHERWISE

NOTED EXCEPT MATERIAL FOR CLAMPS AS PER

STD: 744-656.

2, ALL THREADS ARE AS PER 1S:4218.

3. 25mm ROD IS TO HAVE 24mm THREADING

4. 28mms ROD IS TO HAVE 27mm THREADING.

6

5

+

3 | CuENT

2 [oe SE eS

1_[ ORG NO := 7=44~781 sat ore [PO

ORGNAL SSE °

waoe| cHK0] APP ALTERATION Rev

CAD _NO~ 744-784

existING 8 diR00

sree) WAX

BEAM D | X | attow.

Aaa LOAD kg o 5

BeTAIe TPs ry a

EYE NUT Zzts0| 450

DETAIL “N le 2T 60 oye

elg- |- 4% DETAIL ‘N’

LOCK NUT 26 5

‘a ey e562 |e { oo] °° D ey ues

Slee | el125 | 1950 P17 2 [12 | 75 [63] 14

sere sox | | |alBu [[eie0 Za be | sof es] 18

SUPPLIED By alge 2|[2o%l90 ee" __[ 25 [izs|ioo| 27

SENOOR 7p SSES| 21220] 500 12116" | 28 [145 [117] 30

| ESeS) el250 18", 20" 30 [160|130] 33

auger vino ffi) AS all e270 2a 36 [190]154] «0

Beene Lele) “IE Bifistt2907 350

i aI mm

1 i I[-20"|320 7

qurnauckie |i} §|[2¢"[370 | 4500 “| 2 &

DETAIL “O" & =| F 8

unio Wi Sg q| a SLE

THREAD 1 Z g pz 2

Hancer roo || sa. Ey DETAIL "x"

Dera "Pp Zea] 2 St ———

nom. ewe ||" & e| &| 3 Soe Fs] 8

DA. of | glee} S] eI 2 BS Sy

aig >] 5S 5 ey

° {8 «| x} | | uct umnd\ |p /ricut nano |S

als €| €| 9 8

4 LBS FE) 8 | THREAD THRE

DETAIL ‘0" a8

D Cl aia Try

z 15 [12 [2° [730700] 53,

eye Tre e368 “Fp | s@ [15 [16 | 2"[150] 100] 53

EID Jeet—656 6 8_| 15 | 25 | 2" [200/140] 53.

FIXTURE TYPE-A 9 = NOM. PIPE DIA 70%12",14",16"| 20 | 28 | 3" | 210/150 76

NOTE IN INCHES te", 20" | 20 | 30 | 3"[ 240] 170 78

2a" 20 [36 | 3" |280|210 | 78

1. MATERIAL OF CLAMPS SHALL BE AS PER 7—44~656

CLAMP TYPE-C16. ARS OTHER MATERIAL ARE C.S. LEFT HAND == -@ d1(ROD DIA.)

C.S. UNLESS OTHERWISE NOTED AREAD RQ

SY a

eee qr ps! :

2 BOLT = || DETAIL,

up ed

J D S[ajd

6 el c ae 75 | 12 | 14

DETAIL ‘M’ ze Too [16 [18

sor oe 120 [25 | 27

oO _[aifelcldge[r [c[ | Sar TO 12" 147, 18" | 135] 28 | 30

we"_2" [72 [50] [14/30] 75] e0|r08| 12430) 18,20 750 30 | 33

3,4" |16|40]70] 18130] 75] e0|105|16«1 10] 2a" 765 36 | 39

67, 8” [25|40|12|27|40} 75[100}115|24*120]

{0% 12",14,6"|28 45 16]30145| 75|100)120|27140] NOTES:—

18", 20°] 30|50]16|33[50fi00)00)150|30x150) 2. ALL THREADS ARE AS PER IS:4218

Jar Beleole ssbeoholtaoliselsee 120] 5. 25mme ROD 1S TO HAVE 24mm THREADING

4. 28mme ROD IS TO HAVE 27mm THREADING

6

5

4

3 CUENT

‘SPRING SUPPORT ARGANCEHENT TOR GARE A RSUIATED

2 [re SPAN Sze I aRU oe Nee oat ATO

1 [ORG NO_7-44—784 sut tor 8 | REV9|

ORIGNAL SSUE °

wave] cHko] aPPO| ALTERATION ReV

SPRING BOX TYPE

EXISTING STE

lJ

L (FABRICATED _LENGTHO

| 4

o | x | aaWance

ce UGKS Ky

Se 1 [48

ae 750] 450

sé 2" [60

g\4 = [60

2/3 7 800

=8 # [90

as [slo

als 5° | 160

alg 10" | 190

os 12" [220

als 14" | 230 |" 2600

a 16" [ 270

2 18° [290

20" | 320

26° | 370 | #800

CLAMP _TYPE-C 16

NOTES,

ALL MATERALS ARE CS. UNLESS

OTHERWISE NOTED. EXCEPT

MATERIAL FOR CLAMPS IS AS PER

sto,

ALL THREADS ARE AS PER 1S:4218

25mm ®ROD IS TO MAVE

24mm THREADING,

26mm PROD IS TO HAVE

27mm THREADING,

CAD_NO~ 744-785

FOR DETAIL

744-656

NOM. PIPE OIA

ol FITURE TYPE-A

8 NUT

g caw

2 SS PIPE. i

z| § g a1_ROD

a 2| 2

Z| gf ef 2g wie DeTAL M

<) g) &) | @ ° ap>uy.¢ @

2) av} at Be Tye 12 75 63 14

a) o 3 8] & se ws [90 | es 18

S| & & a 3 oe 25 125 [100 7

7 SMS SAS LS 10", 12", 14", 16"| 28 145, M7 30

78", 20" 30] 160) 130] 38

24" 36 190 154 40,

6

5

4

3 | CuENT

2__| TITLE $6 SOT NCO EO RUD PES BR TE 96-A

1 [DRG NO 7-44-7865 SHT 1 OF 5 | REVg

°

ReV

PRT Ee ae eye io ie ae [ae [ae | 20" [22 oa

[24 | 30 | 45 | 37 | 34 [10 137 | 162 | 178 | 203 | 220 [254 [275 [305

30_| 40 [50 [50 | 50] 100] 150 | 200 | 200 [200 [200 [200 | 300 [300 [300

160 [160 | 160 | 160 | 165 | 165 | 200 [220 | 230 | 230 [275 1270 | 300 [295 [290

;

‘ a

oll co |l20 “

ron pie

PIPE DIA. (NOTE-1)

TOTHK

t

i

EXIST. STEEL|

NSULATED PIPE

PROTECTION SHILD

(NOTE=2)

CBA NOTE:=

1. FOR PIPE SE UP TO 6” ALL PLATE MATERIAL SHALL BE EQUNALENT

REF. LEVEL

=

Tee NOM PIPE IA TO PIPE MATERAL. FOR PIPE SIZE 8” AND ABOVE PLATE MATERIAL

‘smug. (INCHES) SILL BE CARBON STEEL FOR TEMP. UP TO 4001 AND EQUNALENT

ee To PIPE AERIAL FOR TEMP. ABOVE 400°.

2. PROTECTION SHIELD CUT FROM LINE. PIPE.

CLIENT

TALE SUPPORT LUG, SLIDING FOR SARE/INSULATED

PIPE SIZE_1” THRU 24” TYPE CS & CSA

DRG NO 7—44-645 SHT__OF FeVo|

ORGINAL ISSUE

CAD NO~7~44~G45A(SHEET 2 OF 2)

Blol-|wfufa fala

wane] cHKO| APPO| ALTERATION

BOLT SIZE Wiad, WiaaS | wiexS0 MT6xEO)

D Fs 7

R a7 [24 130 [45 |57 | 84 [110 [137 | 162 | 178 | 203 | 220 [254 [275 [305

A 30 40_|-50_|-50_| 80 | 100 150 | 200 | 200 | 200 [200 | 200 | 300 {300 | 300.

5 190 | 190_| 160 | 160_| 190 | 190 | 230 | 230 | 280 [280 [275 [270 | 300 | 295 | 290

c 1 [ia [ia [ie [is [16 [18 [18 [20 [20 [20 120 [20 [20 [20

E 0 fo 017 18s fs fio [010 [10 [10 [10 [10

SLOTTED HOLE te?

FOR PIPE

THRU 6)

so mK BL

von 0; nore youn.

oe rm ! !

ee ip) 4 db

! af. \ H i !

| ("

BARE PIPE

PROTECTION SHILD

(NOTE=2)

CBA =

REF. LEVEL AT

o 1. FOR RE SZE UP To 6" AL PLATE MATERA SAL OE EQUNALET

ee NOM _PIPE_DIA TO PPE MATERIAL FOR PIPE SIZE 8" AND ABOVE PLATE MATERAL

sso. (INCHES) SHALL BE CARBON STEEL FOR TEMP UP TO 490 AND EQUNALENT

= TO PIPE MATERIAL FOR TEMP ABOVE 400°C.

2. PROTECTION SHIELD CUT FROM LINE PIPE.

CLIENT

TALE SUPPORT LUG FIXED FOR BARE/INSULATED

PIPE SIZE_1” THRU 24” TYPE C6 & C6A

DRG NO _7—44~646 SHT__OF FeVo|

ORGINAL ISSUE

CAD NO~ 7~44646A (SHEET 2 OF 2)

Blol-|wfufa fala

wane] cHKO| APPO| ALTERATION

CAD _NO~ 7446068,

~

cut To _sut

THE HEIGHT

C

D= NOM, PIPE DIA

300 (14-24%

]/ 8 sae ioe sas

see asus

TAGE OH

{ CUT_FROM

| exe ee

¢ oa

>

ce} RB} A | bh

we [ive [250 [35

167 | 203 | 300-26

ter [228 [34025

20" [254 [360126] 95 ag ve

2° [276 | 300 [30

see use [2a 305 [400 [77

‘ANGLE IRON [26" [ 330 | 415 30

sez vere [2] 388 | 35 28

sor [ser sis [31

57 [406 | 530_[ 29

ROO # 34" | 432 | 550 32

/ 36 [4st | 505 30

BAS) SSL on 100 x 8

40° [507 | 600 [31

2 az | 533 | 620 | 34

: : ae [610 L650 [=

A

AG.=2

GUIDE 3

SHIH - <—

TYPE 3

A. B

NOM. PIPE SIZE 10 30

SYMBOL

z

5

‘

3 | GuENt

2. [TIE PPE SIODEL FOR GARE PPE TE 56 © Sta

1_| ORG NO:~ 7-44~606 SHT 2 OF 2 REVO

Sana SSE 0

waoe| enna arr ALTERATION Rev a

Me

IsMB_(7) lo

SUDING PLATE. |S

BxGx12 THK,

INSERT PLATE “|g

ExPx1Z THK, |S

&

ge A

is 75x75x6

SUDING PLATE

[bxeei2 Tre

INSERT PLATE

By! [ExFui2 THK.

oy

4

y

f= EAS

snnmceuent wet = 3 smowccwent nee

(CROSS GUIDE) (GUIDE)

Fe

4200

CAD NO~ 7446334

CL —|—Teak

25

SECTION 8 8 secTon ¢ ¢

LiSA_— 3 =N =] rer, teen

Notes

ee NoM. APE OIA

INCHES 1. ALL DIMENSIONS AND SECTIONS "A-AY REFER

ARRANGEMENT TYPE HEIGHT SHEET ~ 1 OF 2

2. PROTECTION SHIELD SHALL 8 NOT

syweou FROM UNE PIPE

GUIDE AND CROSS GUIDE

6

5

+

=| cuenr

2__[ TUE on SFO OF WED GONE STEW WAU WT WEL 8 LW

1_| ORG NO 744-633 SHT_2 OF 2 REV

ORGWAL SUE °

wave} cro] APP ALTERATION REV

10"

16" | 18" | 20"

137

203 | 229 | 254

200

200 | 200 | 300

240

228 | 220 | 250

ofe|>|alo

18

50.

