0% found this document useful (0 votes)

84 views14 pagesMotorola's Quality Improvement in Mexico

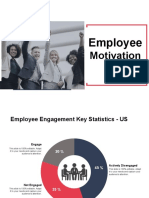

Motorola opened a plant in Guadalajara, Mexico in the 1980s to take advantage of lower costs. By 1987, quality issues emerged and morale was low among both Mexican workers and American managers. To improve quality, Motorola gave the plant more autonomy and designed culturally-sensitive programs to motivate workers, such as flexible lunch hours and health insurance. Quality increased as workers had more input and saw how their work contributed to Motorola's vision.

Uploaded by

Satrio HaryosenoCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

84 views14 pagesMotorola's Quality Improvement in Mexico

Motorola opened a plant in Guadalajara, Mexico in the 1980s to take advantage of lower costs. By 1987, quality issues emerged and morale was low among both Mexican workers and American managers. To improve quality, Motorola gave the plant more autonomy and designed culturally-sensitive programs to motivate workers, such as flexible lunch hours and health insurance. Quality increased as workers had more input and saw how their work contributed to Motorola's vision.

Uploaded by

Satrio HaryosenoCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd