0% found this document useful (0 votes)

295 views35 pages8 - Absorption Part 2

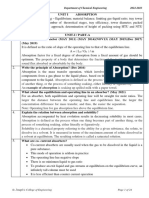

The document discusses the design of plate absorption towers, focusing on the absorption process of solute A from a gas into a liquid. It outlines the material balance for the absorption tower and explains how to graphically determine the number of theoretical trays needed for the process. An example problem is provided, demonstrating the calculation of theoretical and actual trays required for absorbing SO2 from an air stream using water.

Uploaded by

Bảo ĐoànCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

295 views35 pages8 - Absorption Part 2

The document discusses the design of plate absorption towers, focusing on the absorption process of solute A from a gas into a liquid. It outlines the material balance for the absorption tower and explains how to graphically determine the number of theoretical trays needed for the process. An example problem is provided, demonstrating the calculation of theoretical and actual trays required for absorbing SO2 from an air stream using water.

Uploaded by

Bảo ĐoànCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd