100% found this document useful (1 vote)

2K views46 pagesRCC #Short - Notes...

Rcc detail notes

Uploaded by

navneetoraiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

100% found this document useful (1 vote)

2K views46 pagesRCC #Short - Notes...

Rcc detail notes

Uploaded by

navneetoraiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

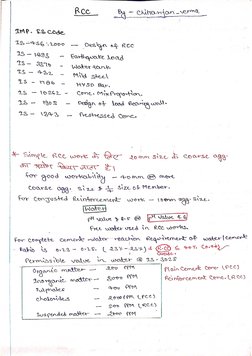

- Basic Concepts of RCC: Provides an overview of key RCC codes and basic concepts like water-cement ratio and concrete strength.

- Concrete and Strength Tests: Describes various concrete tests, strength evaluations, and characteristic compressive strength.

- Reinforcement Details: Discusses reinforcement strategies, grades of steel, and compatibility factors in RCC.

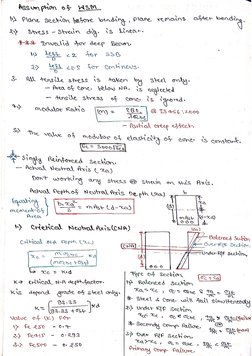

- Stress Methods and Modulus of Elasticity: Covers working stress methods and explores the concept of modulus of elasticity in RCC.

- Moment Resistance: Explains calculations related to moment resistance and lever arm mechanics in RCC.

- Limit State Method: Investigates the limit state design methodology and associated factors of safety.

- Design of Reinforced Sections: Details design parameters and considerations for singly and doubly reinforced sections.

- Flanged Sections: Discourses on economical and structural benefits of flanged beam sections.

- Design of Beam: Focuses on beam design calculations and reinforcement requirements.

- Shear Analysis: Analyzes shear forces in beams, shear transfer mechanism, and related design steps.

- Bond Development and Anchorage: Explores the principles of bond, development length, and anchorage in RCC structures.

- Slab Considerations: Examines types of slabs, slab design criteria, and role in RCC strength distribution.

- Column Design: Dives into column modeling and design, with attention to load handling characteristics.

- Foundation Footing: Focuses on footing design for foundations covering individual and combined footings.

- Water Tank Design: Describes design and structural considerations for water storage tanks under pressure.

- Prestressed Concrete: Details high-strength concrete techniques and stresses involved in prestressing methods.