0% found this document useful (0 votes)

62 views81 pagesFacility Layout Strategies Explained

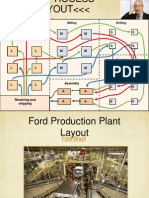

The document discusses facility layout strategies. It describes six common layout types: fixed-position for unique projects, office layout to optimize information flow, process-oriented for low-volume production, retail layout to expose customers to items, warehouse layout balancing storage and handling costs, and product-oriented for repetitive production. The document provides examples of each type and discusses developing layouts using flow analysis and proximity charts. The goal is to optimize space utilization, flows, costs, and employee experience.

Uploaded by

Sou TibonCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

62 views81 pagesFacility Layout Strategies Explained

The document discusses facility layout strategies. It describes six common layout types: fixed-position for unique projects, office layout to optimize information flow, process-oriented for low-volume production, retail layout to expose customers to items, warehouse layout balancing storage and handling costs, and product-oriented for repetitive production. The document provides examples of each type and discusses developing layouts using flow analysis and proximity charts. The goal is to optimize space utilization, flows, costs, and employee experience.

Uploaded by

Sou TibonCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd