Vendor Qualification

Uploaded by

Dharmesh PatelVendor Qualification

Uploaded by

Dharmesh PatelVendor Qualification:

The primary step for Manufacturing is to ensure that API (DS) Vendor Qualification is compiled to

manufacture a FDF- Finished Dosage Form / Formulation (Drug Product) which confirms the

Product Quality.

The same funda is applicable to API for which KSM is sourced for API manufacturing.

Every company will have a different approach for Vendor Qualification / Supplier Approval

Process and the requirements may vary slightly.

But the Universal Approach / Global Outlook for VQ would be almost similar.

For the Benefit of the People who like to know and who wanted to have more about Vendor

Qualification/ Supplier Approval Process, herewith I am giving a Brief knowledge update:

For Example, to qualify a API ( Drug substance),

For Qualifying a Vendor ( Manufacturer) to procure the material , the mere requirements are as

follows:

I. Pre-shipment Sample Evaluation:

3 Consecutive / Continuous Samples submission for testing.

Three samples would be more appropriate.

Some vendors may give only 2 Samples due to the Cost of Material or for any other reason, but it

is to confirm and to ensure that the batches are passing and Manufacturer material is meeting

the requirements to qualify the Vendor.

The need is to look to that extent only. Other criteria are given below:

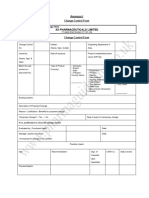

II. As a part of the vendor qualification procedure, the below list of documents to be provided but

not limited to:

1. Vendor Assessment Questionnaire

2. Route of Synthesis

3. Product List

4. Specification and Method of Analysis (STP)

5. Elemental Impurities Declaration / Statement / Risk assessment report

6. MSDS (Material Safety Data Sheet)

7. Residual Solvent Declaration

8. Organic Volatile Impurities

9. Allergen Declarations/ Genetically Modified Organism (GMO) declaration

10. ISO Certificate / any other GMP / Regulatory Approval Certificate (Ex. GMP Certification

MHRA, WHO, EDQM, TFDA, TGA etc.).

11. Packaging material info (Declaration of Standard Pack type)

12. Mfg. Process Flow

13.Nitrosamines impurity declaration / Nitrosamines. Risk Assessment

14. TSE / BSE Declaration

III. Onsite Audit / Physical Audit

In Case, Onsite Audit is not feasible or Viable, then Risk based audit / Remote Audit / Virtual

Audit shall be performed.

IV. Quality Agreement (As per APIC Template)

If all the above parameters are complying, then the Vendor is Qualified & Approved.

As per the Business Exigency or Material Urgency, Procurement / Purchase Team and QA / CQA

teams shall work together to qualify the vendor at a faster pace subjected to ensuring the

Compliance to meet Basic cGMP & Regulatory Requirements.

Other verifications shall be done on different criteria:

A. New Material but Existing Vendor

B. New Vendor and New Material

etc.

Again it is based on the Company's Policy or QA/ CQA Procedures and Business call with Quality

Consciousness’, decision shall be taken.

Hope it is beneficial.