Inventory Management

Course Objective

• After the course, students will be able to

address problems of materials

management and inventory planning and

be able to improve that system.

1

� Detail Objectives

• Classify important material items for

planning and control.

• How to forecast the demand of materials

• When to re-order, how much to order, how

much safety stock should be kept in the

warehouse to meet a certain level of

customer satisfaction

• How to plan/control materials

• Discuss practical issues and solutions

Introduction about

Material Management and

Inventory Planning

2

� Roles of Materials Management

• The basic function of materials

management is coordination. It must

balance the resources of the company and

demand.

• Materials management is involved in two

major areas:

– Manufacturing planning and control

– Physical supply/distribution

Issues

You want to have production cost as low as

practical, not as low as possible. You want to

have low inventory investment but as low as

practical, not as low as possible. The question

you need to answer is what are you going to buy

tomorrow to put into the stockroom and when do

you really need to buy it? Control of future

materials purchases is where you’re going to

save money.

3

� Materials Management System

1. Production control & purchasing functions

2. Vendors

3. Transportation & material handling

equipment for the materials, parts, &

supplies

4. Receiving, storage, & accounting

functions

Materials Management System

4

� Inventory Management System

Inventory

Supplier(s) material Material Production

Control

purchasing handling

Information

10

A Water Tank Analogy for Inventory

Inventory Level

Supply Rate

Inventory Level

Demand Rate

11

5

� Purpose of Inventories

• To protect against uncertainties

• To allow economic production and

purchase

• To cover anticipated changes in demand

or supply

• To provide for transit

12

Inventory Classification:

By Location in Process

• Inputs inventory: Raw materials

• Work-in-Process (WIP) inventory

• Outputs inventory: Finished goods

13

6

� Brain storming and share your

experience

• Describe materials management and

inventory planning activities in your

company. Each person gives at least one

idea about that?

14

Pareto Analysis

(ABC Analysis)

15

7

� ABC Analysis

• Based on “Pareto” concept (80/20 rule)

• Classification of items as A, B, or C

16

Exercise

• Open excel file to do exercise of ABC

analysis

17

8

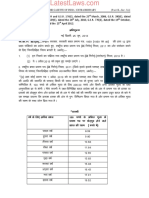

� Example: Annual Usage of Items by Dollar Value

Percentage

of Total

Annual Usage Dollar Dollar

Item in Units Unit Cost Usage Usage

1 5,000 $ 1.50 $ 7,500 2.9%

2 1,500 8.00 12,000 4.7%

3 10,000 10.50 105,000 41.2%

4 6,000 2.00 12,000 4.7%

5 7,500 0.50 3,750 1.5%

6 6,000 13.60 81,600 32.0%

7 5,000 0.75 3,750 1.5%

8 4,500 1.25 5,625 2.2%

9 7,000 2.50 17,500 6.9%

10 3,000 2.00 6,000 2.4%

Total $ 254,725 100.0%

18

Pareto Chart

45.0% 120.0%

40.0%

100.0%

Cumulative % Usage

35.0%

A B C

Percent Usage

30.0% 80.0%

25.0%

60.0%

20.0%

15.0% 40.0%

10.0%

20.0%

5.0%

0.0% 0.0%

3 6 9 2 4 1 10 8 5 7

Item No.

Percentage of Total Dollar Usage Cumulative Percentage

19

9

� Practice

The manager of a restaurant is concerned about the smaller

numbers of customers patronizing his eatery. The number of

complaints have been rising, and he would like some means of

finding out what issues to address and of presenting the findings in

a way his employees can understand them. The manager surveyed

his customers over several weeks and collected the following data.

What are the main problems needed to improve?

--------------------------------------------

Complaint Frequency

--------------------------------------------

Discourteous server 12

Slow service 42

Cold dinner 5

Cramped tables 20

Smoky air 10

---------------------------------------------

20

10