UltraPRO Training

Uploaded by

kashinathUltraPRO Training

Uploaded by

kashinathSensing Systems for Manufacturing

Mechanical Components

Terminology

EMAP TorquePRO REMAP

Electro-Mechanical Assembly Press Rotational Electro-Mechanical Assembly Press

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com

System

Layout

EMAP with

UltraPRO

Controller

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 3

EMAP Press Mechanical Layout

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 4

TorquePRO Mechanical Layout

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 5

REMAP Mechanical Layout

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 6

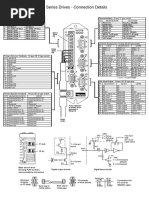

X11 Service Port

24VDC Supply

X1

STO Input

X5 EtherCAT In

X6 EtherCAT Out

Motor Power

X2

Holding Brake X7 Inputs/Outputs

X8 Inputs/Outputs

DC-Bus X10 Feedback

X3

Brake Resistor

X4 Main Power DrivePRO Servo

Drive with

Connections

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 7

3 Phase power connections

X7A EtherCAT in

DrivePRO X7B EtherCAT out

(S700) X2 Motor resolver input

Servo Drive X1 Encoder input

with

Connections Drive control power

Drive control signals

X3 * P-Stop (E-Stop)

* Enable

* STO inputs

Motor power connector

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 8

X1 EtherCAT in

X2 EtherCAT out

Digital

X3 Analog input 1 Signal

X4 Analog input 2

Conditioner

X5 Encoder input 1

(DSC)

X6 Encoder input 2

X7 Proximity switch input

4 Digital outputs

X8

3 Digital inputs

X9 Power in

X10 Power out

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 9

UltraPRO Controller

• IP65 rated enclosure

• Anchor and first node in the UltraPRO

EtherCAT network

• Connector based connections, can be

mounted outside an electrical enclosure

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 10

Safety Drive Enclosure (SDE)

• IP65 rated enclosure

• Connector based

connections

• Can be mounted outside

of an electrical enclosure

• Contains drive and safety

relay

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 11

HMI Screen

• Status Bar

• Readout Panel

• Command Bar

• Serial Number Readout

• Monitor Data Region

• Gauging Data Spreadsheet

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 12

Status Bar Readout Panel

Settings Menu

(Hamburger Menu)

Part Status

Gauging Data Table

Monitor Data

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

Command Bar www.promessinc.com 13

Readout Panel

Defaults to right side of HMI screen

Ability to give live readout of:

Axis positions

Sensor readings

Variable values

Right click to:

Show/Hide readouts

Change decimal places

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com

Command Bar

Step:

Used to step through an UltraPRO program one line at a time

Cycle Start:

Will execute the entirety of the loaded UltraPRO program

Jog:

Opens the manual motion screen. Can also be accessed from the main menu

Soft Stop:

Used to stop the execution of the program through the software. When pressed, the system will stop

running the current program and wait for another command.

Home:

The home button is used to command the system to run a homing routine.

More information on homing is provided later in the presentation

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 15

Status Bar

• Shows Status of Controller

• Ready

• Running

• Faults Click here to find out more

information about controller's

• E-Stop Applied current state.

• Overload

Notifications

• OK/NOK

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com

Serial Numbers

Serial numbers can be entered manually or automatically from the PLC

Captured serial number

for that cycle

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com

Monitor Data Region

Visual Feedback

of different sensor

values along with

monitor strategy.

Zoom functions

Zoom

Pan

Max zoom out

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com

Gauging data Spreadsheet

Information collected in cycle with gauging steps is viewed here.

Multiple data points can be stored depending on application

The last

part ran is Gauging Labels

always at

the top.

Failed parts will be indicated by red cells

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 19

Settings Menu (Hamburger menu)

• New Program • Manual Motion

• Load Program • Service Screen

• Save Program As • More Tools

• Edit Program

• Options

• Program Management

• Switch User

• Modify Variables

• Switch Controller

• Edit System

• Homing Program • About

• System Settings

• Axis Settings

• Global Resources

• User Management

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com

New Program

Used to create new programs

Name must only contain:

Letters

Numbers

Underscores

Name must begin with Letter.

Program will not be stored until “Save to

Controller” is selected in editor tab

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 21

Load Program

• Used to open an existing program

• Program must be stored on the

controller.

• The currently loaded program is listed

first in the list of programs.

• Current program name will be displayed

above the status bar on the main HMI

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com

Save Program As…

• Used to the save currently loaded

program as a different name.

• Creates a copy of the active program

and opens the Editor Tab

• You can save the new program to the

controller

• The original program will remain

intact with all its data.

• The new program will save with a

new name.

* note: the currently loaded program does not

change.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 23

Edit Program

• Used to open the editor for the

selected program.

• The top of the list shows the

currently selected program

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com

Program Management

• Used to manually manage the

program files on the controller.

• Use this to set Binary numbers for the

programs

• Select program, Right side of HMI

will turn into settings for the

selected program

• Can set comments for each program

created.

• Import, Export, Rename, and Delete

Programs

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 25

Modify Variables

• Used to set values for variables in a live environment

• Changes made will not be saved until “Apply” is selected

• As soon as apply is selected the variable changes on the

controller

• Cancel will simply close the window and discard any

pending changes.

• PLEASE NOTE: use extreme caution when using this

tool. Variables can change during a cycle and applying

values will change them immediately.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com

Edit System…

• Edit Homing Program

• Edit System Settings

• Edit Axis Settings

• Global Resources

• User Management

• Import/Export

Further discussion later in the training

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com

Manual Motion

The Manual Motion Screen is used to

manually jog the system. You can jog to a

position or force.

The ready output will go low when the

manual motion is open, and the system

must be homed after any manual

movement is performed.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com

Manual Motion continued

• Position is in real-time

• Force is in real-time

• Incremental Extend/Retract

• These will extend and retract the system for as long as the button is pressed. The

system will go no further than the value in the Positon amount or Force

amount. If the position amount is met, the system will stop and if the increment

button is pressed again, it will then reset the increment counter to zeroThe System

will move at the speed entered into the JOG SPEED setting.

• The System will move until it reaches the max length of the system, overloads, or

reaches the amount specified.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com

Manual Motion continued

Overload

Jog Extend/Retract • This is a value that can be set to protect the system

• These buttons will extend and retract the during the manual Motion.

system for as long as the button is pressed. • Can be set to the max rating of the sensor being

• Not constrained by position amount used.

• Will move at the Jog Speed Setting • By Default, the starting overload value when the

• System will move until it reaches the max manual motion window is opened, is half of the

length of the system or reaches the overload sensors rated value.

value. Jog Speed

Position Amount • The speed at which the unit will move during its

• This is the limit on how far the system will manual motion.

extend or retract while using the • The speed can be changed at any time by typing in a

Incremental buttons new value

• The maximum speed allowed for manual motion is

set by Promess to prevent damage to the equipment.

Please contact Promess for any changes

needed to the default limits.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com

More Tools…

• Part Statistics

• Reset Cycle Counter

• Step Pointer

• Set Serial Number

• Zero Absolute Encoder

• Calibration

• Event Viewer

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 31

Event Viewer

The Event Viewer shows different

errors, program statistics and

system information.

If something isn’t behaving as

expected it should be one of the

first places to go for

troubleshooting.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 32

Settings Menu cont’d

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 33

UltraPRO Editor

and Editing

Programs

UltraPRO Editor

• The editor is opened when selecting

• Edit Program

• New Program

• Edit System…

Note: Program changes cannot be saved if the system is running or

otherwise unable to receive a command.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com

Edit System…

This option contains a subsection of system settings

• Edit Homing Program

• Edit System Settings (Software attributes of Promess system)

• Edit Axis Settings (Physical attributes of Promess hardware)

• Global Resources (Macros, Live Variables, and Variables that are not

program specific)

• User Management (Setting up user rights for specific users)

• Import/Export (Importing of specific system settings, global resources,

programs and axis settings)

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 36

Editing the Homing Program

• This is the program that is run when

the HMI Home Command is

pressed.

• This program will also run when a

homing input is received from the

PLC

• No other motion steps can occur

before the homing step in the

homing program

• Programming process will be

covered later

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 37

System Settings…

• Hardware Tab

• Shows all the components connected to EtherCAT network.

• Setup of all sensors wired into the system

• Setup of I/O communication for the system

• Policies Tab

• Advanced software settings

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 38

DrivePRO outputs

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 39

Fieldbus

Selecting the Fieldbus option in the hardware

tab will show the Fieldbus settings.

Fieldbus Type:

• Ethernet IP

• Modbus TCP

• Profinet

If using Profinet, the networking settings are set

by the PLC

Mapping must match on the UltraPRO and the

PLC.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 40

Inputs and Outputs

• Inputs

• To configure an input, select the input and

choose the function you wish to assign to

the input from the assigned functions

pulldown.

• Outputs

• To configure an output, select the output

and then choose the function you wish to

assign to the output from the assigned

functions pulldown.

• NOTE: Any changes made to the I/O mapping

will require you to Save to the Controller.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 41

Integer/Real Inputs and Outputs

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 42

Digital Inputs

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 43

Digital Outputs

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 44

DSC Sensors

• Label

• This will be the name used for the sensor throughout the

UltraPRO software

• Units

• Selects the units the sensor will show in the software

• Nominal Range

• This is the range of the sensor – typically Promess will set

this 20% higher from the factory

• Enable Overload Protection

• When this box is checked, whenever the value overload

value is exceeded in the software, the press will throw an

overload warning and the press will require a home.

• Promess enables this overload from the factory and should

be consulted before any changes are made to the sensor

settings. Failure to do so may VOID the Promess warranty.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 45

Policies

This tab gives a list of more advanced software

related settings including policies that ar

Changes made to policies will need to be saved

to the controller after editing.

These polices should not be enabled without

guidance from Promess

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 46

Axis Settings

WARNING: Promess sets the axis settings for each system

before shipping. Changing any of these values or properties

without first consulting Promess can result in damage to the

equipment and void any Promess warranty.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 47

Axis Settings

• Axis settings are the properties that tell

the software what type of actuator is

connected to an axis.

• These settings affect how the actuator

responds to a given command.

• There is no need for anyone other

than a Promess engineer to

change any of these settings.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 48

Homing Algorithm Options

• Home to proximity switch and index point (Default for all press systems)

• Ram will retract until the home switch is made

• Ram will extend until off of the home switch

• Motor will stop when the first index point from servo motor resolver or encoder is found

• Find home switch only

• Ram will retract until the home switch is made

• Ram will extend and stop when the home switch changes states

• Find index point only

• Homing routine will terminate at the first index point from the resolver or encoder

• Zero axis only

• Will zero the axis and the servo drive will be enabled

• Move to Zero (Absolute Encoder)

• This feature is only for when a servo motor has an absolute encoder

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 49

Global Resources

• The global resources section is where anything global is done. Global means that

anything added in here will be accessible in any program, unlike program specific

things that are only accessible in program they are created. A globe icon will be added

to any global resource added, this will help identify it as either global or program

specific.

• There are the following global resources:

• Macros

• Variables

• Timers

• Live Variables

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 50

Live Variables

Live variables are continuously calculated in the

background and can be used wherever a signal

can be used.

Types:

• Maximum – Calculates the maximum for the

selected inputs and uses that value.

• Minimum – Calculates the minimum for the

selected inputs and uses that value.

• Sum – Adds or subtracts two or more values.

• Derivative – Calculates the derivative of two

input signals (X value and Y value) based on a

given time delta. The X input signal value

defaults to time.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 51

User Management

Assign different users' access to

various actions within the software.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 52

Import/Export

Export your system configuration to a zip file.

Import specific or all settings in a system

configuration. A backup taken from the

Configuration Utility or a zip file from Export

may be used.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 53

Editing a Part Program

Editing Program Layout

Steps

Monitors and Monitoring Strategy

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 54

Part Program Layout

The programming editor contains a grid structure to support multi-axis functions. The more axes there are,

the more columns.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com

Part Program Layout Continued

Configuration has changes

and needs to be saved to

the controller.

Selected cell

Saves changes over to the

controller.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com

Evaluation Steps

Sets the sensor

value

Starts and stops

monitors created

under the

monitor tab.

Compares the

measurement

to preset

tolerances.

Sends Pass or

Fail output to the

Feature that allows for math PLC.

calculations, boolean

comparisons, and additional

commands.

Sets or resets the

part status

manually.

This step will take a

measure step’s input

formula result and store

it as the master value

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 57

Set Sensor Value

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 58

Gauging

Limits that

determine pass

or fail

Label is required

when storage

enabled.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 59

Monitor Trigger

List of the monitors created under

the monitor tab.

Stop and analyze should be used

to calculate the monitor strategy.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 60

Expression

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 61

Update Part Status

and Set Part Status

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 62

Master

List of Measure

steps found This step will take a measure step’s

within the part input formula result and store it as the

program. master value.

The master value will then be used as

the target value for the specified

measure step.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 63

Program Flow Steps

Used in conjunction with any of

These steps evaluate the Jump steps to command the

conditions and if the flow of the program.

condition is true the program

moves to the Jump Location.

Sets outputs that have been

designated “User Output”

The program waits at this step

until all the axis of motion have

been completed.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 64

Program Flow Steps cont’d…

Exit the

subroutine

End the part

program

Runs the Macro

subroutine

Ends the cycle and

immediately starts Program waits at

another. this point until the

Pauses the condition of the

part input is met.

program.

Clears the

Overload status of Action step (start, stop, reset) for

a step overload. Timer created in Global Resources.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 65

Comment and

Delay

The Delay step holds the program for amount

of time set. The time is in milliseconds.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 66

JumpJumpValue

on Status

Input

Step Step

Step Jump steps and Jump

location

Jumps

Jumps to

to the

Always the Jump

Jump

jumps Location

Location

to the when

Jumpwhen

based the

the

when

Location input

state

the conditionstatus

is met. is true.

is true.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 67

Set User Output and

Wait for Motion.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 68

Macros

Macros are subroutines within a program. A macro can be used to simplify a program by grouping

a block of commands that are repeated several times in a program into one macro. That macro can

then be used inside the program as many times as necessary.

When first creating a program the default location of all steps will be in the Main macro.

To create a new macro, click on the New Macro button. You will then be prompted to give the new

macro a name, spaces are not allowed. Once a name is given, select OK to create the macro.

To delete a macro, select the macro you wish to view and then click the Delete Macro button, this

will delete all program steps within this currently opened macro.

Note: The main macro cannot be deleted.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 69

Run Assign Macro

and Run Macro

The macro to be ran when

this step is executed.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 70

Exit Macro,

End

Program and

Repeat

Cycle

These steps end a subroutine

or part program. Everything that normally occurs with the end

program step (Variable reset, data collection,

The repeat cycle step is used cycle counter iteration, etc.) will occur. ‘

to repeat the cycle. Effectively

the same as an end program The ready output remains low during the

step followed immediately by repeat, so no new PLC commands can come

another cycle start. in.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 71

Axis/Motion Steps

Runs the homing routine set up

in the axis settings. Should

only be used in the Homing

Program.

Move steps will move to the

programmed position Travel of

the system is reached. The Move To Signal step is used

to control the system to a

specified signal reading

The Constant Signal step is

used to control the system to a

specified signal reading and Commands the axis to run at a

maintain that reading. programed velocity until

commanded to stop.

Stops and disables the axis in

the column that is created in

and discards the move queue.

The Measure step is used for

applications where a component

must be pressed to a critical

dimension relative to a datum on

a part.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 72

Move Step

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 73

Move to Signal Step

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 74

Constant

Signal

Step

This step uses

Stop Conditions

to exit the step.

These will be

discussed further

on in the

training.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 75

Apply Velocity Step

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 76

Stop Conditions Stop conditions are found in the

Constant Signal and Apply

Velocity steps.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 77

Measure Step

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 78

Monitors and Monitoring Strategy

UltraPRO has the ability to graph and set limits around the signature curve of a process.

Any sensor signal to the controller can be used to generate a curve.

The reference curve and strategy for the monitor is defined in the monitoring tab in the

program editor.

The data is store along with the gauging data in an 80Gb data buffer on the

controller. Once the data buffer is full the oldest data is replaced with the newest.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com

Monitor Tab continued…

The monitor toolbox is used to

analyze the signals collected

during the monitor.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 80

Toolbox and Monitor Strategy

Each Monitor has a strategy.

A strategy is a composition of functions that produce the

desired analysis of data.

This strategy is visually represented as an outline style layout

called the “strategy tree”

Some of these functions can have functions within them to

analyze the results produced.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 81

Monitor Strategy continued…

In this example, we want to acquire a graph while also

finding the following:

In window “A” we want to find the maximum force

In window “B” we want to find the minimum force

And in the overall process, we also want to find the

maximum force (Which may or may not be the same

value as window “A”

Using this method, we can use one set of data and while

breaking down and analyzing different subsets (The child

functions here)

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 82

Window Functions

Windowing functions are used to slice out particular sections of data for

analysis.

Windows can only have curves for their parents (Acquire, or Transform

functions)

Settings:

Label: This is the desired name requested for this particular window. Keep in

mind, this name will be used when referencing this window in other parts of

the software.

Anchor: This is the point in which the window will be anchored, there are three

settings by default; origin (0,0), begin curve, and end curve. Any Maximum,

Minimum, or Y Crossing located on the same level or higher on the strategy

tree can also be used as anchor points.

Begin Offset: This is the X value where the window offset will start. This must

be an X value less than the End of Window point.

End Offset: This is the X value where the window offset will stop. This must be

an X value greater than the Begin of Window point.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 83

Transform Functions

The transform functions are used to take the current data acquired and then transform it into something else

for additional interpretation.

Delta Y Curve: The delta Y curve takes the current monitor that was acquired and transforms it to create a

new graph showing the delta/change in the y values

Settings:

• Label: the name of this Delta Y graph

• Number of intervals: this value is the amount of intervals in which you would like to break the delta

Y graph into. Example: 1 interval will produce 1 point on the graph. This point would be the

difference between the two Y values at the beginning and end of the window. 10 intervals will

produce 10 points on the graph, each one displaying the delta from the last point made.

Slice Average:

The Slice Average function takes the acquire curve and gives you the ability to “slice down” the data

points into a specified slice width.

Directional Filter:

The direction filter function gives the ability to only show the curve if it is moving in a specific

direction, increasing or decreasing. Typically, it is useful to use the slice average function before

specifying a direction filter to eliminate any small hysteresis in the curve. Any change, large or small in

the direction of the curve will result in the curve being cut off.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 84

Analytical Functions

Analytical functions are used to perform fine-detailed analysis of the input data.

These functions can be the children of both data and window functions.

These will return the computed value across their parent window.

Example:

A maximum function directly under an acquire function will return the maximum for all the

data acquired.

If the maximum function is under a window function, it will return the maximum inside that

window.

Maximum: This function returns a single point representing the maximum Y value and

the X location of that value inside the parent window.

Minimum: This function returns a single point representing the minimum Y value and the

X location of that value inside the parent window.

Average: This function will compute the average value of the data from the parent window

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 85

Markers

X Crossing: This function returns a single point representing the Y value at which the graph crosses

a specified X location inside the parent window.

Settings:

• Label: The name given to the specific function used to be able to reference inside of an expression.

• ‘X’ Location: The crossing point in which you would like to capture the Y value. This value can be

specified using a variable.

• Occurrence Number: Used to handle scenarios where the graph passes by the X location multiple

times, this setting determines which value you would like to capture.

Y Crossing: This function returns a single point representing the X value at which the graph crosses

a specified Y location inside the parent window.

Settings:

• Label: The name given to the specific function used to be able to reference inside of an expression.

• ‘Y’ Location: The crossing point in which you would like to capture the X value. This value can be

specified using a variable or function result.

• Occurrence Number: Used to handle scenarios where the graph passes by the X location multiple

times, this setting determines which value you would like to capture.

Begin Curve

End Curve

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 86

Limits

Limits are functions that can be placed under any other functions (data, window, or

analytical) that will check the parent function against criteria specified in the limit’s

settings and generate a pass or fail signal.

Fixed Upper/Lower Limit: Fixed Limits are limits that are set to a specified

constant value. These straight-line limits are set so that if the value exceeds or falls

below the upper or lower limits, respectively, a fail signal is generated. If desired, an

output can be chosen from a drop-down list to go high if the specified limit fails. Fixed

Upper Limits and Fixed Lower Limits are separate functions.

Relative Upper/Lower Limit: Relative Limits are limits that are automatically

generated based on the reference curve of the monitor. The Relative Offset is used to

determine how far away from the reference curve the limit will be created. If the signal

exceeds or falls below the upper or lower limit, respectively, a Fail signal is generated.

If desired, an output can be chosen from a drop-down list to go high if the specified

limit fails. Relative Upper Limits and Relative Lower Limits are separate functions.

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 87

Calibration

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 88

Calibration

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 89

Contacting Promess

Collect the Job Number information from the system

On Every Major Component

Say “I have an UltraPRO system, the job number is XXXXX-XX.X

Saves time in finding out what system we are working with

Know the Software Version currently on the system

Menu>> About

Call Promess @ 810.229.9334 - Support available 24/7/365

days a year

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 90

THANK YOU!

P.O. Box 748 • Brighton, MI 48116 • 810-229-9334 • promess@promessinc.com

www.promessinc.com 91

You might also like

- Simplicity With Functionality: Commander SK100% (2)Simplicity With Functionality: Commander SK16 pages

- AS2 Series: AC Servo Drive User Manual Lite Version V1.0No ratings yetAS2 Series: AC Servo Drive User Manual Lite Version V1.097 pages

- 988F Series II Wheel Loader Wiring GuideNo ratings yet988F Series II Wheel Loader Wiring Guide2 pages

- MC Series Brushless Servo Driver ManualNo ratings yetMC Series Brushless Servo Driver Manual26 pages

- So Do Cau Hinh Dieu Khien Bom Voi Van Ty LeNo ratings yetSo Do Cau Hinh Dieu Khien Bom Voi Van Ty Le13 pages

- ÒMNITRON FIBER To Serial RS485 Coverter 8780UM-GNo ratings yetÒMNITRON FIBER To Serial RS485 Coverter 8780UM-G1 page

- User's Manual: FX - 4AD Analog Input BlockNo ratings yetUser's Manual: FX - 4AD Analog Input Block6 pages

- ISO 16750 Compliance for Vehicle DisplaysNo ratings yetISO 16750 Compliance for Vehicle Displays2 pages

- D11 & D11R CD Track-Type Tractor Electrical System: Harness and Wire Electrical Schematic SymbolsNo ratings yetD11 & D11R CD Track-Type Tractor Electrical System: Harness and Wire Electrical Schematic Symbols2 pages

- 322C Excavator Electrical System: Area DNo ratings yet322C Excavator Electrical System: Area D2 pages

- QSK60 2-0 Industrial With CENSE Wiring Diagram50% (2)QSK60 2-0 Industrial With CENSE Wiring Diagram1 page

- ZYKT-32R Air Conditioner Controller ManualNo ratings yetZYKT-32R Air Conditioner Controller Manual2 pages

- System CPX-E Digital Input CPX-E - DI - : DescriptionNo ratings yetSystem CPX-E Digital Input CPX-E - DI - : Description19 pages

- CPX F8DE P - Operating Instr - 2021 03b - 8142001g1No ratings yetCPX F8DE P - Operating Instr - 2021 03b - 8142001g18 pages

- Installation Guide Perma STAR CONTROL enNo ratings yetInstallation Guide Perma STAR CONTROL en20 pages

- CPX AP A 16DI D M12 5P - Operating Instr - 2022 07 - 8160713g1No ratings yetCPX AP A 16DI D M12 5P - Operating Instr - 2022 07 - 8160713g116 pages

- Mitsubishi Inverters for Energy EfficiencyNo ratings yetMitsubishi Inverters for Energy Efficiency4 pages

- Modbus Communication: FX3U 485ADP MB 485ADP MBNo ratings yetModbus Communication: FX3U 485ADP MB 485ADP MB17 pages

- Ba B SC AnnualExaminations-2020-final PDFNo ratings yetBa B SC AnnualExaminations-2020-final PDF1 page

- Sample Size Impact on Skewness in AssessmentNo ratings yetSample Size Impact on Skewness in Assessment9 pages

- Business Statistics Module - 1 Introduction-Meaning, Definition, Functions, Objectives and Importance of StatisticsNo ratings yetBusiness Statistics Module - 1 Introduction-Meaning, Definition, Functions, Objectives and Importance of Statistics5 pages

- MASPL QAD F01B Recieving Inspection Report For GE ANo ratings yetMASPL QAD F01B Recieving Inspection Report For GE A1 page

- Faculty Application: Ravi Shanker VidyarthyNo ratings yetFaculty Application: Ravi Shanker Vidyarthy3 pages

- Van Norman 2019 Limitations of Animal Studies For Predicting Toxicity in Clinical TrialsNo ratings yetVan Norman 2019 Limitations of Animal Studies For Predicting Toxicity in Clinical Trials10 pages

- Understanding Sampling Distributions and ErrorsNo ratings yetUnderstanding Sampling Distributions and Errors32 pages

- Wipro Elite NTH Role and Packages: ContentNo ratings yetWipro Elite NTH Role and Packages: Content21 pages