20] 20] 20

to| 10[ 10

M18 x 60

SLOTTED HOLE

‘SLOTTED HOLE

NOM, PIPE DIA,

10 THK, PLATE

)

:

PROTECTION SHIELD

NOT

FOR PIPE 8" THRU 24”

10 THK, py 80

NOM. PIPE DA

EXISTING STEEL

(nP)

FOR PIPE SIZE UP TO 6” ALL PLATE MATERIAL SHALL BE EQUIVALENT TO PIPE MATERIAL. FOR PIPE SIZE 8” AND

ABOVE PLATE MATERIAL SHALL BE CARBON STEEL FOR TEMP. UP TO 400°C AND EQUIVALENT TO PIPE MATERIAL

FOR TEMP, ABOVE 400°C.

PROTECTION SHIELD CUT FROM LINE PIPE.

CAD NO~ 7446464

a

5

‘

rc

[TTC SPT BAD ESE WT a

1 [oR No 744-606 | SHT 2 OF 2

0

ev

INOM, PIPE DIA

CAD NO 7~446614

on TT

iB rat TURNBUCKLE

a 9 ryt REF. DETAIL ‘O° OF 7—44-663

PH Sfx iW (SH. 1 OF 2)

e Se um

ey ele 4

SEG Pry

ze FR HANGER ROD

iB REF. DETAIL “P” OF 7-44-6635

4 (SH. 1 OF 2)

JON, pipe _cLame

<| / TYPE C2 FOR DETAIL

REF. STD. 744-642

D = NOM, PIPE DIA IN INCHES

a}/ajftcl}s

HIA

85

80 TYPE

12 95] 45] 75

115 LENGTH

120)

140 NOM. PIPE SIZE IN INCHES

16 | 160 | 50 | 85

20 524 60 | 95

250

op [292

3201 60 | 105

330 NOTE:—

25 [380] 75 | 115] THIS SUPPORT IS USED AGAINST HANGER

400 SUPPORT TYPE HZ

430

28 75 | 130 | WHERE MORE ADJUSTABILITY IS REQUIRED

480

INSULATED PIPE

6

5

4

3 | CUENT,

2 | Tue EGE Wha ae hee ae a ia PPE

1_[0RG NO: 744-661 sHT 2 oF 2 [RV

ORIGNAL SSUE °

ALTERATION ReV

CAD NO~ 7~446624

di (ROD 0

_f wosas LO

ae ot

EYE_ROD

CARBON STEEL

WELDED Eve

PIPE CLAMP Ty!

FOR DETAIL REF.

S10, 744-642

02

EYE_ROD

IN (INCHES)

&YE ROD

c

als [ae

as | 12 | 7s | 14

so | 16 | a5 | 13 2A — {0

60 | 20 | 95 | 22 Tyee

60 | 22 |105 | 24 LENGTH

WZE IN (INCHES)

75 | 28 | 115 | 27

SYMBOL

75 | 28 |130 | 30

INSULATED_ PIP!

LENGTH OF EYE ROD = (L + C) ~ A oo

6

5

4

3 | CuENT

2_| Te PIPESIZE_1/2°THRU24” TYPE H2&H2A

1 [DRG NO_7-44-662 [set 2 of 2 [REVO]

ORIGNAL SSUE °

ReV

NOM. PIPE DIA IN INCHES

EXISTING STEEL

a BEAM BRACKET

a REF. DETAIL — N

4 OF SHT, 1 OF 2

od

‘TURNBUCKLE

REF. DETAL — 0

OF SHT. 1 OF 2

HANGER ROD

REF, DETAIL — P

OF SHT. 1 OF 2

PIPE CLAMP TYPE-C2

FOR DETAIL Ri

STD. 744-642

CAD NO- 7446634

MAX. ROD

p | aLtoweo. | DIA A

LODE (kg) | d

za 35 Tee

3/4" 90 LENGTH

* 450 12 $8.

- NOM. PIPE SIZE

11/2" 5

> (IN INCHES)

z 130)

> 750 SYMBOL

«| __800 76 180)

o 215

NOTE:—

s] 1200 20 =

1" 290 USE UP TO A TEMPERATURE 350° WITH THE

wo] 1500 2 oo WAX. LOAD CARRYING CAPACITY GIVEN, THIS

- CAN BE USED UP TO 400° MAX. TEMPRETURE

14 330 WITH DUE REDUCTION IN LOAD CARRYING

te | 2100 2 370 ccaPaciTY

187 400

20" 430

INSULATED PIPE

se] 2800 28 te0

é

5

+

3 CUENT

2 Tne PRAGA PE SE

1 |ORG NO 744-663 SHT 2 oF 2 [REVo

ORGRAL BIE °

ccHko| aPPO ALTERATION Rev 25

You might also like

- ROC-MSE-SPC-00157 - 01-Standard Pipe Support PDFNo ratings yetROC-MSE-SPC-00157 - 01-Standard Pipe Support PDF136 pages

- 10070-C63-XX-XXXX-ENB-0001-024 RTP03M 44MPS-Old Pole100% (1)10070-C63-XX-XXXX-ENB-0001-024 RTP03M 44MPS-Old Pole1 page

- 1CB2S40 Piping Material Class Specification: 000-SP-PI02-0191No ratings yet1CB2S40 Piping Material Class Specification: 000-SP-PI02-01915 pages

- 7-13-0003 Rev7 - Hot Insulation Supports For Storage TanksNo ratings yet7-13-0003 Rev7 - Hot Insulation Supports For Storage Tanks3 pages

- Piping Support Standard Specification (190-216)100% (2)Piping Support Standard Specification (190-216)51 pages

- Piping Stress Support Calculation SheetsNo ratings yetPiping Stress Support Calculation Sheets37 pages

- Heat Transfer Equipment Design ParametersNo ratings yetHeat Transfer Equipment Design Parameters6 pages

- Fabricated Tee Strainers: Features OptionsNo ratings yetFabricated Tee Strainers: Features Options3 pages

- PW-CH-CRX19001-GAD-001 - 5 - GENERAL ARRANGEMENT DRAWING - Pig Launcher Receiv..No ratings yetPW-CH-CRX19001-GAD-001 - 5 - GENERAL ARRANGEMENT DRAWING - Pig Launcher Receiv..1 page

- Fire Water Tank Datasheet for Bus FacilityNo ratings yetFire Water Tank Datasheet for Bus Facility10 pages

- Insulation Thickness Calculation of Pipe: T T T T Input Required100% (2)Insulation Thickness Calculation of Pipe: T T T T Input Required3 pages

- Snamprogetti-Desing For Piping Support-2001-138pagesNo ratings yetSnamprogetti-Desing For Piping Support-2001-138pages138 pages

- IS 6392 - 2020-Steel Pipes Flanges - SpecificationNo ratings yetIS 6392 - 2020-Steel Pipes Flanges - Specification62 pages

- SP-P-002 - Rev 1 - Spring Hanger and Support100% (1)SP-P-002 - Rev 1 - Spring Hanger and Support7 pages

- Shell Thickness Calculations for Pressure VesselsNo ratings yetShell Thickness Calculations for Pressure Vessels16 pages

- Approved For Construction: Only Areas Encircled in Red To Be Actioned (Points 5, 6, 7 &8)No ratings yetApproved For Construction: Only Areas Encircled in Red To Be Actioned (Points 5, 6, 7 &8)21 pages

- Jumper Single Suspension String For Cond 2xacsr 240 - 40 Up To 150KV Transmision Line (En)No ratings yetJumper Single Suspension String For Cond 2xacsr 240 - 40 Up To 150KV Transmision Line (En)6 pages

- Reparacion de Una Maquina Caja Reductora LufkinNo ratings yetReparacion de Una Maquina Caja Reductora Lufkin4 pages