0% found this document useful (0 votes)

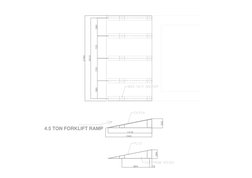

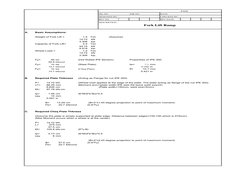

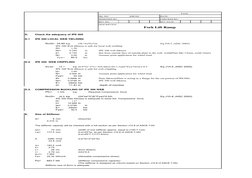

625 views6 pagesFork Lift Ramp Calculation

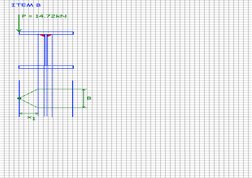

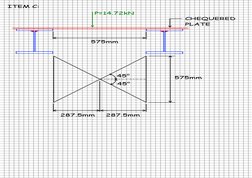

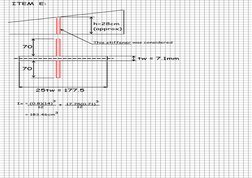

The document provides design calculations for a fork lift ramp. It includes assumptions about the fork lift weight and capacity. It then calculates the required plate thicknesses to support the wheel loads and resists bending. It also checks the adequacy of an IPE 300 section to resist local buckling, web crippling and compression. Finally, it sizes stiffeners to reinforce the plate. The key calculations show that plate thicknesses of 15mm and 8mm are required, and that an IPE 300 section with a 0.591 inch plate flange is adequate to support the design loads.

Uploaded by

rabCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

625 views6 pagesFork Lift Ramp Calculation

The document provides design calculations for a fork lift ramp. It includes assumptions about the fork lift weight and capacity. It then calculates the required plate thicknesses to support the wheel loads and resists bending. It also checks the adequacy of an IPE 300 section to resist local buckling, web crippling and compression. Finally, it sizes stiffeners to reinforce the plate. The key calculations show that plate thicknesses of 15mm and 8mm are required, and that an IPE 300 section with a 0.591 inch plate flange is adequate to support the design loads.

Uploaded by

rabCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd