0% found this document useful (0 votes)

2K views1 pageWheel Loader Checklist

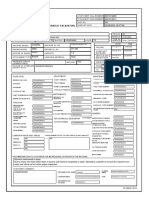

1) The document is a pre-use inspection checklist for a wheel loader used at a worksite in Singapore.

2) It contains over 30 inspection items to check on the wheel loader under both power off and power on conditions.

3) Users must check components like wheels, lights, fluids, controls and the work area, and report any issues found to their supervisor.

Uploaded by

gopiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

2K views1 pageWheel Loader Checklist

1) The document is a pre-use inspection checklist for a wheel loader used at a worksite in Singapore.

2) It contains over 30 inspection items to check on the wheel loader under both power off and power on conditions.

3) Users must check components like wheels, lights, fluids, controls and the work area, and report any issues found to their supervisor.

Uploaded by

gopiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd