lecture note

Construction Commercial management

(QTS 303)

first SEMESTER

2023/2024 SESSION

� First Technical University, Ibadan. Lecture Guide QTS 303 2023

5.6 COMPUTATION OF UNIT RATES

5.6.1 Excavation and Earthworks

Question 3

Carefully build-up unit rates for the items of work extracted from a following Bill of Quantities:

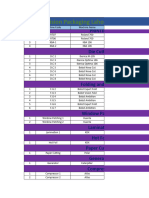

Item Description Qty Unit Rate Amount

(N)

A. Excavating topsoil for preservation

Average 150mm deep 205 m2 ?

B. Excavating trenches with not

Exceeding 1.0m commencing level

300mm below ground level 93 m3 ?

Solutions:

A. Unit Rate for topsoil excavation

Input Resources:

Labour:

Labour output = 5.35m3/man-day

Work Content:

205m2 x 0.15m = 30.75m3

Add:

Bulkage factor

(assume firm soil) 25% = 7.69m3

38.44m3

Man-day Required:

𝑡𝑜𝑡𝑎𝑙 𝑤𝑜𝑟𝑘 𝑐𝑜𝑛𝑡𝑒𝑛𝑡 38.44𝑚3

= 𝐿𝑏𝑎𝑜𝑢𝑟 𝑜𝑢𝑡𝑝𝑢𝑡

= 5.35𝑚3/𝑚𝑎𝑛−𝑑𝑎𝑦

= 7.23 days ≈ 8days

Analysis:

7.23days @ N1,956.42/day = N14,136.24

N14,136.24

Rate/m2 = = N 68.96/m2 (Net)

205𝑚2

Add:

25% P + OH = 17.24

N 86/m2 (Gross)

2 DeDream©

� First Technical University, Ibadan. Lecture Guide QTS 303 2023

B. Unit Rate for Trenches Excavation

Input Resources:

Labour:

Labour output = 3.73m3/man-day

Work Content:

= 93m3

Add:

Bulkage factor

(assume) 25% = 23.25m3

116.25m3

Man-day Required:

𝑡𝑜𝑡𝑎𝑙 𝑤𝑜𝑟𝑘 𝑐𝑜𝑛𝑡𝑒𝑛𝑡 116.25𝑚3

= 𝐿𝑏𝑎𝑜𝑢𝑟 𝑜𝑢𝑡𝑝𝑢𝑡

= 3.75𝑚3/𝑚𝑎𝑛−𝑑𝑎𝑦

= 31 days ≈ 31days

Analysis:

31days @ N1,956.42/day = N 60,649.02

N 60,649.02

Rate/m3 = = N 652.14/m3 (Net)

93𝑚3

Add:

25% P + OH = 163.04

N 815.18/m3 (Gross)

Question 4

Calculate the Amount N for the following item of work:

‘Fabric mesh laid in floors, BS242, weighing 2.61kg/m2 (195m2)’

Solution:

Unit Rate for Fabric Mesh

Input Resources:

(A) i. Mesh (ii) Tying wire (B) Labour laying

Ai. Fabric mesh (2.61kg/m2)

say, 4.8m x 2.40m (11.52m2) @ N 10,500.00 = N 10,500.00

Add:

Waste + Lap (say 20) = 2,100.00

Aii. Tying wire

assume 0.1kg/m2

tying wire required = 0.1kg/m2 x 11.52m2 = 1.152kg

therefore, 1.152kg @ N 120/kg = 138.24 c/f

3 DeDream©

� First Technical University, Ibadan. Lecture Guide QTS 303 2023

b/f = 138.24

B. Labour laying

Labour output = 4m2/hr

11.52𝑚2

Man-hr required = 4𝑚2/ℎ𝑟

= 2.88hrs

Therefore, 2.88hrs @ 356.72/hr = 1,027.35

N 13,765.59

N 13,765.59

Rate/m2 = 11.52𝑚2

= N 1,194.93/m2 (Net)

Add:

25% P + OH = 298.73

N 1,493.66/m2 (Gross)

5.6.2 Earthwork Support

Anything requires to uphold the sides of excavation is known as earthwork support or timbering.

The following constants are average labour output for earthwork support, taking 10m length and

2m deep as basis.

i. Fixing timber, polling boards, wallers and struts m2 18hrs

ii. Stripping ditto m2 9hrs

iii. Unloading timber m3 2hrs

g.l.

150 x 25mm th. Polling Board

@2m centres

100 x 100mm th. Struts

300 x 25mm th. Walling Board

@2m centres

750mm

4 DeDream©

� First Technical University, Ibadan. Lecture Guide QTS 303 2023

Question 5

Earthwork support to foundation not exceeding 2.00m deep distance between opposing faces not

exceeding 1.0m

Solution:

Input Resources:

A. Materials:

i. Polling board, ii. Walling iii. Struts iv. Nails

B. Labour:

i. Fixing ii. Stripping

A Materials

i. Polling board: 12 x 0.15m x 0.025m x 2m = 0.09m3

ii Walling board: 4 x 0.30m x 0.025m x 10m = 0.30m3

iii. Struts: 12 x 0.10m x 0.10m x 0.65m = 0.08m3

0.47m3

NB: Size mostly available in market in scantling lengths

If in market white wood 0.3m x 0.025m x 3.6m = 0.027m3 costs say, N1,200.00

Then, polling board of 0.09m3 required will cost = N 4,000.00

Walling board of 0.30m3 will cost = 13,333.33

Struts of 0.08m3 will cost = 3,555.56

N20,888.89

Add:

10% waste 2,088.89

N 22,977.78

Add:

Unloading and stacking, say, 3.55m3/man-day

0.47𝑚3

Man-day required = , = 0.132 day

3.55𝑚3/𝑚𝑎𝑛 𝑑𝑎𝑦

0.132 day @ N1,956.42/day = 259.02

N 23,236.80

Cost of timer per 4 no. of uses = N 23,236.80

N 23,236.80

Therefore, cost per use =, = N 5,809.20

4 𝑢𝑠𝑒𝑠

iv. Nails (assume 3 uses)

1st use - 0.2kg/m2

2nd use - 0.1kg/m2

3rd use - 0.1.kg/m2

0.4kg/m2

5 DeDream©

� First Technical University, Ibadan. Lecture Guide QTS 303 2023

Area of the trench = 2 x 20m2

For the 2 sides = 20m2 x 2sides = 40m2

Nails for the 40m2 x 0.4kg/m2 = 16.0kg

Add:

10% waste = 1.6kg

17.6kg

Nail = 25kg/bag

17.6𝑘𝑔

Cost of nails required = 25𝑘𝑔/𝑏𝑎𝑔

𝑥 𝑁7,000.00 = N 4,928.00 (for 3 uses)

N 4,928.00

Therefore, cost of nails required for 1 use = 3 𝑢𝑠𝑒𝑠

= N1,642.67

B. Labour

i. Timbering

Say, 53m2/gangday output

40𝑚2

Gang day required = = 0.755 day

53𝑚2/𝑔𝑎𝑛𝑔𝑑𝑎𝑦

Take gang size = (2carpenters + 1 labourer)

i.e. 2 x N 2,853.73 + N 1,956.42 = N 7,663.88

Then, 0.755 day @ N 7,663.88 = N 5,784.06

ii. Stripping off

Say, 40m2/manday output

40𝑚2

Gang day required = = 1 day

40𝑚2/𝑚𝑎𝑛𝑑𝑎𝑦

Take 1 labourer for stripping (i.e. N 1,956.42)

Then, 1 day @ N 1,956.42 = 1,956.42

Total cost labour timbering + stripping = N 7,740.48

Total Summary

A. Materials:

Timber - N 5,809.20

Nails - 1,642.67

B. Labour - 7,740.48

N15,192.35

N15,192.35

Rate/m2 = 40𝑚2

= 379.81 (Net)

Add:

25% P+OH 94.95

N474.76 (Gross)

6 DeDream©

� First Technical University, Ibadan. Lecture Guide QTS 303 2023

5.6.3 Concretework

This has to do with concrete, reinforcement and formwork.

3.3.1 Concrete

There are 3 main initial factors to be considered in the cost of mixing concrete: (i) method

of mixing, (ii) materials and (iii) site transportation and placing. The mixing methods

available are: (i) hand, (ii) potable machine, (iii) reading mix, and (iv) batch plant installed

on site.

Question 6

Plain in-situ concrete (1:3:6 – 39mm aggregate) in foundation, poured against unblinded earth.

(16m3).

Solution:

Where the necessary materials (cement, fine aggregate and coarse aggregate) for preparation of concrete

are sold by the tonne, the conversion of volume of dry materials to weight is important. This is shown as

follows:

1m3 cement - 1.44tonnes

1m3 sand - 1.52tonnes

1m3 coarse aggregate - 1.60tonnes

NB: the ratio of volume to weight may vary for sand and the different type of aggregates used from

location to location.

Input Resources:

A. Materials

i. Cement ii. Sand iii. Course aggregate

B. Plants

i. mixing ii. vibrating

C. Labour:

i. mixing ii. Hosting iii. Placing and compacting

Cement (I ton) delivered to site @ N 2,500/bag = N 50,000.00

Unloading and stacking (say, 20bags/hr)

20𝑏𝑎𝑔𝑠

i.e. 20𝑏𝑎𝑔𝑠/ℎ𝑟 x N 244.60/hr = 244.60

N 50,244.60

Mix by volume:

A(i) For Cement: 1m3 cement x 1.44 tonnes @ N50,244.60 = N 72,352.22

A(ii) For Sand: 3m3 sand x 1.52 tonnes @ N 1,468.05 = 6,694.31

A(iii) For Granite: 6m3 granite x 1.60 tonnes @ N 4,183.07 = 40,157.48

N 119,204.01

Add:

45% Shrinkage + waste 53,641.80

N172,845.81

As the ratio is 1:3:6; this gives a total of 10

7 DeDream©

� First Technical University, Ibadan. Lecture Guide QTS 303 2023

𝐍 172,845.81

Cost/m3 = 𝟏𝟎𝒎𝟑

= N17,284.58/m3

B. Plants:

(i) 10/7 mixer operating @ 5 minutes per cycle:

Cost of hiring the mixer, say - 20,500.00/day

Cost of fueling 10litres of diesel/day @ N 200/litre - 2,000.00/day

N 22,500.00/day

Mixer capacity, say, 2.65m3/hr

i.e. 8hrs = 21.2m3/day

NB: Plant efficiency is 80%, therefore, actual volume turned out will be

80

100

𝑥 21.2m3/day = 16.96m3/day

N 22,500.00

Therefore, cost/m3 = 16.96m3/day

= 1,326.65/m3

(ii) Vibrator:

If cost of hiring is N5,000.00/day

N 5,000.00

Therefore, cost/m3 = 16.96m3/day

= 296.81/m3

Total Cost for plants N1,621.46/m3

C. Labour:

(i) Mixing: (Assume 1gang size = 2mansons + 6 labourers)

i.e. [(2 x N 2,853.73) + (6 x N 1,956.42)] = N 17,445.98/day

(ii) transporting and placing:

(Assume 1gang size = 2mansons + 12 labourers)

i.e. [(2 x N 2,853.73) + (12 x N 1,956.42)] = N 29,184.50/day

N 46,630.48/day

46,630.48/day

Therefore, cost /m3 = 𝟏𝟔.𝟗𝟔𝐦𝟑/𝐝𝐚𝐲

= N 2,749.44/m3

Grand Summary

A. Materials - N17,284.58/m3

B. Plants - 1,621.46/m3

C. Labour - 2,749.44/m3

N21,655.48 (Net)

Add: 25% P+OH 5,413.87

Rate/m3 = N27,069.35 (Gross)

ALTERNATIVELY

Input Resources:

A. Materials

i. Cement ii. Sand iii. Course aggregate

B. Plants

i. mixing ii. vibrating

C. Labour:

i. mixing ii. Hosting iii. Placing and compacting

8 DeDream©

� First Technical University, Ibadan. Lecture Guide QTS 303 2023

A(i) For Cement:

1m3 cement = 28.8bags @ N 2,500/bag = N 72,000.00

Add: Unloading and stacking (say, 12bags/hr)

28.8𝑏𝑎𝑔𝑠

i.e. x N 244.60/hr = 352.22

20𝑏𝑎𝑔𝑠/ℎ𝑟

N72,352.22

A(ii) For Sand:

3m3 of sand is required

If a 3.81m3 tipper load costs N 8,500/lorry load

3𝑚3

Therefore, 3.81𝑚3

= 0.79 trip is required @ N 8,500 = N 6,715.00

A(iii) For Granite:

6m3 of sand is required

If a 3.81m3 tipper load costs N 25,500/lorry load

6𝑚3

Therefore, = 1.579 trip is required @ N 25,500 = N 40,264.50

3.81𝑚3

Material Summary

i. Cement - 72,352.22

ii. Sand - 6,715.00

iii. Granite - 40,264.50

Sub-total - 119,331.72

Add: 45% shrinkage + stockpile waste - 53,699.74

N 173,030.99

As the ratio is 1:3:6; this gives a total of 10

𝐍 173,030.99

Cost/m3 = = N17,303.10/m3

𝟏𝟎𝒎𝟑

B. Plant:

(i) 10/7 mixer operating @ 5 minutes per cycle:

Cost of hiring the mixer, say - 20,500.00/day

Cost of fueling 10litres of diesel/day @ N 200/litre - 2,000.00/day

N 22,500.00/day

3

Mixer capacity, say, 2.65m /hr

i.e. 8hrs = 21.2m3/day

NB: Plant efficiency is 80%, therefore, actual volume turned out will be

80

100

𝑥 21.2m3/day = 16.96m3/day

N 22,500.00

Therefore, cost/m3 = 16.96m3/day

= 1,326.65/m3

(ii) Vibrator:

If cost of hiring is N5,000.00/day

N 5,000.00

Therefore, cost/m3 = 16.96m3/day

= 296.81/m3

Total Cost for plants N1,621.46/m3

9 DeDream©

� First Technical University, Ibadan. Lecture Guide QTS 303 2023

C. Labour:

(i) Mixing: (Assume 1gang size = 2mansons + 6 labourers)

i.e. [(2 x N 2,853.73) + (6 x N 1,956.42)] = N 17,445.98/day

(ii) transporting and placing:

(Assume 1gang size = 2 mansons + 12 labourers)

i.e. [(2 x N 2,853.73) + (12 x N 1,956.42)] = N 29,184.50/day

N 46,630.48/day

46,630.48/day

Therefore, cost /m3 = 𝟏𝟔.𝟗𝟔𝐦𝟑/𝐝𝐚𝐲

= N 2,749.44/m3

Grand Summary

A. Materials - N17,303.10/m3

B. Plants - 1,621.46/m3

C. Labour - 2,749.44/m3

N21,674.00/m3 (Net)

Add: 25% P+OH 5,418.50

Rate/m3 = N27,092.50 (Gross)

5.6.4 Reinforcement

Question 7

Consider the following item of work:

Item Description Qty Unit Rate Amount

(N)

A. Bar 12mm nominal size bent

Horizontal, length 12.0-15.0m 3.17 ton 250,000 792,500

Is the quoted rate reasonable? Give the full details of how you arrived at your answer.

Solution

Unit Rate for 12mm Diameter bar

Input Resources:

(A) Materials:

(i) 12mm diameter bar (ii) Binding wire (iii) Spacers

(B) Labour:

(i) Cutting and bending (ii) Fixing

Materials

Ai. 12mm diameter bar

12mm diameter bar delivered to site @ N160,000.00/ton = N160,000.00/ton

Unloading & Stacking:

Say, 750kg/mad-day (labour output)

Therefore, 1ton will take 1000kg/750kg/man-day = 1.33man-day

1.33man-day @ N1,956.42/day = 2,608.56/ton

10 DeDream©

� First Technical University, Ibadan. Lecture Guide QTS 303 2023

b/f N 162,608.56/ton

Aii. Binding wire

Take 12kg/1000kg

i.e 1000kg requires 12kg/1000kg x 1000kg = 12kg

then 12kg @ N250/kg = 3,000.00

Aiii Spacers and chairs

Assume 5% of cost of reinforcement

i.e. 5% of N120,000.00 = 6,000.00

N 171,608.56/ton

Add: 5% waste 8,580.43

N180,188.99/ton

Labour

Bi. Labour cutting and bending

Take 40.5hrs/ton output

i.e 1ton will cost 40.5hrs/ton @ N356.70/hr = N14,446.35/ton

Bii. Labour fixing

Take 40.5hrs/ton output

i.e 1ton will cost 40.5hrs/ton @ N356.70/hr = N14,446.35/ton

28,892.70/ton

Grand Summary

A. Materials - 180,188.99/ton

B. Labour - 28,892.70

N209,081.69/ton (Net)

Add: 25% P+OH 52,270.42

Rate/ton = N261,352.11/ton (Gross)

The rate quoted is N250,00.00/ton, while the rate arrived at is N261,352.11/ton . The rate

quoted is 0.05% lesser than what is calculated here. Therefore the rate quoted is reasonable

and realistic.

5.7 Block and Brick Work

The materials are bricks and blocks. Concrete block known as block are commonest even for load

bearing walls in Nigeria. Sandcrete block can be obtained in a number of sizes and various

composition, strengths, shapes, etc. it is usually made of (1:6) mixed of sand and cement, which

may be hollowed or solid.

Question 8

225mm thick hollow sandcrete block wall, jointed and bedded in cement and sand mortar (1:4) (of

25mm thick) in stretcher bond. (200m2).

Solution

Input Resources

A. Materials

i. Mortar (cement and sand) ii. Block

B. Labour

i. Mixing of mortar, ii. Laying of blocks

11 DeDream©

�First Technical University, Ibadan. Lecture Guide QTS 303 2023

A. Materials

(i) Mortar

Cement (I ton) delivered to site @ N 2,500/bag = N 50,000.00

Unloading and stacking (say, 20bags/hr)

20𝑏𝑎𝑔𝑠

i.e. x N 244.60/hr = 244.60

20𝑏𝑎𝑔𝑠/ℎ𝑟

N 50,244.60

Mix by volume:

For Cement: 1m3 cement x 1.44 tonnes @ N50,244.60 = N 72,352.22

For Sand: 4m3 sand x 1.52 tonnes @ N 1,468.05 = 8,925.74

N 81,277.96

Add:

45% shrinkage + waste = 36,575.08

N 117,853.04

As the ratio is 1:4; this gives a total of 5

N 117,853.04

Mortar cost/m3 = 5𝑚3

= N 23,570.61/m3

Mortar Required:

Bottom: 0.45m x 0.23m = 0.1035m2

2 Sides: 2 x 0.23m x 0.23m = 0.1058m2

0.2093m2

Ddt: Voids

i.e. 2 x 0.15m x 0.13m 0.039m2

0.1703m2

Now convert to volume, you multiply by mortar thickness

i.e. 0.1703m2 x 0.02m = 0.003406m3/block (mortar required per block)

then, for 9blocks, 9blocks x 0.003406m3/block = 0.03065m3

Add:

10% stockpile waste 0.00306

0.0337m3

Cost of mortar required for 1m2 block = 0.0337m3 x N 23,570.61/m3 = N 794.33

(ii) Blocks

To get number of blocks in 1m2,

1m x 1m 1m x 1m

𝑎𝑟𝑒𝑎 𝑜𝑓 𝑜𝑛𝑒 𝑠𝑖𝑑𝑒 𝑜𝑓 𝑎 𝑏𝑙𝑜𝑐𝑘

= (0.45+0.02)𝑥 (0.225+0.02)

= 8.68 ≈ 9blocks

Therefore, 1m2 ≡ 9blocks

Add:

5% waste = 0.45

9.45 blocks

Cost of blocks is 9.45 blocks @ N 180.00/block = N1,701.00

Total for materials N 2,495.33

12 DeDream©

�First Technical University, Ibadan. Lecture Guide QTS 303 2023

B. Labour:

(i) Mixing: (Assume hand mixing of mortar with labour output of say, 1m3/man-day)

Mortar required is 0.0337m3

0.0337m3

Then, man-day required = 1𝑚3/𝑚𝑎𝑛𝑑𝑎𝑦

= 0.0337day

0.0337day @ N 1,956.60/day = N 65.93

(ii) Laying: (Assume 1gang size = 2mansons + 1labourer

with output of say, 8m2/gang-day)

i.e. [(2 x N 2,853.73) + N 1,956.42] = N 7,663.88/day

Work content is 1m2

1m2

Then, gang-day required = = 0.125day

8𝑚2/𝑔𝑎𝑛𝑔𝑑𝑎𝑦

0.125day @ N 7,663.88/day = 957.99

Total for Labour N1,023.92

Grand Summary

A. Materials - N 2,495.33

B. Labour - 1,023.92

N3,519.25 (Net)

Add: 25% P+OH 879.813

Rate/m2 = N4,399.06 (Gross)

13 DeDream©