0% found this document useful (0 votes)

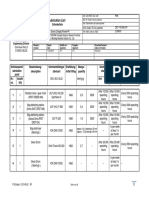

87 views7 pagesEthyl Ethanoate Synthesis Process

This document describes the process of ester synthesis:

1) Carboxylic acids react with alcohols in the presence of an acid catalyst like sulfuric acid to form esters and water.

2) The reaction mixture is heated under reflux to drive the equilibrium towards the products and distilled to separate the ester from other components.

3) The distilled product is further purified by neutralizing acids, extracting the ester with sodium carbonate, removing alcohol with calcium chloride, drying with anhydrous calcium chloride, and finally distilling the pure ester.

Uploaded by

Ngô Ngọc Mai PhươngCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

87 views7 pagesEthyl Ethanoate Synthesis Process

This document describes the process of ester synthesis:

1) Carboxylic acids react with alcohols in the presence of an acid catalyst like sulfuric acid to form esters and water.

2) The reaction mixture is heated under reflux to drive the equilibrium towards the products and distilled to separate the ester from other components.

3) The distilled product is further purified by neutralizing acids, extracting the ester with sodium carbonate, removing alcohol with calcium chloride, drying with anhydrous calcium chloride, and finally distilling the pure ester.

Uploaded by

Ngô Ngọc Mai PhươngCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

/ 7