100% found this document useful (1 vote)

442 views8 pagesHMEL Polysure Grad Leaflet

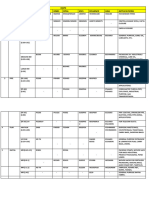

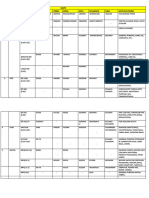

HPCL-Mittal Energy Limited (HMEL) is a joint venture that operates a crude oil refinery and a petrochemical complex, producing significant quantities of Polypropylene (PP) and Polyethylene (PE). The company emphasizes customer service through its accredited Customer Services & Development Center (CSDC), which supports product and application development. HMEL offers a wide range of grades and applications for its polypropylene and polyethylene products, catering to various industries with advanced technology and production capabilities.

Uploaded by

rahulCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

442 views8 pagesHMEL Polysure Grad Leaflet

HPCL-Mittal Energy Limited (HMEL) is a joint venture that operates a crude oil refinery and a petrochemical complex, producing significant quantities of Polypropylene (PP) and Polyethylene (PE). The company emphasizes customer service through its accredited Customer Services & Development Center (CSDC), which supports product and application development. HMEL offers a wide range of grades and applications for its polypropylene and polyethylene products, catering to various industries with advanced technology and production capabilities.

Uploaded by

rahulCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd