100% found this document useful (4 votes)

643 views15 pagesControlLogix for Engineers

The document provides an overview of the Allen Bradley Logix 5000 control system used on SIEMENS turbines in Lincoln. Key components include:

- A Logix 5000 PLC with distributed I/O connections, separate core engine controller, PC-based display system, and fuel/combustion controllers.

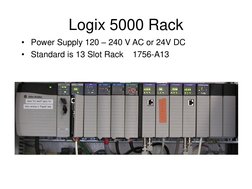

- A standard 13 slot rack housing the processor and power supply.

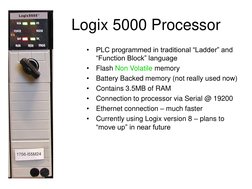

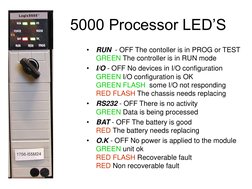

- A Logix 5000 processor programmed in ladder logic and function block programming, with flash memory, battery backup, Ethernet connection, and LED status indicators.

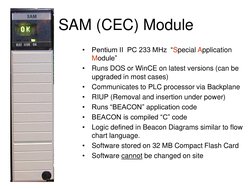

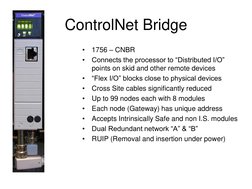

- Additional modules including a controlnet bridge for distributed I/O, devicenet bridge for communication to the ECU, analog and digital I/O modules, and an Ethernet

Uploaded by

hobergerCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

100% found this document useful (4 votes)

643 views15 pagesControlLogix for Engineers

The document provides an overview of the Allen Bradley Logix 5000 control system used on SIEMENS turbines in Lincoln. Key components include:

- A Logix 5000 PLC with distributed I/O connections, separate core engine controller, PC-based display system, and fuel/combustion controllers.

- A standard 13 slot rack housing the processor and power supply.

- A Logix 5000 processor programmed in ladder logic and function block programming, with flash memory, battery backup, Ethernet connection, and LED status indicators.

- Additional modules including a controlnet bridge for distributed I/O, devicenet bridge for communication to the ECU, analog and digital I/O modules, and an Ethernet

Uploaded by

hobergerCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

- Introduction: Provides an overview of the ControlLogix based system and its application in Siemens turbines at Lincoln.

- Basic System Overview: Outlines the main components and functionalities of the Logix 5000 system including I/O connections and PC display system.

- Logix 5000 Rack: Describes specifications and configurations for the Logix 5000 rack including power supply and slot standard.

- Logix 5000 Processor: Details the processor features, memory specifications, and connectivity options for enhanced data processing and communication.

- 5000 Processor LED Indicators: Explains the function and status indications for LED lights on the Logix 5000 processors, including error and activity signals.

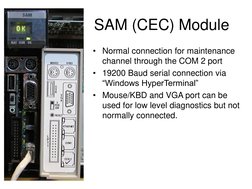

- SAM (CEC) Module: Introduces the SAM module’s capabilities including application code execution and diagnostic communication via terminal ports.

- ControlNet Bridge: Covers the ControlNet Bridge module's role, configuration, and connectivity specifications for integrated network communication.

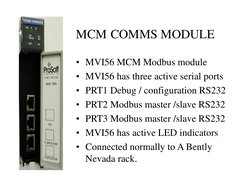

- MCM COMMS MODULE: Details the communication functionalities and port options available in the MCM COMMS Module for Modbus networking.

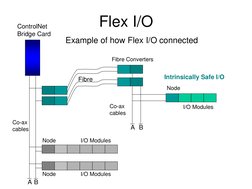

- Flex I/O Overview: Illustrates the Flex I/O connection setups using diagrams showcasing fibre and coaxial cable integrations.

- DeviceNet Bridge: Explains the functionality and benefits of the DeviceNet Bridge for connecting the processor to other devices.

- Ethernet Communication: Details Ethernet communication capabilities and setup to ensure smooth data transmission across systems.

- DC Input Module: Specifies features including channel capacity, detection configurations, and programmable capabilities of the DC Input Module.

- DC Output Module: Describes channel configurations, state detection, and power management features of the DC Output Module.

- Analog Input Module: Provides an overview of analog input specifications, detection capabilities, and alarm functionalities for system monitoring.