0% found this document useful (0 votes)

9 views1 pageRe H080EY

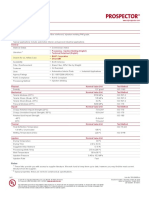

Repol H080EY is a homopolymer recommended for Tubular Water Quench and Cast Film applications, featuring slip and antiblock additives. It is suitable for textile overwraps and various packaging needs, meeting regulatory requirements for safe use with food and pharmaceuticals. The document provides typical characteristics and storage recommendations for the product.

Uploaded by

vedmailingCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

9 views1 pageRe H080EY

Repol H080EY is a homopolymer recommended for Tubular Water Quench and Cast Film applications, featuring slip and antiblock additives. It is suitable for textile overwraps and various packaging needs, meeting regulatory requirements for safe use with food and pharmaceuticals. The document provides typical characteristics and storage recommendations for the product.

Uploaded by

vedmailingCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd