Bulletin PD-2.264 rev.

D 05/02

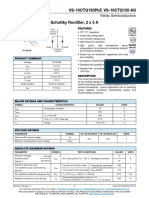

400CNQ... SERIES

SCHOTTKY RECTIFIER 400 Amp

TO-244AB

Major Ratings and Characteristics Characteristics

IF(AV) Rectangular waveform VRRM range IFSM @ tp = 5 s sine VF TJ @ 200Apk, TJ=125C (per leg) range

Description/ Features

The 400CNQ center tap, high current, Schottky rectifier module series has been optimized for very low forward voltage drop, with moderate leakage. The proprietary barrier technology allows for reliable operation up to 150 C junction temperature. Typical applications are in switching power supplies, converters, free-wheeling diodes, welding, and reverse battery protection. 150 C TJ operation Center tap module High purity, high temperature epoxy encapsulation for enhanced mechanical strength and moisture resistance Very low forward voltage drop High frequency operation Guard ring for enhanced ruggedness and long term reliability

400CNQ... Units

400 35 to 50 29,000 0.52 A V A V

- 55 to 150

80.01 [3.150] 40.26 [1.585] 39.75 [1.565] COMMON CATHODE

10.41 [.410] 9.65 [.380]

20.32 [.800] 17.78 [.700]

LUG TERMINAL ANODE 1

LUG TERMINAL ANODE 2

2X

7.49 [.295] 6.99 [.275]

34.925 [1.375] REF. 63.50 [2.500] 60.96 [2.400]

4.95 [.195] 4.70 [.185]

1/4-20 SLOTTED HEX

BASE COMMON CATHODE

23.55 [.927] 20.42 [.804]

15.75 [.620] 14.99 [.590] 3.35 [.132] 3.02 [.119]

92.71 [3.650] 90.17 [3.550] NOTES: 1. DIMENSIONS ARE SHOWN IN MILLIMETERS [INCHES]. 2. CONTROLLING DIMENSION: MILLIMETER

Modified JEDEC Outline TO-244AB Dimensions in millimeters and (inches)

Document Number: 93326

www.vishay.com 1

�400CNQ... Series

Bulletin PD-2.264 rev. D 05/02

Voltage Ratings

Part number

VR Max. DC Reverse Voltage (V) VRWM Max. Working Peak Reverse Voltage (V)

400CNQ035 400CNQ040 400CNQ045 400CNQ050

35 40 45 50

Absolute Maximum Ratings

Parameters

IF(AV) Max. Average Forward Current IFSM EAS IAR * See Fig. 5 (Per Leg) (Per Device)

400CNQ Units Conditions

200 400 29,000 3400 180 40 A mJ A 5s Sine or 3s Rect. pulse Following any rated load condition and with 10ms Sine or 6ms Rect. pulse rated VRRM applied A 50% duty cycle @ TC = 114 C, rectangular wave form

Max. Peak One Cycle Non-Repetitive Surge Current (Per Leg) * See Fig. 7 Non-Repetitive Avalanche Energy (Per Leg) Repetitive Avalanche Current (Per Leg)

TJ = 25 C, IAS = 40 Amps, L = 0.22 mH Current decaying linearly to zero in 1 sec Frequency limited by TJ max. VA = 1.5 x VR typical

Electrical Specifications

Parameters

VFM Max. Forward Voltage Drop (Per Leg) * See Fig. 1 (1)

400CNQ Units Conditions

0.57 0.73 0.52 0.68 V V V V mA A V m @ 200A @ 400A @ 200A @ 400A TJ = 25 C TJ = 125 C TJ = TJ max. TJ = 25 C TJ = 125 C VR = rated VR

IRM

Max. Reverse Leakage Current (Per Leg) * See Fig. 2 (1)

20 1 0.32 0.81 10,300 5.0 10000

VF(TO) Threshold Voltage rt Forward Slope Resistance CT Max. Junction Capacitance (Per Leg) LS Typical Series Inductance (Per Leg) dv/dt Max. Voltage Rate of Change

(1) Pulse Width < 300s, Duty Cycle <2%

pF VR = 5VDC, (test signal range 100Khz to 1Mhz) 25C nH From top of terminal hole to mounting plane V/ s (Rated VR)

Thermal-Mechanical Specifications

Parameters

TJ Tstg Max. Junction Temperature Range Max. Storage Temperature Range

400CNQ Units Conditions

-55 to 150 -55 to 150 0.20 0.10 0.10 C C C/W DC operation C/W DC operation C/W Mounting surface , smooth and greased * See Fig. 4

RthJC Max. Thermal Resistance Junction to Case (Per Leg) RthJC Max. Thermal Resistance Junction RthCS wt T to Case (Per Package) Typical Thermal Resistance, Case to Heatsink Approximate Weight Mounting Torque Base Mounting Torque Center Hole Terminal Torque Case Style

Min. Max. Typ. Min. Max.

79 (2.80) g (oz.) 24 (20) 35 (30) Kg-cm 13.5 (12) (Ibf-in) 35 (30) 46 (40) TO - 244AB Modified JEDEC

Document Number: 93326

www.vishay.com 2

�400CNQ... Series

Bulletin PD-2.264 rev. D 05/02

10 0 0 10 0 00 1 0 00 10 0 100 C 10 1 0.1 0 .01 0 T J = 150 C T J = 125 C T J = 25 C 10 Jun ctio n C a pa citan ce - C T (pF) 1 0 00 0 5 10 15 20 25 30 35 40 45 Reverse V olta ge - V R (V ) 75 C 50 C 25 C T J = 15 0 C 125 C

In sta n tan eous F or wa rd C urren t - I F (A )

1 00

Rev er se C urre nt - I R (m A )

Fig. 2 - Typical Values Of Reverse Current Vs. Reverse Voltage (Per Leg)

T J = 25 C

1 0 0.2 0.4 0 .6 0.8 1 1 .2 Forw a rd V olta ge D rop - V FM (V )

10 0 0 0 10 20 30 40 50 Reverse V oltag e - V R (V )

Fig. 1 - Max. Forward Voltage Drop Characteristics (Per Leg)

1 Th ermal Im pedan ce Z thJC ( C /W )

Fig. 3 - Typical Junction Capacitance Vs. Reverse Voltage (Per Leg)

0 .1

D D D D D

= = = = =

0.75 0.50 0.33 0.25 0.20

PD M

0 .01 Sing le Pu lse (Therm al Resistance) Notes:

t1 t2

1. D uty fac tor D = t 1 / t 2 2. Peak TJ = P D M x Z thJC+ T C 0.0 1 0 .1 1 10

0 .00 1 0 .00 00 1

0.0 00 1

0.0 01

t 1 , Recta ng ular Pulse Duratio n (Seco nd s)

Fig. 4 - Max. Thermal Impedance ZthJC Characteristics (Per Leg)

Document Number: 93326

www.vishay.com 3

�400CNQ... Series

Bulletin PD-2.264 rev. D 05/02

1 60 Allow a ble C ase Tem perature - ( C ) 1 50 A verag e Pow e r Lo ss - (W a tts) 1 40 1 30 1 20 1 10 1 00 90 80 70 60 0 50 100 1 50 2 00 25 0 30 0 Averag e Forw a rd C urren t - I F(A V) (A)

se e no te (2)

2 00 1 80 1 60 1 40 1 20 RM S Lim it 1 00 80 60 40 20 0 0 50 100 150 2 00 25 0 30 0 Averag e Forw ard C urrent - I F(AV) (A ) DC DC D D D D D = = = = = 0.20 0.25 0.33 0.50 0.75

Sq uare w a ve (D = 0.50) 80% Rated V R ap plied

Fig. 5 - Max. Allowable Case Temperature Vs. Average Forward Current (Per Leg)

100000 No n-Repe titive Surge C urren t - I FSM (A) At Any Rated Loa d C ond ition An d W ith Rated V RRM Ap plied Follow ing Surg e

Fig. 6 - Forward Power Loss Characteristics (Per Leg)

10000

1000 10

100

1000

10000

Square W a ve Pulse D uration - t p (m icrosec)

Fig. 7 - Max. Non-Repetitive Surge Current (Per Leg)

L H IG H-SPE ED SW ITC H FR EE-W H E EL D IO D E 40H FL40 S02 V d = 25 V olt

D UT

IRFP460 Rg = 25 ohm

C URRE NT M O N ITO R

Fig. 8 - Unclamped Inductive Test Circuit

(2) Formula used: TC = TJ - (Pd + PdREV) x RthJC ; Pd = Forward Power Loss = IF(AV) x VFM @ (IF(AV) / D) (see Fig. 6); PdREV = Inverse Power Loss = VR1 x IR (1 - D); IR @ VR1 = 80% rated VR

Document Number: 93326

www.vishay.com 4

�400CNQ... Series

Bulletin PD-2.264 rev. D 05/02

Data and specifications subject to change without notice. This product has been designed and qualified for Industrial Level. Qualification Standards can be found on IR's Web site.

IR WORLD HEADQUARTERS: 233 Kansas St., El Segundo, California 90245, USA Tel: (310) 252-7105 TAC Fax: (310) 252-7309 05/02

Document Number: 93326

www.vishay.com 5

�Legal Disclaimer Notice

Vishay

Notice

The products described herein were acquired by Vishay Intertechnology, Inc., as part of its acquisition of International Rectifiers Power Control Systems (PCS) business, which closed in April 2007. Specifications of the products displayed herein are pending review by Vishay and are subject to the terms and conditions shown below. Specifications of the products displayed herein are subject to change without notice. Vishay Intertechnology, Inc., or anyone on its behalf, assumes no responsibility or liability for any errors or inaccuracies. Information contained herein is intended to provide a product description only. No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this document. Except as provided in Vishay's terms and conditions of sale for such products, Vishay assumes no liability whatsoever, and disclaims any express or implied warranty, relating to sale and/or use of Vishay products including liability or warranties relating to fitness for a particular purpose, merchantability, or infringement of any patent, copyright, or other intellectual property right. The products shown herein are not designed for use in medical, life-saving, or life-sustaining applications. Customers using or selling these products for use in such applications do so at their own risk and agree to fully indemnify Vishay for any damages resulting from such improper use or sale. International Rectifier, IR, the IR logo, HEXFET, HEXSense, HEXDIP, DOL, INTERO, and POWIRTRAIN are registered trademarks of International Rectifier Corporation in the U.S. and other countries. All other product names noted herein may be trademarks of their respective owners.

Document Number: 99901 Revision: 12-Mar-07

www.vishay.com 1