0% found this document useful (0 votes)

27 views21 pagesHazcom Training

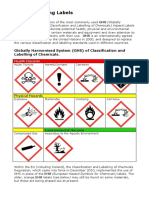

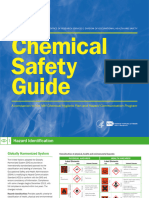

The Globally Harmonized System (GHS) of Classification and Labeling of Chemicals aims to standardize chemical labeling and safety data sheets to improve employee protection and facilitate international trade. Key changes to the Hazard Communication Standard include standardized labeling elements, a uniform format for Safety Data Sheets, and the use of pictograms to convey hazard information. Compliance timelines for GHS implementation began in December 2013, with ongoing updates expected as the system evolves.

Uploaded by

subhashCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

27 views21 pagesHazcom Training

The Globally Harmonized System (GHS) of Classification and Labeling of Chemicals aims to standardize chemical labeling and safety data sheets to improve employee protection and facilitate international trade. Key changes to the Hazard Communication Standard include standardized labeling elements, a uniform format for Safety Data Sheets, and the use of pictograms to convey hazard information. Compliance timelines for GHS implementation began in December 2013, with ongoing updates expected as the system evolves.

Uploaded by

subhashCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd