100% found this document useful (1 vote)

907 views17 pagesTOFD

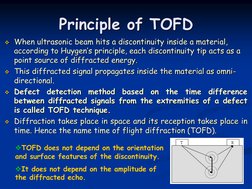

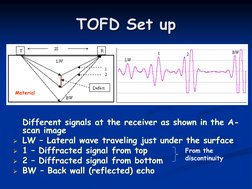

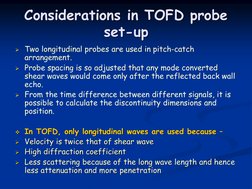

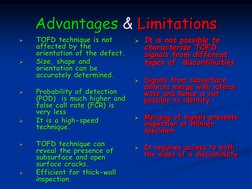

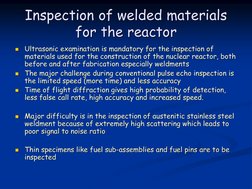

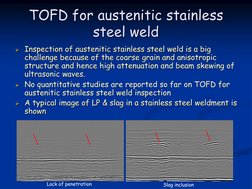

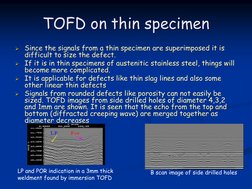

Time of Flight Diffraction (TOFD) is an ultrasonic testing technique that detects defects by measuring the time difference between diffracted ultrasonic signals from the extremities of a defect. TOFD can accurately determine defect size, shape, and orientation without depending on surface features or signal amplitude. While TOFD is effective for thick materials, challenges include differentiating merged signals in thin specimens and high scattering in austenitic stainless steel welds. Various signal processing techniques have aimed to address these issues, including wavelet transforms, machine learning classifiers, and embedded signal identification.

Uploaded by

Lương Hồ VũCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

907 views17 pagesTOFD

Time of Flight Diffraction (TOFD) is an ultrasonic testing technique that detects defects by measuring the time difference between diffracted ultrasonic signals from the extremities of a defect. TOFD can accurately determine defect size, shape, and orientation without depending on surface features or signal amplitude. While TOFD is effective for thick materials, challenges include differentiating merged signals in thin specimens and high scattering in austenitic stainless steel welds. Various signal processing techniques have aimed to address these issues, including wavelet transforms, machine learning classifiers, and embedded signal identification.

Uploaded by

Lương Hồ VũCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd