0% found this document useful (0 votes)

19 views1 pageMonitoring Equipment Checklist

This document provides a checklist for inspecting occupational monitoring equipment. It contains over 100 items to review in gas detectors, combustion analyzers, air flow measurement, dust analyzers, noise measurement, temperature measurement, lighting measurement, and vibration measurement. The equipment must be in good condition and have valid calibration certificates in order to operate safely.

Uploaded by

ScribdTranslationsCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

19 views1 pageMonitoring Equipment Checklist

This document provides a checklist for inspecting occupational monitoring equipment. It contains over 100 items to review in gas detectors, combustion analyzers, air flow measurement, dust analyzers, noise measurement, temperature measurement, lighting measurement, and vibration measurement. The equipment must be in good condition and have valid calibration certificates in order to operate safely.

Uploaded by

ScribdTranslationsCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

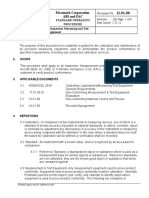

IMF-HIN09-01

INSPECTION OF OCCUPATIONAL MONITORING EQUIPMENT

(CHECKLIST FOR USE OF: INDUSTRIAL HYGIENE)

CIA / E.E.: .................................................. CARRIED OUT BY: ...............................

AREA: ........................................................ DATE: ..............................................

NOMBRE DEL EQUIPO: ………………………………………………… SERIES N° ............................................

FRECUENCIA DE CHEQUEO: DIARIO

No. ITEMS TO BE VERIFIED CORRECTIVE MEASURES /

GOOD BAD NOT APPLICABLE RESPONSIBLE DATE CONTROL

Preventive measures

GAS DETECTORS

1 Team status (external structure)

2 Status of CO, O2, CH4, NO2 sensors VENTIS MX4

3 State of the CO, O2, CO2, NO2, HCN MINIWARN sensors

4 CO sensor state TANGO TX1

5 NHE Sensor State - GFG

6 Hg JEROME sensor status

7 Condition of regeneration team JEROME

8 Hydrogen sensor state PROPRO GASBADGE

9 Status of IBRID MX6 sensors

10 Battery charge

11 State of the buckle (crocodile)

12 Equipment cleaning

Current calibration certificate

COMBUSTION ANALYZER

1 Equipment status (external structure)

2 State of CO, NO2 sensors

3 State of measurement probes

4 Equipment case condition

5 Battery charging

6 Equipment cleaning

7 Current calibration certificate

AIR FLOW MEASUREMENT

1 Team status (external structure)

2 State of hot wire sensor

3 Battery (batteries) charging

4 Battery status of the rangefinder.

5 Cleaning of the equipment

6 Valid calibration certificate

DUST ANALYZERS

1 Team status (external structure)

2 Team monitor status Haz dust

3 Cyclone GS state and dust adapter

4 IOM sampler status and Haz dust adapter

5 EPAM 5000 equipment monitor status

6 Status of impactor EPAM 5000 team

7 Head state of EPAM 5000 equipment

8 Battery charging

9 Cleaning of the equipment

10 Valid calibration certificate

NOISE MEASUREMENT

1 Equipment status (external structure)

2 SVANTEK microphone cable status

3 Calibrator status SVANTEK

4 Condition of the SONOMETER

5 Windbreak state SOUND LEVEL METER

6 Microphone state SOUND LEVEL METER

7 Battery (cell) charging

8 Equipment cleaning

9 Valid calibration certificate

TEMPERATURE MEASUREMENT

1 Team status (external structure)

2 Extractable bar state QUESTEMP

3 State of balloons (wet, dry, and black) QUESTEMP

4 Cable status (head, ankle, and abdomen) QUESTEMP

5 Condition of QUESTEMP thermal anemometer equipment

6 Battery charge

7 Equipment cleaning

8 Current calibration certificate

MEASUREMENT OF LIGHTING

1 Equipment status (external structure)

2 Status of the monitor Luxmeter EXTECH

3 Status of the EXTECH sensor equipment

4 Battery charging

5 Cleaning of the equipment

6 Valid calibration certificate

VIBRATION MEASUREMENT

1 Status of the equipment (external structure)

2 Status of the monitor of the VIBROMETER equipment

3 Status of sensor cables hand arm VIBROMETER

4 Whole body sensor cable status VIBROMETER

5 State of the dish VOBROMETER

6 Battery charge

7 Cleaning of the equipment

8 Current calibration certificate

Note: The following items must be in optimal condition; otherwise, the equipment CANNOT OPERATE: 1,2,3

Inspector's signature.