0% found this document useful (0 votes)

93 views25 pagesPrecipitation Methods in Downstream Processing

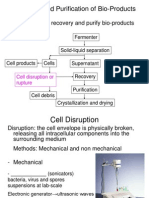

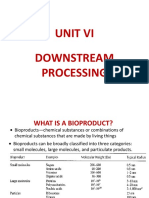

The document discusses downstream processing which involves the isolation and purification of biotechnological products from fermentation broth into a form suitable for intended use. The key steps include:

1) Removal of insolubles like cells and debris through filtration or centrifugation.

2) Isolation of the product using techniques like ultrafiltration, extraction, chromatography which fractionates and concentrates the product.

3) Purification of the product using more precise techniques like chromatography to remove closely resembling contaminants.

4) Final polishing through processes like crystallization, drying and sterilization to obtain a stable, transportable product. Precipitation using salts, organic solvents or polymers is a useful technique used

Uploaded by

SHAHZADCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

93 views25 pagesPrecipitation Methods in Downstream Processing

The document discusses downstream processing which involves the isolation and purification of biotechnological products from fermentation broth into a form suitable for intended use. The key steps include:

1) Removal of insolubles like cells and debris through filtration or centrifugation.

2) Isolation of the product using techniques like ultrafiltration, extraction, chromatography which fractionates and concentrates the product.

3) Purification of the product using more precise techniques like chromatography to remove closely resembling contaminants.

4) Final polishing through processes like crystallization, drying and sterilization to obtain a stable, transportable product. Precipitation using salts, organic solvents or polymers is a useful technique used

Uploaded by

SHAHZADCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd