71% found this document useful (7 votes)

5K views3 pagesSteel Bracket Design

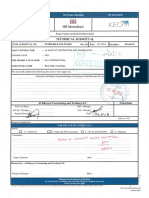

The document summarizes the design of a steel bracket to support a skylight. It calculates the load factors and forces acting on the bracket. The load per meter is 1.55 kN and each bracket must support 1.22 kN. It then checks the shear capacity of two 10mm expansion bolts and the 7mm thick steel bracket to withstand the forces. Both the bolts and bracket are determined to be safe and a 100mm x 100mm x 7mm angle bar bracket with two 10mm bolts is adopted for the design.

Uploaded by

randy_pabilonaCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

71% found this document useful (7 votes)

5K views3 pagesSteel Bracket Design

The document summarizes the design of a steel bracket to support a skylight. It calculates the load factors and forces acting on the bracket. The load per meter is 1.55 kN and each bracket must support 1.22 kN. It then checks the shear capacity of two 10mm expansion bolts and the 7mm thick steel bracket to withstand the forces. Both the bolts and bracket are determined to be safe and a 100mm x 100mm x 7mm angle bar bracket with two 10mm bolts is adopted for the design.

Uploaded by

randy_pabilonaCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

- Design of Steel Bracket

- Load Calculations

- Shear on Bracket