100% found this document useful (1 vote)

3K views15 pagesCSWA Sample Test 1

Uploaded by

danielalvarado114Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

3K views15 pagesCSWA Sample Test 1

Uploaded by

danielalvarado114Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

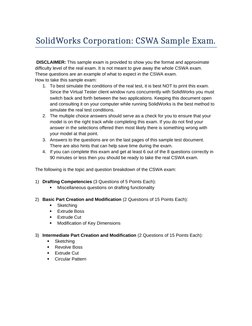

- Introduction and Exam Breakdown: Provides an overview of the sample exam's purpose and lists the types and distribution of questions in the CSWA exam.

- Sample Test: Initiates the sample test section containing questions simulating the actual exam format with solutions based on theoretical knowledge.

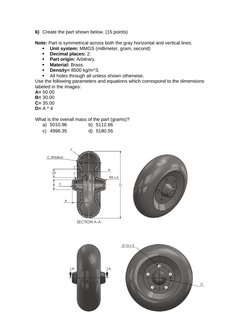

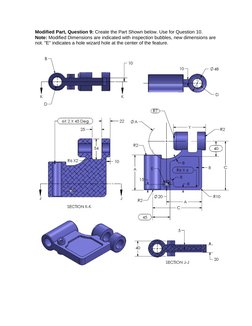

- Detailed Questions and Examples: Details example questions used in the CSWA exam, focusing on CAD model building and modification tasks for testing proficiency in SolidWorks.