100% found this document useful (1 vote)

163 views26 pagesProduction Planning Control

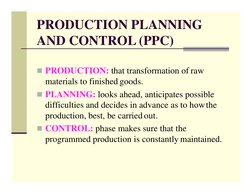

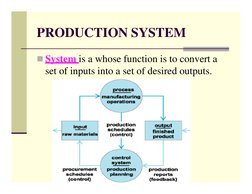

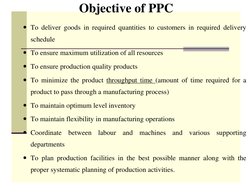

The document discusses production planning and control (PPC). It describes PPC as having three main components - production, planning, and control. Planning looks ahead to anticipate issues, while control ensures planned production is maintained. Key aspects of PPC include production planning, routing, scheduling, loading, dispatching, follow up, inspection, and corrective measures. The objective of PPC is to efficiently deliver quality products to customers on time and maximize resource utilization.

Uploaded by

Amogh KulkarniCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

163 views26 pagesProduction Planning Control

The document discusses production planning and control (PPC). It describes PPC as having three main components - production, planning, and control. Planning looks ahead to anticipate issues, while control ensures planned production is maintained. Key aspects of PPC include production planning, routing, scheduling, loading, dispatching, follow up, inspection, and corrective measures. The objective of PPC is to efficiently deliver quality products to customers on time and maximize resource utilization.

Uploaded by

Amogh KulkarniCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd