0% found this document useful (0 votes)

136 views2 pagesWOOD DrillPressSpeedChart

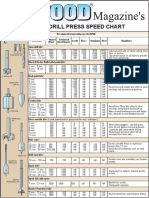

The document provides a comprehensive drill press speed chart detailing recommended operating speeds (RPM) for various types of drill bits across different materials including softwood, hardwood, acrylic, brass, aluminum, and steel. It includes specific notes on lubrication, the use of center punches, and techniques to prevent overheating and improve hole quality. Additionally, it emphasizes safety precautions and the importance of using the correct speeds to avoid damage to the materials and tools.

Uploaded by

essential2112Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

136 views2 pagesWOOD DrillPressSpeedChart

The document provides a comprehensive drill press speed chart detailing recommended operating speeds (RPM) for various types of drill bits across different materials including softwood, hardwood, acrylic, brass, aluminum, and steel. It includes specific notes on lubrication, the use of center punches, and techniques to prevent overheating and improve hole quality. Additionally, it emphasizes safety precautions and the importance of using the correct speeds to avoid damage to the materials and tools.

Uploaded by

essential2112Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd