Professional Documents

Culture Documents

Basic Material - AZpiping

Uploaded by

Nguyen Anh TungOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Basic Material - AZpiping

Uploaded by

Nguyen Anh TungCopyright:

Available Formats

Using within min. -29 C to max.

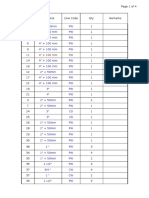

425 C General The Carbon Equipvalent (CE) for carbon steel intended for welding shall not exceed 0.43% base on the long formula: CE=C + Mn / 6 + ( Cr + Mo + V ) / 5 + ( Cu + Ni ) / 15 Service Non-corrosive piping system ( fresh water, plant air, nitrogen, fuel gas, etc.) ASTM A106 Gr.B, API 5L Gr.B ASTM A234 Gr.WPB ASTM A105

A) Carbon Steel

Applications

Pipes Fittings

Natural Rubber->NR Styrene Butadiene Rubber->SBR Neoprene Rubber->CR Butyl Rubber->IIR Chlorosulphonated polyethylene->CSM Nitrile Butadiene Rubber->NBR, HNBR Ethylene Propylene Rubber->EPDM Fluoroelastomers->FKM Perfluoro Polymer->FFKM Fluor-Silicone Rubbers->VMQ, PMQ, FMQ Polyurethane Rubbers->AU,EU Glassfibre Rainforced Epoxy->GRE Glassfibre Rainforced Vinylester->GRV No use in hydrocarbon and methanol system Maxinternal design temperature 20 bargs Design temperature range for -40 C up to 95C for epoxy and up to 80 C for vinylester Commonlly used for the sea water system in offshore Using Glassfibre Rainforced Plastic->GRP General Forgings ASTM A350 Gr.LF2 General Using if the minimum service temperature is below -29 C Service Pipes Low temperature non-corrosive piping system ( flare system ) ASTM A333 Gr.6 ASTM A420 Gr.WPL6 Forgings

I) Elastomeric B) Low Temp Carbon Steel

Applications

Fittings

The use of austenitic stainless steel in offshore is limited to a maximum service temperature of 60 C Using when the corrosion rate is too high to use carbon steel ( typical more than 3mm or 6mm max. corrosion allowance for the design life ) Any hydrostatic testing of austenitic stainless steel shall be conducted with water containing less than 2 mg/kg chlorides, and any open ends sealed after drying to ensure no moisture ingress. Service Pipes Application Fuel gas, chemical injection, instrument air, wet hydrocarbon ( corrosive ). ASTM A312 Gr.TP304/304L, ASTM A312 Gr.TP316/316L ASTM 403 Gr.WP304/304L, ASTM 403 Gr.WP316/316L ASTM A182 Gr.F304/304L, ASTM A 182 Gr.F316/316L

H) Non-Metallic

C) Austenitic Stainless Steel

Plasticised Polyvinyl chloride->PVC Unplasticised PVC->UPVC Polyethylene->PE Polyamide->PA Polypropylene->PP PolyTetraFluoroEthyleme->PTFE Polychlorotrifluoroethylen->PCTFE Perfluoralkoxy->PFE Fluorinated ethylene propylene->FEP Polyvinylidenefluoride->PVDF Polyphenylenesulpone->PPS Cross-linked Polyethylene->PEX Polyketone->PK Polyetheretherketone->PEEK Including Inconel and incoloy Commonly used because of the high ppm Monel is a nickel-copper alloy, 10%~90% commonly used Service: sea water Monel Fluoropolymers

Basic Material

Fittings Forgings

www.azpiping.com

G) Thermoplastic

General

Using when the the design condition is exceed the limit do SS316 Any hydrostatic testing of austenitic stainless steel shall be conducted with water containing less than 2 mg/kg chlorides, and any open ends sealed after drying to ensure no moisture ingress. Service

D) Duplex Stainless Steel

Application

Pipes Fittings Forgings

ASTM A790 UNS S31803 ASTM A815 UNS S31803 ASTM A182 Gr.F51

Nickel Alloys Cr-Mo heat resistant steel contain 0.5~9% Cr and 0.5~1.0% Mo. Carbon content max 0.20% General Supplied in normalized and tempered, quenched and tempered or annealed condition These Alloy Steels are used up to max temperature about 650 C Elevated Temperature Services Pipes Appication Fittings Forgings ASTM A 335 Gr.P11, A335 Gr.P22 ASTM A234 Gr.WP11, A234 Gr.WP22 ASTM A182 Gr.F11, A182 Gr.F22

Cu-Ni 90/10, Cu-Ni 70/30 Services: sea water piping system Good corrosion resistance, especially chlorite induced pitting and stress-corrosion cracking Good resistance to oxidizing media, e.g. nitric acid Resistance to reducing media superior to non-alloyed titanium

Copper-Nickel

F) Non-Ferrous Alloy

Non-Alloyed grade Titanium Alloyed grade

E) Alloy Steel

General

Application with temperature form 0 C to 195C, Nickel steels is typically used Pipes ASTM A 333 Gr.3 ASTM A420 Gr.WPL3 ASTM A350 Gr.LF3

Low Temperature Services Application Fittings Forgings

You might also like

- Cepsa Fundicol Synt Ehc: Lubricants For Industrial UseDocument2 pagesCepsa Fundicol Synt Ehc: Lubricants For Industrial UseVladislav TrempoletsNo ratings yet

- Weld Fitting Flange Astm SpecsDocument1 pageWeld Fitting Flange Astm SpecsAZU-OKPONo ratings yet

- Dezurik Eccentric Plug Valves Pec Pef 12 3 Pec Eccentric Plug Valves Technical 12-00-1bDocument12 pagesDezurik Eccentric Plug Valves Pec Pef 12 3 Pec Eccentric Plug Valves Technical 12-00-1bOleg ShkolnikNo ratings yet

- DIN 28091-2 GasketDocument20 pagesDIN 28091-2 Gasketengfaridmalk100% (1)

- Ferolite Nam 32 Steel PDFDocument2 pagesFerolite Nam 32 Steel PDFMittapelly praveenNo ratings yet

- Piping Materials ChartDocument1 pagePiping Materials ChartAitazaz AhsanNo ratings yet

- Comments - Bulk Material Inspection For VRF and Electrical - Transcom - 21.09.01Document2 pagesComments - Bulk Material Inspection For VRF and Electrical - Transcom - 21.09.01Pritam MitraNo ratings yet

- CSM For RollDocument14 pagesCSM For RollThanhNhựtNo ratings yet

- Presion de DiseñoDocument1 pagePresion de DiseñocmosquerNo ratings yet

- BTG 11.12.22-11.18.22 T-1 PDFDocument1 pageBTG 11.12.22-11.18.22 T-1 PDFKimberly DayoNo ratings yet

- Anderol 3057MDocument1 pageAnderol 3057MsanathcgrNo ratings yet

- 18crnimo7-6: Steel GradeDocument4 pages18crnimo7-6: Steel GradeFINNING CATNo ratings yet

- Grafilit EM: Properties Appropriate Industries & ApplicationsDocument2 pagesGrafilit EM: Properties Appropriate Industries & ApplicationsFrancisco José Espinosa MásNo ratings yet

- Heat Exchangers: Corrosion ResistantDocument16 pagesHeat Exchangers: Corrosion ResistantIsaac IglesiasNo ratings yet

- Ecoline Est 150-600Document21 pagesEcoline Est 150-600Yosses Sang NahkodaNo ratings yet

- CameronBOP Rubbers TemperatureDocument1 pageCameronBOP Rubbers TemperatureMarc LefrancqNo ratings yet

- Copper Pipe C12200Document1 pageCopper Pipe C12200Yowhannes TsehayeNo ratings yet

- JSL Indian Railways Specific GradesDocument43 pagesJSL Indian Railways Specific GradesNagarajan GNo ratings yet

- Certificado Empaques No AsbestoDocument2 pagesCertificado Empaques No AsbestoTATIANA POSADANo ratings yet

- BMCG Presentation Cii08012010mDocument21 pagesBMCG Presentation Cii08012010mimtyazmNo ratings yet

- Astm SpecificationDocument9 pagesAstm SpecificationHARSHANo ratings yet

- SourceDocument1 pageSourceQuy NguyenNo ratings yet

- Val-Comp Z45XDocument1 pageVal-Comp Z45XDaniel04pvNo ratings yet

- The Proxy Server Is: Datasheet:ASTM - Valve, Material SpecificationsDocument12 pagesThe Proxy Server Is: Datasheet:ASTM - Valve, Material SpecificationsfazlulfaisalNo ratings yet

- HTTP WWW Pressbolt Com Astm A193 b7, b7m, b8, b8m, b16, A320 l7, l7m, l43 Studbolts HTMLDocument2 pagesHTTP WWW Pressbolt Com Astm A193 b7, b7m, b8, b8m, b16, A320 l7, l7m, l43 Studbolts HTMLMashudi FikriNo ratings yet

- BS Code ListDocument10 pagesBS Code ListCarol SantosNo ratings yet

- PVC Formolon 680 K70Document1 pagePVC Formolon 680 K70Osmar ContrerasNo ratings yet

- Metal Cutting GasDocument21 pagesMetal Cutting GasSuyog ShingareNo ratings yet

- Grafilit IQ: Properties Appropriate Industries & ApplicationsDocument2 pagesGrafilit IQ: Properties Appropriate Industries & ApplicationsFrancisco José Espinosa MásNo ratings yet

- Opper Alloy No. Temper Astm B111 C44300 Hsn70-1 O61 Astm B111 C68700 Hai77-2 Astm B111 C70600 Bf210-1-1 O61 H55 Astm B111 C71500 Bfe30-1-1 O61 Hr55Document8 pagesOpper Alloy No. Temper Astm B111 C44300 Hsn70-1 O61 Astm B111 C68700 Hai77-2 Astm B111 C70600 Bf210-1-1 O61 H55 Astm B111 C71500 Bfe30-1-1 O61 Hr55Mohammed NazeerNo ratings yet

- Troubleshooting of ADGAS' Benfield HiPure Plant of Natural Gas Sweetening Using Process SimulationDocument15 pagesTroubleshooting of ADGAS' Benfield HiPure Plant of Natural Gas Sweetening Using Process SimulationBRUCE QUARENo ratings yet

- 123HAN BPS 02 - Rev.2Document1 page123HAN BPS 02 - Rev.2ABDUL RAHMAN ALI MIRNo ratings yet

- Fire EquipmentDocument7 pagesFire Equipmentamal_postNo ratings yet

- In0126 GB PF 2008 05 BDocument2 pagesIn0126 GB PF 2008 05 BCuong Hoang100% (1)

- Astm A335 Blog 9Document3 pagesAstm A335 Blog 9RELIABLE PIPES & TUBESNo ratings yet

- Bab 3 MaterialsDocument29 pagesBab 3 Materialsyaya haryadiNo ratings yet

- A 553 Type 1 and Details of Low Temp ServicesDocument11 pagesA 553 Type 1 and Details of Low Temp Servicesروشان فاطمة روشانNo ratings yet

- Vulkco SELLADO DE FLUIDOSDocument1 pageVulkco SELLADO DE FLUIDOS54856743No ratings yet

- 20Mncr5: Steel GradeDocument3 pages20Mncr5: Steel GradeRajat DubeyNo ratings yet

- 1 TDS - KIMMCO-ISOVER Glass Mineral Wool Batt-Blanket - KBR - 24kg - 25mm - FSK - Formal-1Document3 pages1 TDS - KIMMCO-ISOVER Glass Mineral Wool Batt-Blanket - KBR - 24kg - 25mm - FSK - Formal-1Kareem HelalNo ratings yet

- BMCG PresentationDocument21 pagesBMCG PresentationishuNo ratings yet

- 3 A) PDS - E - JER - v4.1Document4 pages3 A) PDS - E - JER - v4.1Anish KarthikeyanNo ratings yet

- SBLP Iii 137401-P-Et-001-B Piping ClassDocument34 pagesSBLP Iii 137401-P-Et-001-B Piping ClassKathia Espinoza RojasNo ratings yet

- Purgador BimetalicoDocument2 pagesPurgador BimetalicoEugenio DíazNo ratings yet

- DSM-0274.0 Bronze AlloysDocument5 pagesDSM-0274.0 Bronze AlloyskerbaubiruNo ratings yet

- HidraulicaDocument4 pagesHidraulicaAntonio Anatoly Viamont PintoNo ratings yet

- Fig. 980 ANSI Ductile Iron Fully Lugged Butterfly Valve Class 150Document1 pageFig. 980 ANSI Ductile Iron Fully Lugged Butterfly Valve Class 150kikokiko KarimNo ratings yet

- SA 387 Grade 91 Class 2Document4 pagesSA 387 Grade 91 Class 2briang-2No ratings yet

- Merkel SealsDocument43 pagesMerkel SealsAmandioNo ratings yet

- Astm C361M-14Document26 pagesAstm C361M-14diego rodriguez100% (1)

- BMCG PresentationDocument21 pagesBMCG PresentationmarkandeyaNo ratings yet

- BMCG Presentation Cii08012010mDocument21 pagesBMCG Presentation Cii08012010mSHRINIVASNo ratings yet

- AL 29-4C Alloy For Heating and VentilatingDocument7 pagesAL 29-4C Alloy For Heating and Ventilatingيو ليلNo ratings yet

- Essential Rubber Formulary: Formulas for PractitionersFrom EverandEssential Rubber Formulary: Formulas for PractitionersRating: 3 out of 5 stars3/5 (1)

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363No ratings yet

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39Rating: 5 out of 5 stars5/5 (1)

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20From EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20No ratings yet

- Crosby Eye Bolt G 291Document1 pageCrosby Eye Bolt G 291pandiangvNo ratings yet

- Xylan Offshore FlierDocument2 pagesXylan Offshore FlierpandiangvNo ratings yet

- Studding Outlet DimensionDocument2 pagesStudding Outlet DimensionpandiangvNo ratings yet

- As Me Certificate Holder ReportDocument5 pagesAs Me Certificate Holder ReportpandiangvNo ratings yet

- Peppers Catalogue Approved AccessoriesDocument16 pagesPeppers Catalogue Approved AccessoriespandiangvNo ratings yet

- Wind Load SheetDocument2 pagesWind Load SheetpandiangvNo ratings yet

- UBC DIVISION-III (Wind Design) : Ce Combined Height, Exposure & Gust Factor CoeffDocument4 pagesUBC DIVISION-III (Wind Design) : Ce Combined Height, Exposure & Gust Factor CoeffpandiangvNo ratings yet

- Guidance Notes RevisionDocument8 pagesGuidance Notes RevisionpandiangvNo ratings yet

- Design and Development PlanningDocument6 pagesDesign and Development PlanningpandiangvNo ratings yet

- S2 - Jaw and Jaw-136Document1 pageS2 - Jaw and Jaw-136pandiangvNo ratings yet

- ASME Section II C 2015 ChangesDocument3 pagesASME Section II C 2015 Changespandiangv0% (1)

- Input:-: Design of Base Plate Length of Base Plate (MM) W 0.11 Width of Base Plate (MM) A (MM) B (MM) Axil Load (M.T)Document6 pagesInput:-: Design of Base Plate Length of Base Plate (MM) W 0.11 Width of Base Plate (MM) A (MM) B (MM) Axil Load (M.T)pandiangvNo ratings yet

- Load-Carrying Capacity Analysis On Derrick of Offshore Module Drilling RigDocument12 pagesLoad-Carrying Capacity Analysis On Derrick of Offshore Module Drilling RigpandiangvNo ratings yet

- WRC Input InstructionDocument2 pagesWRC Input InstructionpandiangvNo ratings yet

- TMCP Steels For Offshore StructuresDocument3 pagesTMCP Steels For Offshore StructurespandiangvNo ratings yet

- Level Gauge, Level Switch ModelDocument8 pagesLevel Gauge, Level Switch ModelpandiangvNo ratings yet

- Graphite PSM AsDocument2 pagesGraphite PSM AspandiangvNo ratings yet

- N1192-ST - Colour CoadingDocument4 pagesN1192-ST - Colour CoadingpandiangvNo ratings yet

- WRC Input InstructionDocument1 pageWRC Input InstructionpandiangvNo ratings yet

- Heat TreatmentDocument13 pagesHeat TreatmentpandiangvNo ratings yet

- Api2000rev.6 02-13Document33 pagesApi2000rev.6 02-13pandiangvNo ratings yet

- As 5016-2004 Metallic Materials - Conversion of Hardness ValuesDocument10 pagesAs 5016-2004 Metallic Materials - Conversion of Hardness ValuesSAI Global - APAC0% (1)

- Api 6DDocument12 pagesApi 6Dcarlosalex200050% (2)

- Sanitary Design & Construction of Food EquipmentDocument8 pagesSanitary Design & Construction of Food EquipmentDavidSugiantoSutantoNo ratings yet

- Basic Depressuring Why 1Document4 pagesBasic Depressuring Why 1Jamie RapajonNo ratings yet

- Pipe Shoe CatalogDocument32 pagesPipe Shoe CatalogDodi Egga DarmwanaNo ratings yet

- Hardenability Based Steel Selection PDFDocument2 pagesHardenability Based Steel Selection PDFsivajirao70No ratings yet

- CSWIP Welding Inspection Notes and Questions (Said)Document138 pagesCSWIP Welding Inspection Notes and Questions (Said)Ericson Cabigao100% (1)

- Review of Selective Laser Melting, Materials and ApplicationsDocument22 pagesReview of Selective Laser Melting, Materials and ApplicationsLe Thanh LongNo ratings yet

- Girder-Slab System Design Guide v2.0 PDFDocument20 pagesGirder-Slab System Design Guide v2.0 PDFManoj GehlodNo ratings yet

- HEsteel SerbiaDocument26 pagesHEsteel SerbiaYogesh GuptaNo ratings yet

- A407-07 (2013) Standard Specification For Steel Wire, Cold-Drawn, For Coiled-Type SpringsDocument3 pagesA407-07 (2013) Standard Specification For Steel Wire, Cold-Drawn, For Coiled-Type Springstjt4779No ratings yet

- Manual Treadmill Cycle": Minor Project Report ON " Submitted To Maharishi Markandeshwar Deemed To Be UniversityDocument16 pagesManual Treadmill Cycle": Minor Project Report ON " Submitted To Maharishi Markandeshwar Deemed To Be UniversityShrwan GyawaliNo ratings yet

- Classification of SteelsDocument3 pagesClassification of SteelsHaider EjazNo ratings yet

- Hot Dip Galv TechnologyDocument9 pagesHot Dip Galv TechnologyjeigocNo ratings yet

- Fluidized Bed Freezer Quotation (MELIDocument8 pagesFluidized Bed Freezer Quotation (MELIrichardNo ratings yet

- (3 Tip Type) : Product Description Chart GradeDocument2 pages(3 Tip Type) : Product Description Chart GradeRodrigo E. González NavarreteNo ratings yet

- Structural Behavior of Steel-Concrete Composite BeamDocument12 pagesStructural Behavior of Steel-Concrete Composite BeamJaime Morales BazalduaNo ratings yet

- MMT Bohler M303extra Feature ArticleDocument4 pagesMMT Bohler M303extra Feature ArticlegvmindiaNo ratings yet

- Metastable Iron-Carbon (Fe-C) Phase DiagramDocument3 pagesMetastable Iron-Carbon (Fe-C) Phase DiagramupenderNo ratings yet

- Certificados para Produtos em Aço 10204 PDFDocument2 pagesCertificados para Produtos em Aço 10204 PDFAna GamaNo ratings yet

- Orissa: Oriya BhubaneswarDocument33 pagesOrissa: Oriya BhubaneswarBhavani PrasadNo ratings yet

- Viking Johnson ProductsDocument31 pagesViking Johnson ProductsAlvin MiraNo ratings yet

- Equipment Inspection Guideline For Pressure vessel-API 510Document8 pagesEquipment Inspection Guideline For Pressure vessel-API 510Ahsun HabibNo ratings yet

- Piping Material - GuidanceDocument17 pagesPiping Material - GuidanceAlfon50% (2)

- SMS Meer Blankstahl-Schaelen enDocument16 pagesSMS Meer Blankstahl-Schaelen enSukhvinder SinghNo ratings yet

- A S-1 C S-1: Foundation Plan Roof Deck Framing PlanDocument3 pagesA S-1 C S-1: Foundation Plan Roof Deck Framing PlanMelloween Bernardo BarnacheaNo ratings yet

- Roof Drain System, SealsDocument2 pagesRoof Drain System, SealsgabrielardanzaNo ratings yet

- Paper Clip ExperimentDocument5 pagesPaper Clip ExperimentqamhNo ratings yet

- Malz Grup KaynakDocument43 pagesMalz Grup KaynakÜmit Uçak100% (1)

- Premier ValvesDocument12 pagesPremier Valvesneelkant sharmaNo ratings yet