0% found this document useful (0 votes)

81 views34 pagesProcurement and Supply Management

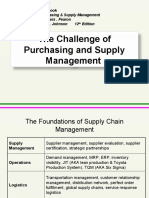

This chapter discusses procurement and supply management. It covers inbound logistics for different industries and defines materials management as planning and controlling material flows. Key activities include procurement, evaluating importance of purchases, and managing the procurement process. Procurement aims to identify needs, evaluate suppliers, and receive products. The chapter also discusses electronic procurement and how the internet has expanded procurement options.

Uploaded by

rajnew7Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

81 views34 pagesProcurement and Supply Management

This chapter discusses procurement and supply management. It covers inbound logistics for different industries and defines materials management as planning and controlling material flows. Key activities include procurement, evaluating importance of purchases, and managing the procurement process. Procurement aims to identify needs, evaluate suppliers, and receive products. The chapter also discusses electronic procurement and how the internet has expanded procurement options.

Uploaded by

rajnew7Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

/ 34