100% found this document useful (2 votes)

290 views49 pagesStrategy and Logistics

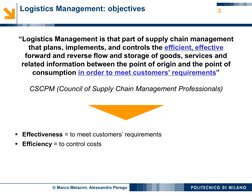

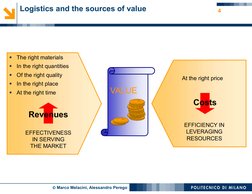

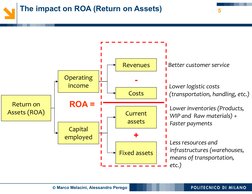

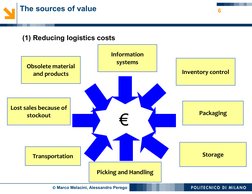

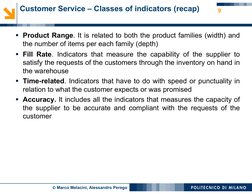

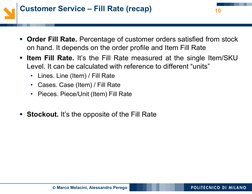

This document discusses key concepts in logistics management. It defines logistics management and its objectives to meet customer requirements effectively and efficiently. It explores how logistics can create value through reducing costs and increasing revenues. It also recaps important customer service metrics like fill rate, timeliness, and accuracy that are used to measure effectiveness. Logistics strategies must balance the relationship between costs to provide various service levels and the margins achieved from different customer segments.

Uploaded by

nicco.deca123Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (2 votes)

290 views49 pagesStrategy and Logistics

This document discusses key concepts in logistics management. It defines logistics management and its objectives to meet customer requirements effectively and efficiently. It explores how logistics can create value through reducing costs and increasing revenues. It also recaps important customer service metrics like fill rate, timeliness, and accuracy that are used to measure effectiveness. Logistics strategies must balance the relationship between costs to provide various service levels and the margins achieved from different customer segments.

Uploaded by

nicco.deca123Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Logistics and the Sources of Value: Discusses how logistics generates value through efficient resource management and meeting consumer needs effectively.