Professional Documents

Culture Documents

Electrolytic Carburetor Breaks Water Into Hydrogen and Oxygen for Fuel

Uploaded by

max386Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrolytic Carburetor Breaks Water Into Hydrogen and Oxygen for Fuel

Uploaded by

max386Copyright:

Available Formats

Patented July 2, 1935

2,006,676

United States Patent Office 2,006,676

Electrolytic Carburetor Charles H. Garrett, Dallas, Texas Application July 1, 1932, Serial No. 620,364 Renewed November 30, 1934

5 Claims (Cl. 204-5)

This invention relates

to

carburetors

and

it

has

particular

reference to an electrolytic carburetor by means of

which water may

be broken up into its hydrogen and oxygen constituents and the gases so formed suitably mixed with air.

The principal object

of

the invention is to provide in a device of by means of which water may be and the constituents

the character described, a mechanism readily decomposed into its

constituents,

intimately mixed with each other and with air.

Another object of

the

invention

is

to

provide means whereby the

electrolyte level in the carburetor may be maintained at a more or less constant level regardless of fluctuations in fluid pressure at

the fluid inlet of the carburetor.

Another object of the invention relative amount of

is

to

provide

means

whereby the may be

air mixed with the hydrogen and

oxygen

regulated as desired.

Still another object

of

the invention is the provision of means to gases during periods in which

prevent loss of hydrogen and oxygen

these gases are not being drawn from the carburetor.

Still another object whereby the hydrogen formed in separate invention is the

of and

the

invention is the provision

of

means

oxygen resulting from electrolysis may be and a further object of the the

compartments, of

provision

means to periodically

reverse

direction of current flow and thereby alternate the evolution of the gases in the separate compartments, to be later intermingled.

With the foregoing

objects

as

paramount, features

the of

invention

has and

particular reference to its salient arrangement of parts, drawings, wherein: taken in

construction

connection

with the

accompanying

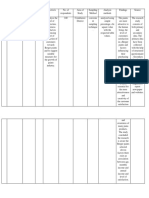

Figure 1 is a view in vertical section of one form of carburetor. Figure 2 is a modified form. Figure 3 is a diagrammatic view of a pole changer, showing its

actuating mechanism, and Figure 4 is a wiring diagram for shown in Figure 2. the modified form of carburetor

Continuing more in detail with the drawings, reference

is primarily

directed to Figure 1 in which the reference numeral 1 designates the carburetor housing, which is preferably constructed of bakelite or The housing 1 is so designed as chamber 2 and gas generating

other suitable insulating material.

to divide the carburetor into a float

chamber 4, connected by a fluid passage 3.

Water UNDER PRESSURE opening 5 which

is

FORCED

into

the

carburetor

through

an

communicates

with

the float chamber 2 through the the needle valve orifice 7, is not in

medium of the sediment chamber 6 which is closed operation. by a 9 needle

and

valve 8 when the device

A float

surrounds

the needle valve 8 and is free to Depending from the cover 10 to intervals on

move vertically relative thereto.

the float chamber 2 are two ears 11, located at spaced opposite sides of the needle valve 8. the ears 11, as shown.

The members 12 are pivoted to

The weighted outer ends of the members 12 inner ends are received in an attached to the

rest on top of the float 9, and their annular groove in needle valve 8.

the collar 13 which is rigidly

Within the gas

generating

chamber 4, a series of spaced, depending member 15 to which a wire bolt 17, which

plates 14 are suspended from a horizontal

16 has electrical contact through the medium of the extends inwardly through horizontal member 15. the housing 1 and

is threaded into the

A second series of plates 18 is located

intermediate

the plates 14

and attached to the horizontal member 19, and has electrical contact with the wire 20 through the bolt 21.

A gas passageway

22,

in

which

butterfly chamber

valve 23 is located, 4 through an orifice with the gas

communicates with the gas generating 24. An air inlet chamber the 25 has

communication A

passageway 22 above

orifice

24.

downwardly opening check

valve 26 is in control of the openings 27, and is held inoperatively closed by means of light spring 28.

An adjustable auxiliary air valve

29 is provided in the wall of the

gas passageway 22, which air valve is closed by the 23 when the butterfly valve is

butterfly valve

closed, but communicates with the

outside air when the butterfly valve is open.

The operation of the device is as follows :

The chambers 2 and 4 are first

filled

to

the

level

'a'

with

solution of weak sulphuric acid or other electrolyte the passage of

not changed by

current therethrough, and the opening 5 is connected

to a tank of water, not shown.

The wire 16 is next connected to

the

positive

pole

of

a storage to the a

battery or other source of direct current and the negative pole. Since the solution current within will the

wire

20

carburetor

is

conductor of electricity, hydrogen will be

flow

therethrough plates

and 18

given off from the negative or cathode

and oxygen from the positive or anode plates 14.

The butterfly valve

23

is opened and the gas passageway 22 brought a partial vacuum. Atmospheric to pressure forced oxygen

into communication with acting on the top of in

the check valve 26 causes it dotted lines. The

be and

downwardly as shown

hydrogen

liberated from the water at the plates

18 and 14 are drawn upwardly where they are

through the orifice 24 covered by the check valve 30 subsequently mixed with air entering through

the openings 27 and

through the auxiliary air valve 29.

When it is desired to reduce the the plates 18 and

flow

of

hydrogen and oxygen from the device is

14, the current flowing through

reduced, and when

the current is interrupted the flow ceases.

When

the butterfly valve 23 is moved to

closed position, the check valve Any EXCESS GAS given

26 is automatically closed by the spring 28. off during these operations

IS STORED in the space above the fluid

where it is ready for subsequent use.

Water is converted

into

its gaseous

constituents

by

the

device

herein described, but electrolyte in the

the dilute sulphuric acid or REMAINS UNCHANGED, in

other

suitable

carburetor

since it is not

destroyed by electrolysis, and the made of bakelite electrolyte. and

parts

contact therewith are attacked by the

lead or other material not

The structure shown

in

Figure

2 is substantially the same as that that the modified structure by means

shown in Figure 1 with the exception

embraces a larger gas generating chamber which is divided of an insulating plate

31 and is further provided with a depending gas generating chamber 33 from in the same

baffle plate 32 which separates the the float chamber manner as in 34

in which the float 35 operates 1.

Figure of

Moreover, the structure shown in Figure 2 depending plates 36 which are

provides a series

spaced

electrically connected to the wire 37, and a second series of similar plates 38 which are electrically connected to the wire 39 36 by the insulating plate 31.

and are spaced apart from the plates

Gases generated on the surfaces of the plates 36 and through the orifice 39a into

38 pass upward

the gas passageway 40 where they are

mixed with air as explained in the description of Figure 1.

A pipe 51 bent as shown in Figure

passes

downwardly through the apertures 'a'

housing of the carburetor and has a series of spaced

in its horizontal portion beneath the plates 36 and 38.

An upwardly

opening check valve

53

is

in control of the air inlet 54.

When a

partial vacuum exists in the chamber 33, air is drawn in through the opening 54 and subsequently passes 'a'. upwardly through the apertures on the

This air tends to remove any bubbles of gas collecting 38 and also tends to cool the electrolyte.

plates 36 and

The check

valve 53 automatically closes when carburetor and thereby out of the opening 54.

a gas pressure exists within the being forced

prevents the electrolyte from

In order to

provide

for

alternate evolution of the gases from the shown in Figure 3 is provided,

plates 36 and 38, a pole changer 41,

which is actuated periodically by the motor 42 which drives the worm 43 and the gear 44 and causes oscillations of the member 45 which is connected by a spring 46 to the arm 47, thereby causing the pole

changer to snap from one position to the other.

In operation, the carburetor shown in Figure 2 is connected as shown in the wiring diagram of Figure 4. current A storage battery 48 or other is connected to a variable as

suitable source of rheostat 49, switch shown.

direct 50,

pole changer 41 and to the

carburetor

Thus the rate of evolution of the gases can be controlled by the rheostat 49 and the desired alternate evolution the carburetor is accomplished

the setting of

of the gases in the compartments of

by means of the periodically operated pole changer 41.

Manifestly, the construction

shown

is

capable

of

considerable

modification and such modification as is considered within the scope and meaning of the appended claims is also considered within the

spirit and intent of the invention.

What is claimed is:

1)

An electrolytic carburetor including to control means

an

anode and a cathode, within from

float means

the level of the electrolyte to mix the gases

said carburetor,

resulting

electrolysis with air, and a

check

valve independent of said

float means to control ingress of air to said carburetor.

2)

An electrolytic carburetor including anode and cathode plates, actuated valve in control of the electrolyte level

a float

within said

carburetor, means to mix the gases resulting from

electrolysis with air, a check valve in control of said means, a second check valve independent of said float actuated valve

to prevent loss of gases from said carburetor.

3)

An electrolytic carburetor for producing mixtures of hydrogen, and electrically

oxygen and air, including a series of spaced connected anode within said plates

partially immersed in the electrolyte of electrically anode plates, connected a float

carburetor, a series spaced between

cathode plates

said

operated valve in control of the electrolyte level within said carburetor, an air inlet to said carburetor and a check valve in control of said air inlet.

4)

An

electrolytic carburetor for generating hydrogen and oxygen

gases from water and for mixing said gases with air, including an anode and cathode paritally immersed in an to electrolyte replace the

within said carburetor, float actuated means water consumed whereby to maintain a

constant fluid level

within said device, means for

mixing the said gases with air,

and a check valve in control of said latter means.

5)

An electrolytic carburetor including an anode means

and

a cathode,

float actuated

to control the level of the electrolyte to mix the gases resulting from

within said carburetor, means

electrolysis with air, a check valve in control of said latter means and means to periodically reverse the direction of

current through said carburetor. Charles H. Garrett

The drawings are;

Figure 1 is a view in vertical section of one form of carburetor.

Figure 2 is a modified form.

Figure 3 is a diagrammatic view of a pole changer, showing its actuating mechanism, and

Figure 4 is a wiring diagram for the modified form of carburetor shown in Figure 2.

You might also like

- EASSON ES 8A DRO User Manual PDFDocument114 pagesEASSON ES 8A DRO User Manual PDFJulio CezarNo ratings yet

- Starlite PDFDocument35 pagesStarlite PDFPuturrú De FuáNo ratings yet

- Explosive Train HandbookDocument366 pagesExplosive Train HandbookSanja PekicNo ratings yet

- How To Make Sodium PerchlorateDocument17 pagesHow To Make Sodium PerchlorateKing90No ratings yet

- Hydrostatics PressureBDocument13 pagesHydrostatics PressureBmontaser.nalawiNo ratings yet

- CES 2020 Summary: by Frank Egle, I/EZ-I (Slide 1-46), Dr. Harald Altinger I/EF-XS (Slide 47-50)Document50 pagesCES 2020 Summary: by Frank Egle, I/EZ-I (Slide 1-46), Dr. Harald Altinger I/EF-XS (Slide 47-50)mazuedNo ratings yet

- IBP - Help For Standard Keyfigures PDFDocument311 pagesIBP - Help For Standard Keyfigures PDFSaurabh KulkarniNo ratings yet

- Comparative Experimental Investigation of Oxyhydrogen (HHO) Production Rate Using Dry and Wet CellsDocument8 pagesComparative Experimental Investigation of Oxyhydrogen (HHO) Production Rate Using Dry and Wet CellsNam stareNo ratings yet

- BE4 Rocket EngineDocument2 pagesBE4 Rocket Enginetarx441No ratings yet

- Hydrogen Peroxide-Optimal For Turbo Machinery and Power ApplicationsDocument17 pagesHydrogen Peroxide-Optimal For Turbo Machinery and Power ApplicationsVeljko Korvin KokovićNo ratings yet

- Hydrogen Peroxide Gas GeneratorsDocument17 pagesHydrogen Peroxide Gas GeneratorsCliff ThriveNo ratings yet

- Flatback Airfoil Wind Tunnel ExperimentDocument37 pagesFlatback Airfoil Wind Tunnel Experimentvictoria100% (1)

- OP 1157 3.5 and 5 in Aircraft Rockets 3.25 Motor 1945Document17 pagesOP 1157 3.5 and 5 in Aircraft Rockets 3.25 Motor 1945FrancescoNo ratings yet

- Generator Bushing DesignsDocument10 pagesGenerator Bushing DesignsPradeep_VashistNo ratings yet

- Rocket Propulsion: Combustion InstabilityDocument28 pagesRocket Propulsion: Combustion InstabilityKannan RamarajNo ratings yet

- AWCY? Apple PieDocument8 pagesAWCY? Apple PieCWONo ratings yet

- Airforce Airgun ManuaLDocument15 pagesAirforce Airgun ManuaLmanicmonkeyNo ratings yet

- Polymer Blends and CompositesDocument25 pagesPolymer Blends and CompositesHamza ChelaliNo ratings yet

- Patented May 28, 1912.: Air 4. - GentsDocument12 pagesPatented May 28, 1912.: Air 4. - GentsСлэйтер Строительная компанияNo ratings yet

- Swagelok Tubing DataDocument8 pagesSwagelok Tubing DataSyahirul Alim100% (1)

- A. Ghuohu.: (No Model.)Document3 pagesA. Ghuohu.: (No Model.)dgfsduuwio100% (1)

- Kinetic Launcher For UAVDocument13 pagesKinetic Launcher For UAVLord Vario100% (1)

- SVT40 ManualDocument23 pagesSVT40 Manualandy2205No ratings yet

- Adams Rite Product Catalog: U.S. & Canada Effective February 1, 2019Document11 pagesAdams Rite Product Catalog: U.S. & Canada Effective February 1, 2019Angelo Colombo RauterNo ratings yet

- MAX11kManual Rev A PDFDocument12 pagesMAX11kManual Rev A PDFJorge Mercado NajeraNo ratings yet

- Pressure Air GunDocument7 pagesPressure Air GunyuehanNo ratings yet

- Filament Wound Fuselage With Cocured StiffenersDocument12 pagesFilament Wound Fuselage With Cocured Stiffenersmecheng88No ratings yet

- Externally Fired Microturbine FlyerDocument1 pageExternally Fired Microturbine FlyerPaulFerry100% (1)

- Supersonic Wind TunnelDocument15 pagesSupersonic Wind TunnelAseem TanejaNo ratings yet

- Railgun Thesis: 600-kJ Power Supply Design for 1.2-m Naval RailgunDocument103 pagesRailgun Thesis: 600-kJ Power Supply Design for 1.2-m Naval Railgunari wiliamNo ratings yet

- Instructions For Making The Inflatable KiteDocument15 pagesInstructions For Making The Inflatable KiteLuka NikitovicNo ratings yet

- Y6 DIY Assembly Instructions WEBDocument12 pagesY6 DIY Assembly Instructions WEBAmru ZulNo ratings yet

- Project Sentry Gun Sentry Controller v5: Setup InstructionsDocument1 pageProject Sentry Gun Sentry Controller v5: Setup InstructionsVenkatesh MadasamyNo ratings yet

- Effect of Shaped Charge Liner Surface Finish on Jet Break-UpDocument10 pagesEffect of Shaped Charge Liner Surface Finish on Jet Break-Upwarrior_2008No ratings yet

- Alternator Frame: Turbine DiameterDocument4 pagesAlternator Frame: Turbine DiameterDennyHalim.com50% (2)

- Uav Monopulse AntennaDocument7 pagesUav Monopulse AntennaognianovNo ratings yet

- Steyr AUG Barrel 14Document3 pagesSteyr AUG Barrel 14ouraltn2001No ratings yet

- Lincoln Welding SP 170t Im794Document36 pagesLincoln Welding SP 170t Im794Anonymous hR3e8SsNo ratings yet

- Rocket EngineDocument22 pagesRocket Enginedevhx100% (1)

- SDS - Hardtop XP Comp A - Marine - Protective - English (Uk) - United Kingdom - 3140 - 18.07.2013Document15 pagesSDS - Hardtop XP Comp A - Marine - Protective - English (Uk) - United Kingdom - 3140 - 18.07.2013NPTNo ratings yet

- Consolidated: Consolidated Safety Valve Type 1700-2-S and 1700-3-SDocument69 pagesConsolidated: Consolidated Safety Valve Type 1700-2-S and 1700-3-SSravan DasariNo ratings yet

- Cream Puffs Recipe Easy HomemadeDocument1 pageCream Puffs Recipe Easy HomemadeThomas SjölingNo ratings yet

- Air Boat Safety Manual ProcedureDocument9 pagesAir Boat Safety Manual ProcedureittehadNo ratings yet

- Hydro Fuel CellDocument48 pagesHydro Fuel CellRoberto Rojas FlorentinoNo ratings yet

- John Niles Et Al - Mitigating Shaped Charge Jet ImpactDocument20 pagesJohn Niles Et Al - Mitigating Shaped Charge Jet ImpactMermaczNo ratings yet

- Glock Magazine IdentificationDocument2 pagesGlock Magazine IdentificationSteve JohnsonNo ratings yet

- 3D-printed PC 1911 crossbow pistolDocument32 pages3D-printed PC 1911 crossbow pistolpabloNo ratings yet

- Project Pulse-Jet Group 4: Jeffrey Dennen Justin Marriott Brian Melo Matthew SkillinDocument37 pagesProject Pulse-Jet Group 4: Jeffrey Dennen Justin Marriott Brian Melo Matthew SkillinultimatesrNo ratings yet

- Pulse Detonation EngineDocument29 pagesPulse Detonation Enginev2brother100% (6)

- Electrolytic Nickel Phosphorus PlatingDocument34 pagesElectrolytic Nickel Phosphorus PlatingKhoa Vũ100% (1)

- Vortex Tube ManufacturingDocument3 pagesVortex Tube ManufacturingSameer JainNo ratings yet

- AUtomotive Heat ExchangerDocument28 pagesAUtomotive Heat ExchangersantoshkumarvenuNo ratings yet

- Common Smart SubmunitionDocument11 pagesCommon Smart SubmunitionАлександар Нуждић50% (2)

- SD-1 Minisport Pilot Operating HandbookDocument19 pagesSD-1 Minisport Pilot Operating HandbookŁukasz50% (2)

- AR 190-11 Physical Security of Arms, Ammunition, and ExplosivesDocument122 pagesAR 190-11 Physical Security of Arms, Ammunition, and ExplosivesKevin BravoNo ratings yet

- Leader USAR Sentry enDocument1 pageLeader USAR Sentry enForum PompieriiNo ratings yet

- Coil Springs Ride Height: Guide ToDocument1 pageCoil Springs Ride Height: Guide ToalexvikingplusNo ratings yet

- Orange PI ZeroDocument19 pagesOrange PI Zerosondaya86No ratings yet

- Carbon Ion A New Category of Energy Storage Devices Technical White PaperDocument16 pagesCarbon Ion A New Category of Energy Storage Devices Technical White PaperRahul RahuNo ratings yet

- Carburador de Hidrógeno PatE8Document7 pagesCarburador de Hidrógeno PatE8Maximo CozzettiNo ratings yet

- GT LL: NN W///, WM)Document5 pagesGT LL: NN W///, WM)lfilippiniNo ratings yet

- Rotating double shell heat exchange drumDocument5 pagesRotating double shell heat exchange drumaegosmithNo ratings yet

- Us 2109297Document6 pagesUs 2109297lfilippiniNo ratings yet

- VFD module specification guideDocument17 pagesVFD module specification guideMikhailNo ratings yet

- Sample - Table - Literature ReviewDocument11 pagesSample - Table - Literature ReviewKeyur KevadiyaNo ratings yet

- Ekiti Subeb Past Questions and AnswersDocument41 pagesEkiti Subeb Past Questions and AnswersSandra Gkbchall0% (1)

- 2 CEMEX Synhelion CemNet Webinar VFDocument15 pages2 CEMEX Synhelion CemNet Webinar VFChophel TashiNo ratings yet

- Common Errors in Sm21Document1 pageCommon Errors in Sm21Subramani SambandamNo ratings yet

- Ahmad Hassan PDFDocument2 pagesAhmad Hassan PDFAhmad HassanNo ratings yet

- Progress Test 02Document21 pagesProgress Test 02andrewlaurenNo ratings yet

- Resume - Game DevelopmentDocument1 pageResume - Game Developmentapi-498982826No ratings yet

- Monitor driver informationDocument1,071 pagesMonitor driver informations npNo ratings yet

- Testing and Sampling Parameters for Boiler Water FeedDocument17 pagesTesting and Sampling Parameters for Boiler Water FeedGuruNo ratings yet

- A Project Report On Knowledge ManagementDocument6 pagesA Project Report On Knowledge ManagementBharati KudambalNo ratings yet

- Act Sheet For RoboticsDocument4 pagesAct Sheet For RoboticsErah Kim GomezNo ratings yet

- Bank Account Details enDocument4 pagesBank Account Details enAliyev ElvinNo ratings yet

- RG Coaxial Cable Types and SpecsDocument8 pagesRG Coaxial Cable Types and SpecsedgarputongNo ratings yet

- css12 m2Document7 pagescss12 m2ONHS J MejiaNo ratings yet

- Video Games - Checklist, Research #1 and 2, Rubric, and TimelineDocument6 pagesVideo Games - Checklist, Research #1 and 2, Rubric, and Timelinefin vionNo ratings yet

- WEG Programing Manual 10003989140 SSW900 enDocument167 pagesWEG Programing Manual 10003989140 SSW900 enAntonio Sergio Correa JuniorNo ratings yet

- Osy Chapter 3Document19 pagesOsy Chapter 3NNo ratings yet

- A Colony of Blue-Green Algae Can Power A Computer For Six MonthsDocument4 pagesA Colony of Blue-Green Algae Can Power A Computer For Six MonthsDr Hart IncorporatedNo ratings yet

- Quantifying The Seasonal Cooling Capacity of Green Infrastr 2020 LandscapeDocument21 pagesQuantifying The Seasonal Cooling Capacity of Green Infrastr 2020 Landscape熙槃No ratings yet

- Concept-and-Technical-Drawing-RelationshipDocument13 pagesConcept-and-Technical-Drawing-RelationshipcyeishamaekielaNo ratings yet

- Index AcknowledgementDocument2 pagesIndex AcknowledgementdbshgdcvNo ratings yet

- Hybrid Pile Foundations IPWE SeminarDocument22 pagesHybrid Pile Foundations IPWE Seminarrohit100% (1)

- IncidentXP Software Manual - For Release 9.2Document101 pagesIncidentXP Software Manual - For Release 9.2mpinto2011100% (1)

- Literature Review of Marketing PlanDocument6 pagesLiterature Review of Marketing Planc5nc3whz100% (1)

- SG110CXPV Grid-Connected Inverter User ManualDocument101 pagesSG110CXPV Grid-Connected Inverter User ManualAizat AlongNo ratings yet

- Build Java REST APIs Step-by-StepDocument2 pagesBuild Java REST APIs Step-by-StepAthar RiazNo ratings yet